Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Lift system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

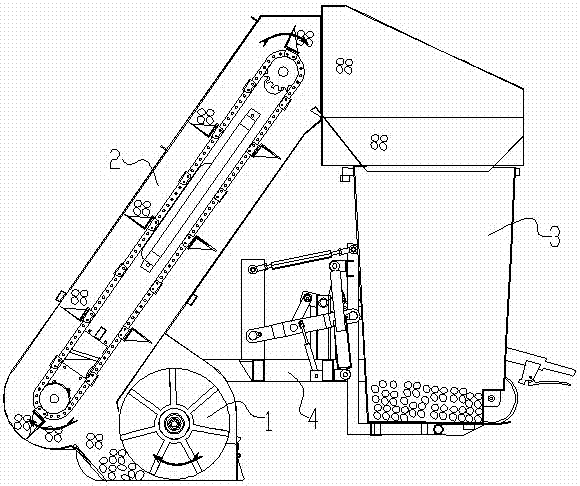

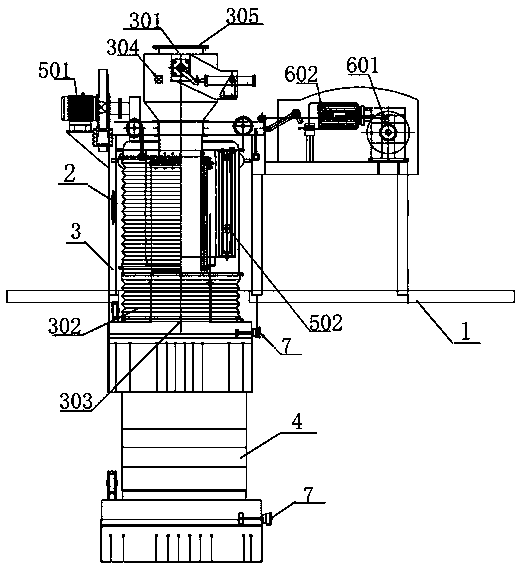

Chain-plate compost turning machine

InactiveCN103497017AImprove efficiencyLong turning distanceBio-organic fraction processingOrganic fertiliser preparationDrive wheelAutomatic control

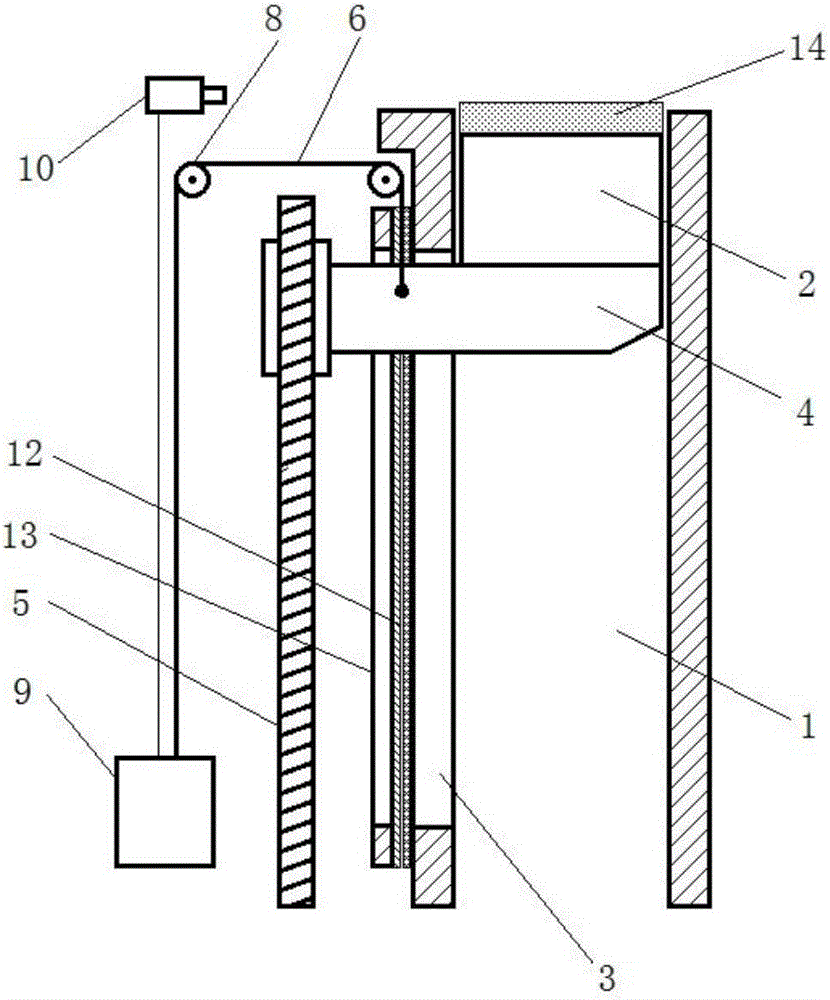

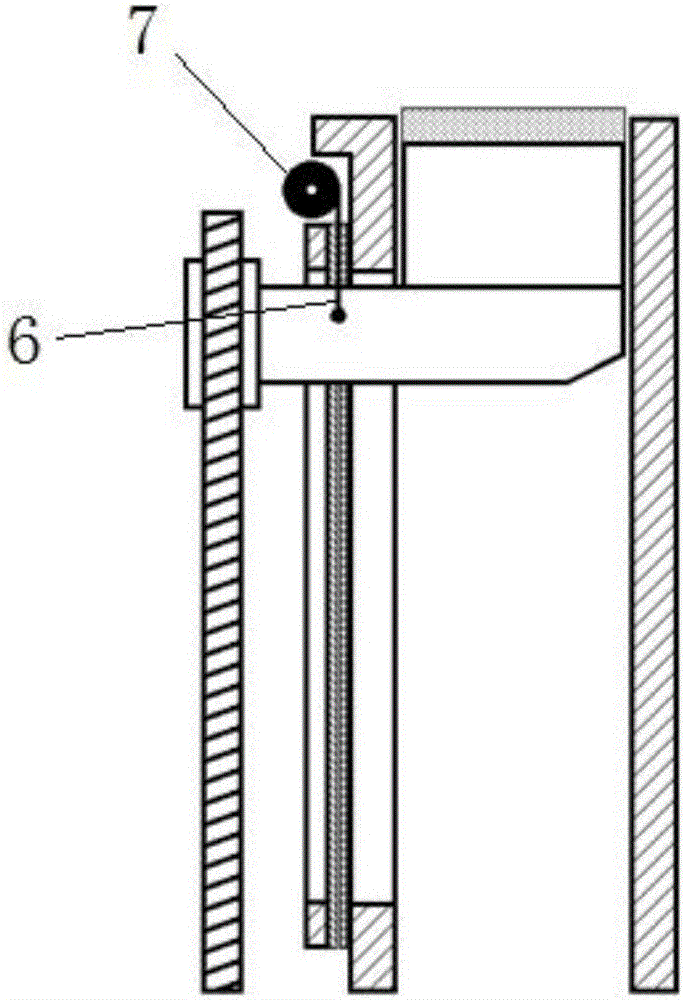

The invention discloses a mechanical device, in particular a chain-plate compost turning machine for production of organic compost. The chain-plate compost turning machine comprises a frame, a travelling mechanism, a chain-plate turning mechanism, a lifting system and an automatic control system. A driven wheel set and a driving wheel set are mounted at front and rear ends of the lower portion of the frame respectively. The driving wheel set is driven by a travelling motor set which is connected through a spindle. The driving wheel set is disposed on a travel rail of the travelling mechanism, and meanwhile, the chain-plate turning mechanism and the lifting system are driven by corresponding motors, thus coordinative operation of the systems is achieved. The chain-plate compost turning machine has the advantages that two travelling motors are used for control so that continuous operation of the machine is ensured; compost material in a fermenting tank is thrown, aerated and mixed by a rotary chain-plate hooked-tooth turning and scattering mechanism, efficiency is high, turning distance is long, turning is thorough, fermenting period can be shortened effectively, and compost quality is improved; the chain-plate compost turning machine is more adaptive and flexible.

Owner:HANGZHOU HUAXIN MECHANICAL & ELECTRICAL ENGINEERING CO LTD

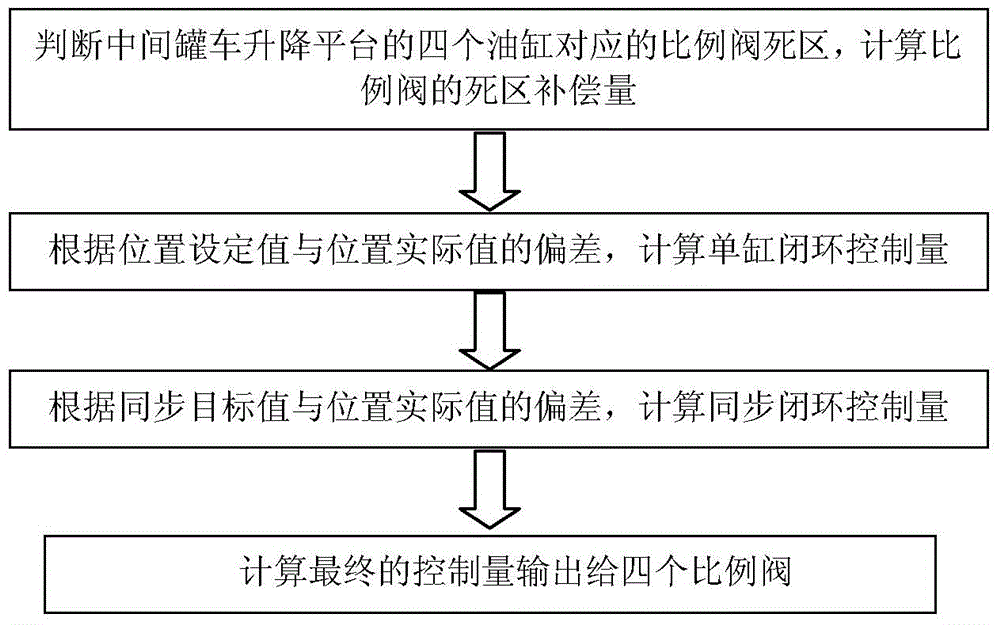

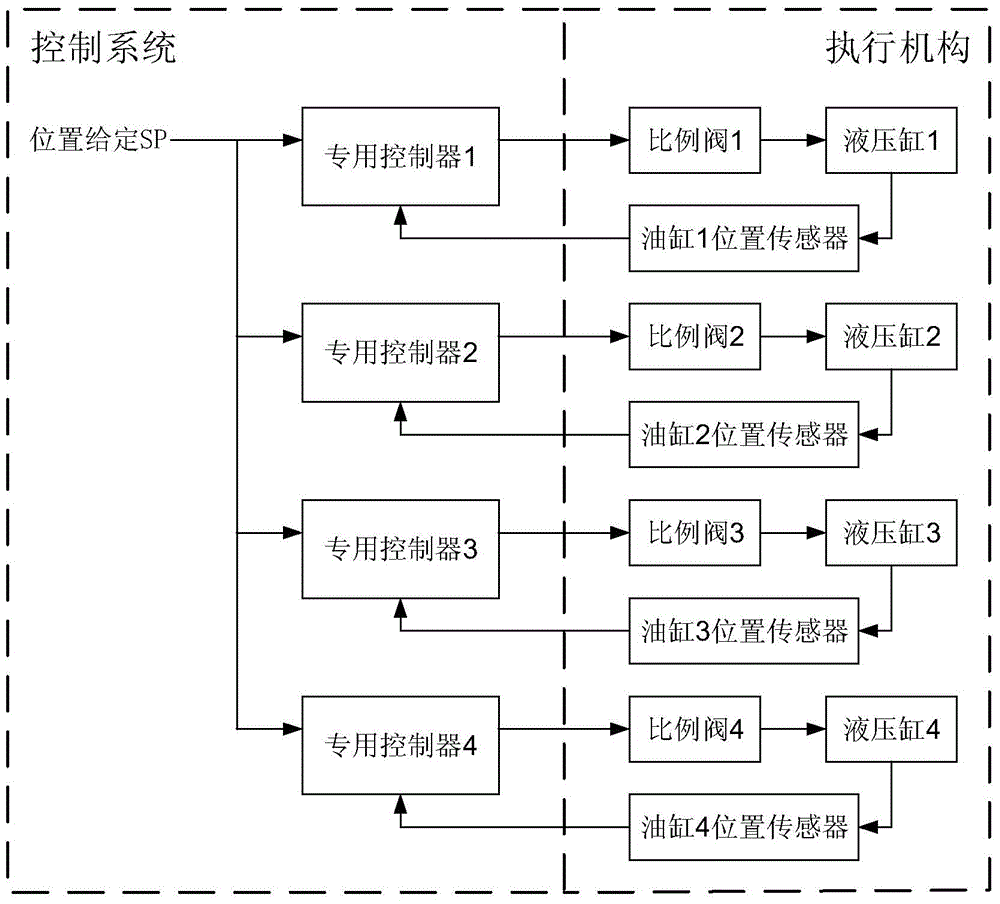

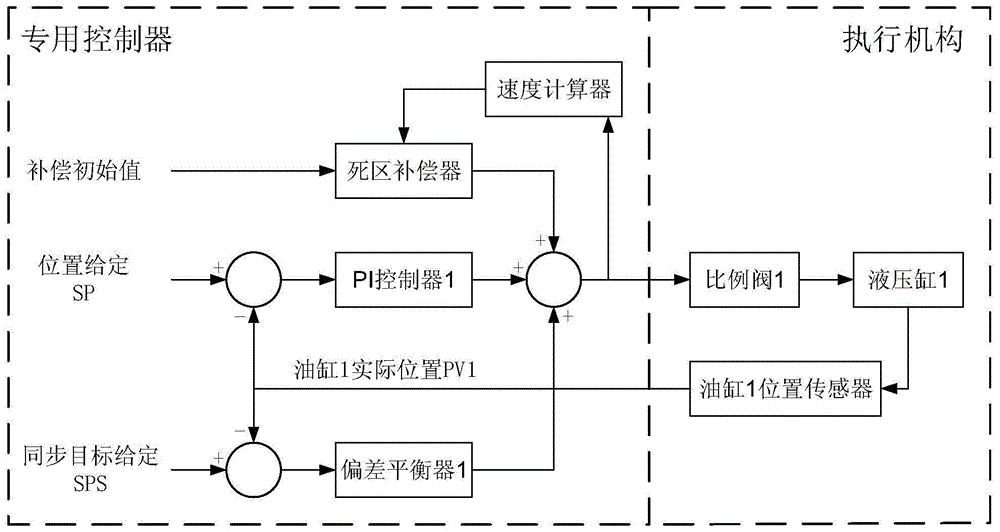

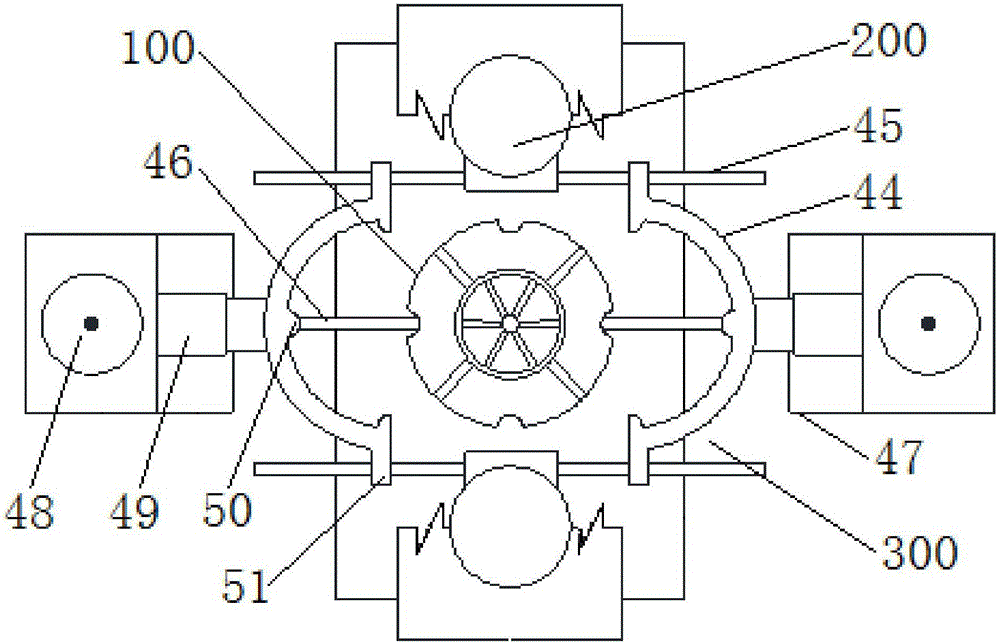

Deviation-balancing-based lifting synchronization control method and apparatus of tundish car

Owner:中冶赛迪电气技术有限公司

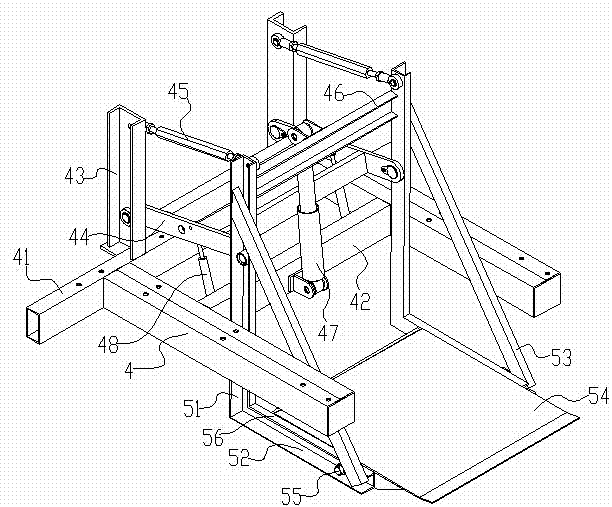

Device suitable for ring shear test and soil sample preparation of vertical shearing surface

ActiveCN106840810AAvoid breaking unevennessUniform stressPreparing sample for investigationMaterial strength using steady shearing forcesLift systemEngineering

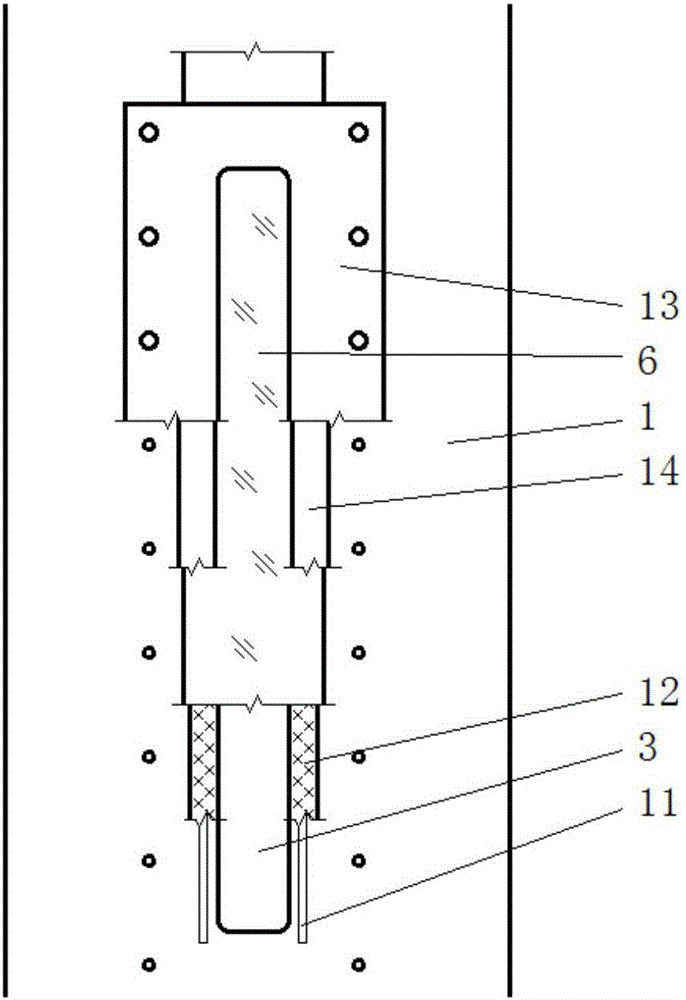

The invention relates to a device suitable for ring shear test and soil sample preparation of a vertical shearing surface. The device comprises a shearing box, a lifting system, a power rotating system, a monitoring control system, a soil sample preparation system and a frame, wherein shearing plates are uniformly fixed on an annular base plate along the radial direction of the annular base plate; an outer cover of the shearing box is covered on the annular base plate and the shearing plates and is assembled and fixed with the annular base plate through a guide strip and a guide slot; the outer cover of the shearing box is connected with a rotating force arm of the power rotating system and is used for transmitting torque; a coupling pressing plate is aligned and embedded into a central hole of a top plate of the outer cover of the shearing box and is driven by the lifting system to load normal force; the annular base plate is aligned and embedded into a cylindrical support platform; and under the effect of driving torque, an inner cylindrical side wall generated by the circling motion of the annular base plate under the driving of the shearing plates is the vertical shearing surface. According to the invention, the shearing displacement and the uniform distribution of the shearing stress on the shearing surface can be guaranteed, the thickness of the vertical shearing surface is not limited and the device has the functions of sample preparation and vertical shearing test.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

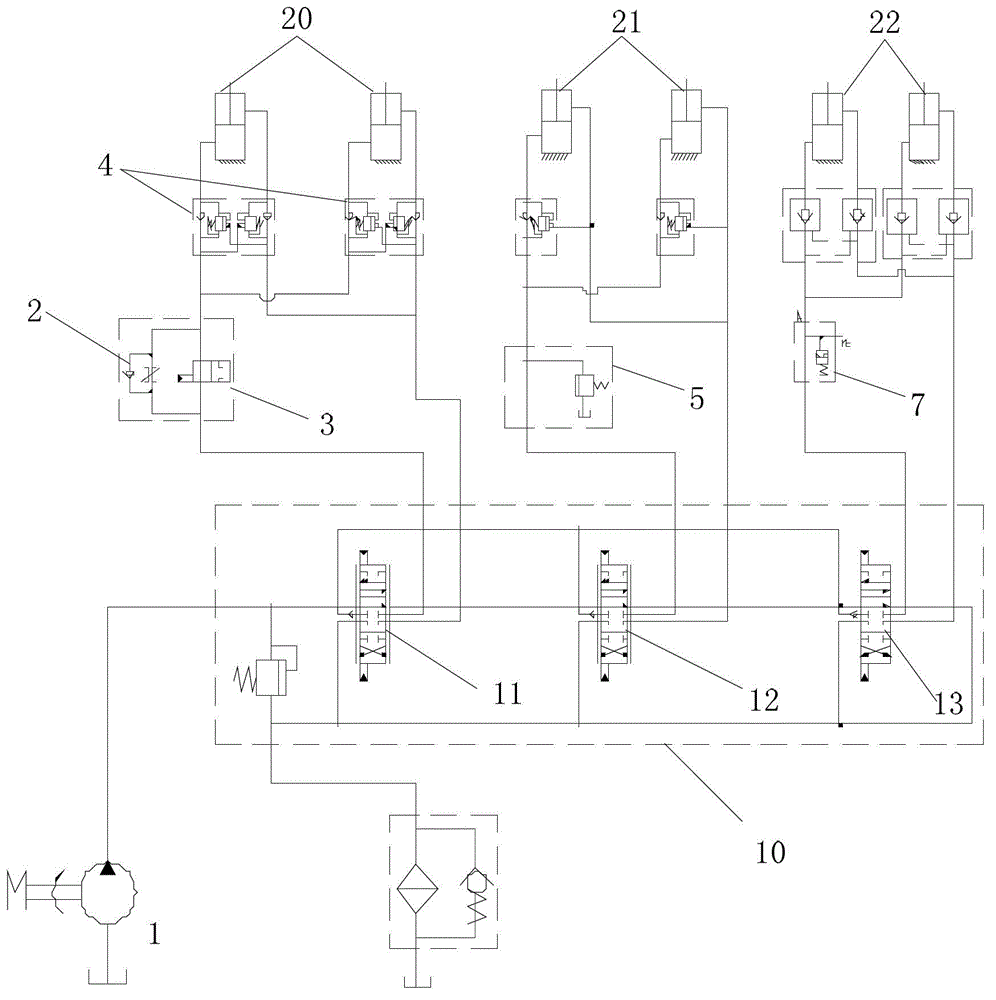

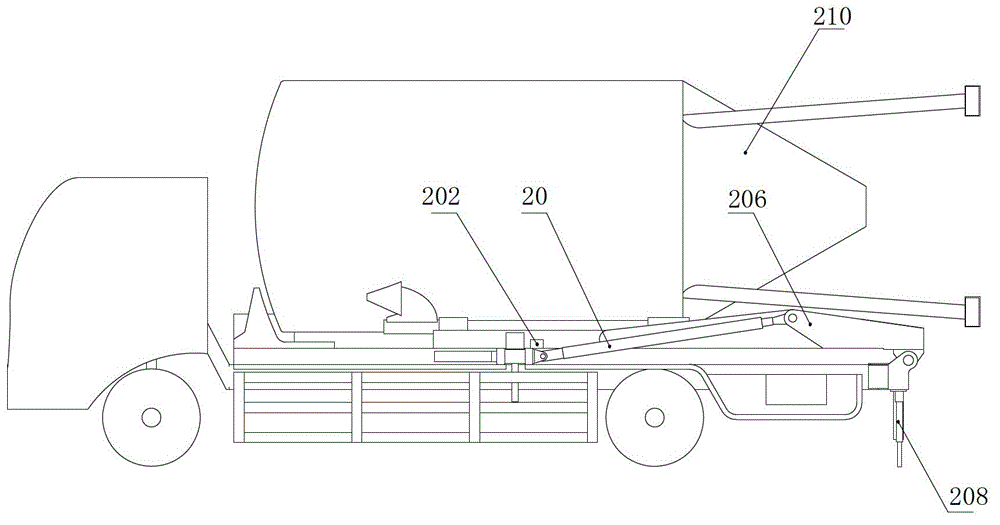

Garbage bin lifting system for sweeper

ActiveCN104499447ARealize manual descending operationEasy loading and unloadingRoad cleaningHydraulic cylinderRoad surface

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

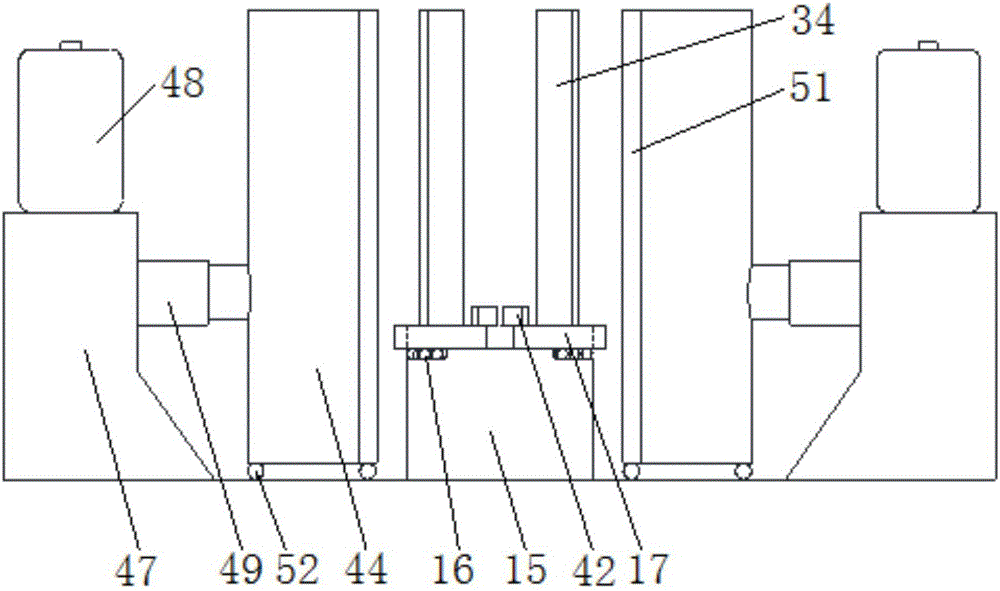

Additive manufacturing formation cylinder lifting system, formation cylinder and additive manufacturing equipment

InactiveCN106270511AImprove sealingIncrease forming heightAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringCantilever

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

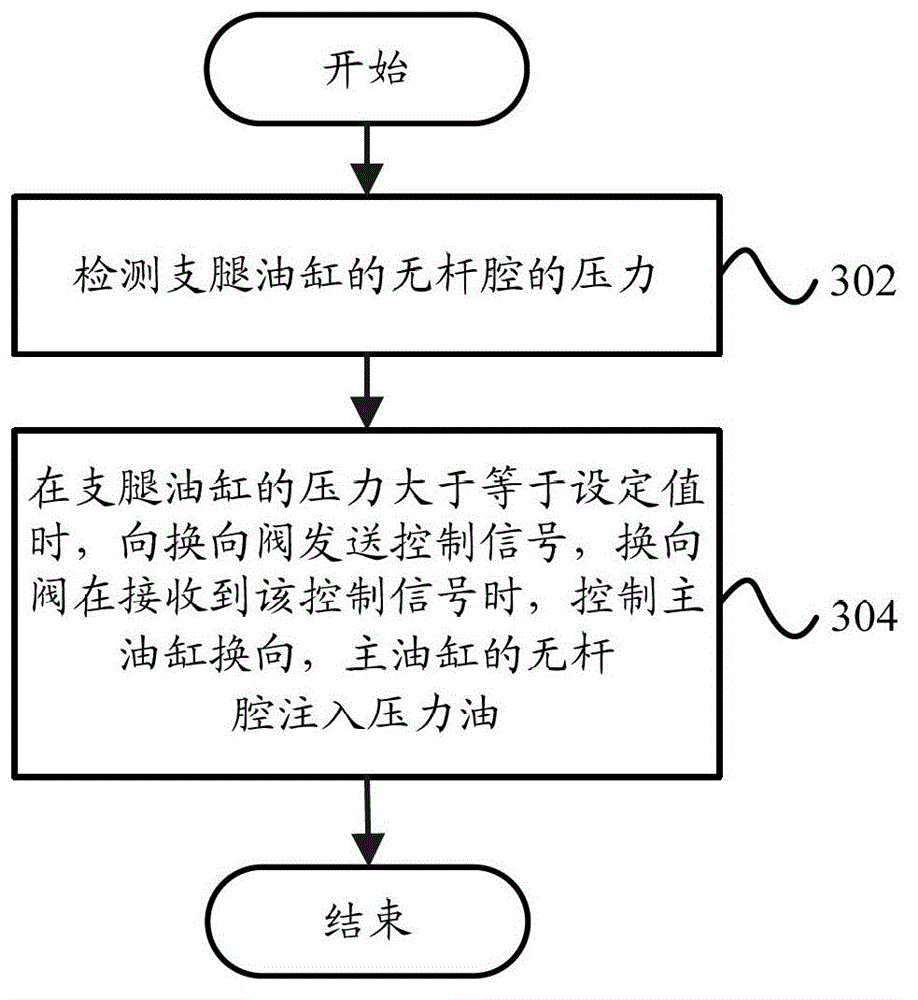

Advanced protecting system and advanced protecting method for support legs of demountable tanker carrier

Owner:SANY HEAVY IND CO LTD (CN)

Integrated bulk machine

PendingCN109573665AEliminate pollutionMeet silo requirementsConveyorsLoading/unloadingFastenerLift system

The invention discloses an integrated bulk machine. The bulk machine comprises a machine body supporting seat, a PLC controller, a silo, a dust collecting system, a lifting system and a telescopic barrel, wherein the silo is arranged on the machine body supporting seat in a penetrated mode and is fixedly connected by a fastener; the dust collecting system comprises a dust collecting fan, a dust collecting pipeline and a dust collecting filter barrel; the silo comprises a feeding port, a collecting bin, a discharging port and a curved valve; and the discharging port is fixedly connected with the telescopic barrel, the lifting system matches the telescopic barrel, and the PLC controller is respectively connected with the dust collecting fan, and the curved valve and the lifting system in a communicated mode. The integrated bulk machine has the advantages that each component cooperates with each other, and the machine is reasonable in design; by means of the machine body supporting seat,the whole device system is stabilized; by means of the dust collecting system, the dust pollution caused by transferring the powder can be eliminated; and by means of the lifting system, the change ofthe length of the telescopic barrel can be achieved, so that the whole device is capable of meeting the requirements of a silo of a vehicle body with different heights, the whole device is easy to operate and convenient to transfer, and the bulk machine has wide adaptability and high stability.

Owner:NANTONG AORUN BUILDING MATERIAL TECH

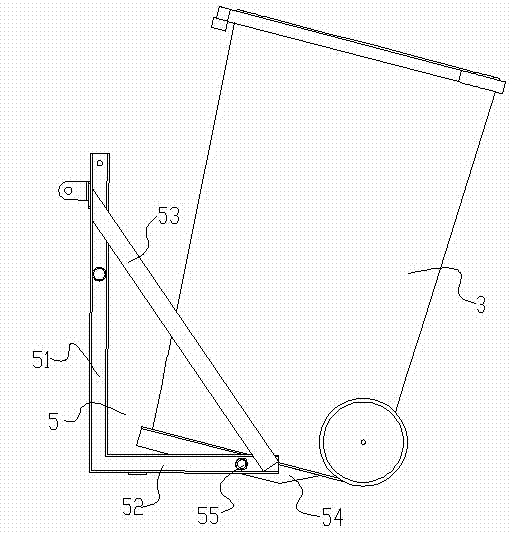

Lifting system

A lifting system for lifting a lifting platform through use of a lifting assembly. The lifting assembly having a vertical support rail and a control arm that is pivotally connected to the vertical support rail about a first pivot axis. A support beam being connected to the lifting platform the support beam having an engaging member near its proximal end that engages the vertical support rail to provide translational movement of the support beam along the vertical support rail. The control arm having an engaging member engaging the support beam at a location spaced from the vertical support rail to provide translational movement of the engaging member with respect to the support beam. A stabilizer arm is pivotally connected to the control arm and pivotally near the proximal end of the support beam. Movement of the lifting platform causing translational movement of the engagement members.

Owner:ELEVATOR

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap