Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The carrying capacity of a biological species in an environment is the maximum population size of the species that the environment can sustain indefinitely, given the food, habitat, water, and other necessities available in the environment. In population biology, carrying capacity is defined as the environment's maximal load, which is different from the concept of population equilibrium. Its effect on population dynamics may be approximated in a logistic model, although this simplification ignores the possibility of overshoot which real systems may exhibit.

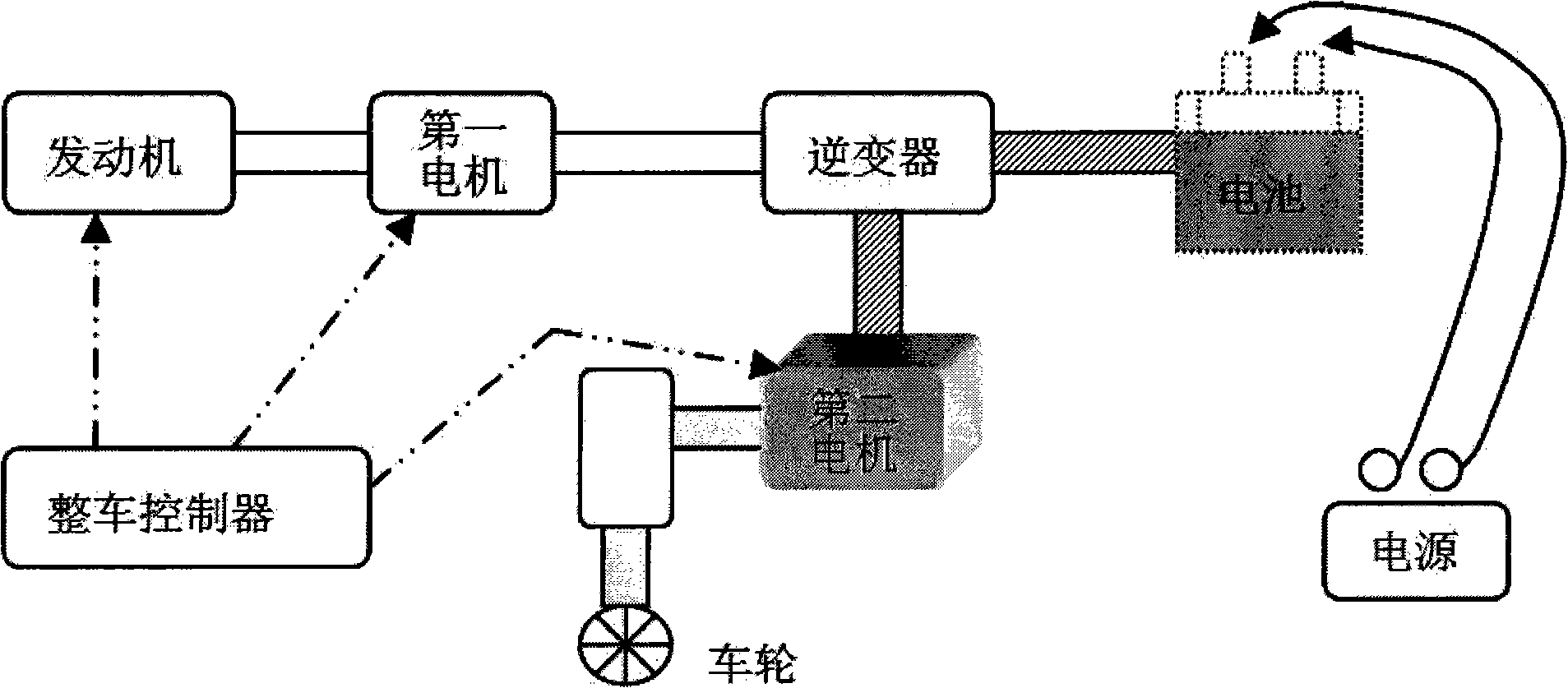

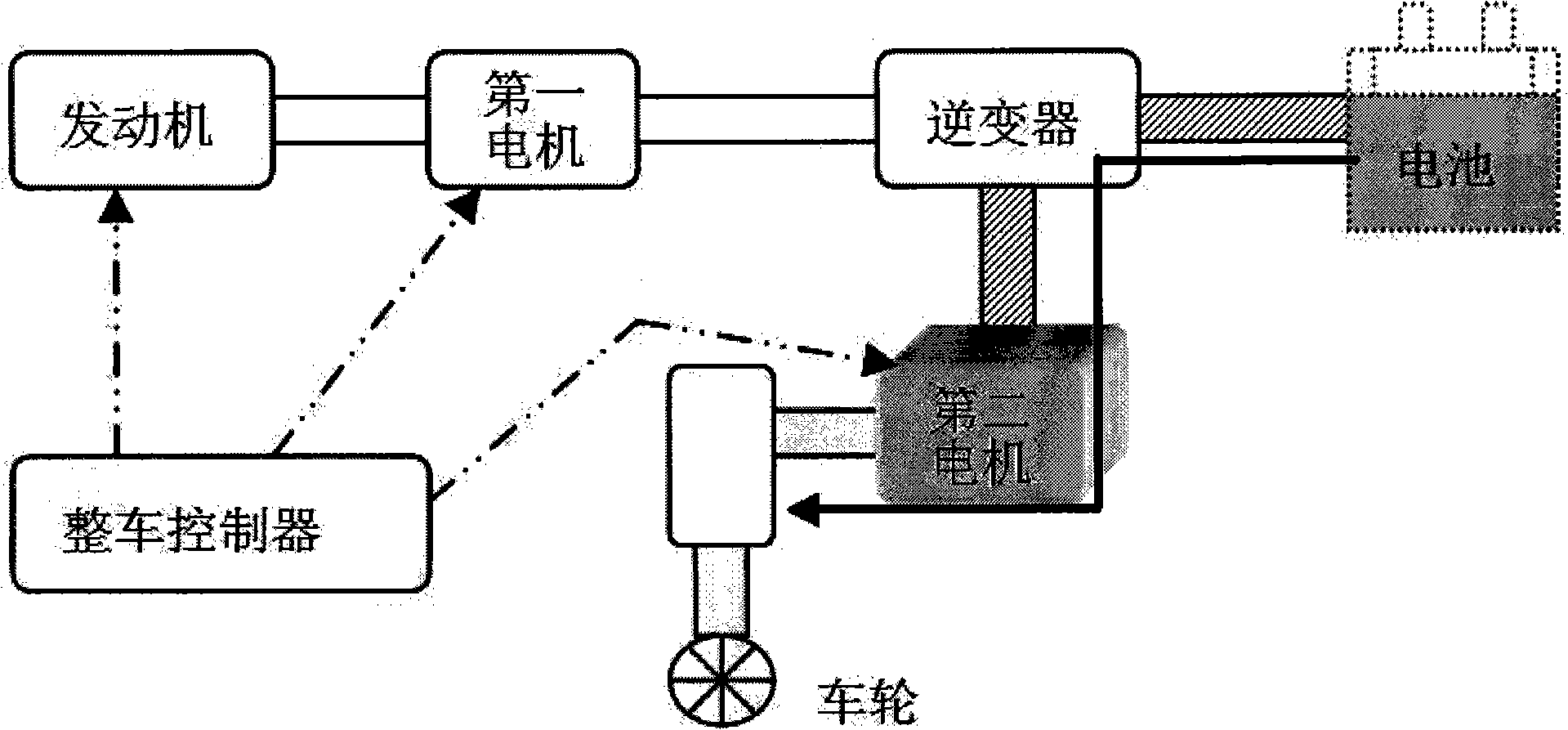

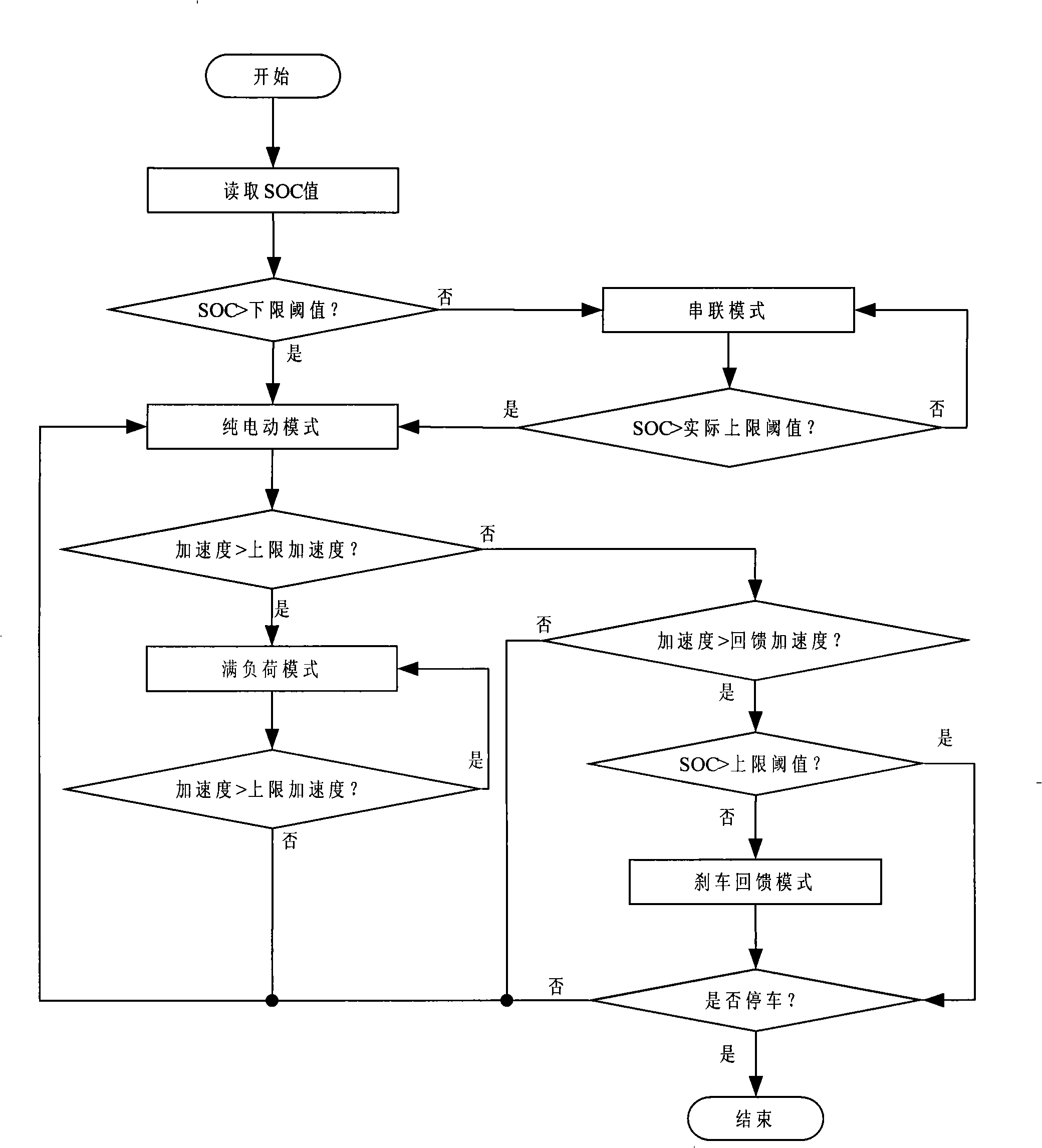

Driving method and system of tandem type hybrid vehicle

Owner:BYD CO LTD

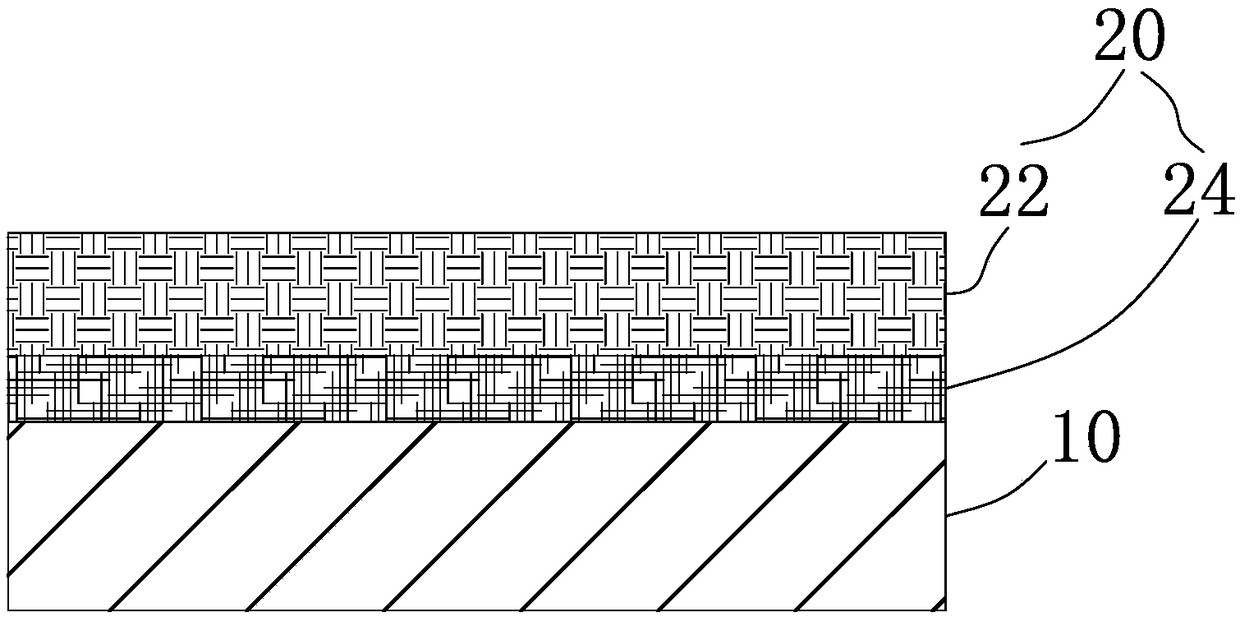

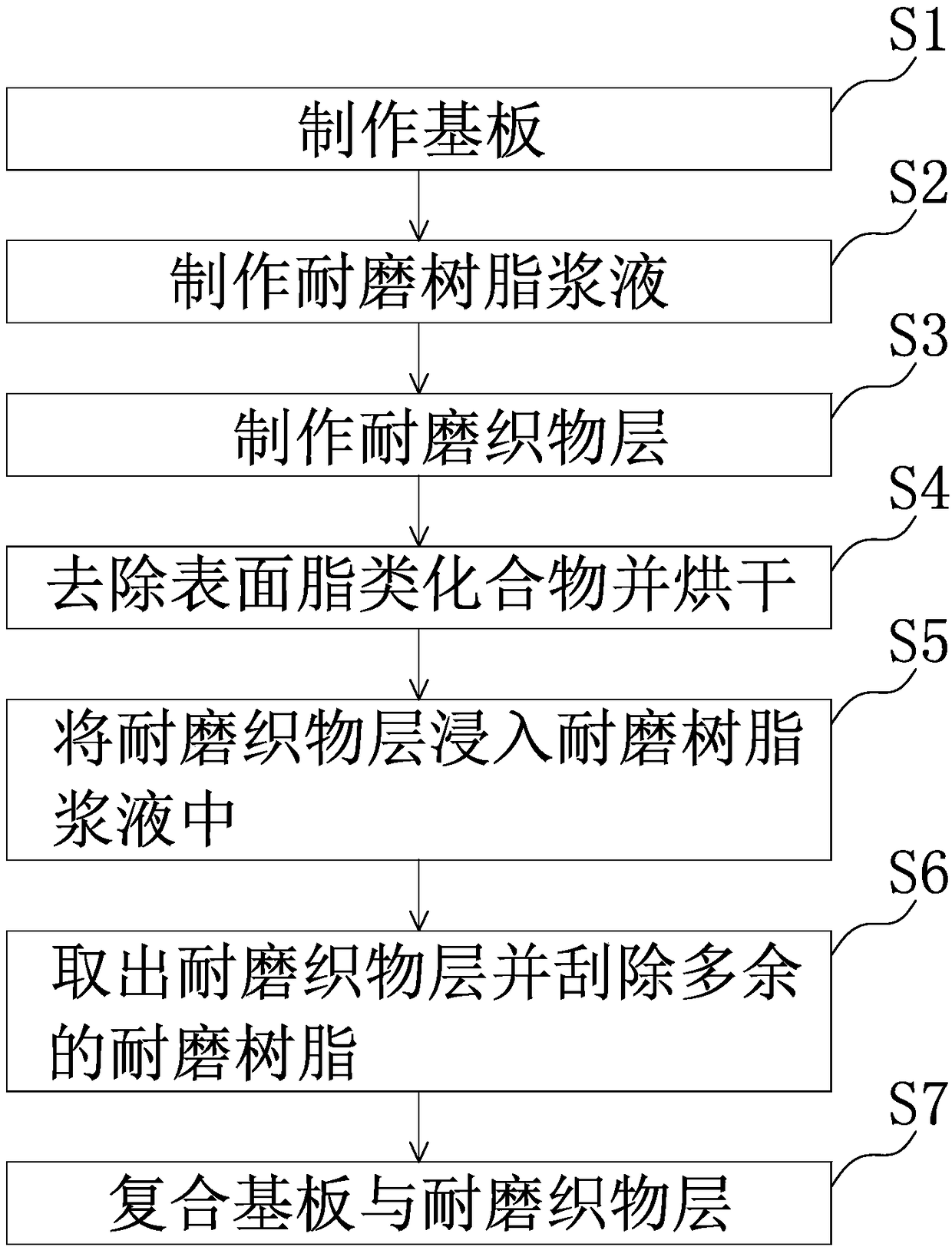

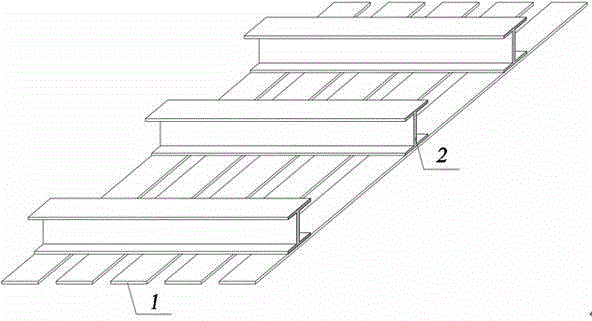

Wear-resistant non-metal composite board and production method thereof

ActiveCN108437585AReduced carrying capacityExtended service lifeLamination ancillary operationsSynthetic resin layered productsPolyesterEpoxy

Owner:JIASHAN CSB PLASTIC BEARING TECH CO LTD

Catalyst used in oxidative desorption of carbon monoxide in hydrogen and preparation method for catalyst

ActiveCN102921431AReduce usageReduce dosageHydrogen separationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationCarrying capacity

Owner:DALIAN CATALYTIC ENG TECH

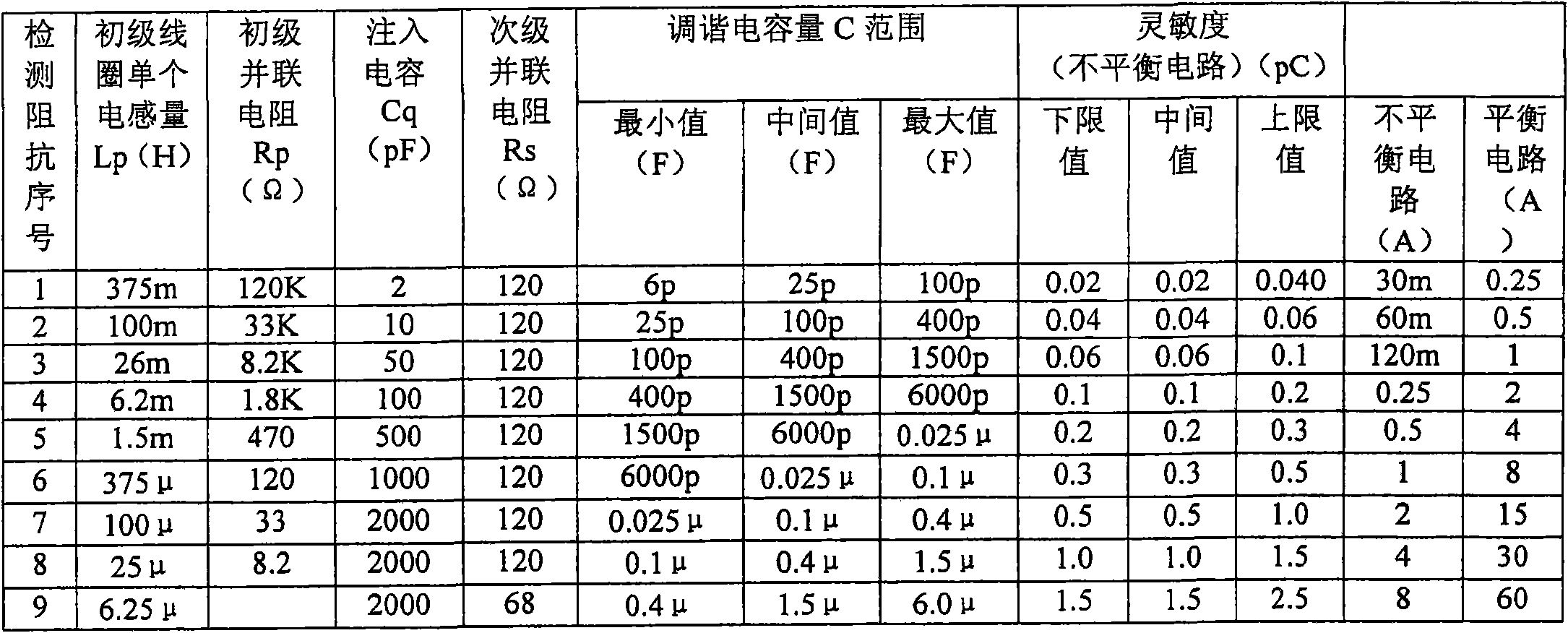

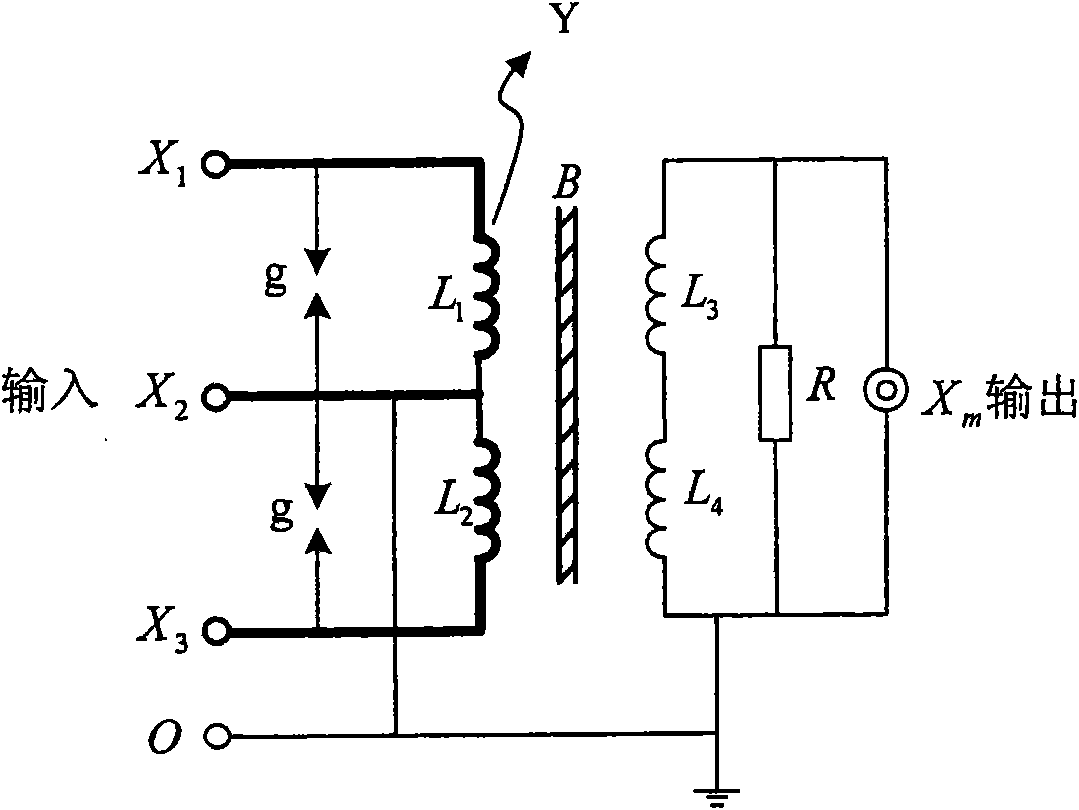

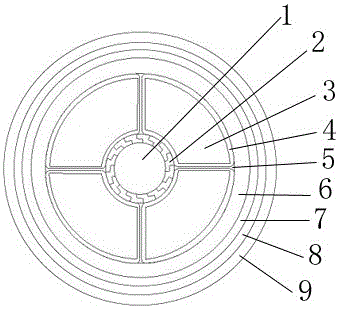

Detection impedance

ActiveCN101769947AHigh sensitivityHigh voltage and large measuring currentTesting dielectric strengthBase element modificationsCapacitanceHigh pressure

Owner:NORTH CHINA ELECTRICAL POWER RES INST +2

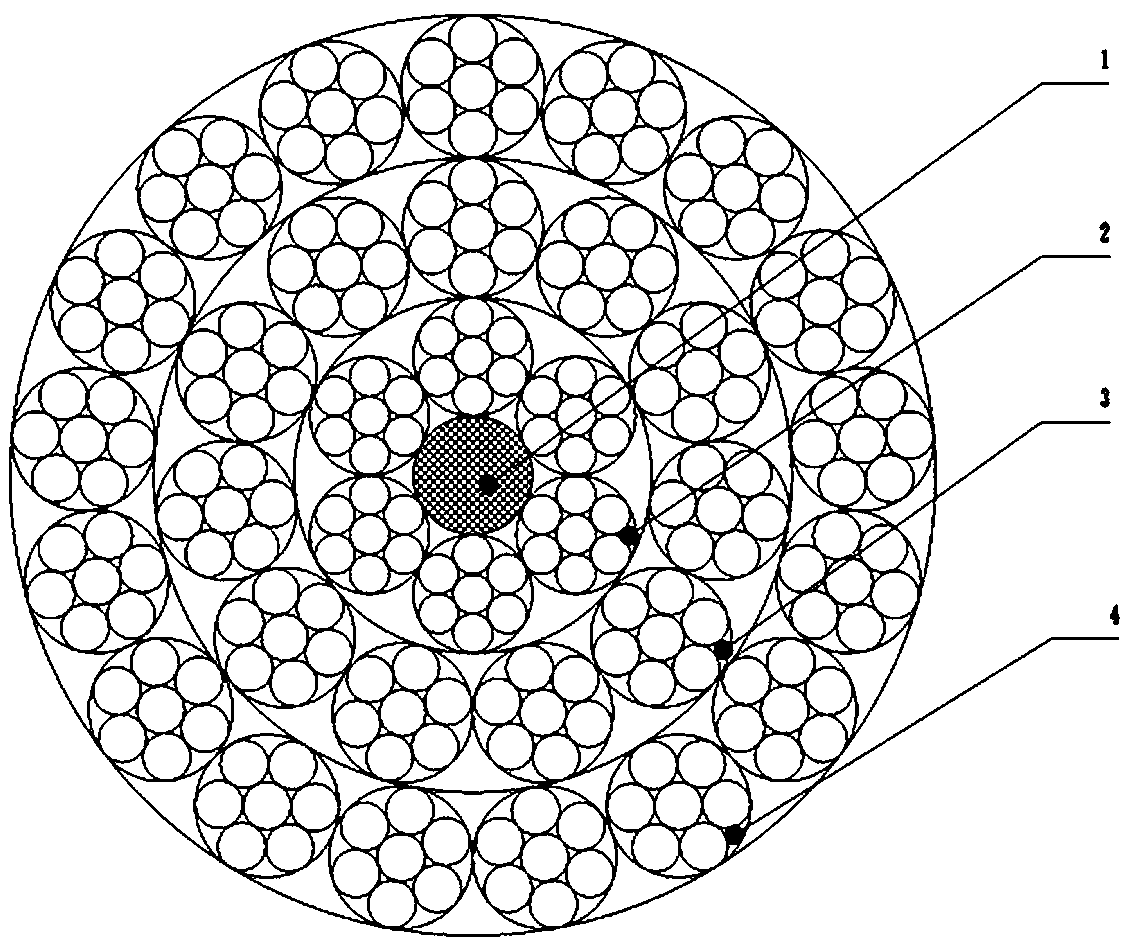

Structure design method of strand compacted non-rotating steel wire rope with diameter of 45mm

PendingCN110055781ACompact structureImprove fatigue resistanceRope making machinesFiberCarrying capacity

Owner:GUIZHOU WIRE ROPE

Super-large section hollow split conductor-type water-blocking control cable for train

InactiveCN106531329ALarge sectionImprove transmission capacityNon-insulated conductorsInsulated cablesPolyesterElectrical conductor

Owner:WUXI JIANGNAN CABLE

HCT slicer precision adjusting method

Owner:ANYANG PHOENIX PHOTOVOLTAIC TECH

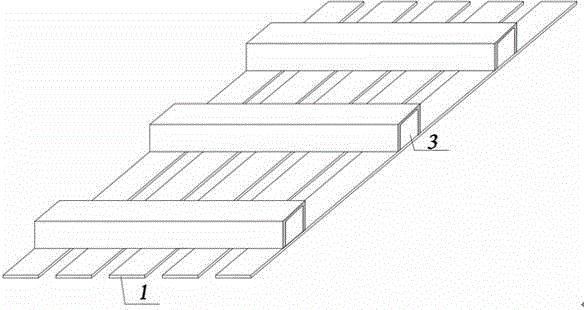

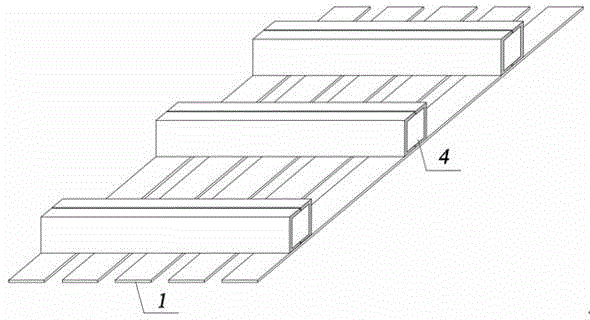

Composite type anti-settling plate basis with railing gaps in bottom plate and manufacturing method thereof

InactiveCN104631483ASimple preparation processGuaranteed stiffnessFoundation engineeringCarrying capacityEngineering

Owner:TIANJIN UNIV

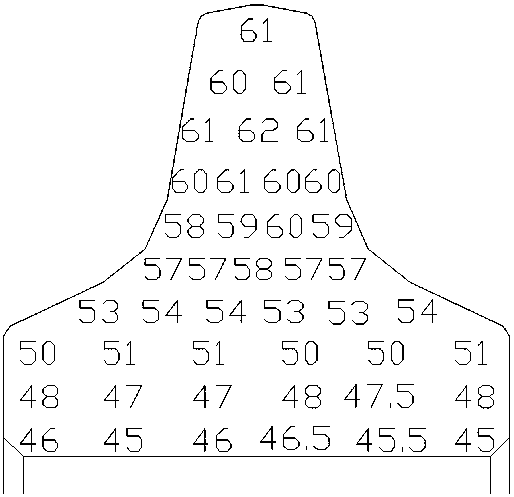

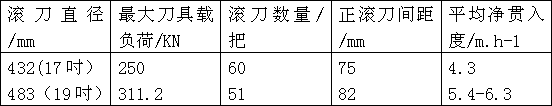

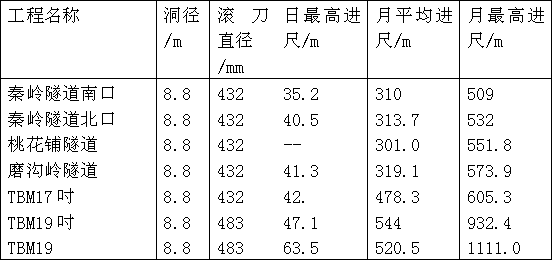

Tunneling machine heavy-load hobbing cutter ring

Owner:HULUDAO LITIAN HEAVY IND MACHINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap