Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Parameter control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control parameters can be products, process or machine that multiple controlling are required for the provide good quality material to customers, through control parameter supplier are monitoring and controlling process stages that material is pass with expect the parameters are maintain as required to quality product manufactured.

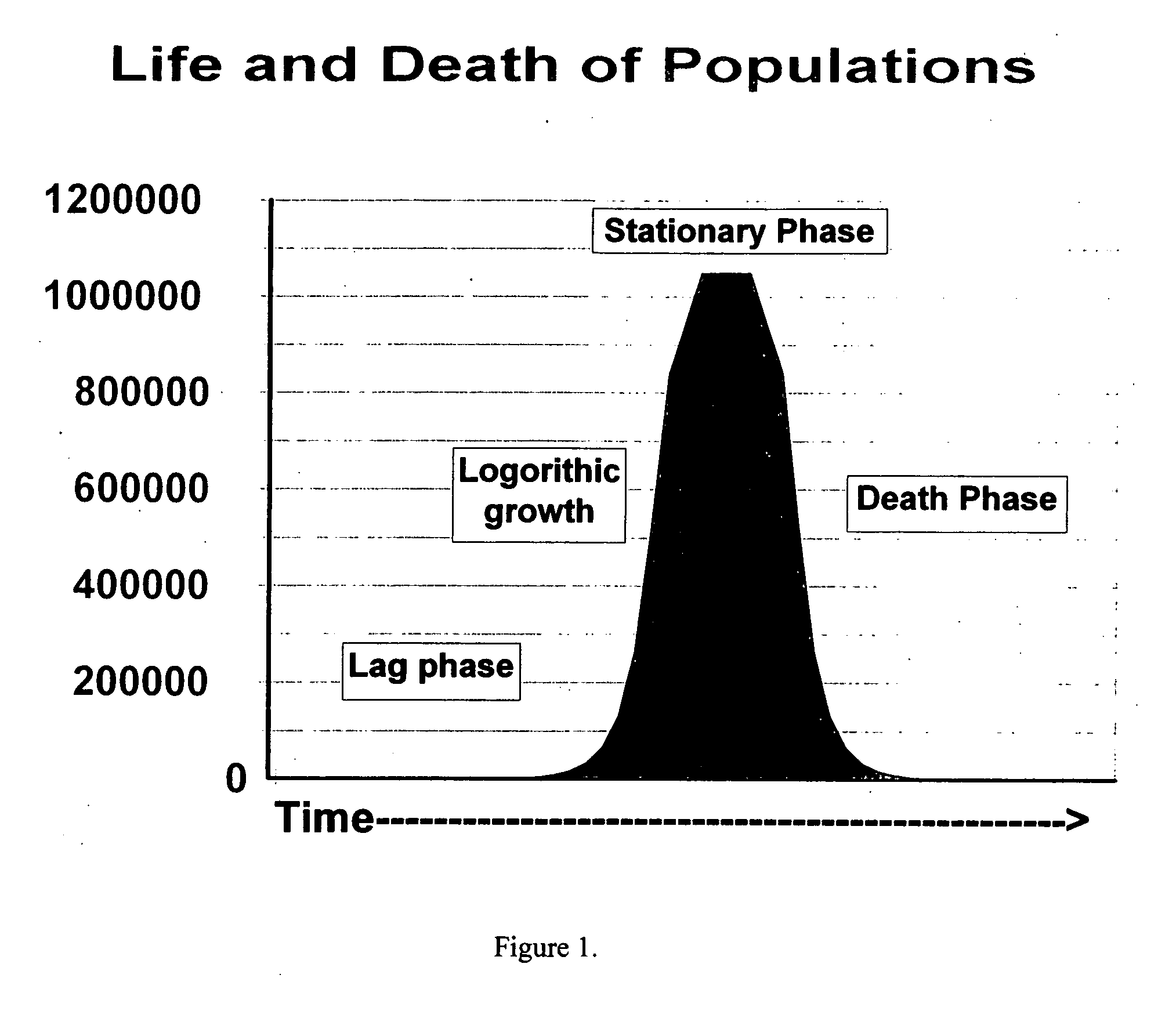

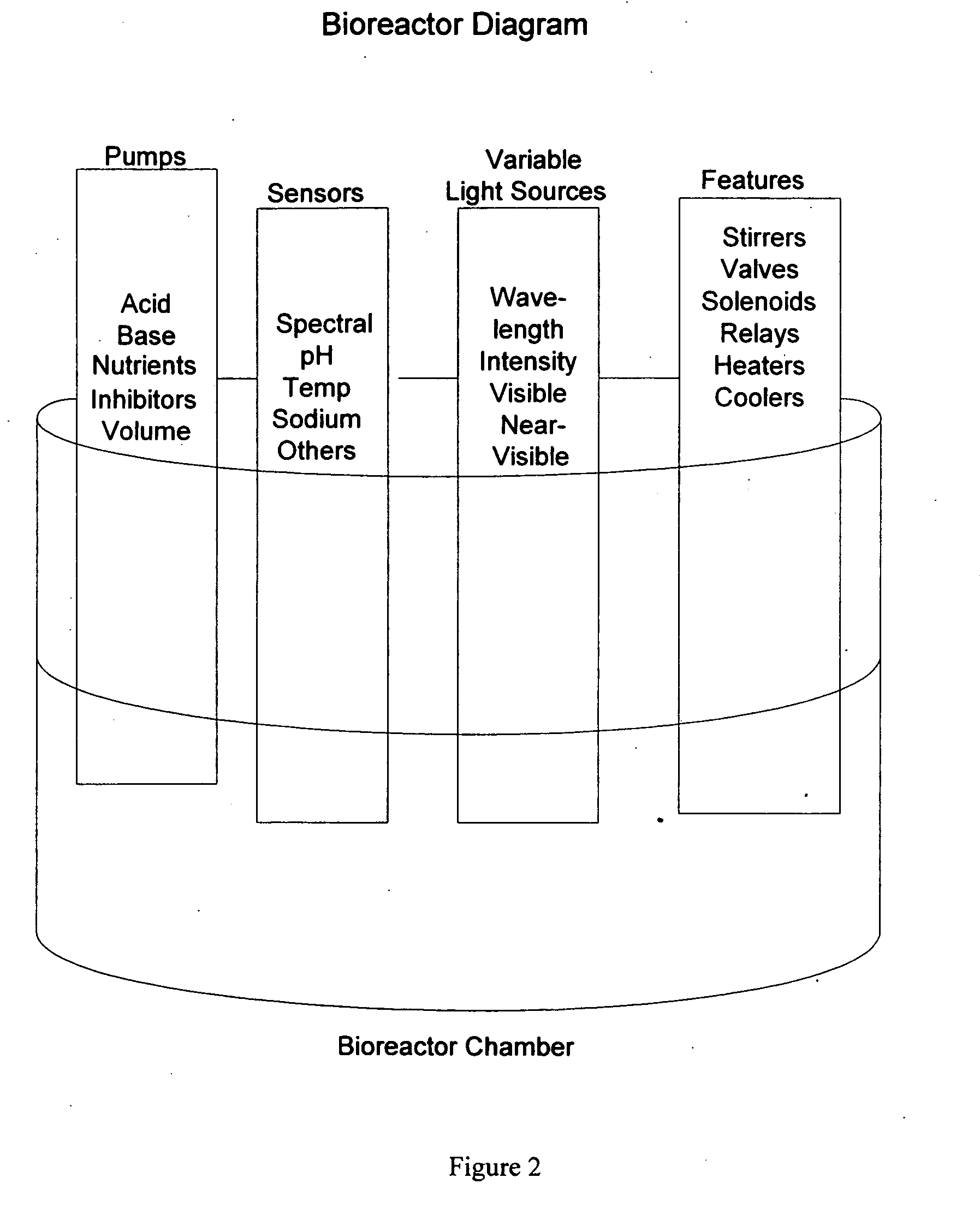

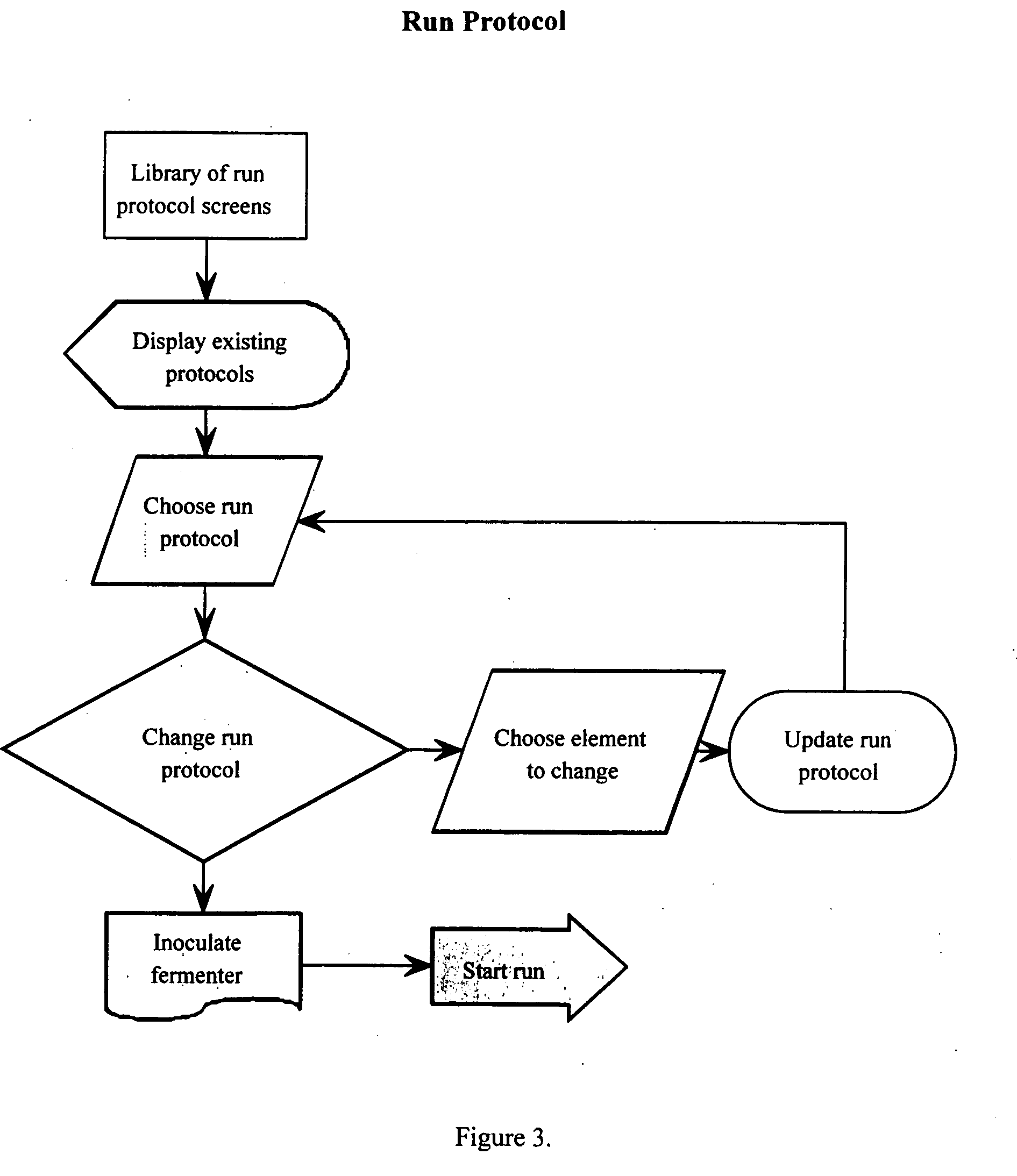

Decision-making spectral bioreactor

InactiveUS20050208473A1Bioreactor/fermenter combinationsBiological substance pretreatmentsComputer generationParameter control

Owner:KRICHEVSKY MICAH I +4

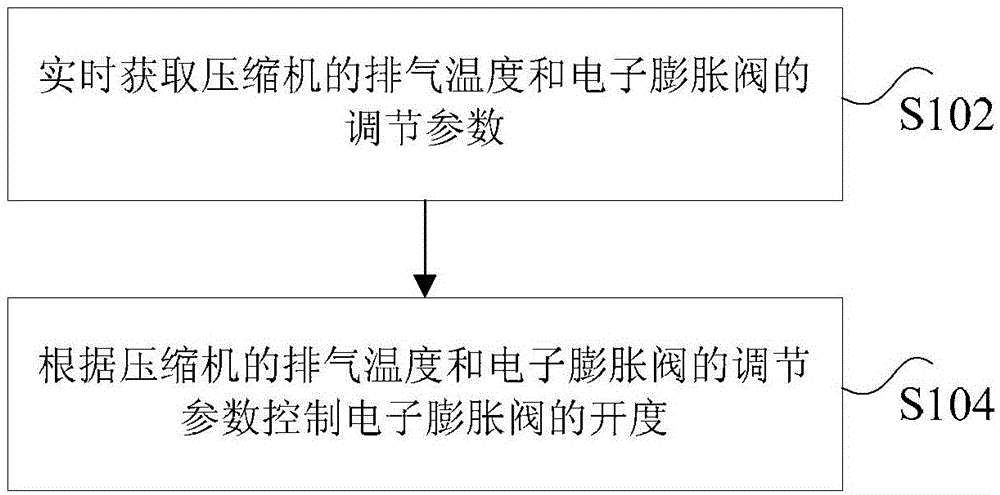

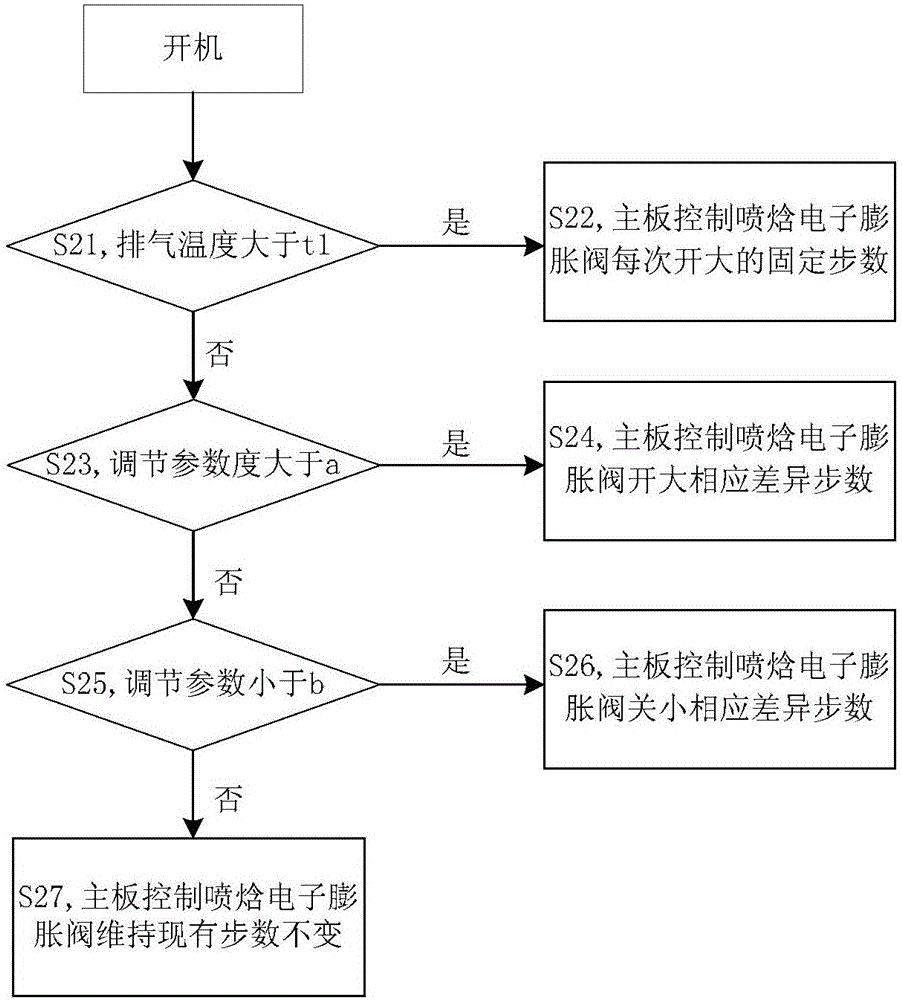

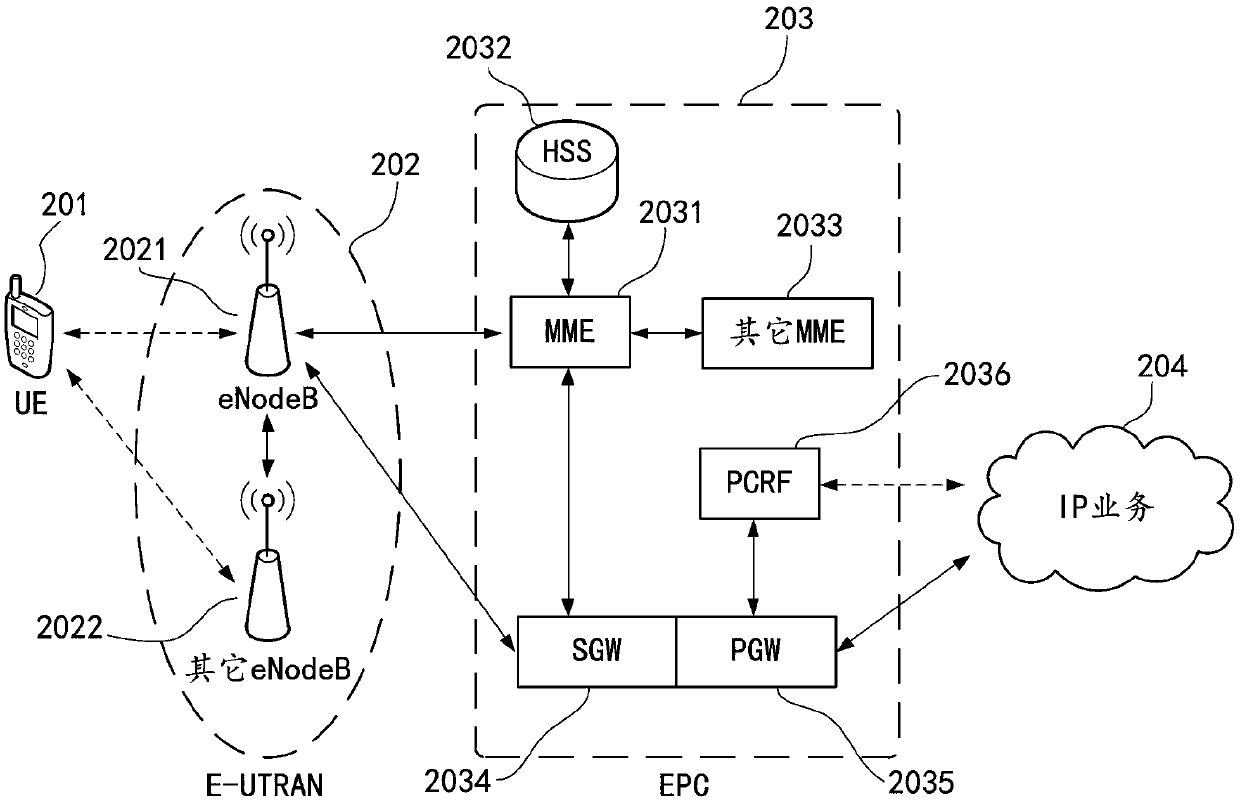

Method, system and device of air injection of air conditioning system and air conditioner

ActiveCN106642520AReduce the impact of controlsImprove reliabilityMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

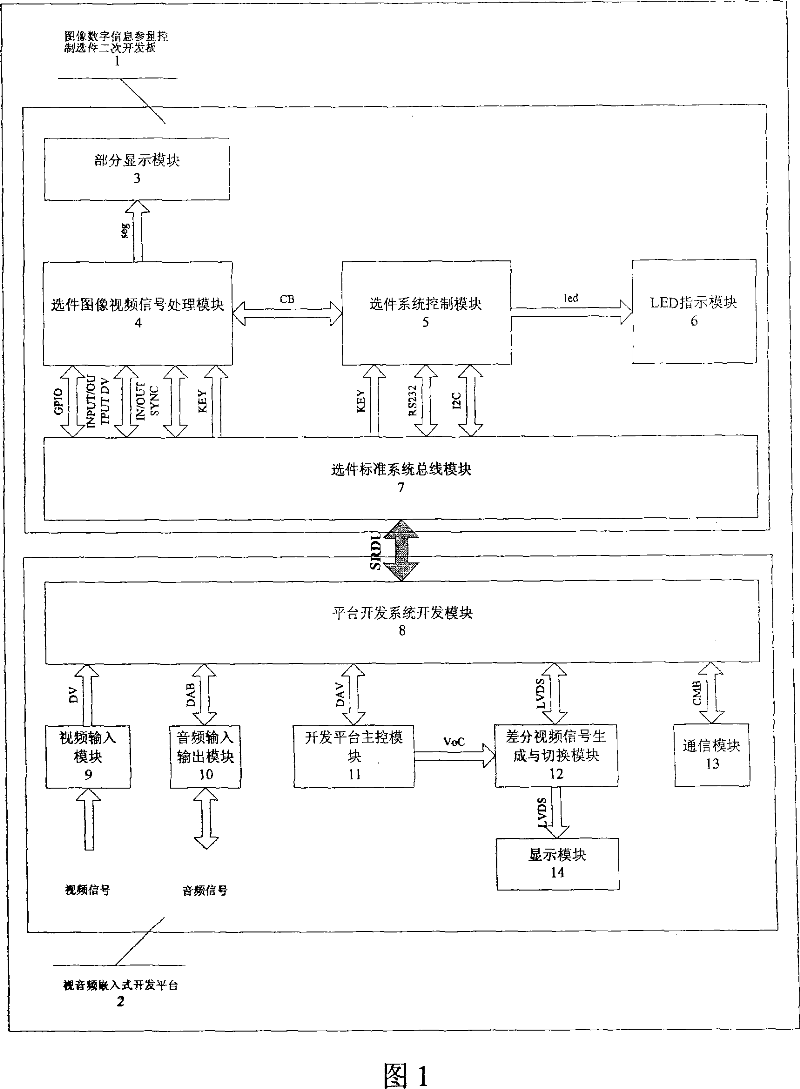

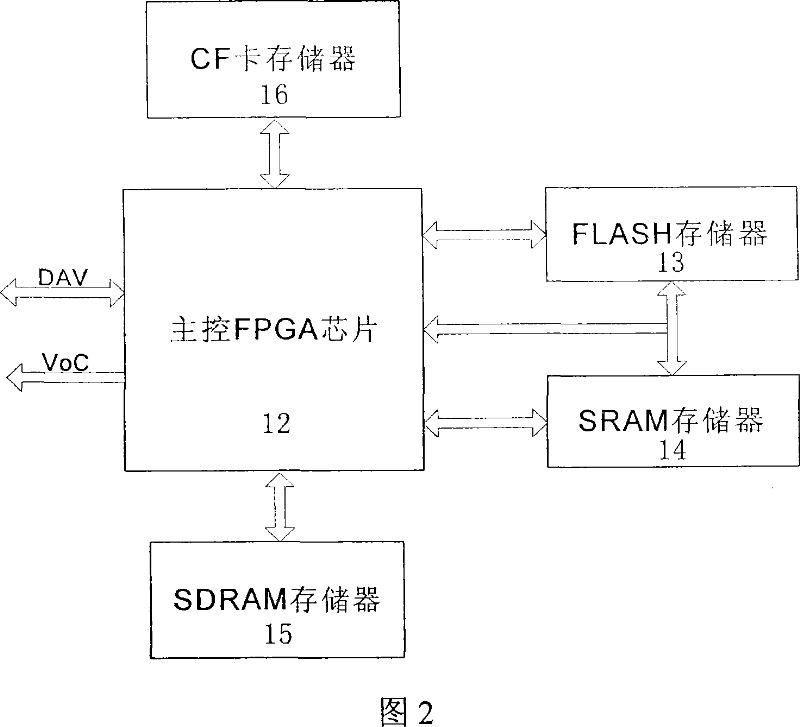

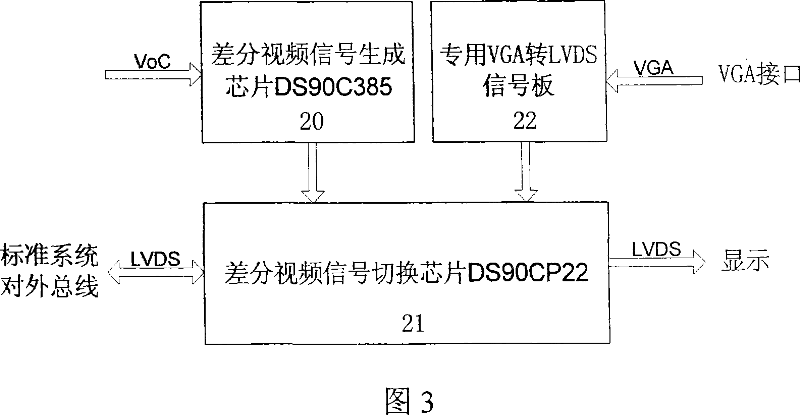

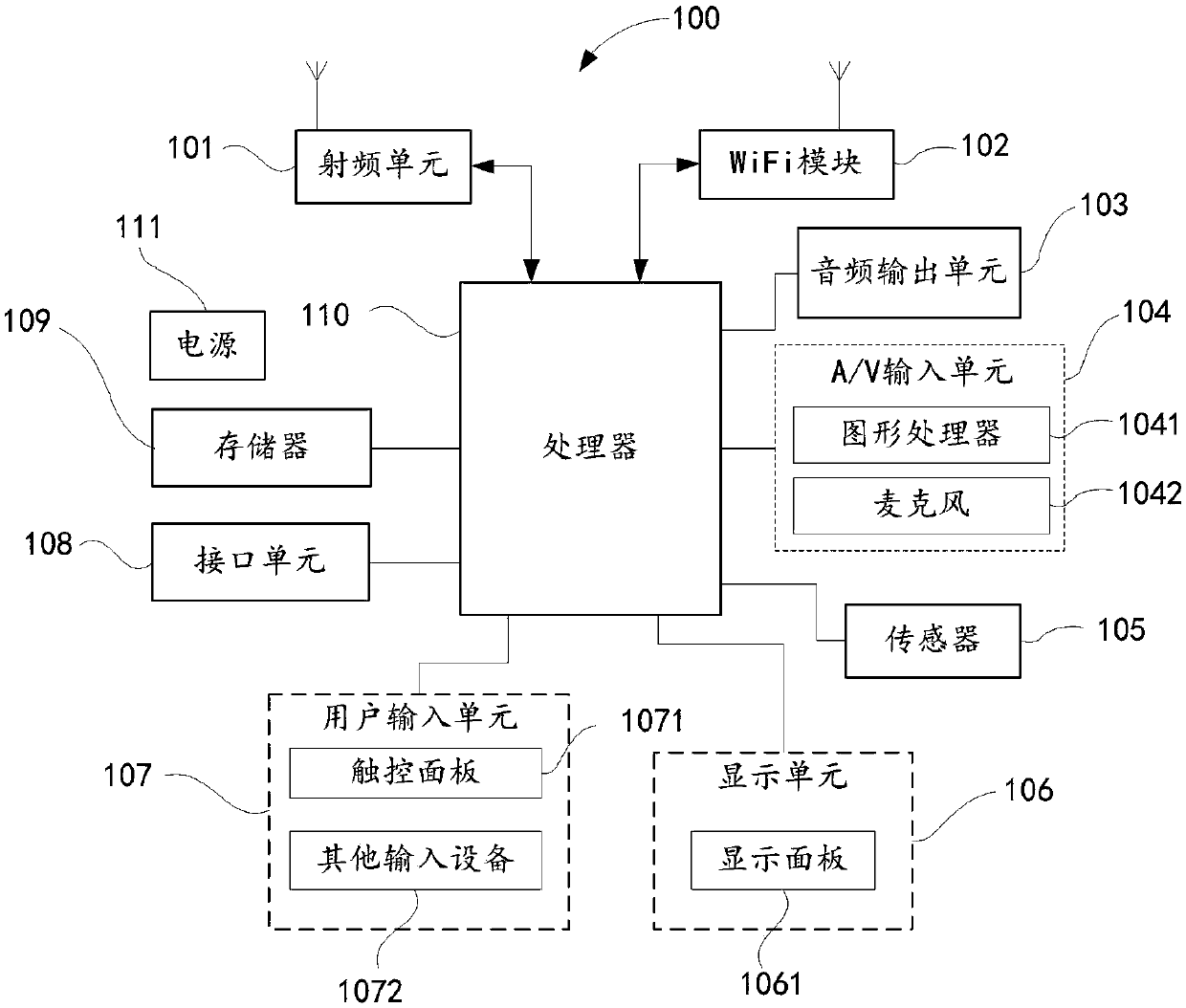

Image digital information parameter controlling parts selection secondary development plate based on audio/video embedded development platform

InactiveCN101038578ALarge storage capacityOptimizationTelevision system detailsColor television detailsComputer moduleParameter control

Owner:SHANGHAI UNIV +1

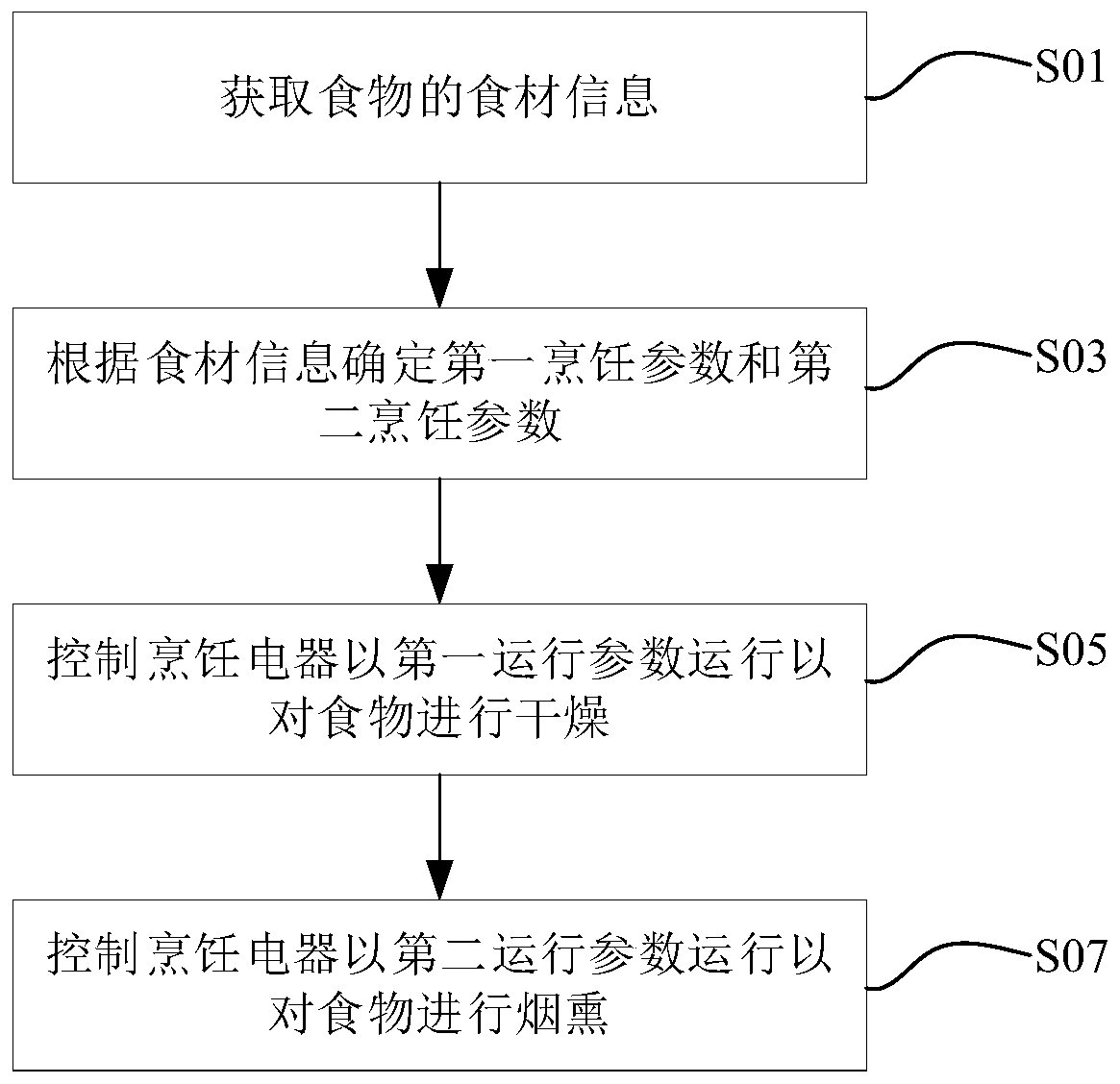

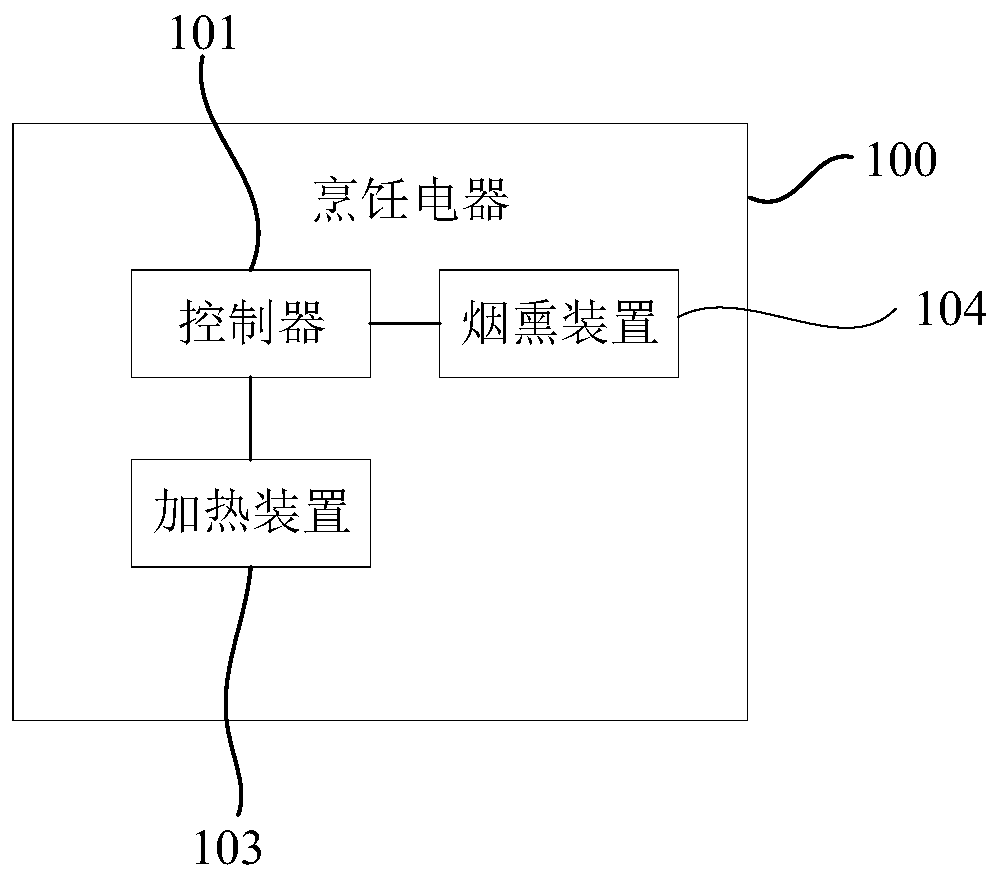

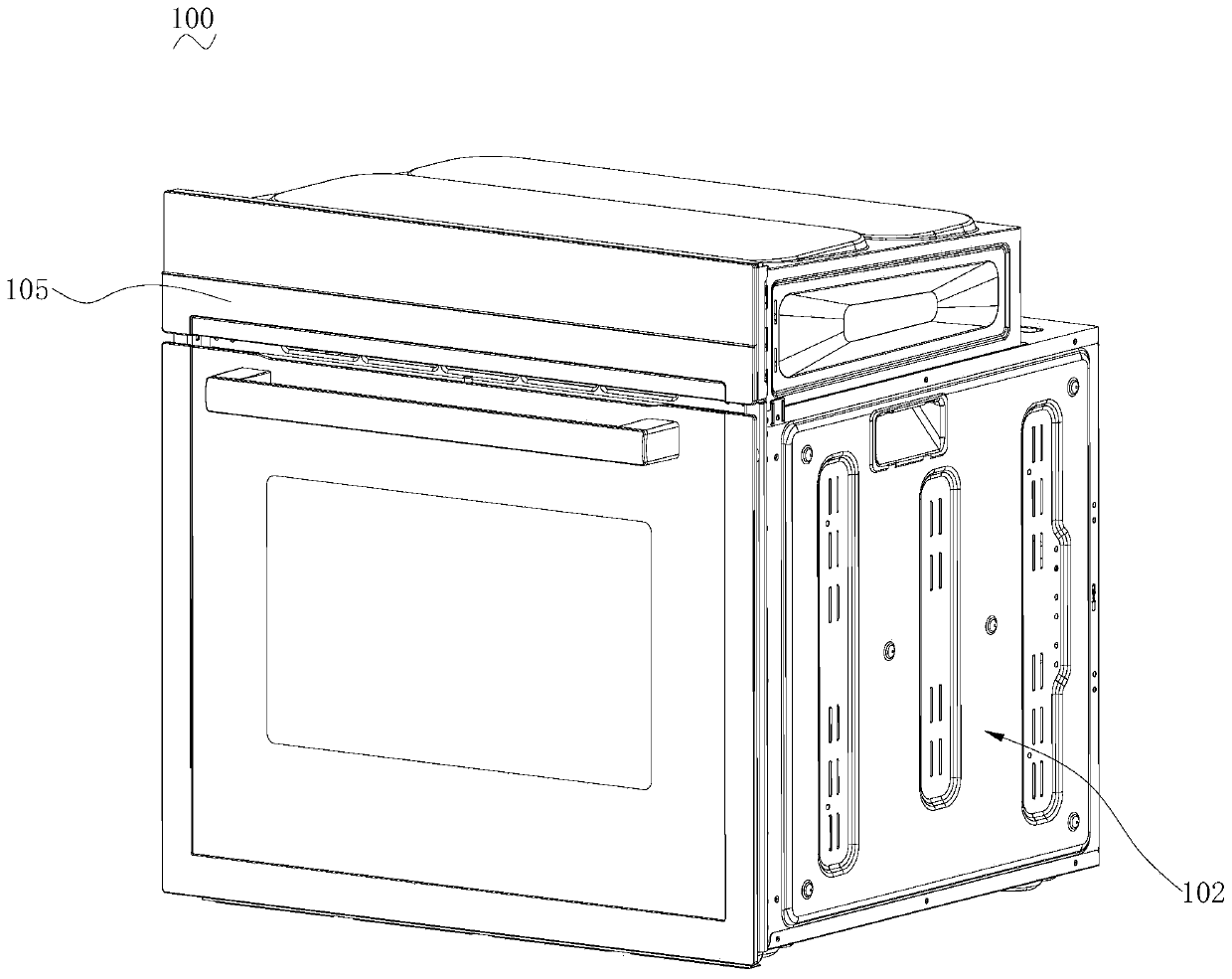

Control method, cooking electric appliance and computer readable storage medium

The invention discloses a control method, a cooking electric appliance and a computer readable storage medium. The control method comprises the steps: acquiring food material information of food; determining a first cooking parameter and a second cooking parameter according to the food material information; controlling a cooking electric appliance to operate according to the first cooking parameter so as to dry the food; and after the operation of the cooking electric appliance according to the first cooking parameter, controlling the cooking electric appliance to operate according to the second cooking parameter so as to smoke the food. According to the control method, the cooking electric appliance and the computer readable storage medium, the cooking electric appliance can operate according to the first operating parameter to properly dry the food materials, so that the moisture content distribution on the surfaces of the food materials is relatively uniform, and then the cooking electric appliance operates according to the second operating parameter to smoke the food. In this way, the cooking electric appliance can smoke food more uniformly.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

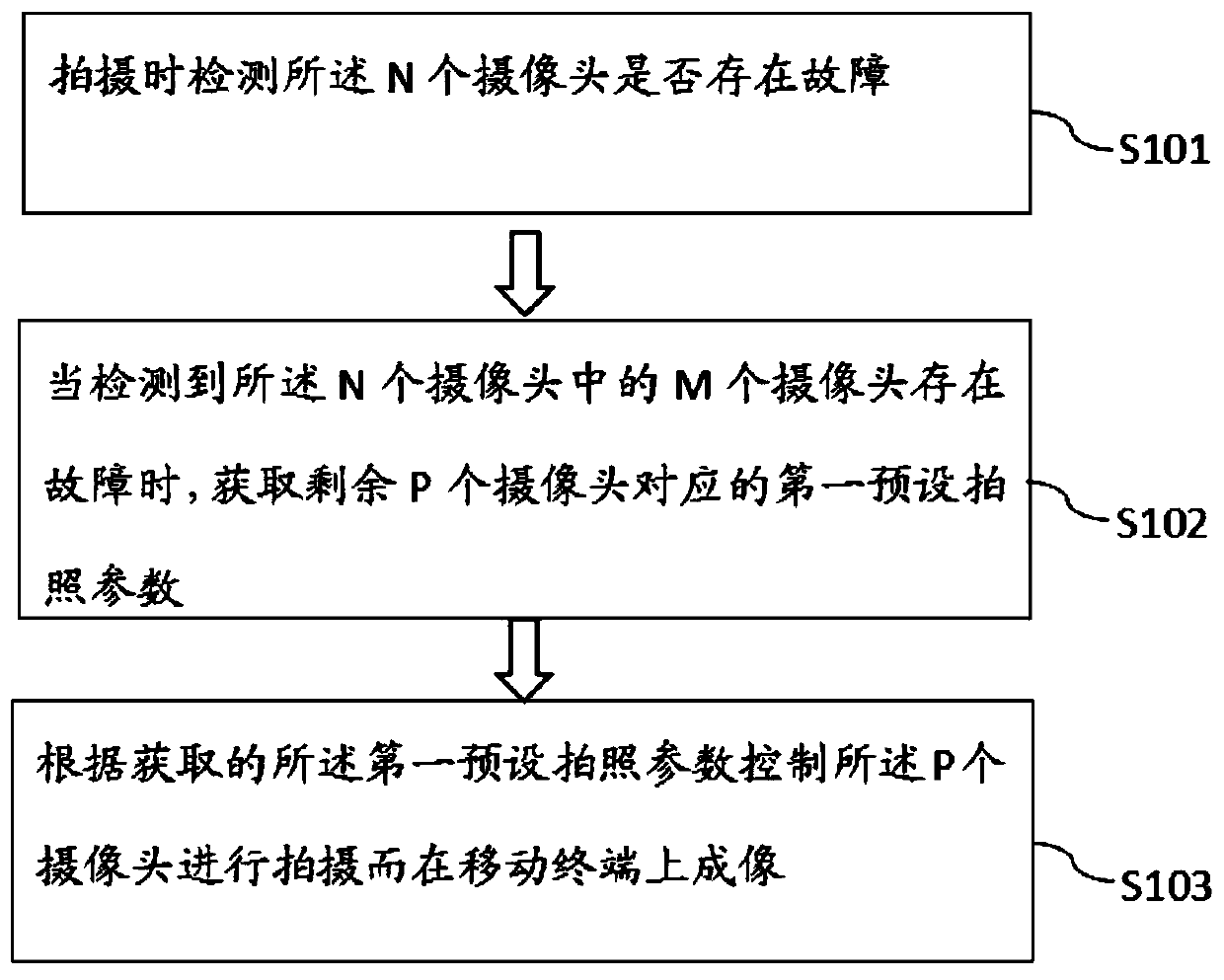

Camera shooting method, storage medium and mobile terminal

InactiveCN109639986ATelevision system detailsColor television detailsComputer graphics (images)Shooting method

Owner:NUBIA TECHNOLOGY CO LTD

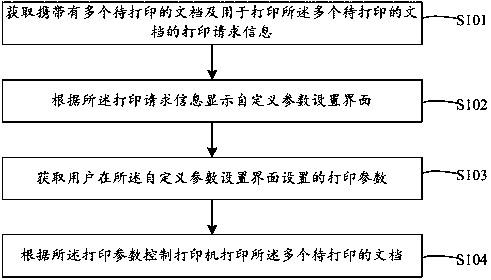

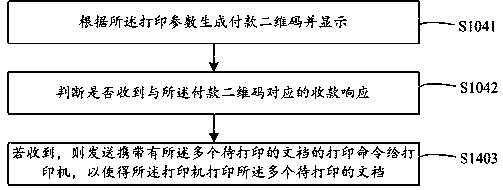

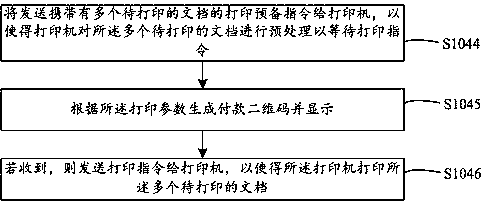

Batch printing control method, device and electronic equipment

Owner:广东印萌科技有限公司

Steel plate straightening method

The invention provides a steel plate straightening method. The steel plate straightening method comprises the steps that whether a rolled steel plate is abnormal or not is judged, if the rolled steelplate is abnormal, steel plate parameters of the steel plate are input, new straightening parameters are obtained through calculation according to the steel plate parameters, the new straightening parameters are sent to a basic automatic control system, and the basic automatic control system controls a straightener to straighten according to the new straightening parameters. According to the steelplate straightening method, calculating the steel plate parameters of the abnormal steel plate is carried out to obtain the new straightening parameters, the straightener is controlled to straightenaccording to the new straightening parameters, and the straightened abnormal steel plate is obtained, so that the shape of the steel plate is guaranteed, and the waste quantity is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Automatic electromagnetic impurity removing machine for cigarette

ActiveCN104307629AConducive to purity requirementsFree from abnormal wear or even damageMagnetic separationControl systemEngineering

The invention provides an automatic electromagnetic impurity removing machine for cigarette. The automatic electromagnetic impurity removing machine comprises a machine body, a material conveying passage running through the machine body and at least one removed impurity collection box with an upward opening and fixed with the machine body, wherein at least one powerful electromagnetic assembly is arranged above the removed impurity collection box and the material conveying passage, the powerful electromagnetic assembly is connected with a transmission mechanism, the transmission mechanism and the powerful electromagnetic assembly are further connected with a control system, and the control system controls the powerful electromagnetic assembly to move above the material conveying passage and the removed impurity collection box through the transmission mechanism. The automatic electromagnetic impurity removing machine for cigarette is high in automation degree, reasonable and compact in structure, simple and convenient to operate and convenient to achieve parameter control, and can effectively solve the problem that a cigarette material contains a large amount of iron impurities, so as to greatly improve the impurity removal effect, which is conducive to the purity demand of the material needed in the subsequent procedures and is conducive to protect the key components in the equipment from being abnormally worn or damaged by the iron impurities.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

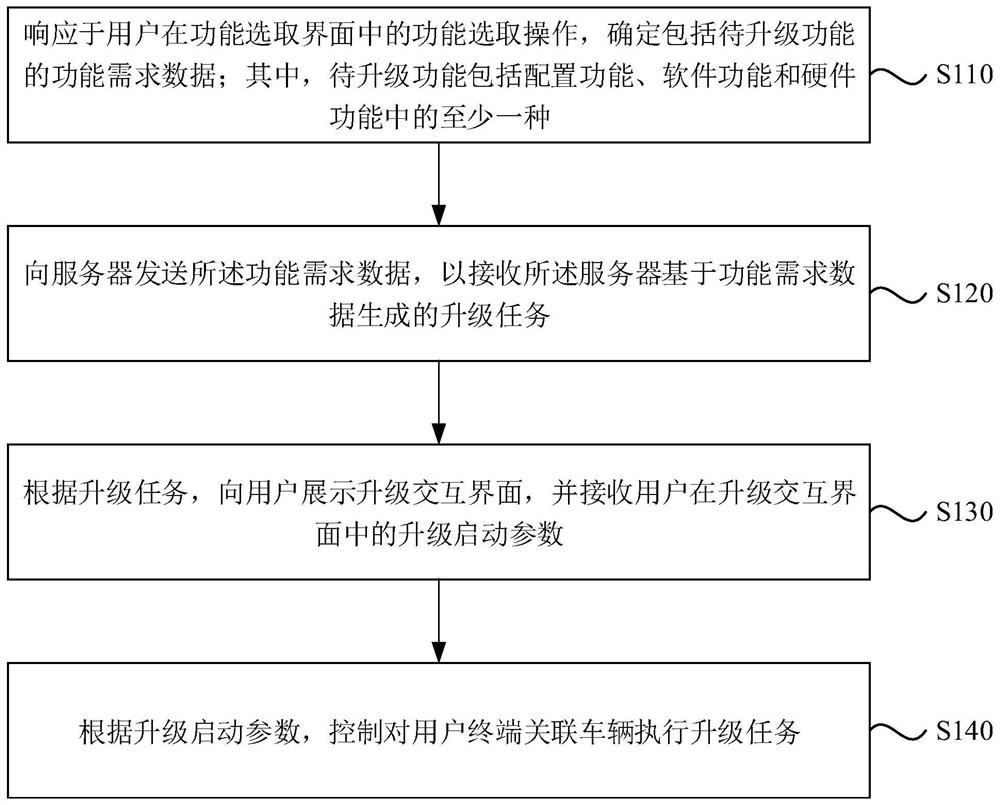

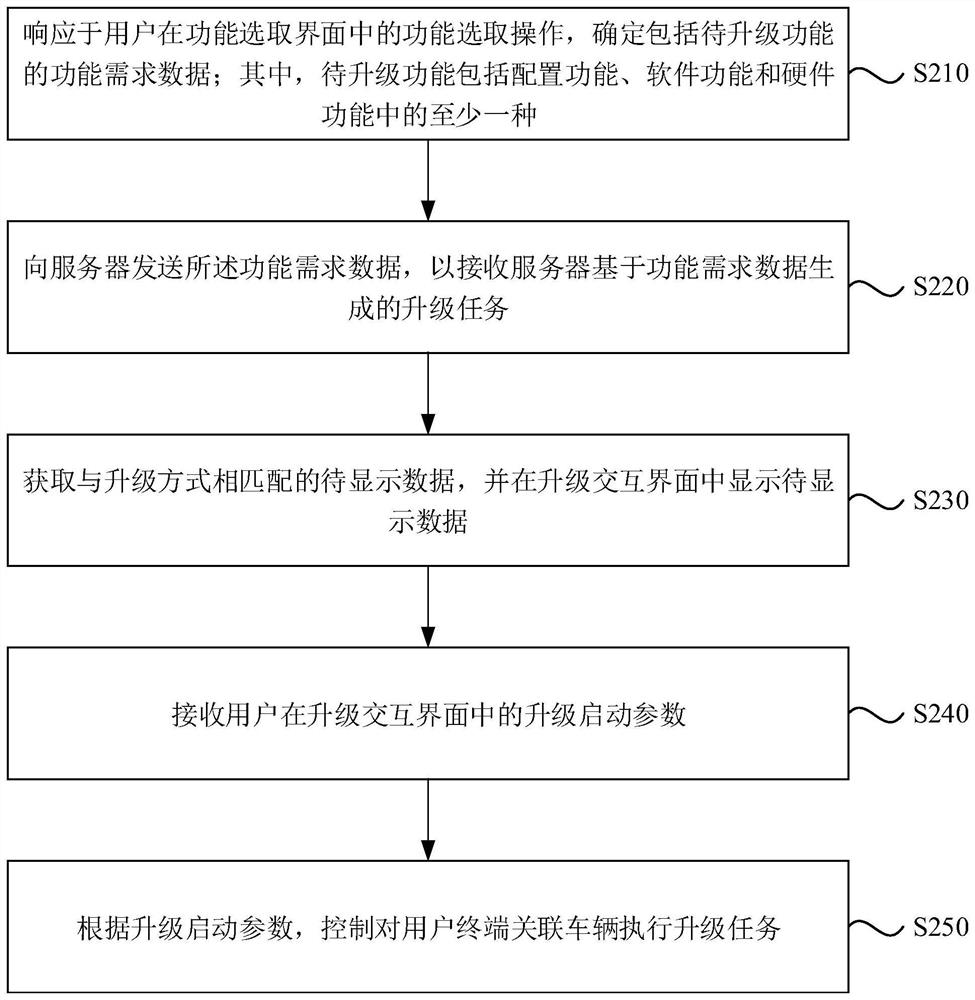

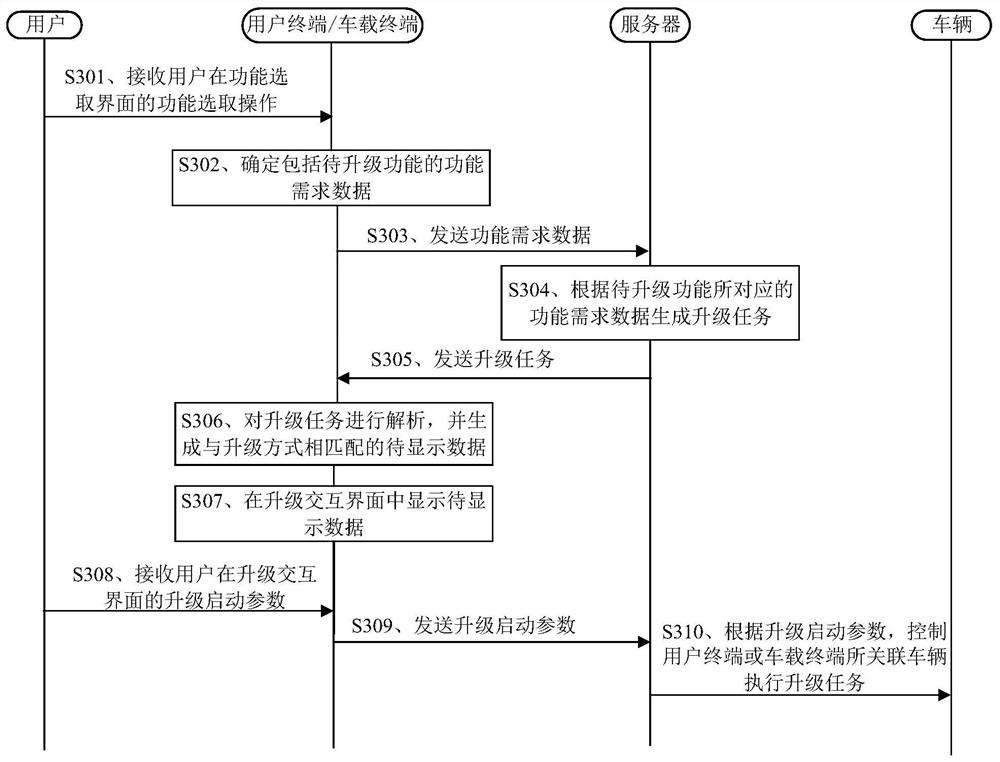

Vehicle upgrading method, device and equipment and storage medium

PendingCN113721955AReduce waste of resourcesReduce financial burdenExecution for user interfacesSoftware deploymentProduction lineInteraction interface

Owner:CHINA FIRST AUTOMOBILE

A manufacture method of U-shaped electric heating tube

Owner:镇江裕太防爆电加热器有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap