Tail gas treatment device for finished diatom ooze stirring kettle

A treatment device and tail gas treatment technology, applied in transportation and packaging, separation methods, filtration and separation, etc., can solve the problems of harmful gas leakage, external air pollution, and inability to purify harmful gases multiple times, so as to enhance the purification effect and avoid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

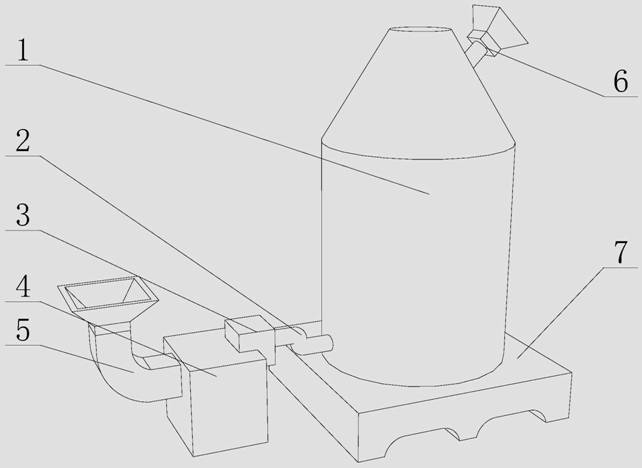

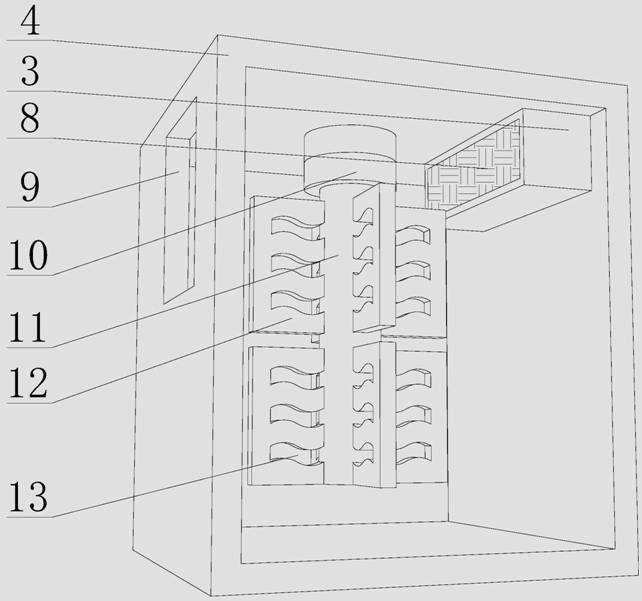

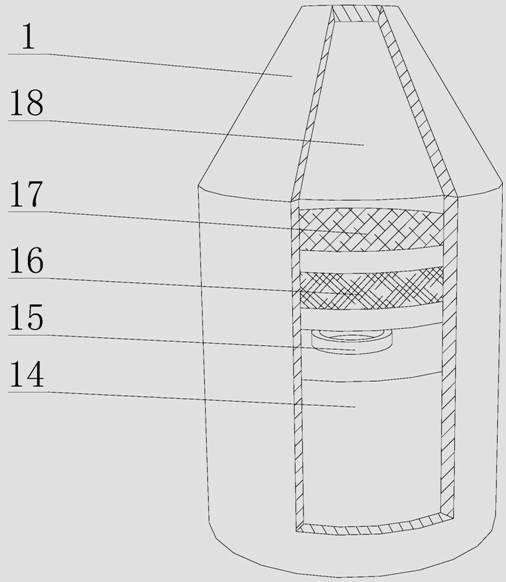

[0036] Such as figure 1 - Figure 5As shown, the present invention provides a finished diatom mud stirred tank tail gas treatment device, including a treatment device main body 1, a gas input pipe 2 and a diatom mud stirred tank 4, and the surface side of the treatment device main body 1 is provided with a gas input pipe 2. A diatom mud stirring tank 4 is arranged on the left side of the main body 1 of the processing device. An air pump 3 is arranged inside the diatom mud stirring tank 4. The air pump 3 is used to absorb the harmful gas generated by the stirring tank. The main body of the processing device 1 is provided with a bacteria disinfection box 14, which is used to eliminate bacteria in the gas by ultraviolet light, and a secondary filter 18 is provided inside the processing device main body 1, and the secondary filter 18 is used to eliminate harmful gases. Perform multiple purifications, the left side of the gas input pipe 2 is fixedly installed on the right side of the

Embodiment 2

[0038] Such as Figure 1-5 As shown, on the basis of Example 1, the present invention provides a technical solution: the inner wall of the processing device main body 1 and the top of the first gas filter plate 16 are provided with a second gas filter plate 17, and the surface of the second gas filter plate 17 The four sides are fixedly installed on the inner wall of the main body 1 of the processing device. The first gas filter plate 16 and the second gas filter plate 17 in the main body of the processing device 1 are combined to perform secondary filtration and purification of the gas. The surface of the secondary filter 18 is fixed around the surface. Installed on the inwall of the processing device main body 1, the inwall of the bacteria disinfection box 14 is provided with a gas temporary storage 22, the gas temporary storage 22 in the bacteria disinfection box 14 can store the gas temporarily, and the gas temporary storage 22 The bottom is fixedly installed on the bottom en

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap