Cement grinding expert optimization system

A cement powder and expert technology, applied in the field of cement grinding expert optimization system, can solve problems such as different grinding characteristics, uneven grinding power consumption, uneven system output, etc., and achieve the effect of improving the degree of spherification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] 1. Roller press through type pre-grinding process system

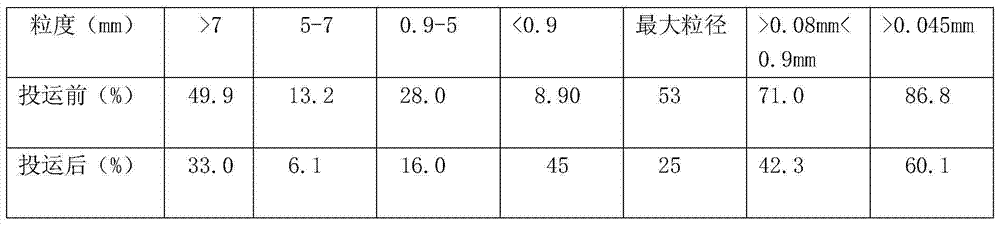

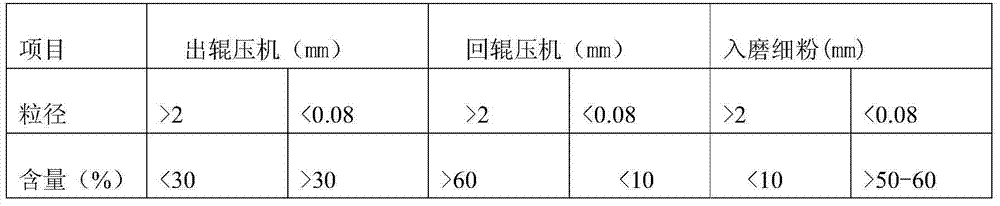

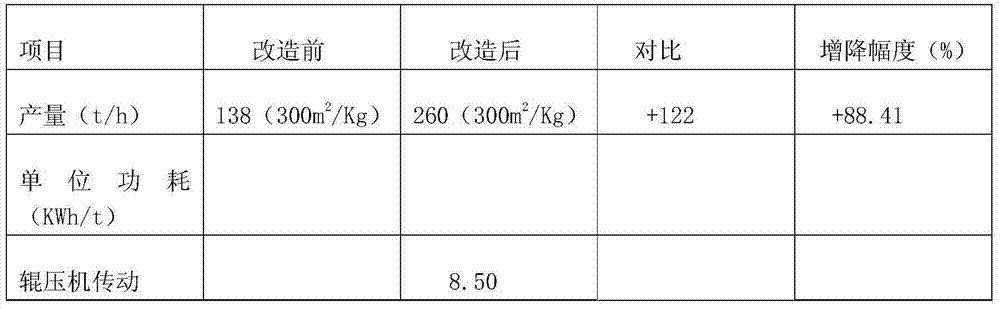

[0008] Up to now, the grinding system is still used by a small number of enterprises. Generally, the processing capacity of the roller press is small. Although the production potential of the follow-up tube mill is rich, the front-end roller press does less work in one extrusion (roller The extrusion force of the press is 6000KN / m2-7000KN / m2, the ratio of the capacity of the roller press to the system is about 200%, and the power consumption per unit throughput is about 2.5kwh / t-3.0kwh / t), which is only equivalent to general extrusion Crushing function, during the extrusion process, a certain amount of side material can participate in the circulation, and the extruded material is directly put into the mill without classification (the 80um sieve of the 80um material after extrusion is 70%-80%, and the specific surface area is only 100m2 / kg About), the system production increase range is 20%-60%, and the average p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap