Surface-modified ultraviolet blocking powder and ultraviolet blocking composition including same

a technology of ultraviolet blocking powder and composition, which is applied in the field of surface-modified ultraviolet blocking powder and ultraviolet blocking composition, can solve the problems of skin irritation, difficult to enhance biocompatibility, and decrease in titer, and achieves superior stability and uniformity, high biocompatibility, and superior biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

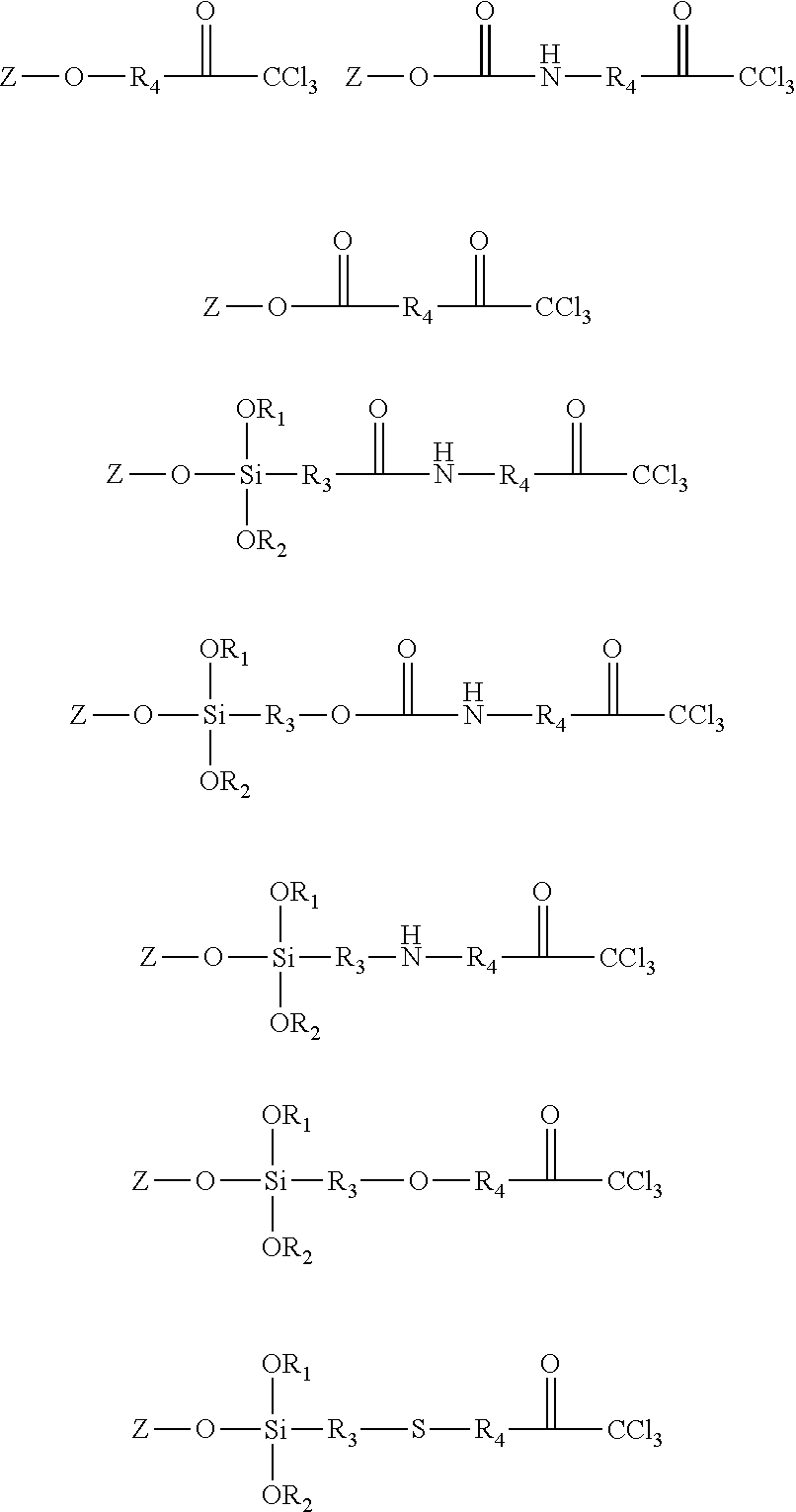

(1) Preparation of UV blocking powder having trichloroacetyl group

[0053]20 g of titanium dioxide (after drying), 600 g of toluene, and 2.0 g of trichloroacetyl isocyanate were placed in a 1 L flask, stirred under reflux at 50˜100° C. for 5˜10 hr, and then cooled to room temperature. The mixture was centrifuged to remove the supernatant (the solvent layer), dispersed in THF and then centrifuged again. These procedures were repeated until the unreacted trichloroacetyl isocyanate was completely removed, followed by drying in a vacuum to remove the residual THF solvent and then drying in a vacuum, thus obtaining a UV blocking powder having a trichloroacetyl group.

(2) Preparation of Surface-Modified UV Blocking Powder

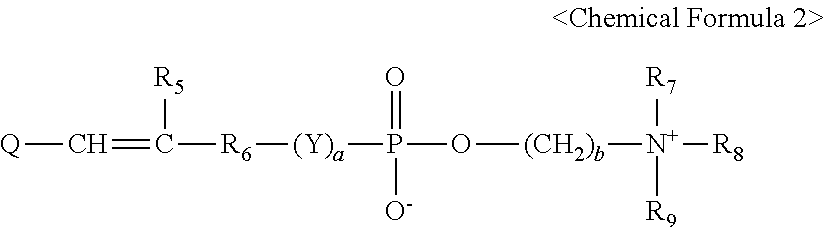

[0054]20 g of the UV blocking powder having a trichloroacetyl group, 4 g of MPC (Methacryloyloxyethyl phosphorylcholine), 0.04 g of Mo(CO)6, and 200 g of ethanol were placed in a 500 L flask, and maintained at 50˜90° C. for 1˜4 hr and thus polymerized. Cooling to room temperatu

example 2

(1) Preparation of UV Blocking Powder Having Trichloroacetyl Group

[0056]The present example was carried out in the same manner as in Example 1, with the exception that, before reaction between titanium dioxide (after drying) and trichloroacetyl isocyanate, titanium dioxide was reacted with tetraethoxysilane (TEOS) and then with trichloroacetyl isocyanate.

[0057]20 g of titanium dioxide (after drying), 600 g of toluene, and 30 g of tetraethoxysilane (TEOS) were placed in a 1 L flask, stirred under reflux at 70˜120° C. for 5˜10 hr and then cooled to room temperature. Subsequently, centrifugation to remove the supernatant (the solvent layer), dispersion in THF, centrifugation and drying in a vacuum were performed, thus obtaining a powder comprising titanium dioxide and tetraethoxysilane.

[0058]20 g of the powder comprising titanium dioxide and tetraethoxysilane, 200 g of methanol, and 20 g of 0.01M HCl were placed in a 1 L flask, stirred at 20˜70° C. for 30 min˜hr, centrifuged to remove the

example 3

(1) Preparation of UV Blocking Powder Having Chloroacetyl Group

[0062]20 g of titanium dioxide (after drying), 600 g of toluene, and 2.0 g of chloroacetyl isocyanate were placed in a 1 L flask, stirred under reflux at 50˜100° C. for 5˜10 hr and then cooled to room temperature. Subsequently, centrifugation to remove the supernatant (the solvent layer), dispersion in THF and centrifugation were performed. These procedures were repeated until the unreacted chloroacetyl isocyanate was completely removed, followed by drying in a vacuum to remove the residual THF solvent and then further drying in a vacuum, thus obtaining a UV blocking powder having a trichloroacetyl group.

(2) Preparation of Surface-Modified UV Blocking Powder

[0063]20 g of the UV blocking powder having a chloroacetyl group, 4 g of MPC (Methacryloyloxyethyl phosphorylcholine), 0.04 g of Mo(CO)6, and 200 g of ethanol were placed in a 500 L flask, and maintained at 50˜90° C. for 1˜4 hr and thus polymerized. Subsequently, cooling

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap