Inductive heating device, system and method for rapidly improving temperature uniformity of flowing liquid

An induction heating device and induction heating technology, applied in the direction of induction heating device, induction heating, fluid heater, etc., can solve the problems of uneven temperature distribution of the heater and decrease in thermal efficiency, and achieve the purpose of improving the uniformity of temperature distribution and increasing the temperature , Improve the effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

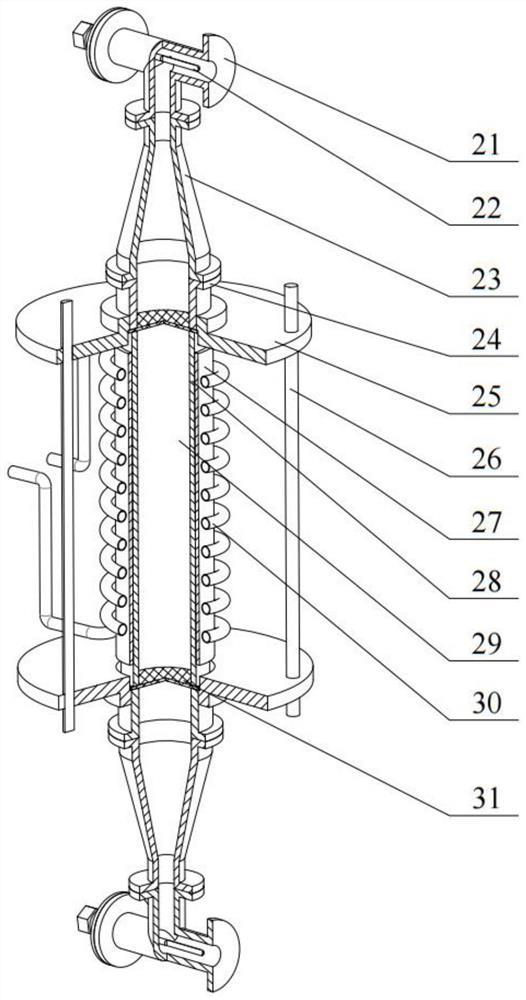

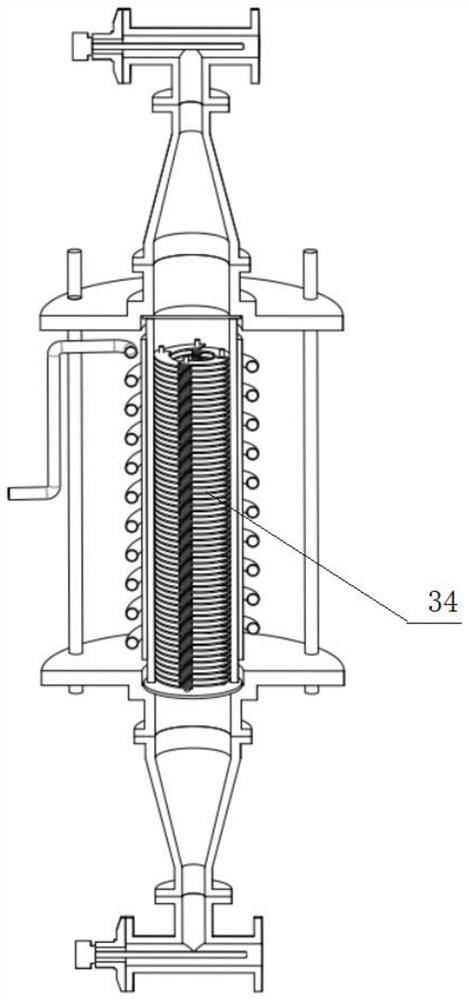

[0059] like figure 2 , 3 shown,

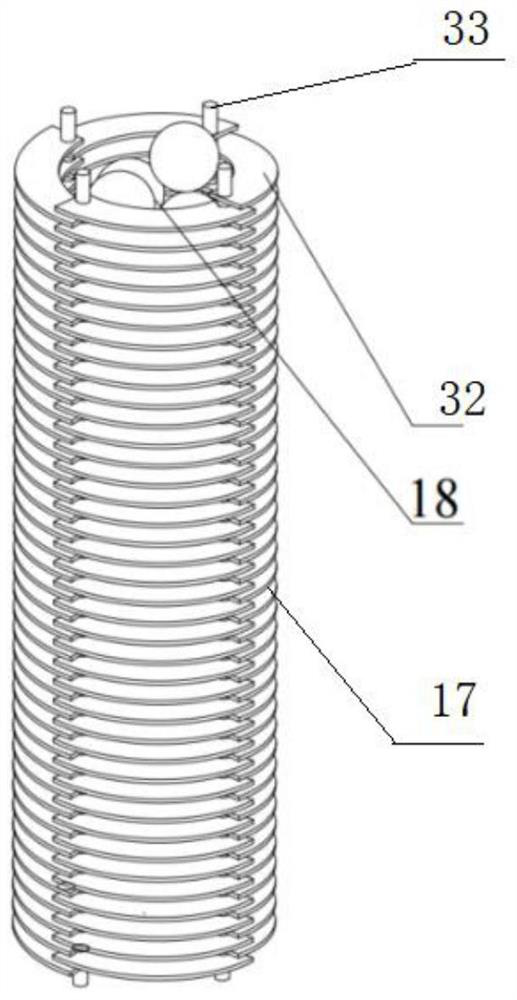

[0060] The inner component of the induction heating is the susceptor combined heater 34, which includes the susceptor 17 and the metal particles 18. The susceptor 17 is composed of several metal arc-shaped sheets 32 end-to-end spliced into a ring-shaped sheet unit, and the ring-shaped sheet unit is connected by the connecting column 33. The sheet units are axially stacked, the outer edge of the metal arc sheet 32 of the susceptor 17 is close to the inner wall of the heater cylinder 28, and the core position of the susceptor 17 is reserved for the fluidization of the metal particles 18 Or stacked cavities in which metal particles 18 are filled. A helical inclination angle of 2-4° is formed between each layer of ring-shaped sheet units of the susceptor 17 . Preferably, a helical inclination angle of about 3° is formed between each layer of annular sheet units of the susceptor 17 .

[0061] After the susceptor is combined, it can be closely

Embodiment 2

[0064] like Figure 4 , 5As shown, the inner member of the induction heating is a crossed thin plate heater 35, which is formed by a plurality of intersecting fan-shaped thin plates 20 connected end to end by connecting rods 19 and stacked axially. The smallest unit is a plurality of intersecting metal sheets. The intersecting thin-plate heater 35 uses a plurality of intersecting thin plates as the smallest unit, and multiple sets of intersecting thin plates are stacked on each other. Finally, the purpose of making the liquid spirally flow in the heater 12 and mixing with each other is achieved. On the basis, the volume of the heater 12 located in the skin depth is increased through the multi-plate crossing, and the heat conduction of the metal itself makes the temperature of the flow field in the heater 12. The distribution reaches a relatively uniform state. The fan-shaped thin plate 20 has a helical inclination angle of 10-20°, and preferably the fan-shaped thin plate 20 ha

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap