Electric cable shield structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

EXAMPLE

[0040]Hereafter, the present invention will be detailed more concretely using practical examples; however, the present invention must not be limited to the examples described hereafter.

Example

Example 1

—Examination of Shield Effect of Magnesium Shield—

[0041]To evaluate the shield effect of the magnesium shield of the present invention, several experiments were conducted. The evaluation examinations described hereunder were conducted by using Absorption Clamp Test specified in IEC SPECIFICATION (IEC1196-1, IEC61196-1).

[0042]Commercially available LAN cable (category 6, total length 7 m, available from SANWA SUPPLY INC., Type Number KB-T7E-07) was used as the electric cable.

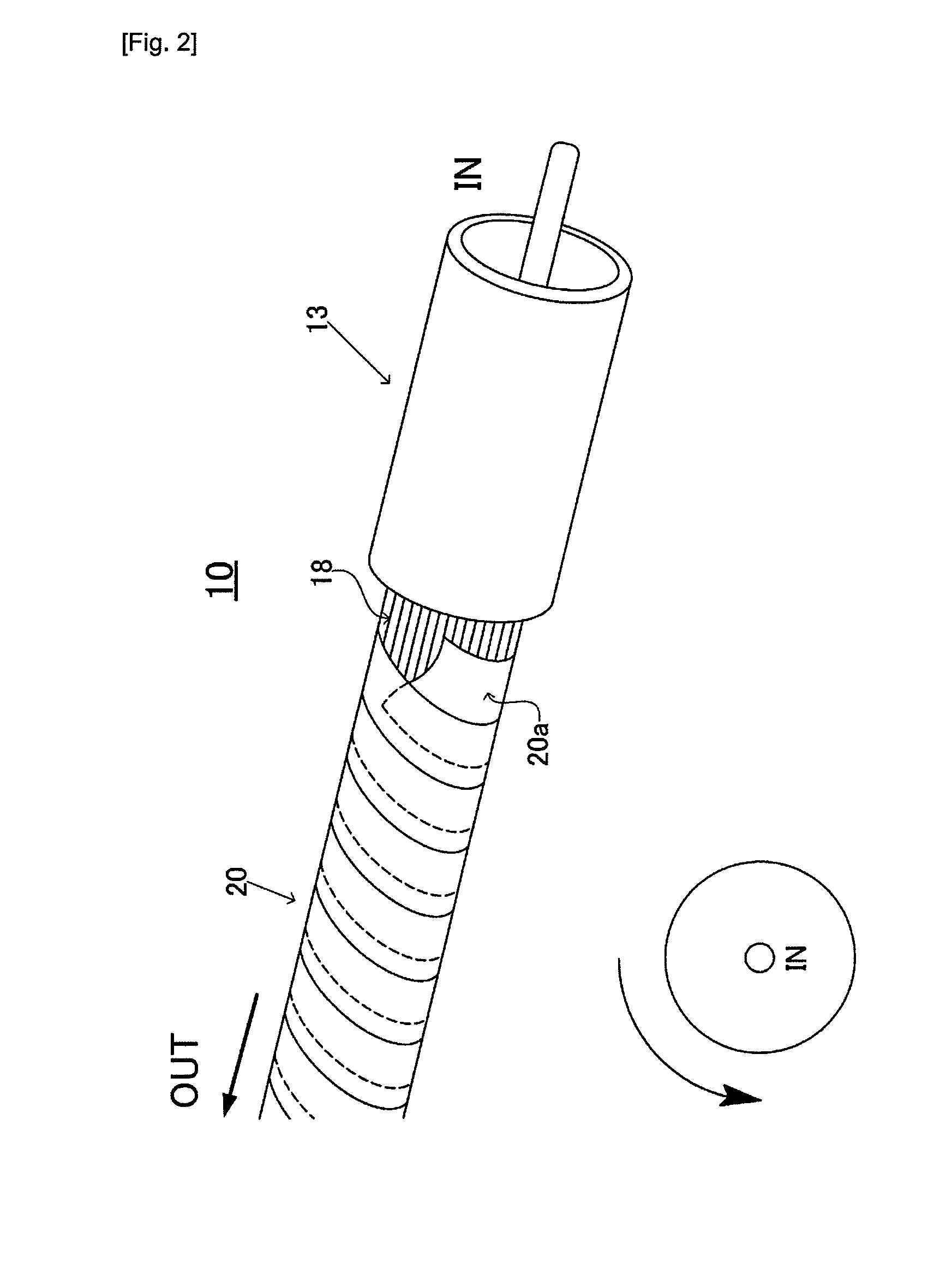

[0043]An aluminum alloy tape (width 20 mm, thickness 45 micro-meters, magnesium content percentage 95-96%, Aluminum 3%, Zinc 1%, Product Serial Number AZ31B, available from NIPPON KINZOKU CO., LTD.) was wound spirally to the above LAN cable such that the spiral was developed to be counter clock wise when viewed from the IN end. The tape winding was performed by evenly overlapping about one half of the tape width each other with starting from the IN end and finishing the OUT end direction so as not to remain

Example

Example 2

[0048]—Examination of Effect on Sounds by Magnesium Shield—

[0049]A sense of hearing test was conducted by connecting audio apparatuses with the cables implemented with the magnesium shield structure of the present invention.

[0050]—Preparation of Magnesium Shield Cable—

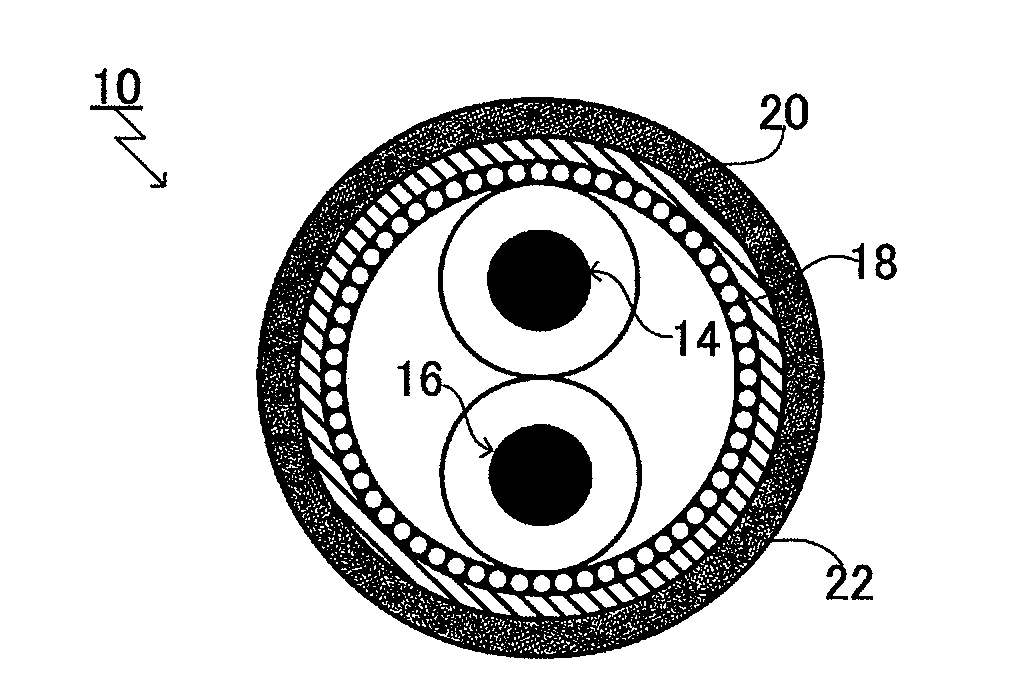

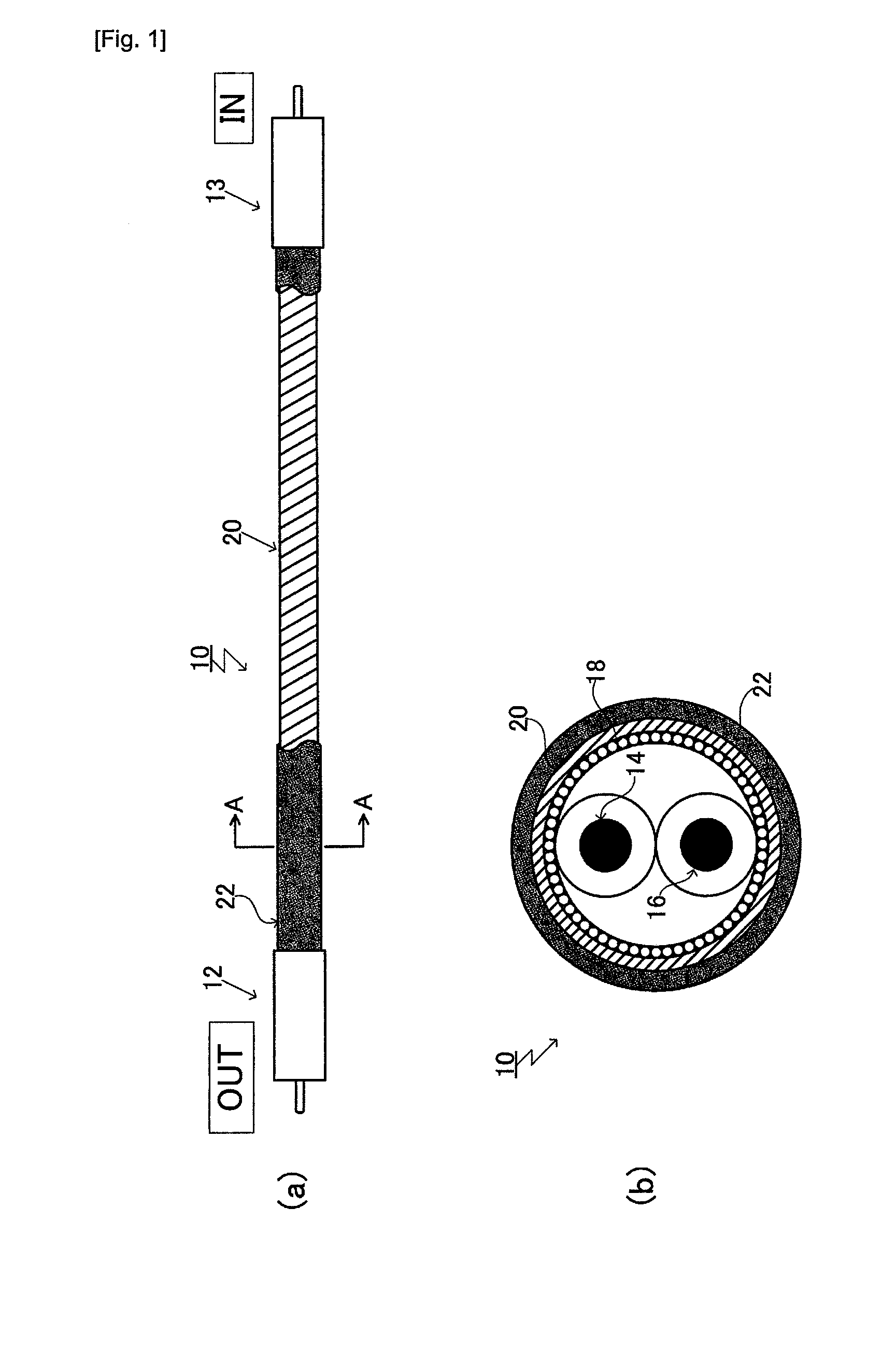

[0051]The magnesium shield cable of the present embodiment was prepared by using a conventional audio cable. FIGS. 6(a)-(c) shows a preparation steps of the magnesium shield cable as the time sequence of the production process and in each of the figures, the side view and the cross sectional view (along with A-A line) of each processes are depicted. Hereafter, the formation of the magnesium shield cable will be described with referencing FIG. 6.

[0052]As shown in FIG. 6(a), first of all, the audio cable commercially available was selected. The audio cable 30 was a popular and commercially available RCA cable (Product Number K-1, available from KRYNA PRO CO., Total length 1000 mm) which was shielded by the copper b

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap