Polymer powder storage and/or transport and/or degassing vessels

a technology of polymer powder and storage tank, which is applied in the direction of antibody medical ingredients, chemical/physical/physico-chemical processes, chemistry apparatus and processes, etc., can solve the problems of regular powder flowability of applications, and achieve the effect of high production ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

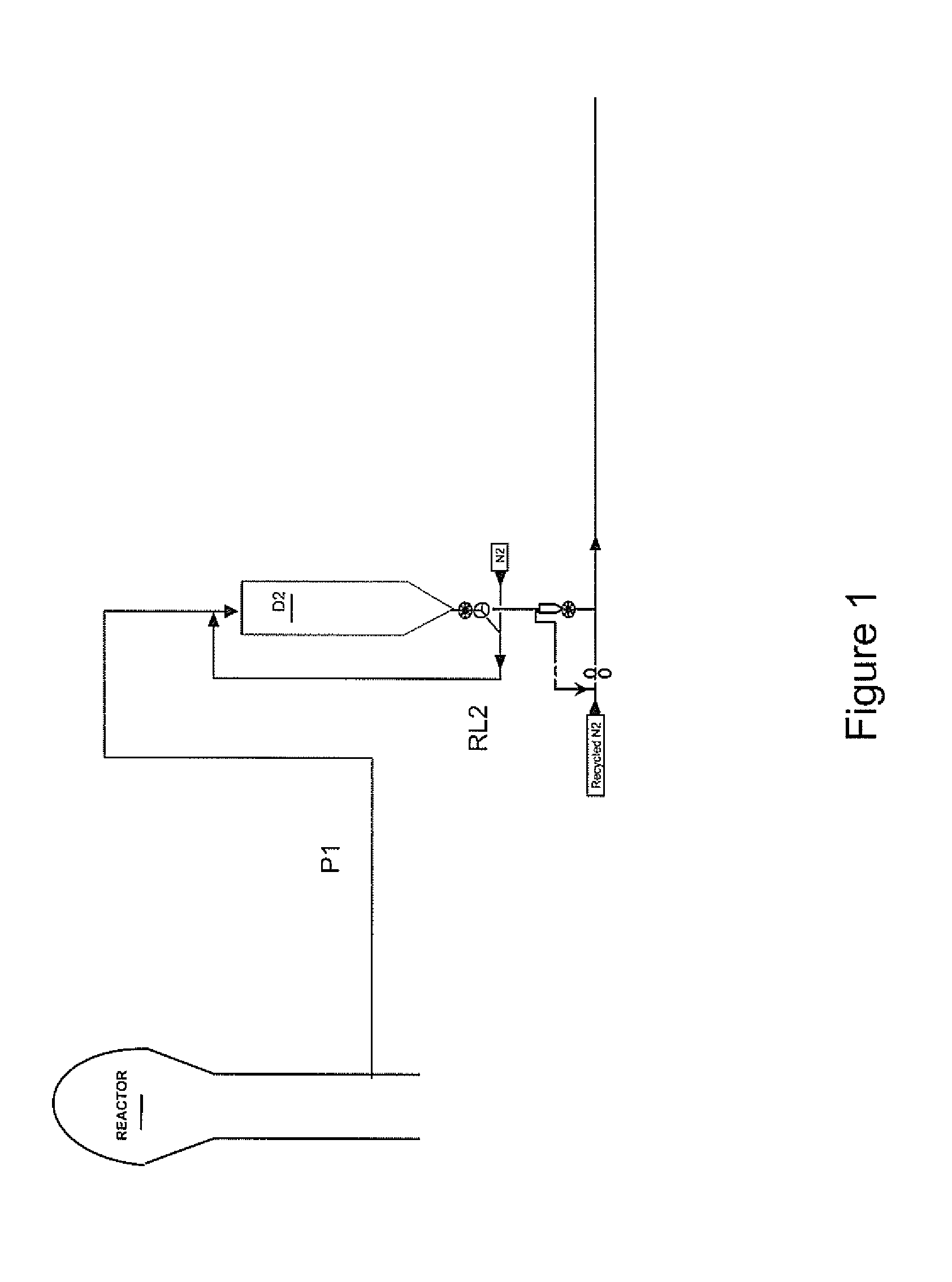

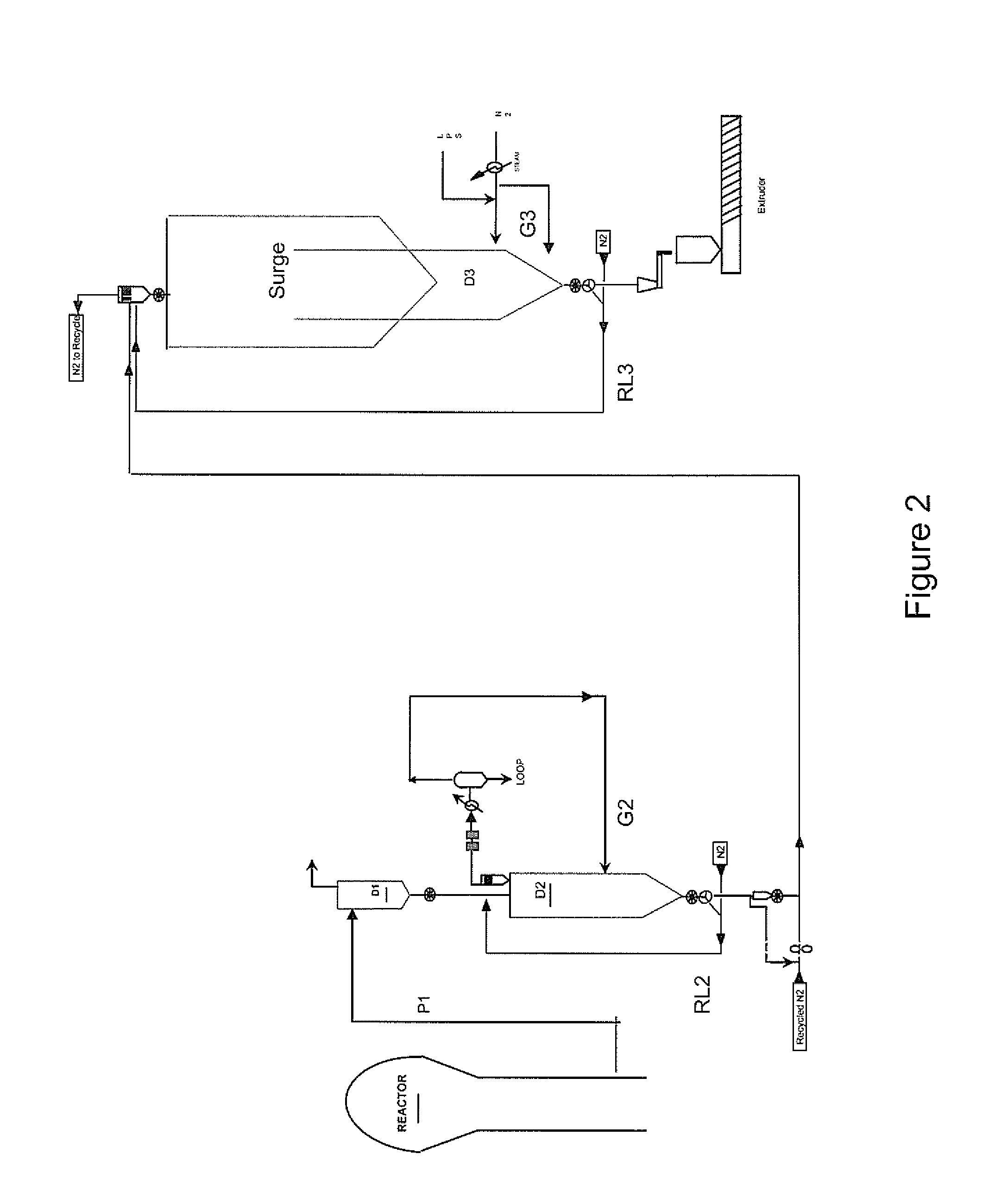

[0083]In its broadest aspect, an embodiment of the present invention is described in FIG. 1 or FIG. 2 wherein the polymer powder degasser vessel (D2 or D3)—comprising the polymer powder recirculation line (which can be RL2 or RL3)—is located downstream of the polymerization reactor and upstream of the polymer powder extruder wherein said powder is transformed into pellets.

[0084]In FIG. 1, the polymer powder P1 which is withdrawn from the fluidised bed gas phase polymerisation reactor is entered into the polymer powder degasser vessel D2.

[0085]In another embodiment, which is described in FIG. 2, the degassing line comprises two polymer powder degasser vessels in series (D2 and D3), both of which comprising their respective polymer powder recirculation line (RL2, RL3).

[0086]It will also be apparent from the FIG. 2 that RL3 represents a specific recirculation embodiment of the present invention wherein two silos (the polisher silo D3 and the surge silo) are used in series; indeed, the rei

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap