Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Calibration curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In analytical chemistry, a calibration curve, also known as a standard curve, is a general method for determining the concentration of a substance in an unknown sample by comparing the unknown to a set of standard samples of known concentration. A calibration curve is one approach to the problem of instrument calibration; other standard approaches may mix the standard into the unknown, giving an internal standard.

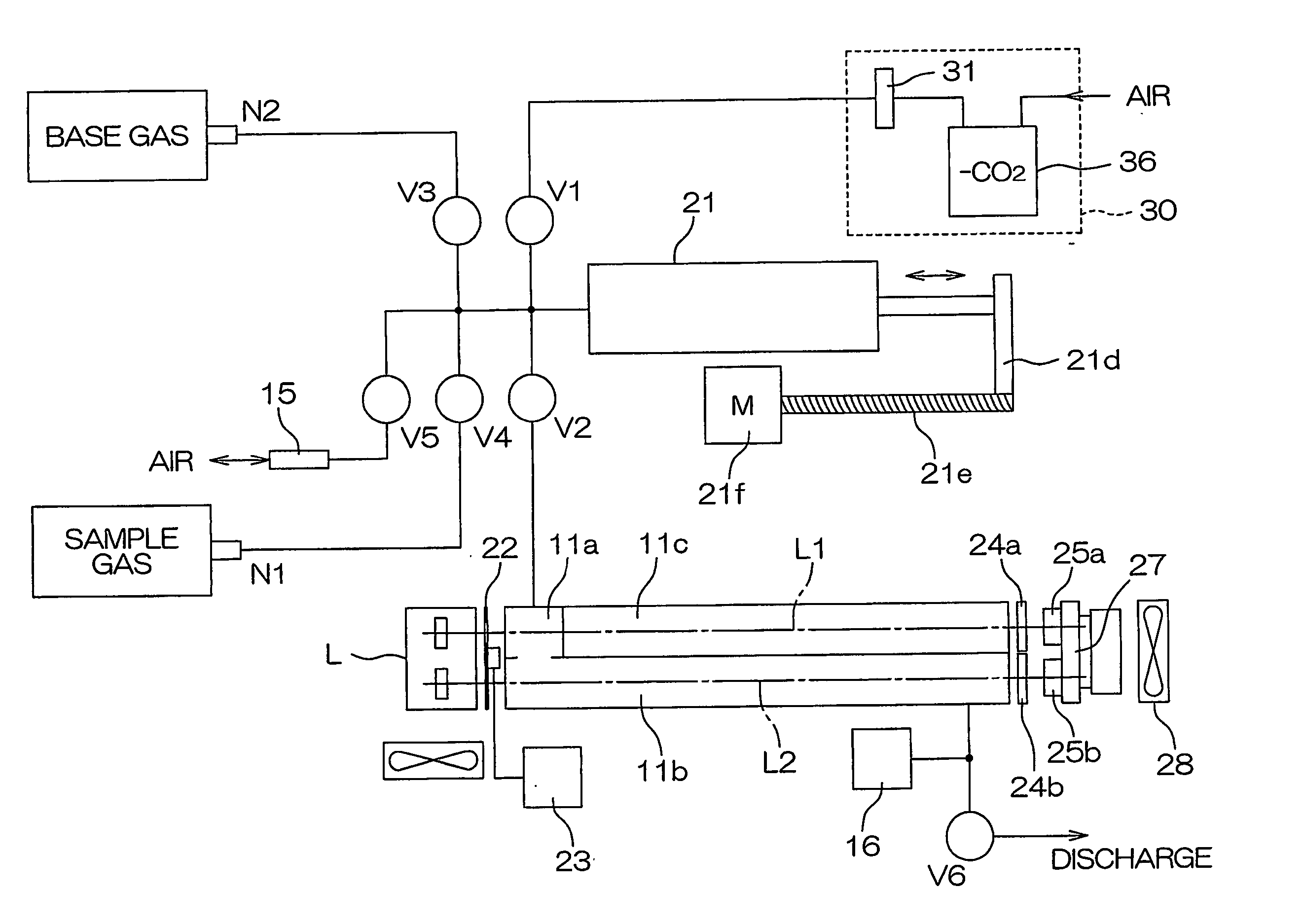

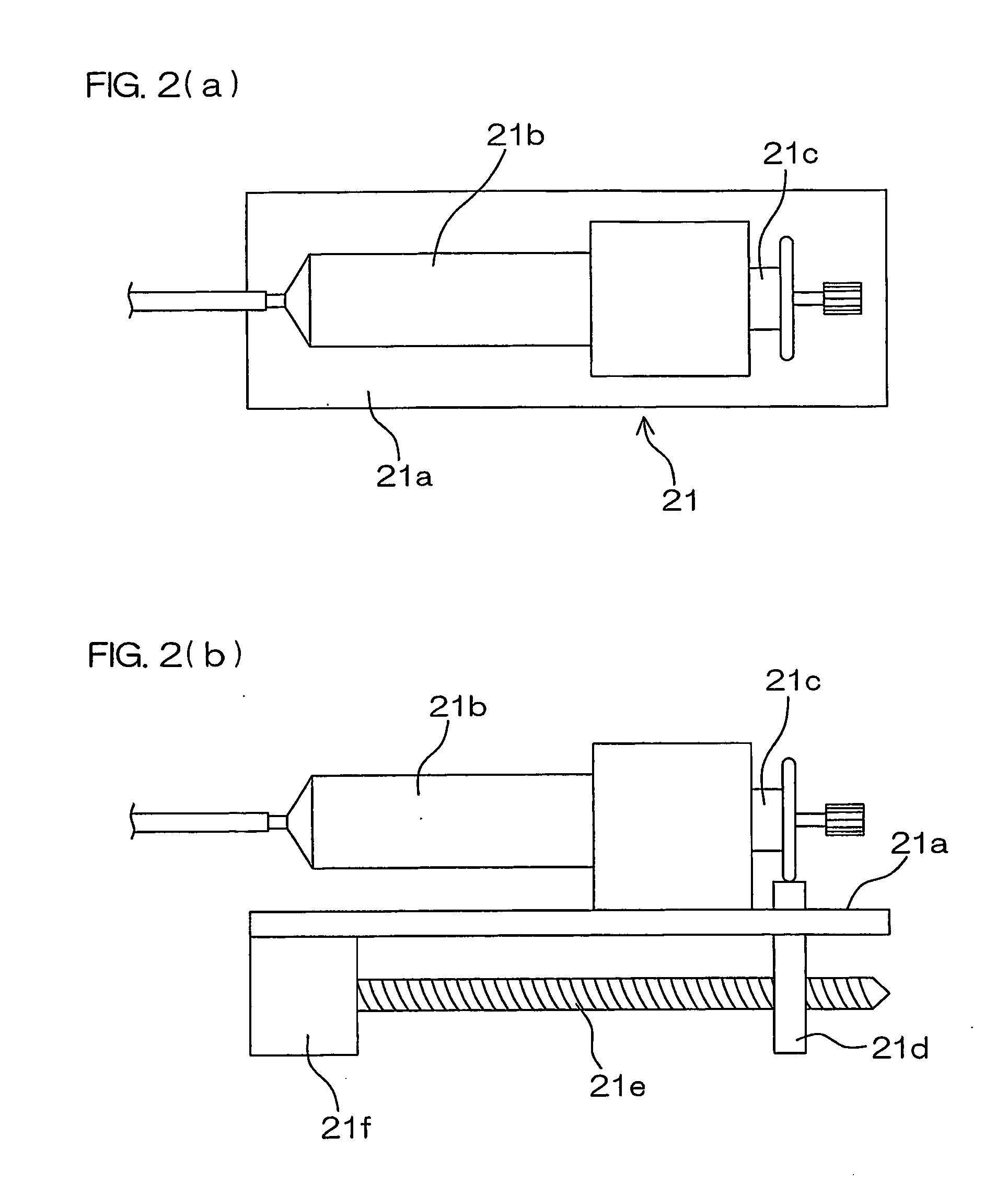

Gas injection amount determining method method in isotope gas analysis, and, isotype gas analyzing and measuring method and apparatus

ActiveUS20070077167A1Improve precisionGood reproducibilityWeather/light/corrosion resistanceWithdrawing sample devicesGas analysisExhaust valve

Owner:OTSUKA PHARM CO LTD

Apparatus and method to calibrate servo sensors in a noisy environment

InactiveUS6865052B2Alignment for track following on tapesRecord information storageEngineeringCalibration curve

A method and apparatus to calibrate a servo sensor disposed on a tape head located adjacent a moving magnetic tape is disclosed where that magnetic tape includes at least one servo edge comprising an interface between a first recorded signal and a second recorded signal, and where the servo sensor provides a servo signal, and where an independent position sensor provides an IPS signal. The method first samples the servo signal and the IPS signal, calculates a transfer function, and forms a first calibration curve. The method then forms an average residual error value. If that average residual error exceeds the maximum allowable residual error, then the method applies an offset to the first calibration curve to form a second calibration curve. That second calibration curve is saved for subsequent use during, for example, read / write / erase operations.

Owner:INT BUSINESS MASCH CORP

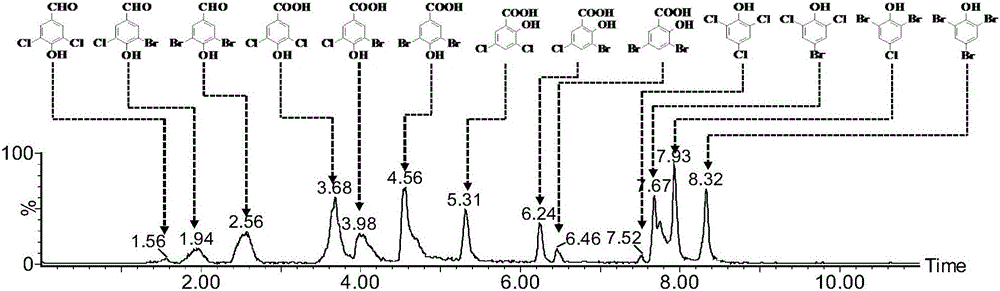

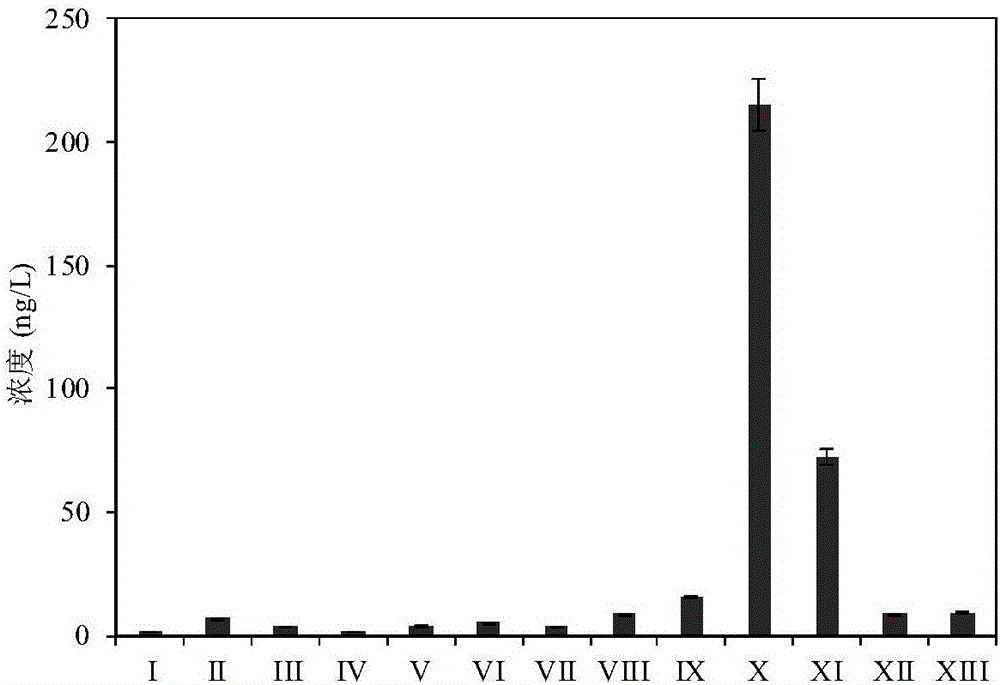

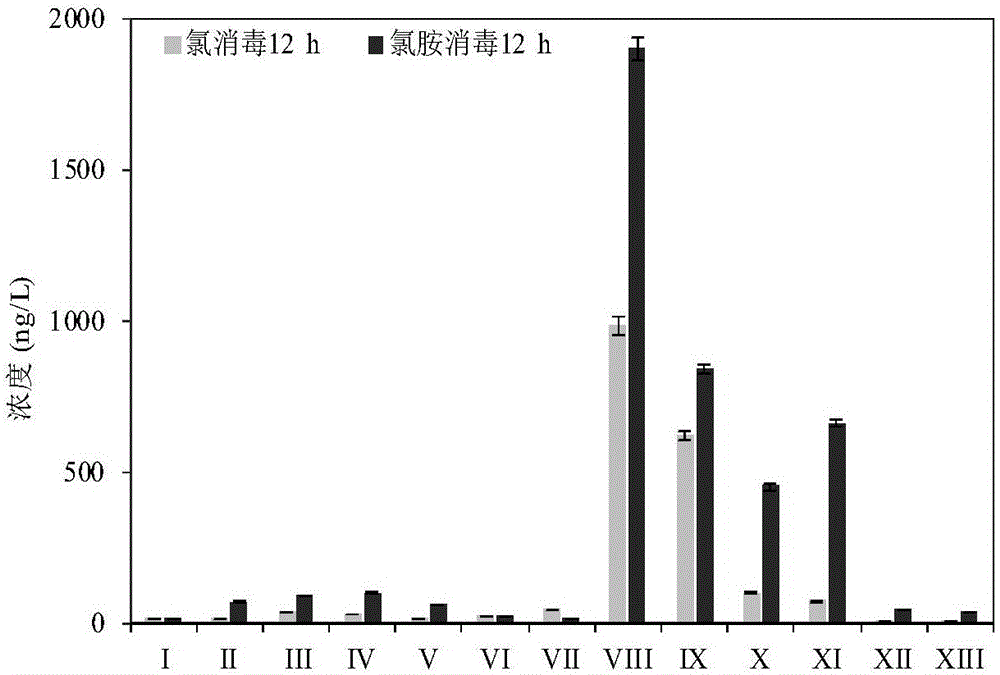

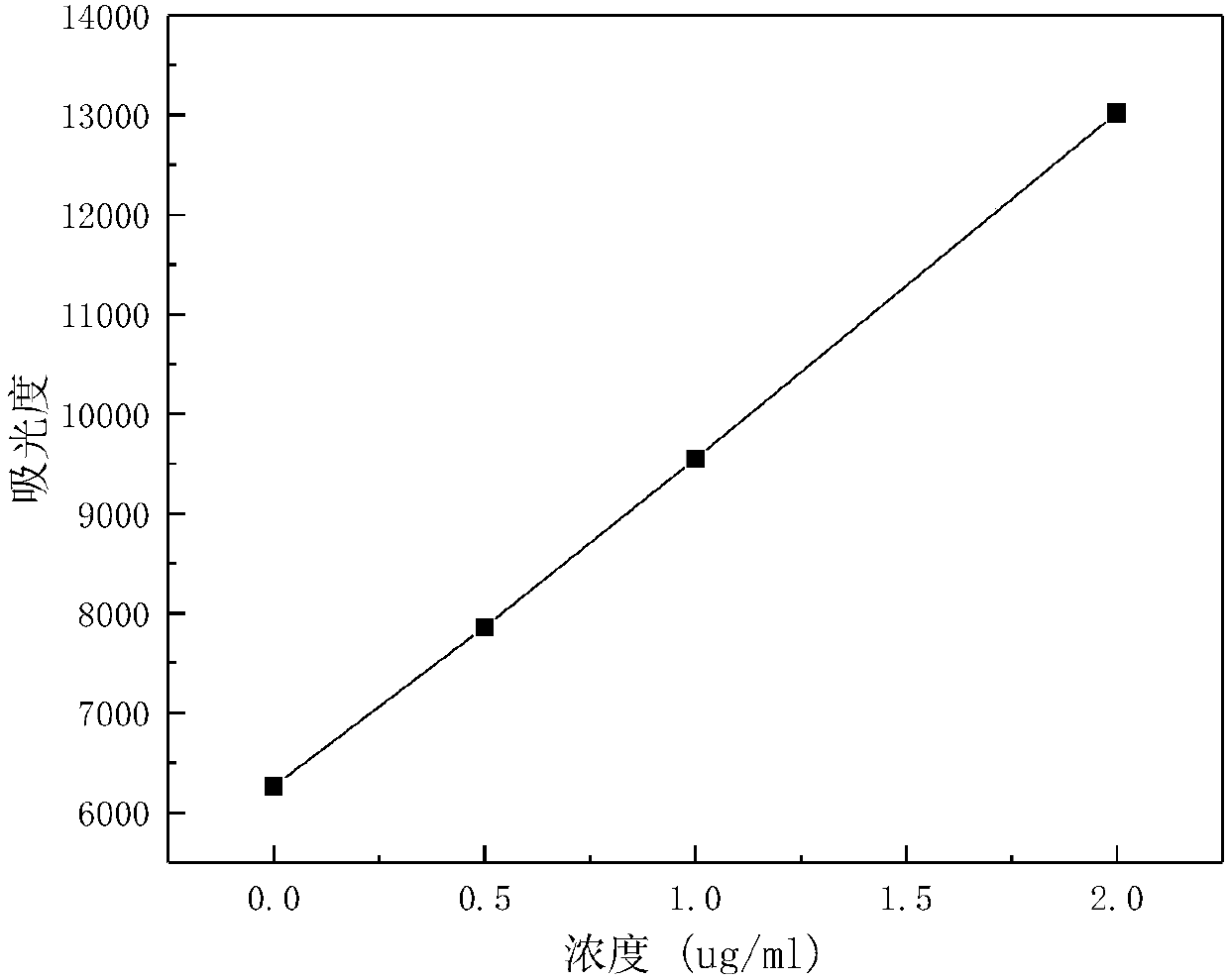

Method for detecting polar phenol type chlorinated/brominated disinfection by-products in water

Owner:NANJING UNIV

Analyte concentration measuring method, particle containing agglutinated fluorescent material, and inspection device

InactiveUS20190226988A1Satisfactory detection sensitivityMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceAggregation-induced emissionAnalyte

This analyte concentration measuring method including:preparing a mixed solution by mixing a sample solution containing an analyte, with a solution containing aggregation-induced emission fluorescent material-containing particles that have a binding partner which binds with the analyte and that agglutinate and fluoresce when the analyte binds to the binding partner;measuring the fluorescence intensity generated from the aggregation-induced emission fluorescent material-containing particles in the mixed solution; andcomparing a fluorescence intensity calibration curve for analyte concentration with the fluorescence intensity, and associating the fluorescence intensity with the analyte concentration in the mixed solution. Employing agglutinating-luminescent-material-containing particles enables measurements to be carried out with a satisfactory detection sensitivity while suppressing background fluorescence.

Owner:SEKISUI CHEM CO LTD +1

Method for measuring content of calcium in anthracite

InactiveCN107807119APreparing sample for investigationAnalysis by thermal excitationMuffle furnaceCalibration curve

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap