Housing assembly and electronic device

a technology of electronic devices and housings, applied in the field of communication, can solve problems such as reducing the screen ratio of mobile phone screens, and achieve the effect of increasing the screen ratio of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

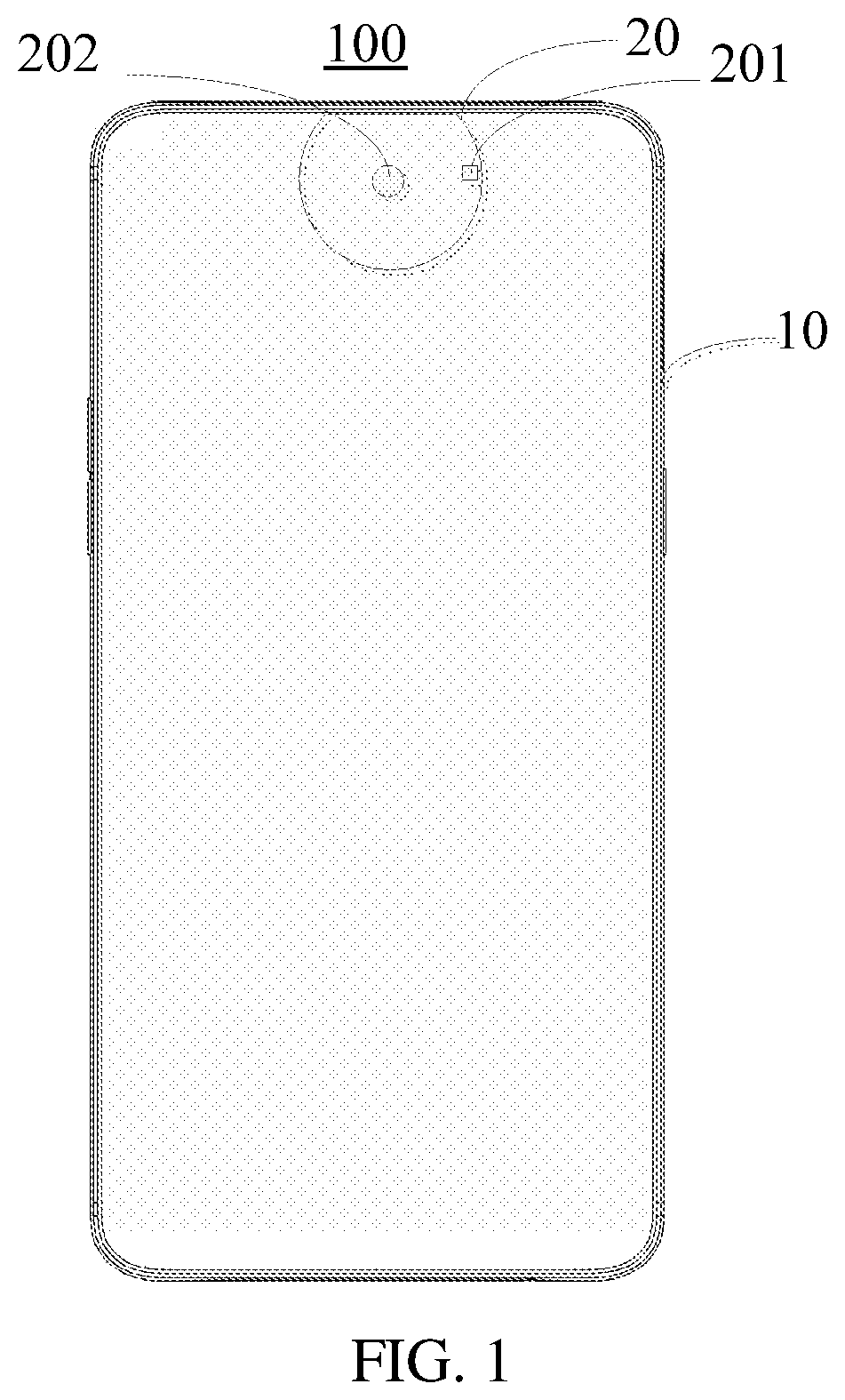

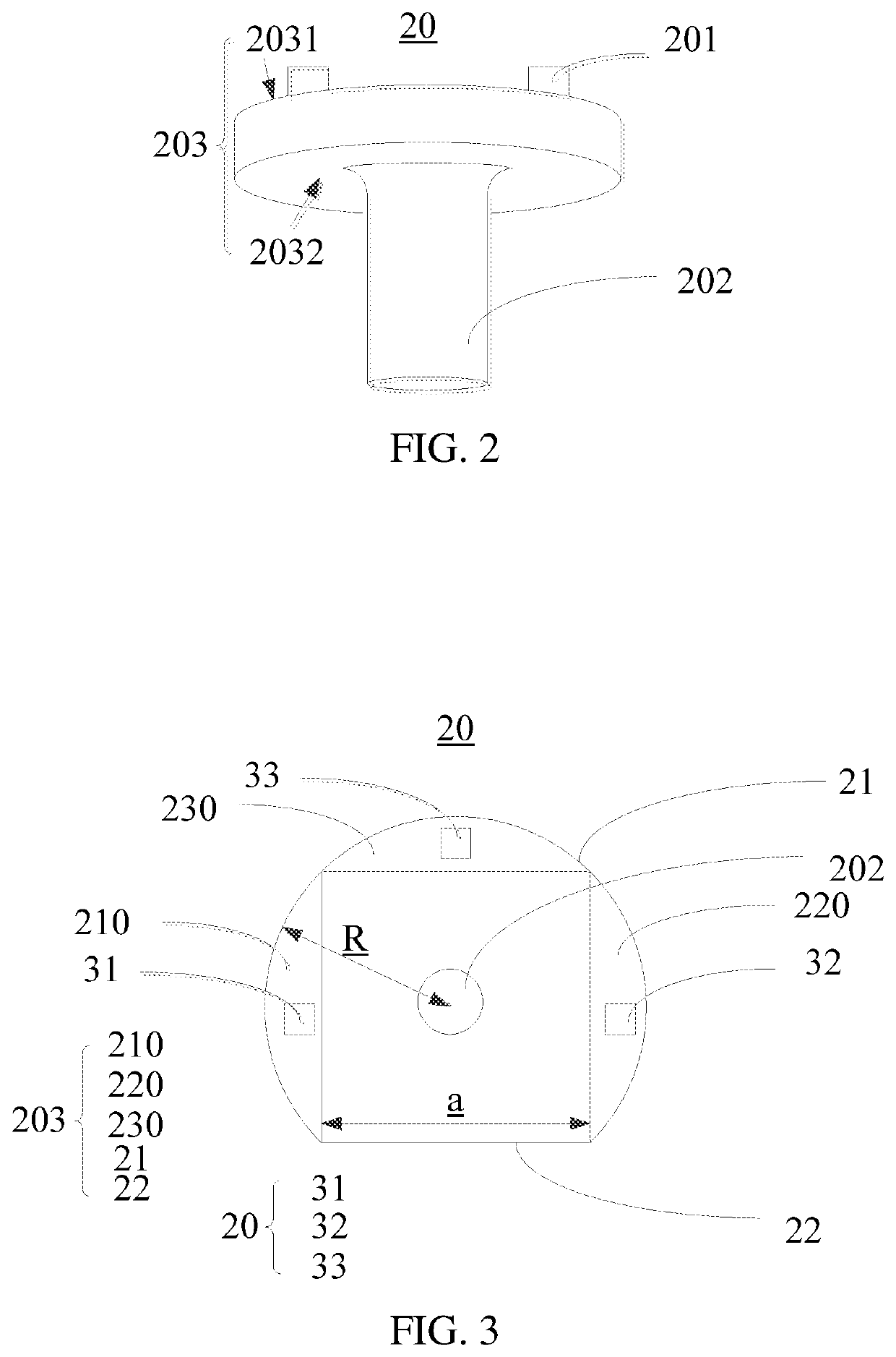

[0035]Please refer to FIG. 1. FIG. 1 is a schematic structural view of a housing assembly in accordance with the present application. An embodiment of the present application provides a housing assembly 100 including a housing 10, a functional module 20 disposed in the housing 10, wherein the functional module 20 includes a plurality of functional components 201 and a rotating shaft 202. The functional modules 201 each are rotatable with respect to the rotating shaft 202, so that each of the functional component 201 is rotatable to a position outside the housing 10.

[0036]For example, the housing 10 can be a metal housing such as a magnesium alloy or a metal such as stainless steel. Certainly, the housing 10 may also be a plastic housing or a ceramic housing. As another example, the housing 10 may include a plastic portion and a metal portion, and the housing 10 may be a housing structure of mutually matched metal and plastic. Specifically, a metal part can be formed first, for example,

second embodiment

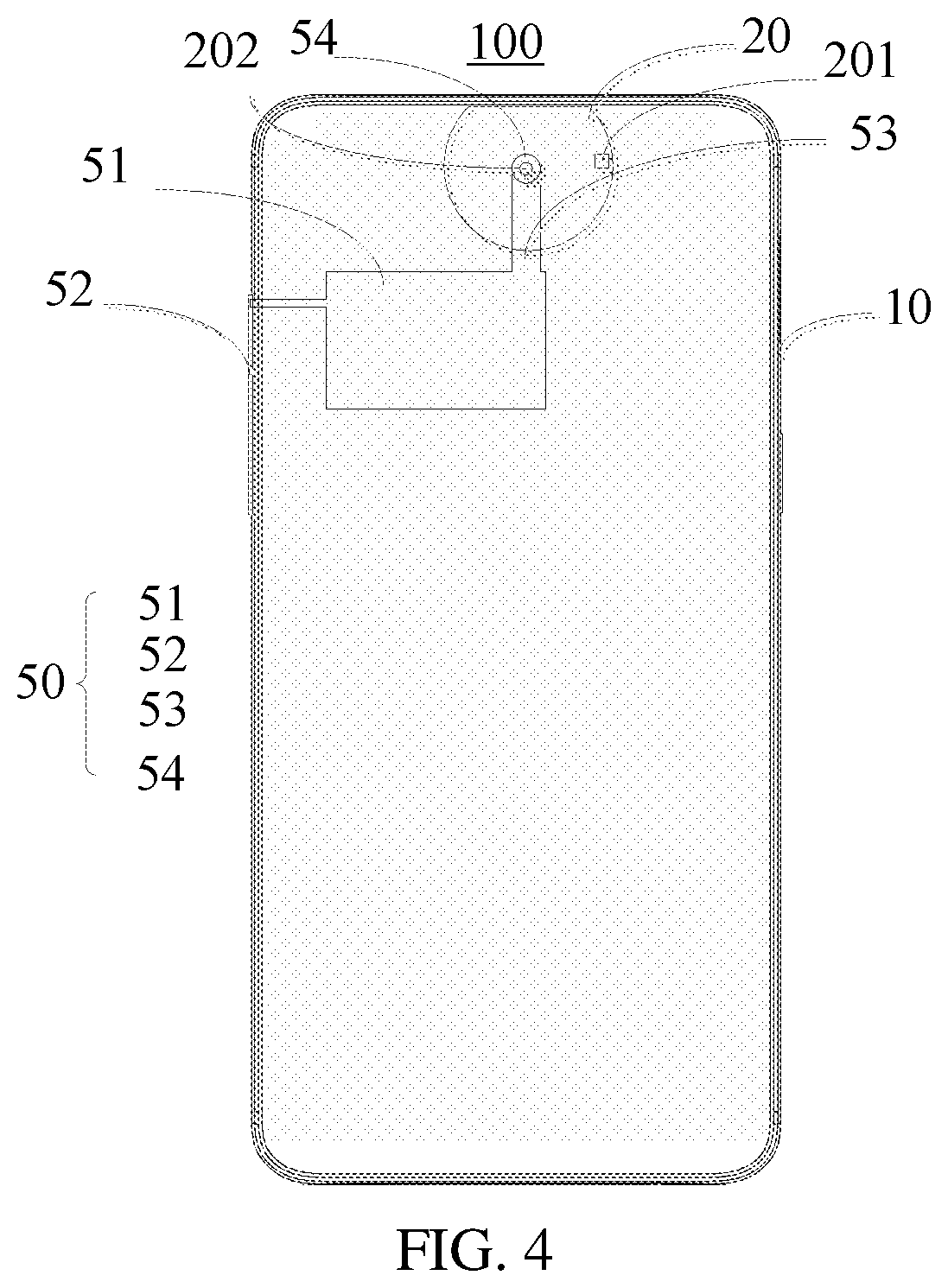

[0046]Please refer to FIG. 4. FIG. 4 is a schematic structural view of a housing assembly in accordance with the present application.

[0047]The housing assembly 100 further includes a driving module 50, wherein the driving module 50 is electrically connected with the functional module 20, so that any of the functional components201 is rotatable to a position outside the housing 10.

[0048]The driving module 50 is configured to drive the functional module 20 to rotate with respect to the rotating shaft 202. The driving module 50 includes a driving motor. The driving motor can drive the rotating shaft 202 to rotate over a gear transmission or a belt drive, thereby to allow the rotating shaft 202 to drive the function module 20 to rotate.

[0049]Furthermore, please continue referring to FIG. 4. The driving module 50 includes a driving member 51 disposed in the housing 10; a control member 52 disposed on an outside of the housing 10 and electrically connected to the driving unit 51; and a conne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap