Pugging type silicon rubber structured control agent

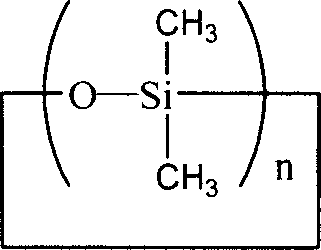

A technology of acid catalyst and siloxane, which is applied in the field of mixing type silicone rubber structure control agent, can solve the problems of reducing tear strength, reducing mechanical properties of silicone rubber, increasing tear permanent deformation and resilience, etc., to achieve Improve tear resistance and resilience, improve tear resistance and resilience, and improve mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1

[0029] Take 310g of DMC and perform vacuum distillation to remove 14g of DMC and water, then add 105g of methyl vinyl dimethoxy silane, stir evenly, heat to 100 ℃, add 21g of granular activated clay, stir and react at constant temperature for 1 hour, then slowly Warm up to 120℃ and continue to stir and keep the reaction for 3 hours, then cool to normal temperature, filter to remove activated clay, filtrate 120℃, -0.1Mpa vacuum distillation to remove 30g of low molecular substances, finally get 364g colorless, transparent liquid, its viscosity 6.5mm 2 / s, the methoxy group content is 8.82% (the methoxy group content is a weight percentage, the same hereinafter), and the vinyl content is 14.0% (the vinyl content is a mole percentage, the same hereinafter).

Example Embodiment

[0030] Example 2

[0031] Take 310g of DMC and perform vacuum distillation to remove 14g of DMC and water, then add 128g of methyl vinyl diethoxy silane, stir evenly and then heat to 120°C, add 21g of granular activated clay, stir for 4 hours and cool to room temperature. , Filter to remove activated clay, the filtrate is distilled under reduced pressure at 120°C and -0.1Mpa to remove 32g of low-molecular substances, and finally 384g of colorless and transparent liquid with a viscosity of 7.0mm 2 / s, the ethoxy content is 12.8%, and the vinyl content is 13.8%.

Example Embodiment

[0032] Example 3

[0033] Take 310g of DMC and perform vacuum distillation to remove 14g of DMC and water, then add 105g of methyl vinyl dimethoxy silane, stir evenly, heat to 100 ℃, add 21g of granular activated clay, stir and react at constant temperature for 1 hour, then slowly Warm up to 120°C and continue to stir and keep the reaction for 3 hours, then cool to 64°C, add 24g of water to 78°C and keep the reaction for 3 hours, cool to room temperature, filter to remove the activated clay, and remove the filtrate by distillation under reduced pressure at 120°C and -0.1Mpa 25g low-molecular substances, finally get 390g colorless, transparent liquid with a viscosity of 11.0mm 2 / s, the hydroxyl content is 3.02%, the methoxy content is 5.29%, and the vinyl content is 13.2%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap