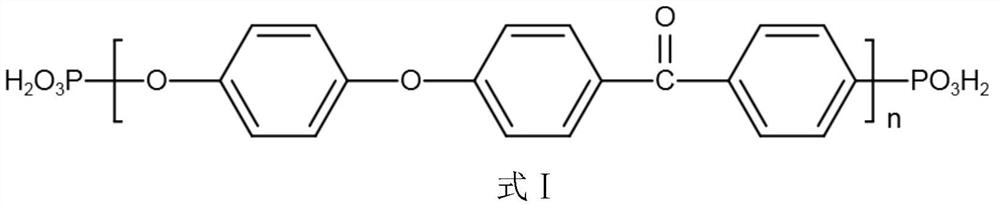

Polyether-ether-ketone with improved hydrophilicity and/or thermal stability and preparation method thereof

A polyetheretherketone and thermal stability technology, applied in the field of polyetheretherketone and its preparation, can solve problems such as product performance defects and thermal degradation, and achieve the effects of easy processing, small viscosity change, and reduction of bacterial adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Sodium carbonate and potassium carbonate were dried under vacuum at 100°C to remove moisture before use.

[0048] (2) Add 165g of hydroquinone (1.50mol) and 335.6g of 4,4'-difluorobenzophenone to a (3L) four-necked flask equipped with a turbine stirring device, a temperature detector, and a nitrogen inlet Ketone (1.537mol), 1040g diphenyl sulfone (4.770mol), 180.15g anhydrous sodium carbonate (1.70mol), 5.22g anhydrous potassium carbonate (0.038mol), stir, blow nitrogen for 30min, record as system 1.

[0049] (3) Raise the temperature of system 1 to 140°C at a rate of 2°C / min, then raise the temperature to 220°C at a rate of 1°C / min, and keep it for 30 minutes; continue to raise the temperature of system 1 to 300°C, the heating time is 50 minutes, and keep it for 70 minutes.

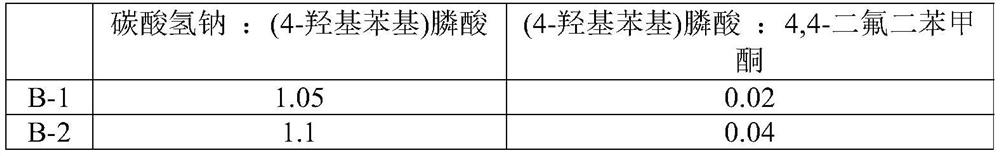

[0050](4) prepare the reaction flask that is equipped with stirrer and temperature probe in addition, add 6.53g (4-hydroxyphenyl) phosphonic acid (0.0375mol), 3.36g sodium bicarbonate (0.04mo

Embodiment 2

[0059] The steps are basically the same as in Example 1, except that step (9) is not included to obtain dry granular product B.

Embodiment 3

[0061] The steps of Example 1 are basically the same, except that steps (4) and (5) are not included to obtain dry granular product C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap