Multi-unit inspection full-automatic solidification point analytical method

An analysis method, fully automatic technology, applied in the direction of analyzing materials, material analysis through optical means, material inspection products, etc., can solve the problems of complex analysis steps, long analysis cycle, cumbersome, etc., to shorten the analysis time and improve the analysis accuracy , the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

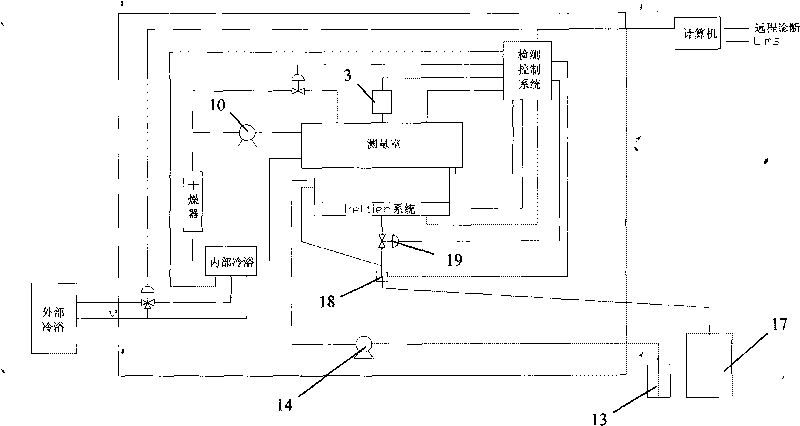

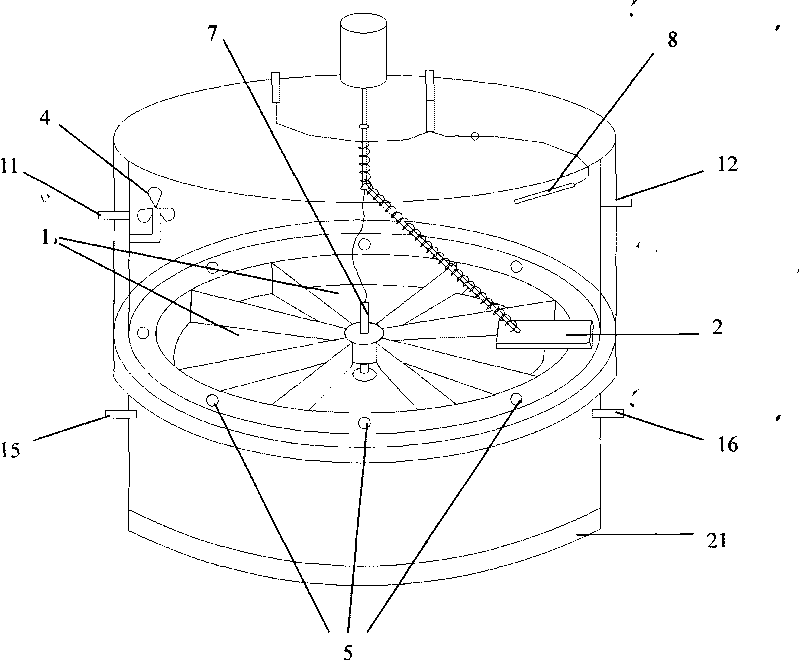

[0024] A multi-unit patrol inspection automatic condensation point analysis method, the operation steps are as follows:

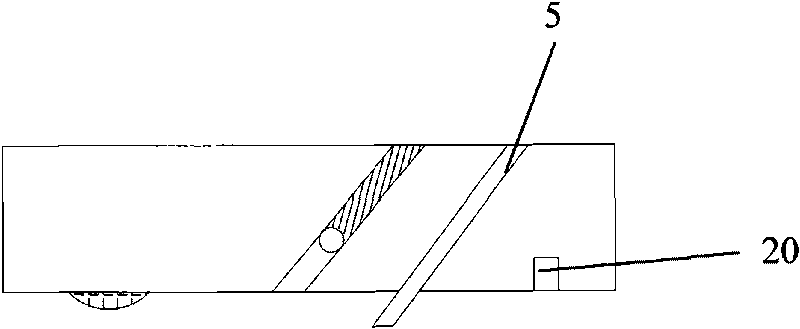

[0025] a. Divide the sample into relatively independent multiple identical detection units, and in the same external environment, blow the controlled dry air to the surface of a detection unit that is cooling the sample every 1°C, and use an optical detector to check the unit The movement of the sample surface; when the liquid sample is clear, the incident beam is reflected on the bottom mirror, and the reflected beam is absorbed by the black surface of the measurement chamber, and the optical detector can only detect a weak light intensity; with the temperature of the sample , crystallization will appear in the sample, and the scattered light generated by the crystallization will be significantly enhanced and will be detected by the optical detector. The analyzer will determine that the sample has crystallization and reduce the cooling speed; when the sample t

Embodiment 2

[0042] A multi-unit patrol inspection automatic condensation point analysis method, the operation steps are as follows:

[0043] a. Divide the sample into relatively independent multiple identical detection units, and in the same external environment, blow the controlled dry air to the surface of a detection unit that is cooling the sample every 1°C, and use an optical detector to check the unit The movement of the sample surface; when the liquid sample is clear, the incident beam is reflected on the bottom mirror, and the reflected beam is absorbed by the black surface of the measurement chamber, and the optical detector can only detect a weak light intensity; with the temperature of the sample , crystallization will appear in the sample, and the scattered light generated by the crystallization will be significantly enhanced and will be detected by the optical detector. The analyzer will determine that the sample has crystallization and reduce the cooling speed; when the sample t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap