Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29 results about "Cement Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement is often supplied as a powder, which is mixed with other materials and water. A cement is a binder, a substance used for construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together.

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

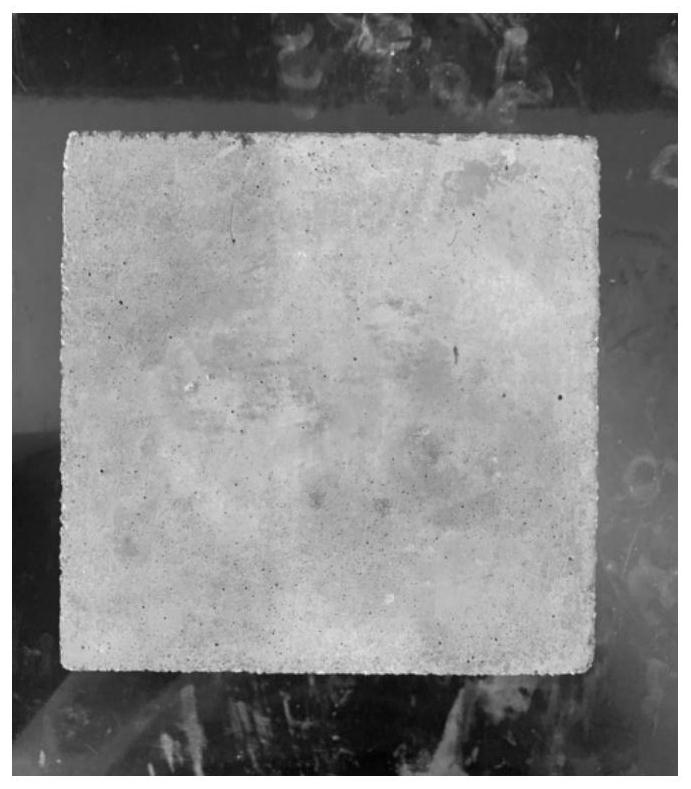

Antistatic geothermal floor

InactiveCN104234374AFast heat conductionImprove the status quo of performance defectsFlooring insulationsWater-setting substance layered productMagnesiumAntistatic agent

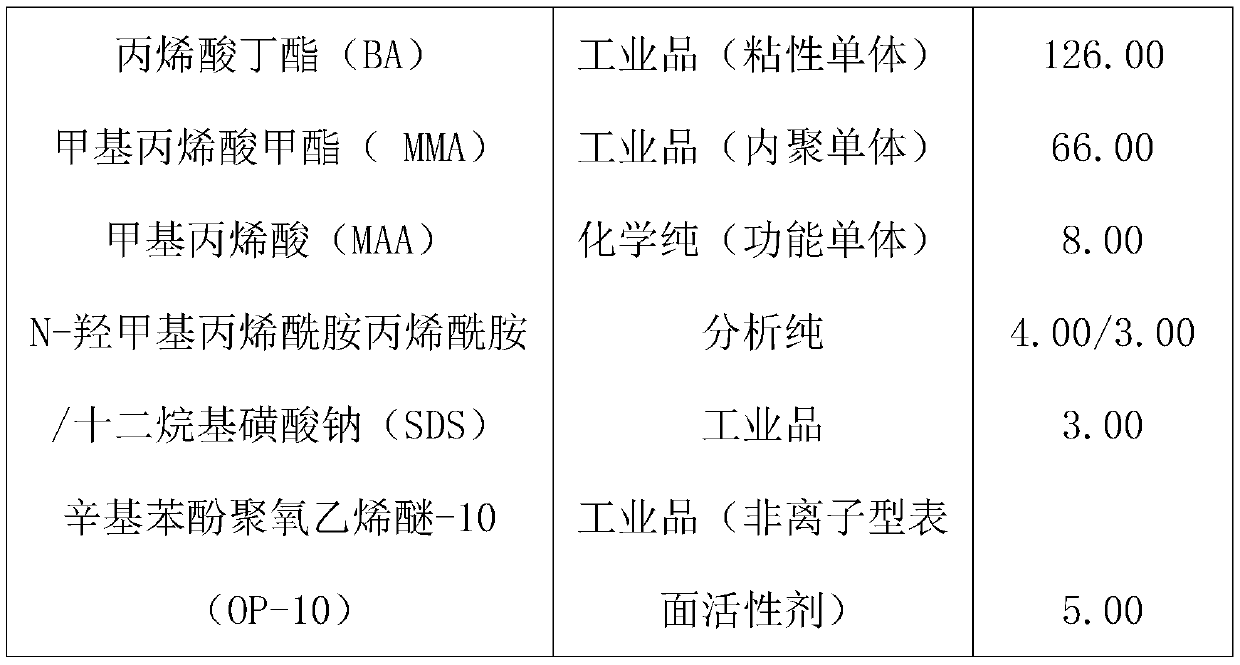

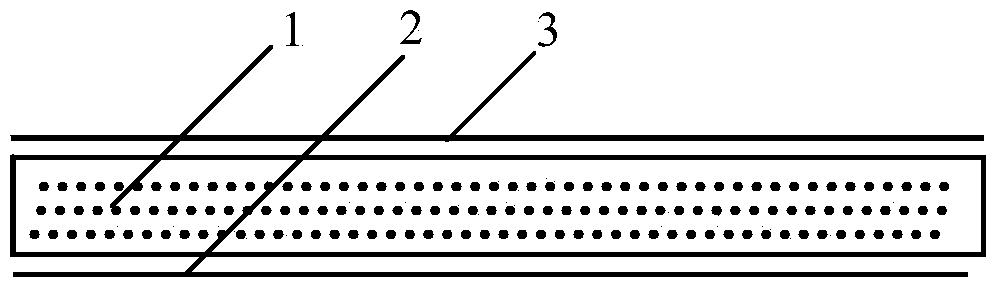

The invention relates to an antistatic geothermal floor. The antistatic geothermal floor is characterized by comprising a decorative layer on an upper surface, an antistatic layer on a lower surface, and a core layer sandwiched between the upper surface layer and the lower surface layer, wherein the core layer is a sheet material made of magnesium oxysulfate cement and bamboo fibers. The antistatic geothermal floor has the beneficial benefits that 1, the magnesium oxysulfate cement which has high combination degree with the bamboo fibers and does not corrode the bamboo fibers covers the bamboo fibers to form a floor core layer which meets a fire resistance requirement, the antistatic layer is compounded on the lower surface of the core layer to meet the requirement of a geothermal floor, and the present situation that the existing geothermal floor has defective performance is improved; 2, the sheet material for manufacturing the core layer is made of a mixture in a semi-dry state, and is formed by pressing, maintaining pressure and curing, so that the requirement of high strength of the antistatic geothermal floor is met; 3, the antistatic layer made of a composite material meets an antistatic requirement, and meanwhile, has high heat conductivity, so that the heat conductivity of the floor is improved, the utilization rate of heat is improved, and energy conservation and emission reduction are facilitated.

Owner:NG TERASUN AIR DUCT

High-elastic plastic runway and construction method thereof

ActiveCN111749078AGood runway mechanical propertiesImprove mechanical propertiesIn situ pavingsGround pavingsEpoxyPolyurethane adhesive

The invention discloses a high-elastic plastic runway and a construction method thereof. The high-elastic plastic runway sequentially comprises a base layer, a waterproof bonding layer, an elastic layer, a bonding layer and a surface layer from bottom to top, wherein the base layer is a cement base layer or an asphalt base layer; the waterproof bonding layer is a water-borne epoxy resin layer; theelastic layer is a mixture of a foamed polyurethane material and EPDM particles, and the mass ratio of the foamed polyurethane material to the EPDM particles is 1:(0.5-2); the bonding layer is made of a polyurethane adhesive; the surface layer is a mixture of a polyurethane adhesive and EPDM particles, and the mass ratio of the polyurethane adhesive to the EPDM particles is 1:(5-6). The high-elastic plastic runway is good in mechanical property, excellent in buffering and damping effect, resistant to aging, non-toxic, environmentally friendly and capable of being widely applied to indoor places such as kindergartens.

Owner:WUHAN RUITIAN NEW MATERIAL TECH CO LTD

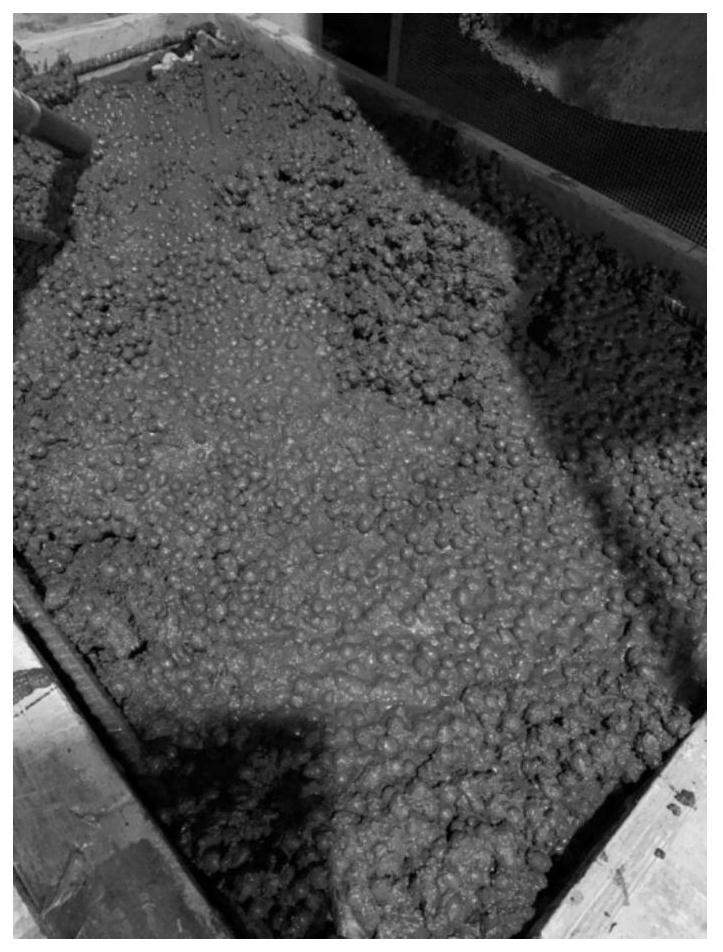

Efficient nitrogen and phosphorus removal granular preparation and production process thereof

InactiveCN107055649AEasy to makeReduce energy consumptionWater treatment parameter controlWater contaminantsDodecyl sulfatePotassium ferrate

The invention relates to an efficient nitrogen and phosphorus removal granular preparation. The granular preparation is prepared from raw materials in parts by weight as follows: 20-100 parts of potassium ferrate, 20-100 parts of bentonite, 1-5 parts of disodium EDTA, 10-50 parts of cement and 1-5 parts of a sodium lauryl sulfate aqueous solution. The concentration of the sodium lauryl sulfate aqueous solution is 2-3 g / L. The production technology of the efficient nitrogen and phosphorus removal granular preparation comprises the steps as follows: (1) potassium ferrate, bentonite, disodium EDTA and cement are mixed and stirred uniformly in proportion, a mixture is obtained; (2) the sodium lauryl sulfate aqueous solution is added to the mixture in step (1) and mixed and stirred uniformly, granulation and drying are performed, and the granular preparation is obtained. The efficient nitrogen and phosphorus removal granular preparation and the production process thereof have the benefits that energy consumption is low in the preparation process of nitrogen and phosphorus removal granular preparation, preparation is simple, no secondary pollution is caused to the environment, and the heavy metal adsorption effect is good.

Owner:YIKANG TECH CO LTD

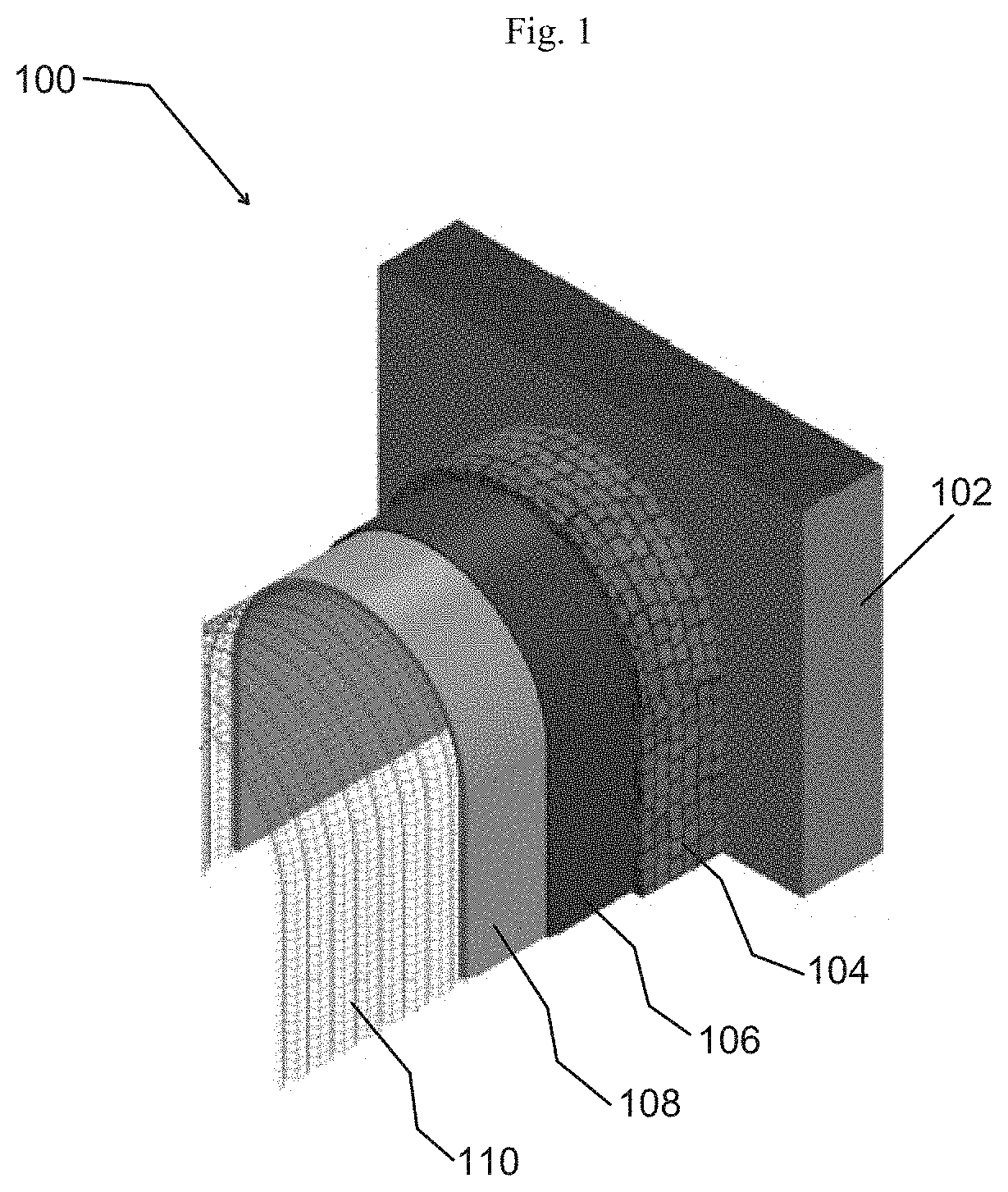

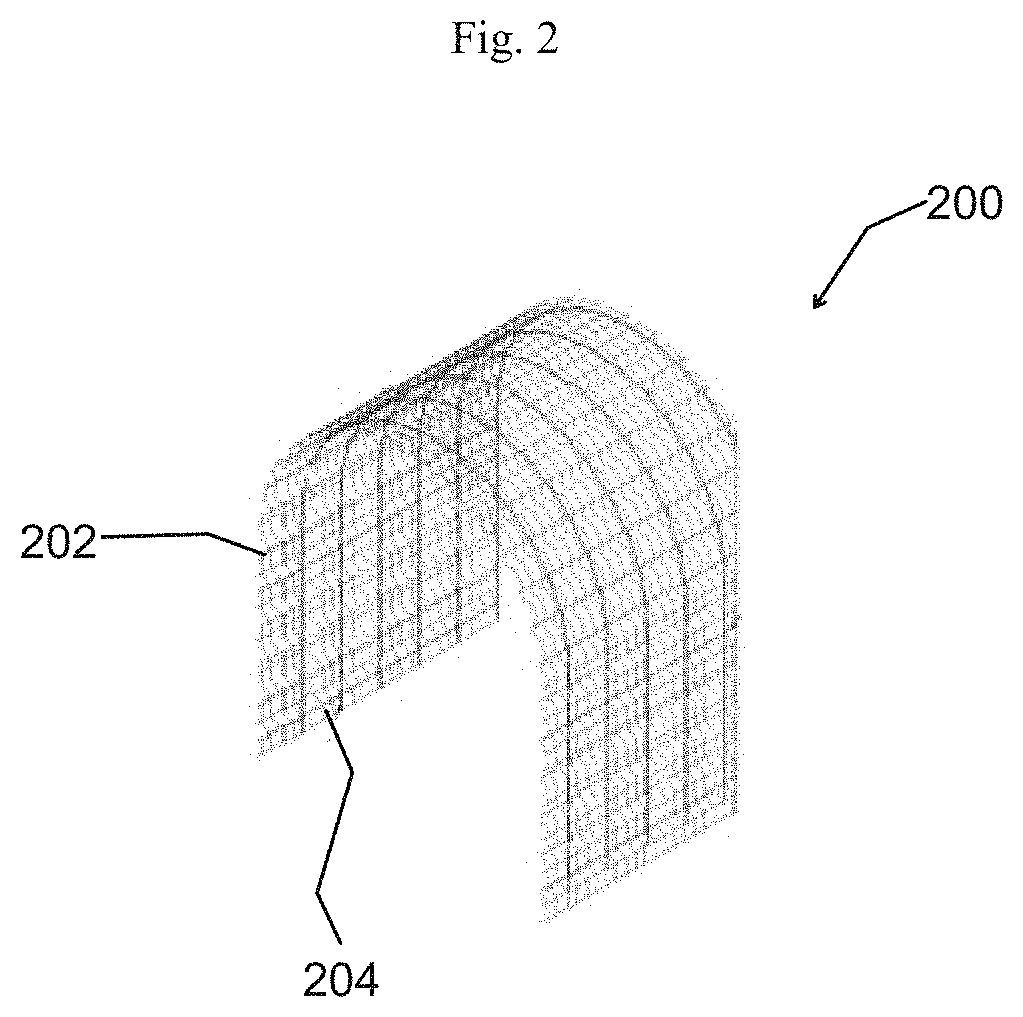

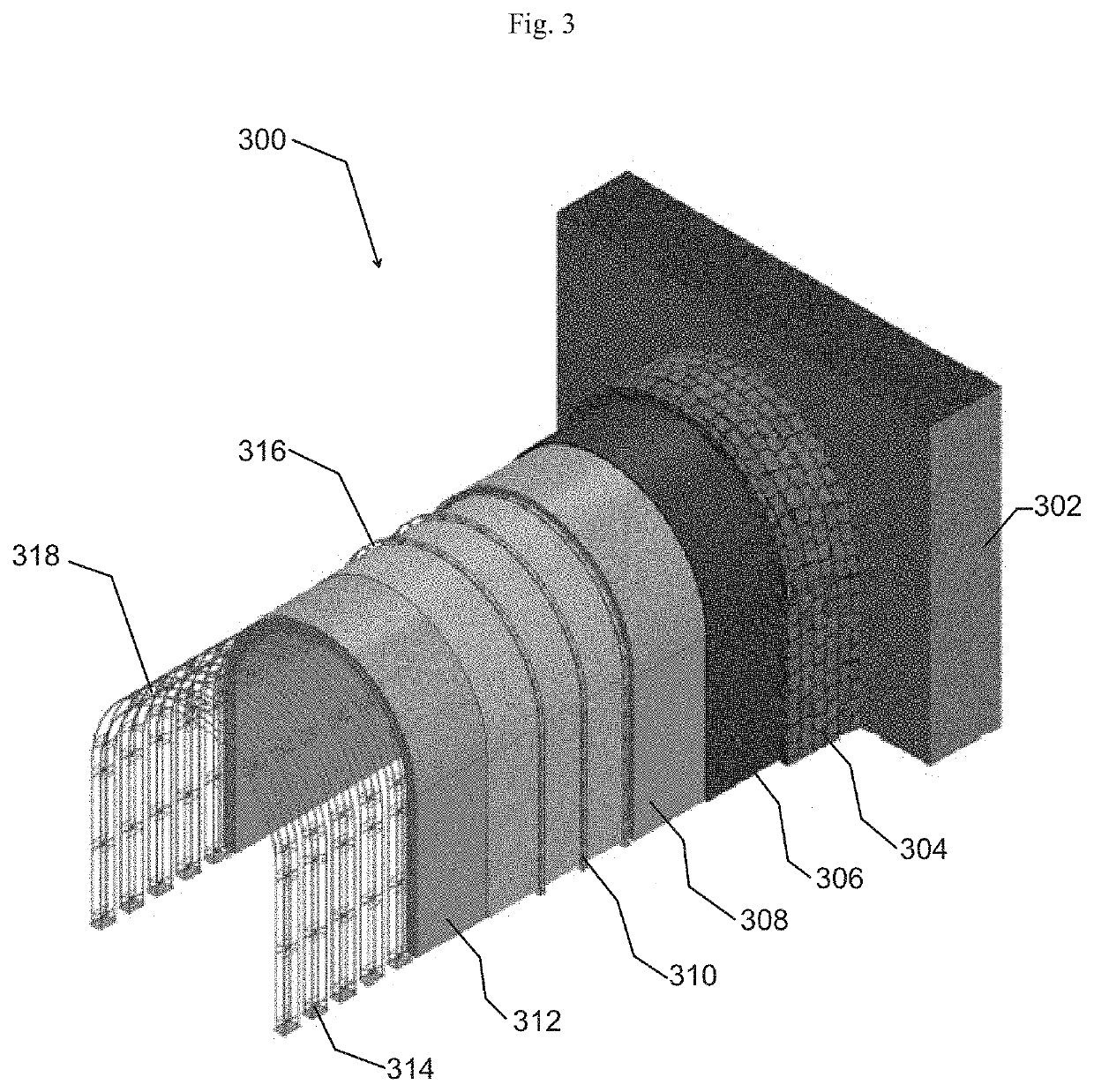

Underground support system and method

ActiveUS20200263542A1Improve versatilityPrevent crashUnderground chambersTunnel liningUnderground spaceCement Material

Owner:DSI TUNNELING LLC

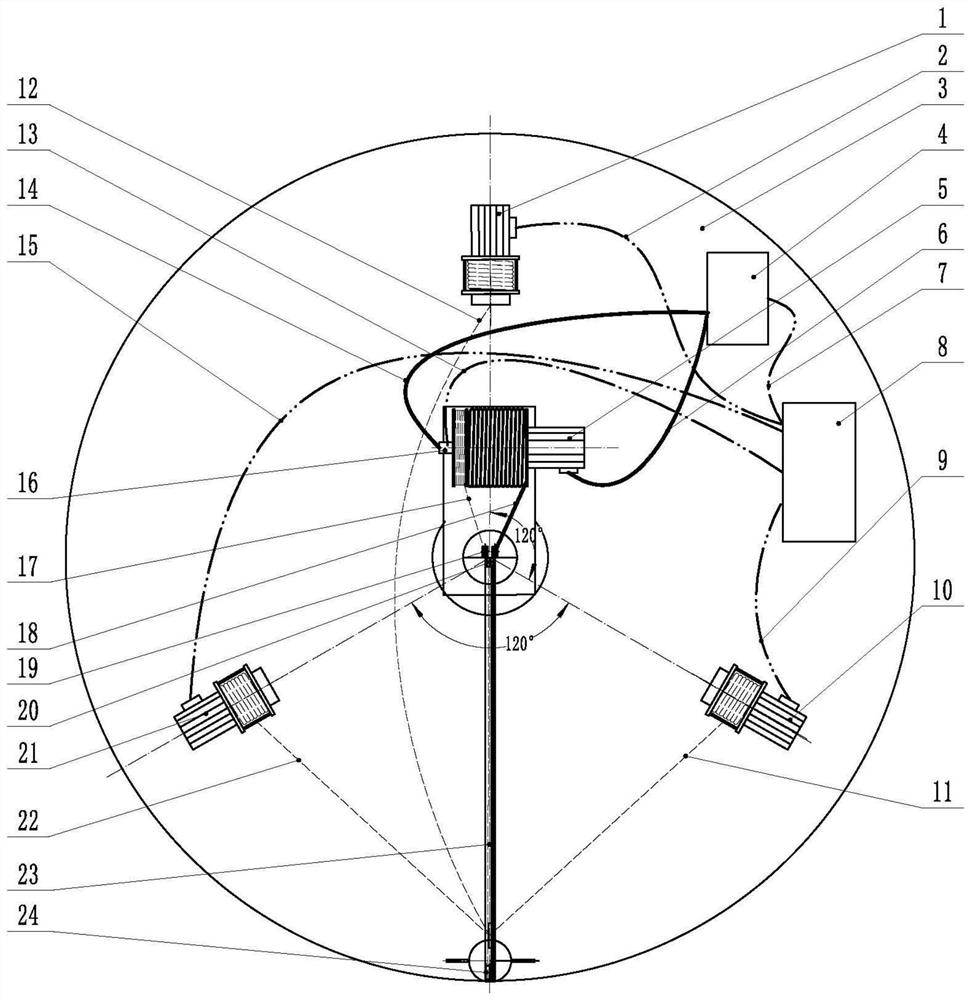

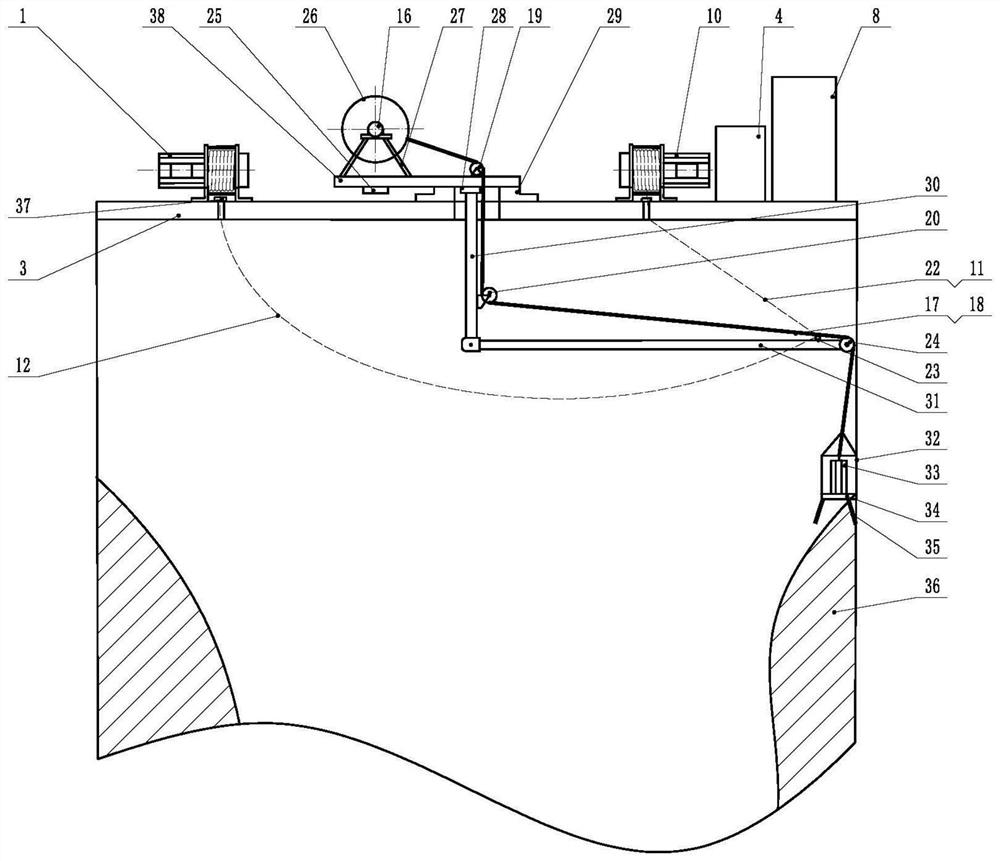

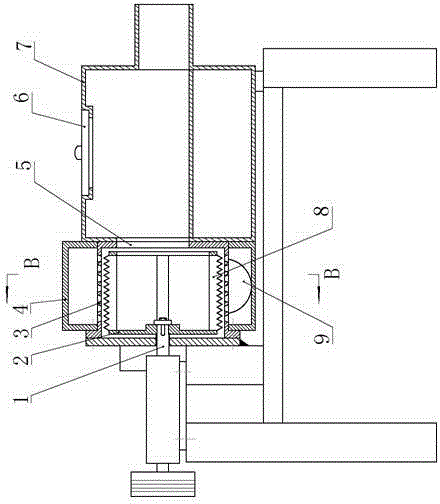

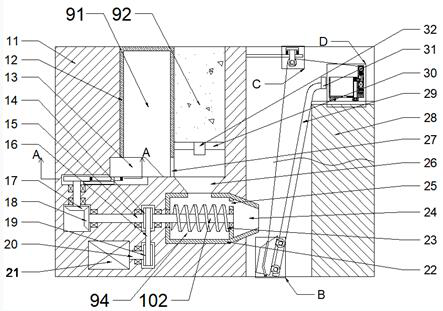

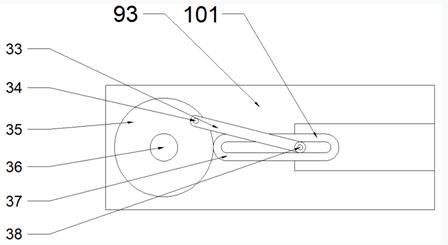

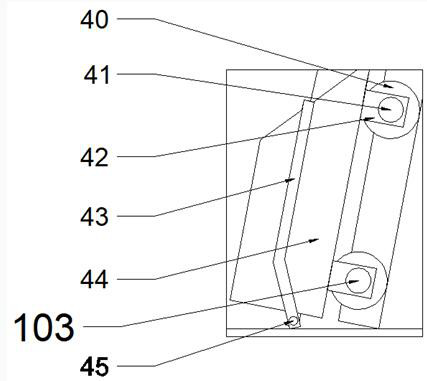

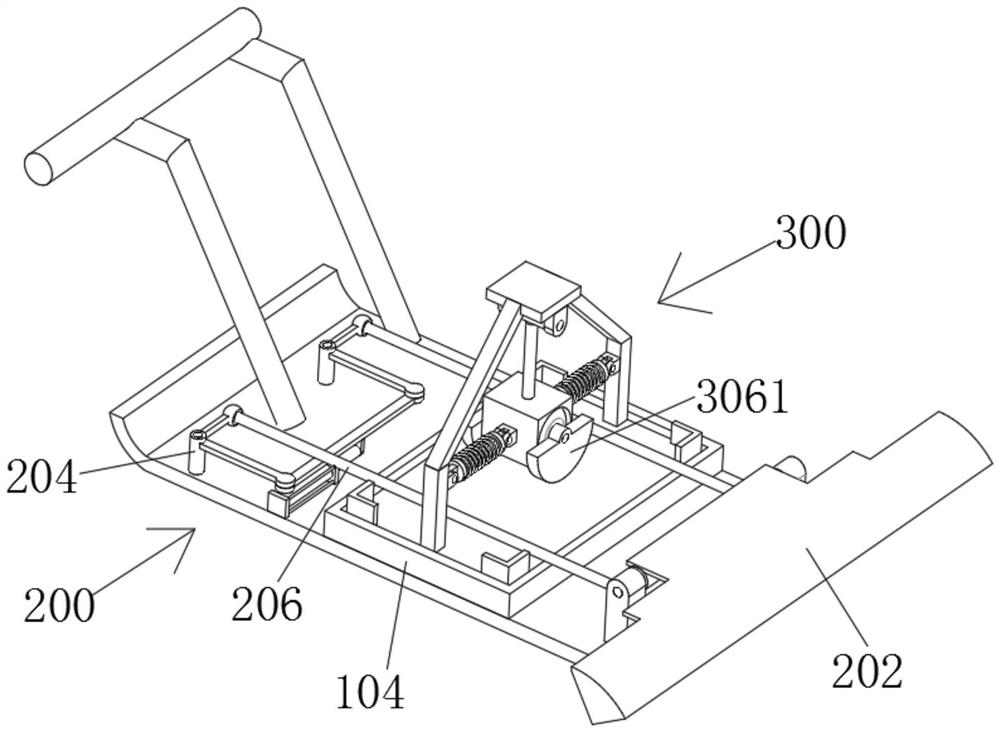

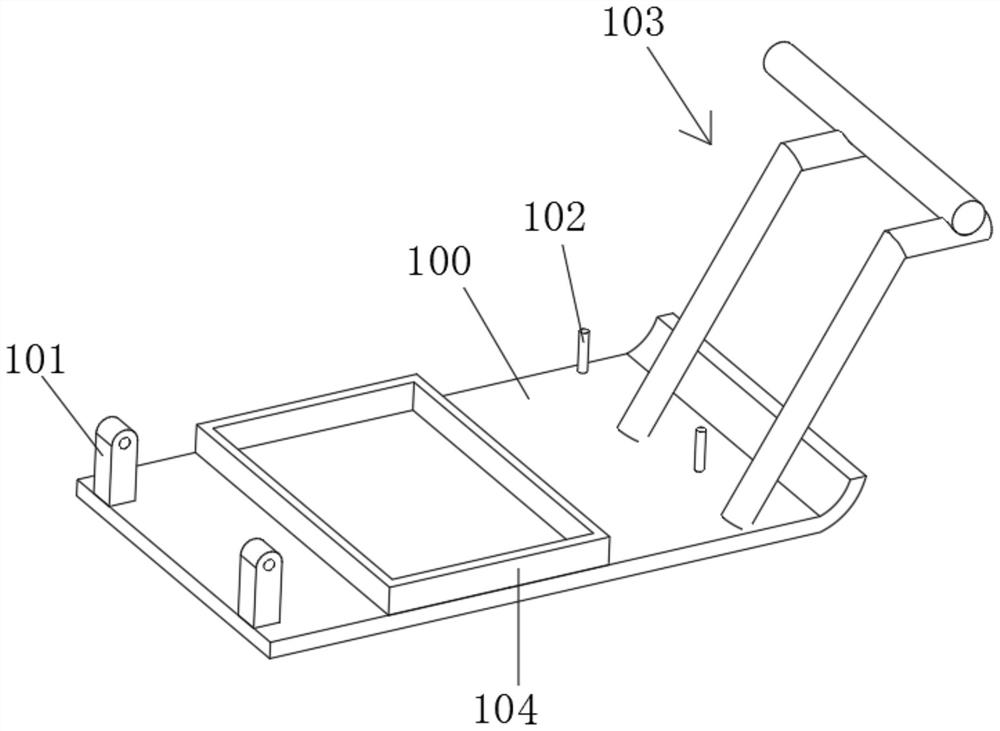

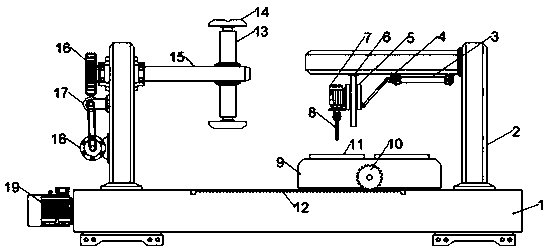

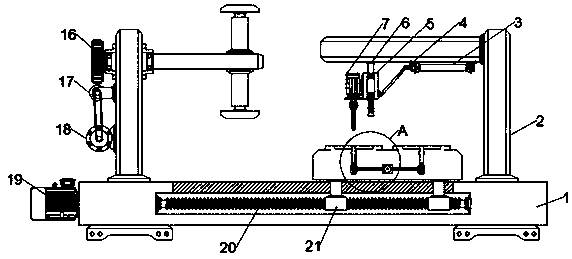

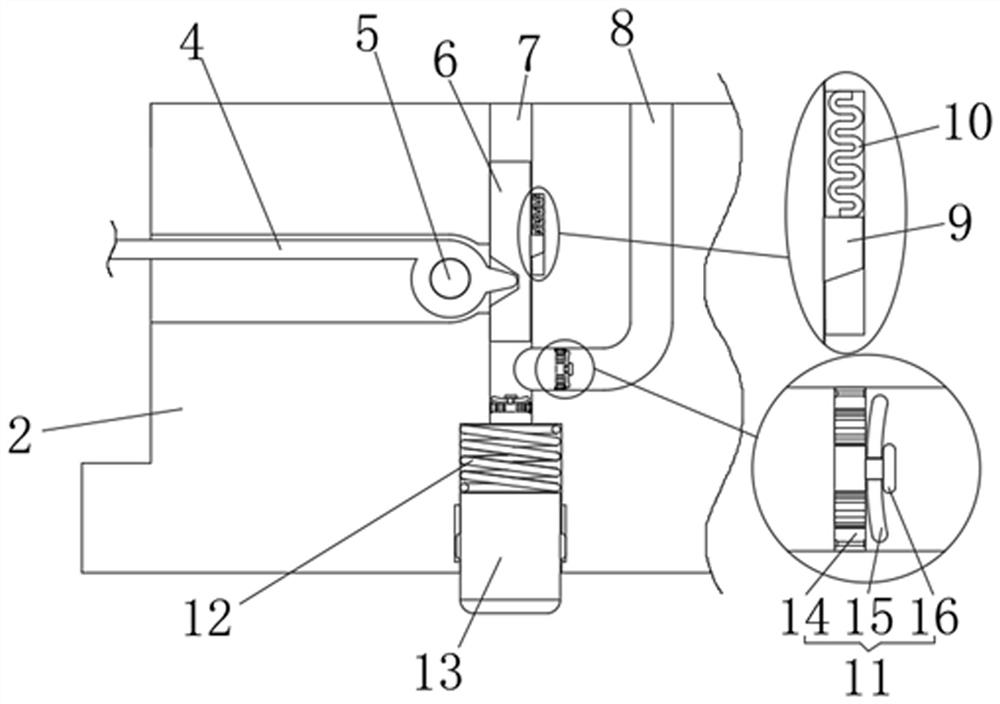

Multi-rope traction warehouse cleaning machine

PendingCN112337900ACleaning processes and apparatusBulk storage containerCantilevered beamCement Material

Owner:HUAQIAO UNIVERSITY

Shield grouting material and preparation method thereof

Owner:北京华阳众信建材有限公司

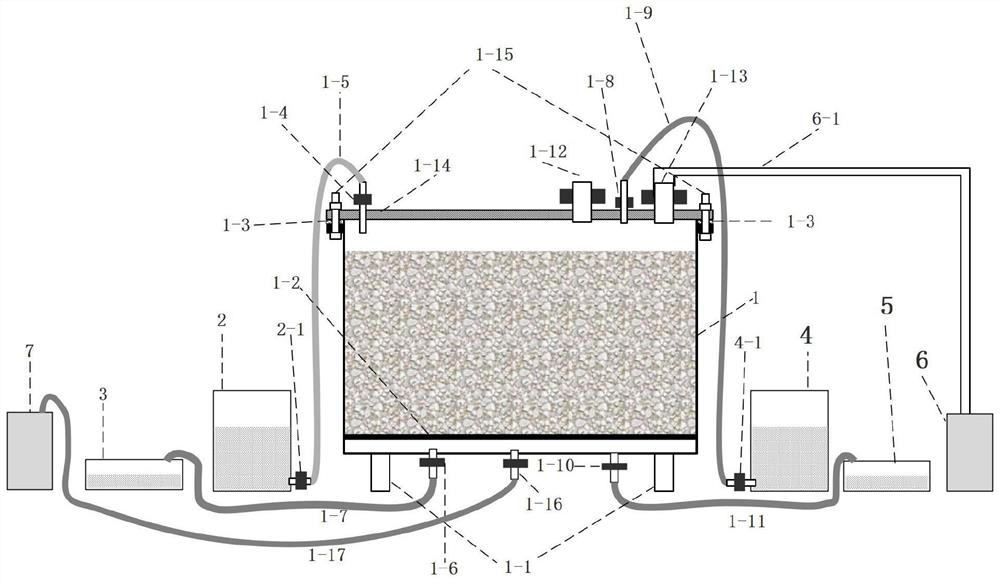

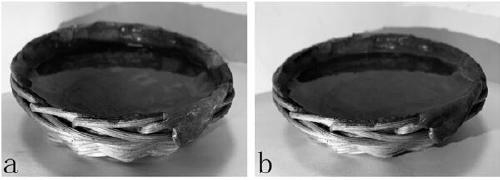

Reinforced regenerated surface porous material, preparation method and application thereof, and device for preparing reinforced regenerated surface porous material

ActiveCN112225480ARepair Mechanical PropertiesAvoid strong alkaline environmentMicroorganismNitrogen source

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

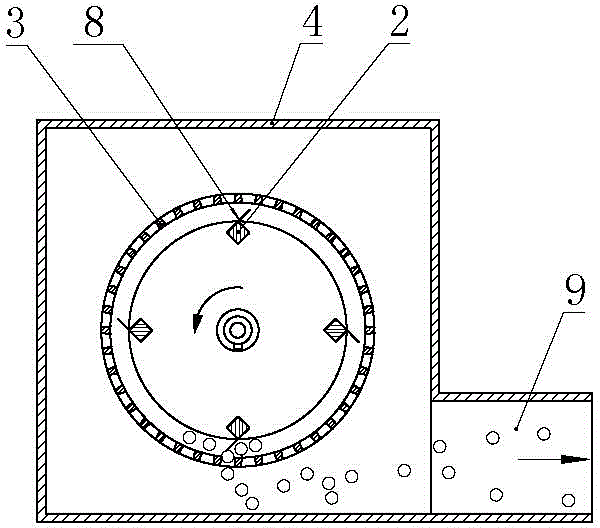

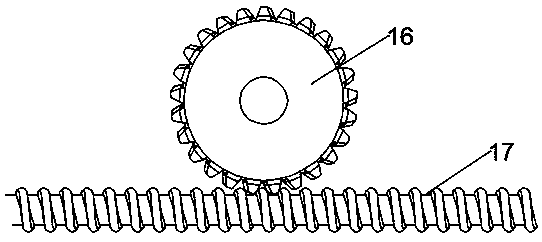

Treatment machine for increasing surface roughness of plastic foam particles

InactiveCN104690954ASmooth entryStir wellRough surfaceSuction force

Owner:LONGKOU ZHENGREN ENERGY SAVING BUILDING MATERIALSEQUIP MFG

Automatic pouring equipment for high-rise building

ActiveCN112589953AAutomatic pouring is convenientRealization of automatic pouringSolid waste managementFeeding arrangmentsWater storageArchitectural engineering

Owner:山东清河建工有限责任公司

Glass fiber composite cement and preparation method thereof

InactiveCN110698096ACement productionIndustrial wasteCement Material

Owner:衡阳县海华水泥有限责任公司

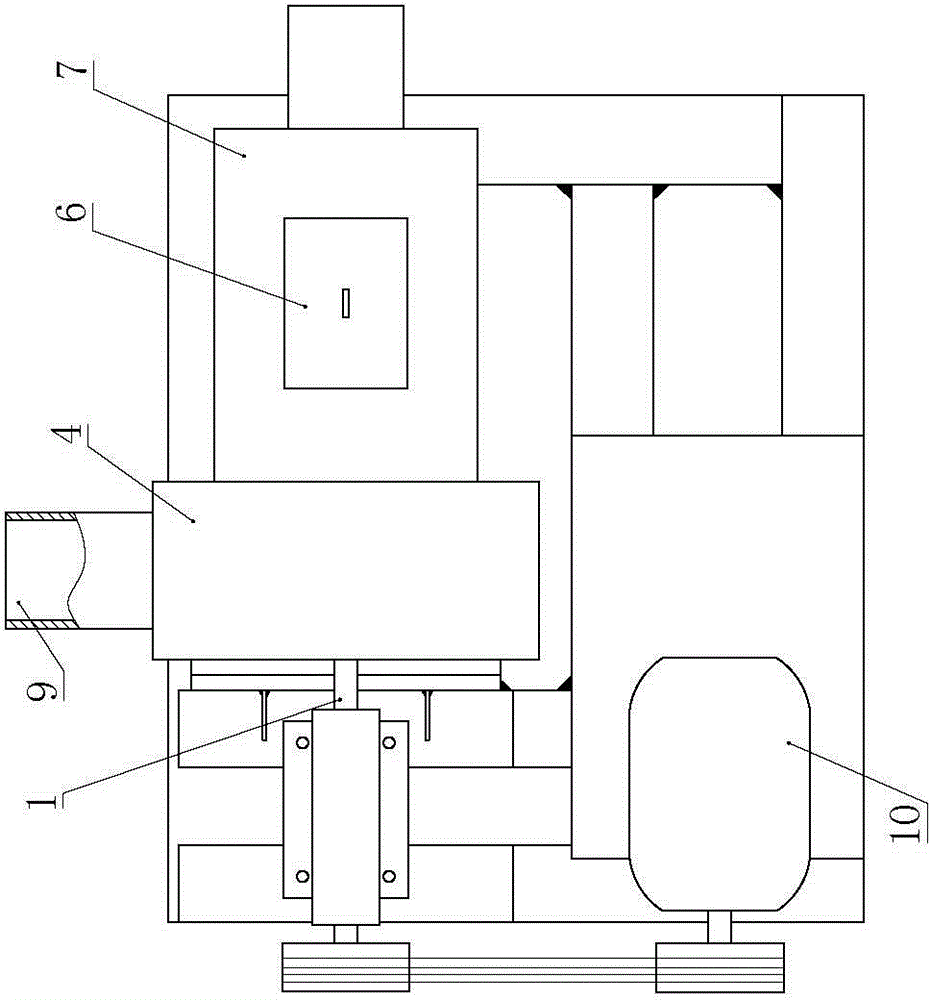

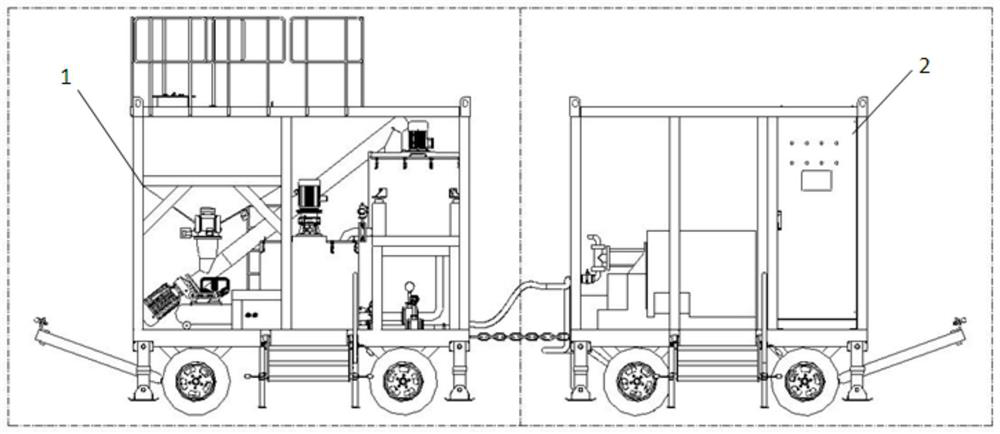

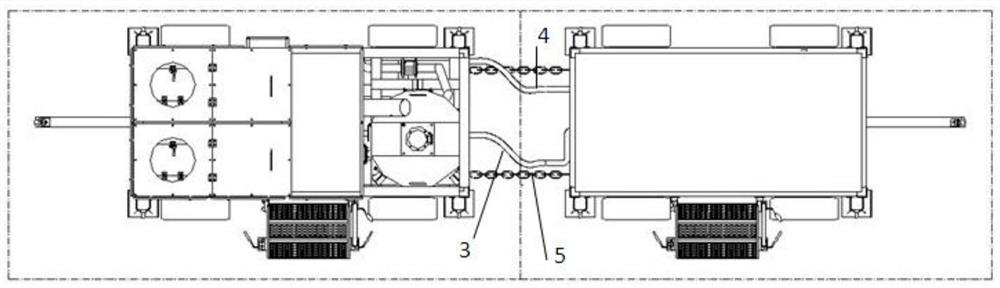

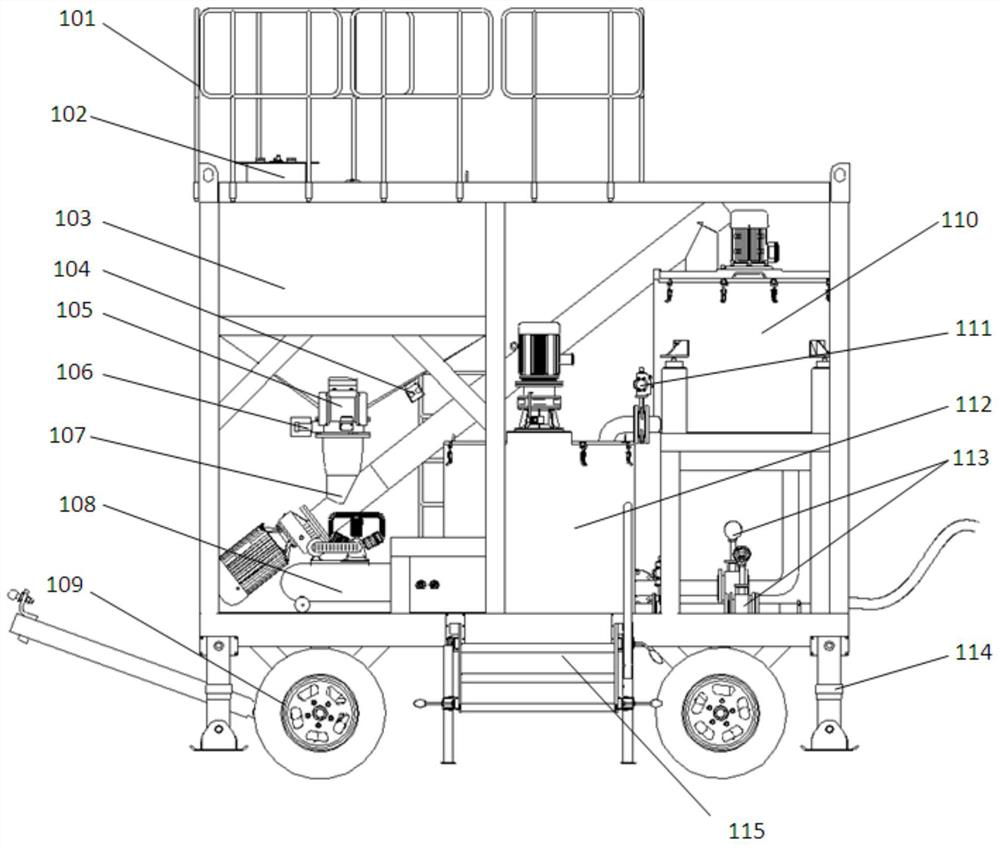

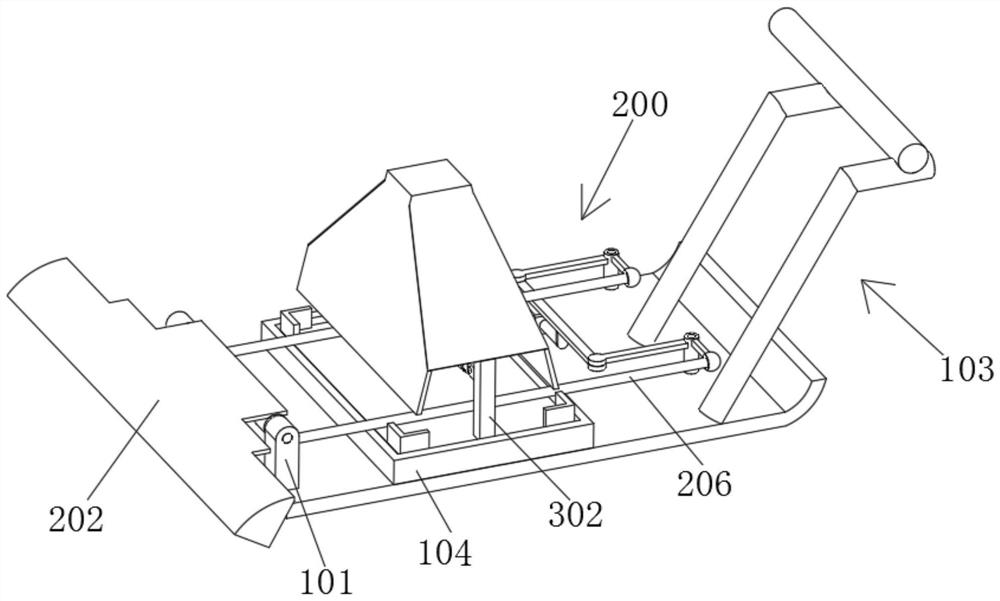

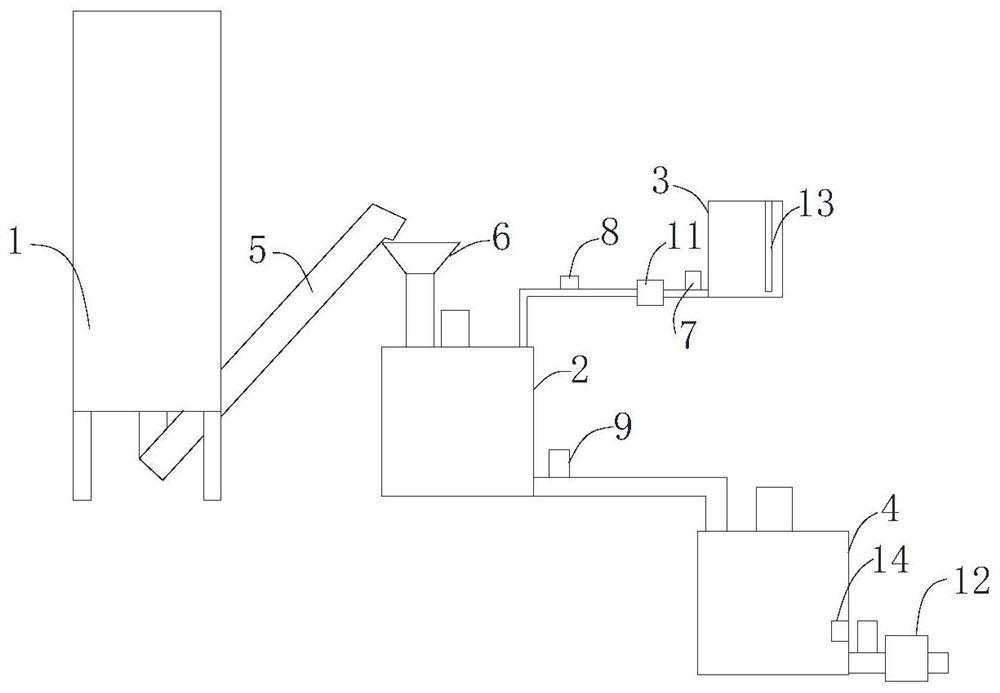

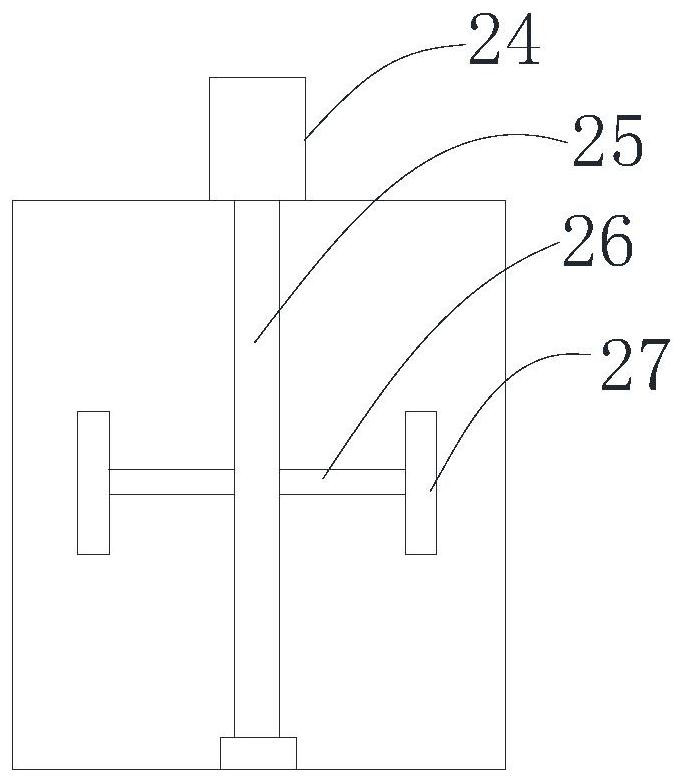

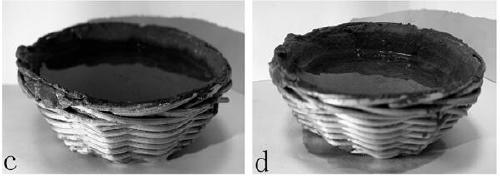

Movable grouting equipment

PendingCN112443341ASolving Dispersion ProblemsSolution volumeUnderground chambersMixing operation control apparatusControl cellCement grout

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Ground leveling mortar treatment equipment and using method thereof

ActiveCN112411973AAvoid repeated applicationImprove work efficiencyBuilding constructionsMechanical engineeringMechanics

Owner:湖南涵海新型建材有限公司

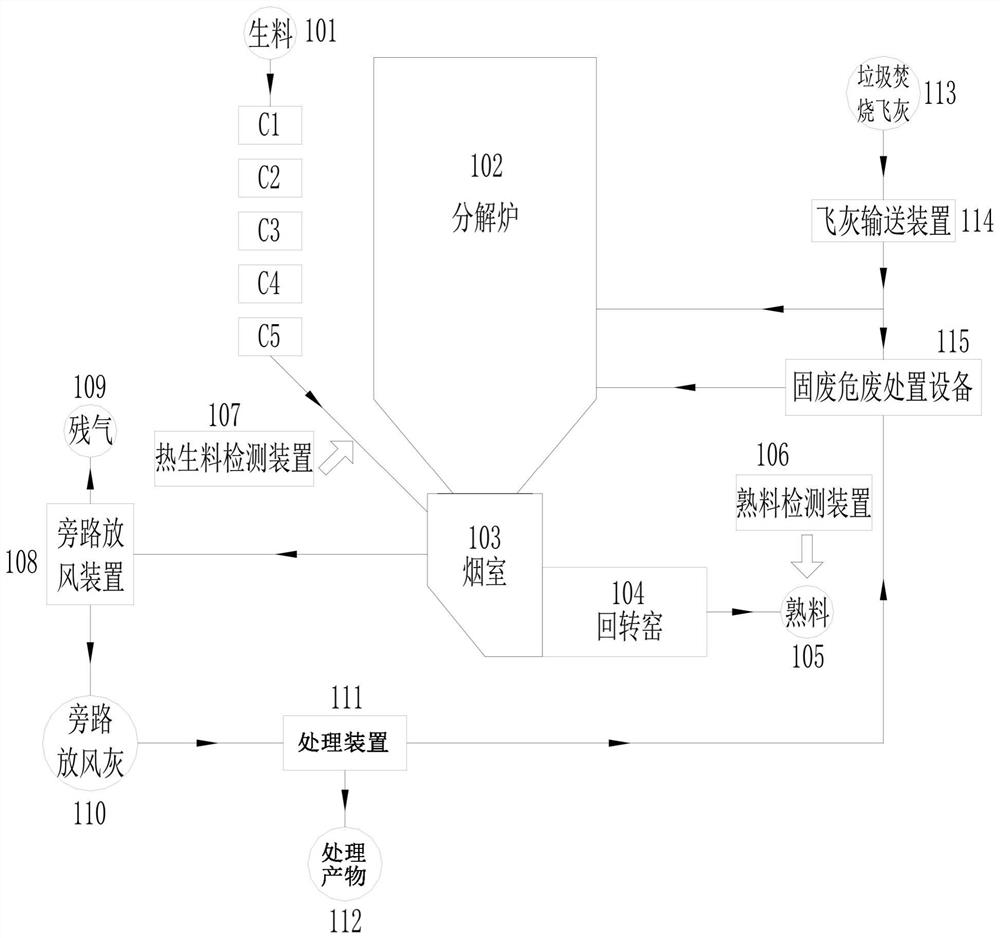

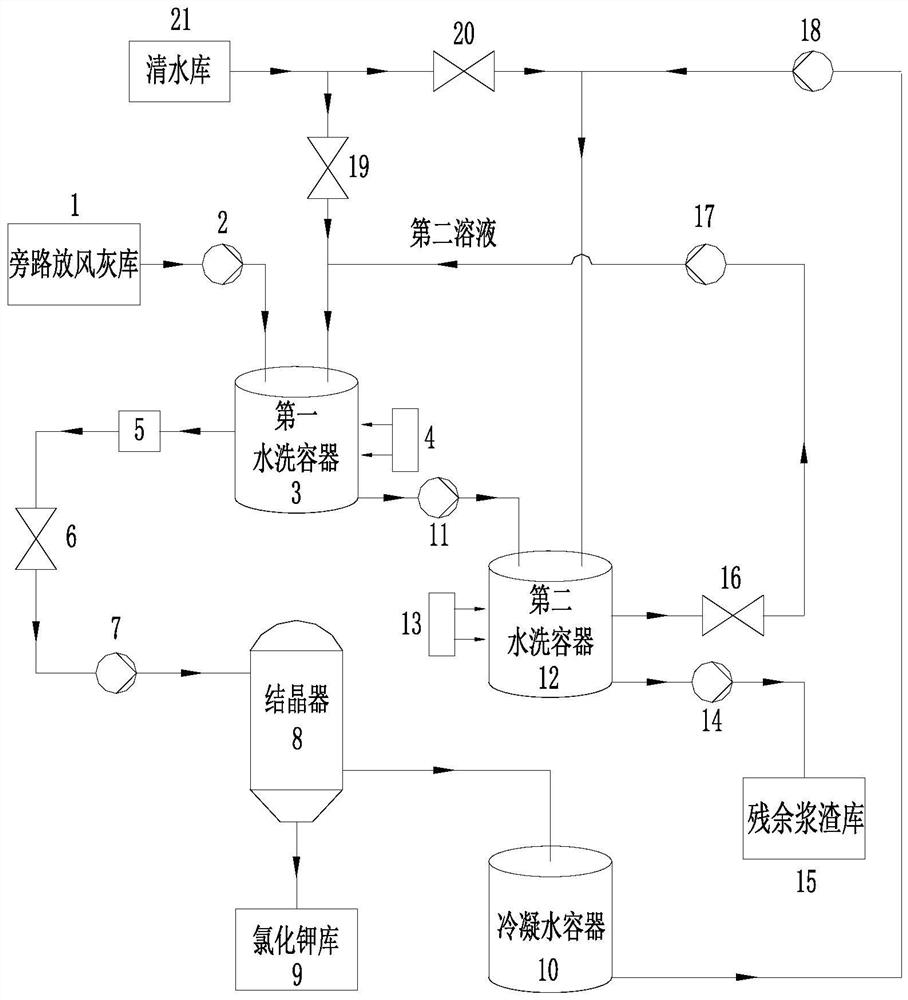

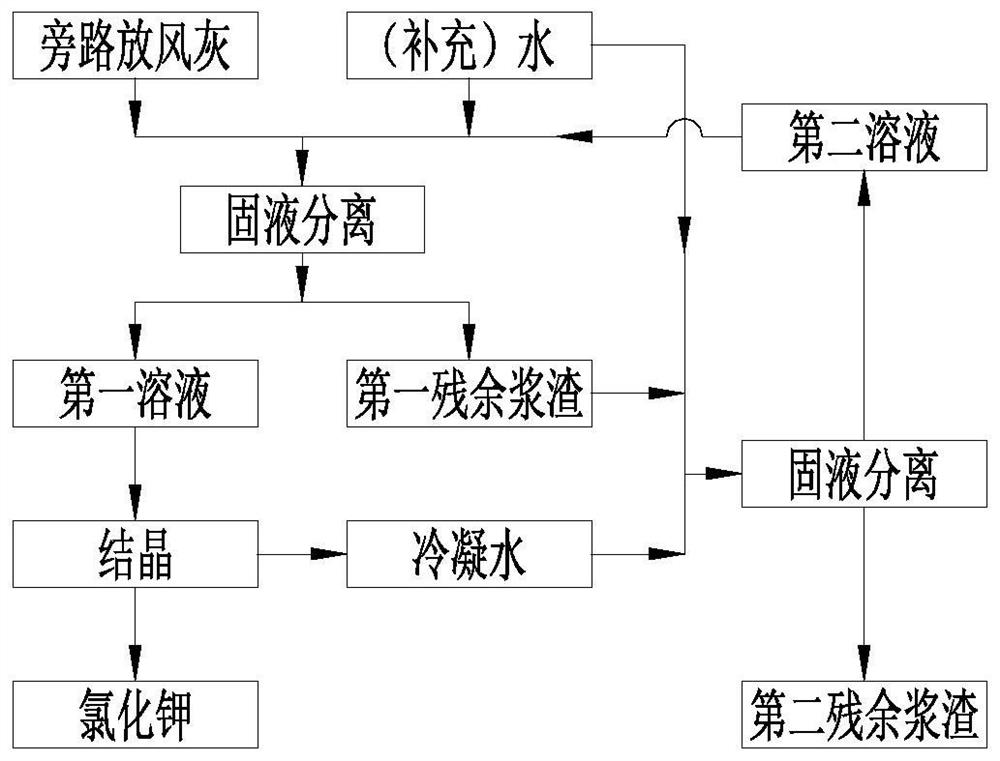

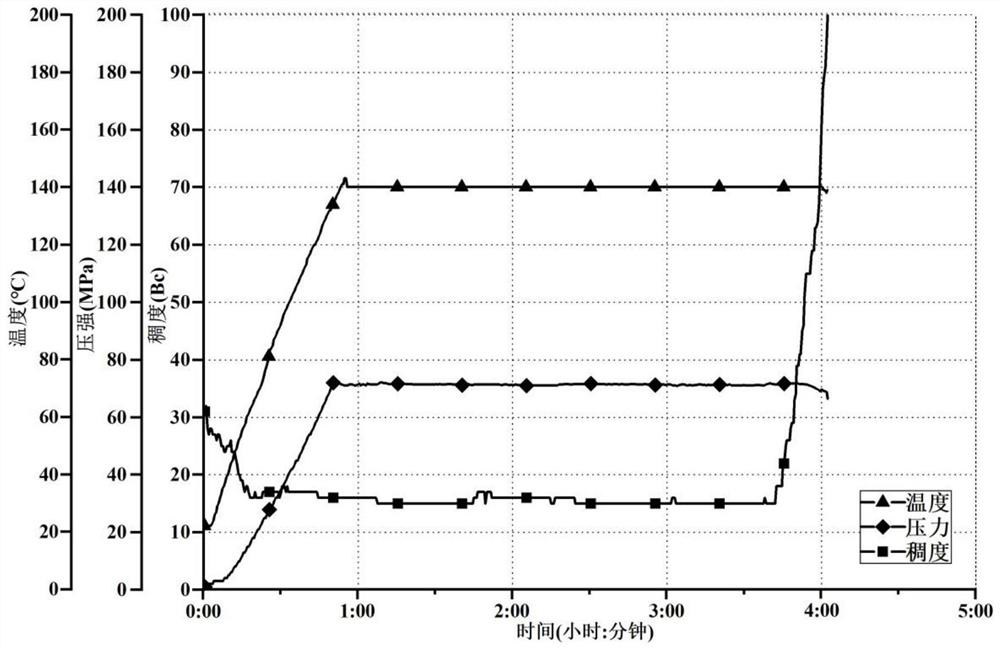

Method for monitoring and treating chlorine in cement clinker production system for co-treating waste incineration fly ash and cement clinker production system thereof

PendingCN114368922AReduce disposal costsReduce shipping costsMaterial analysis using wave/particle radiationUsing liquid separation agentClinker (waste)Process engineering

Owner:北京优巨源环保工程技术有限公司

Acidic lithium slag-Portland cement-silica fume composite cementing material and preparation method thereof

ActiveCN110877970AImprove flexural performanceAccurate control of densityCeramicwareFoaming agentSludge

The invention discloses an acidic lithium slag-Portland cement-silica fume composite cementing material. The composite cementing material comprises Portland cement, acidic lithium slag, silica fume, agraphene material, iron tailings and a light filler. The invention further discloses a preparation method of the composite cementing material. The preparation method comprises the following steps: taking and uniformly mixing fly ash, 15-25 parts by weight of sludge, oyster shell powder, clay, water and fusible foaming particles, granulating the obtained mixture, and firing the granulated mixtureto obtain the light filler; mixing the Portland cement with silica fume, and grinding the obtained mixture to obtain a first ground product; respectively grinding the acidic lithium slag, the graphenematerial and the iron tailings; mixing the first ground product, the acidic lithium slag powder, the graphene powder and the iron tailing powder to obtain a second ground product; and uniformly mixing the second ground product with the light filler to obtain the finished cementing material product. A foaming agent is not used, the density of the material is controlled by utilizing the light filler, and the material density can be accurately controlled, so that the quality of the finished product is improved.

Owner:HUNAN LVSHENG TECH DEV CO LTD

Light-weight middle-high pressure mold and preparation method thereof

ActiveCN112142408AAffect productionAvoid deformationCeramic shaping apparatusPortland cementWater reducer

Owner:JOMOO KITCHEN & BATHROOM

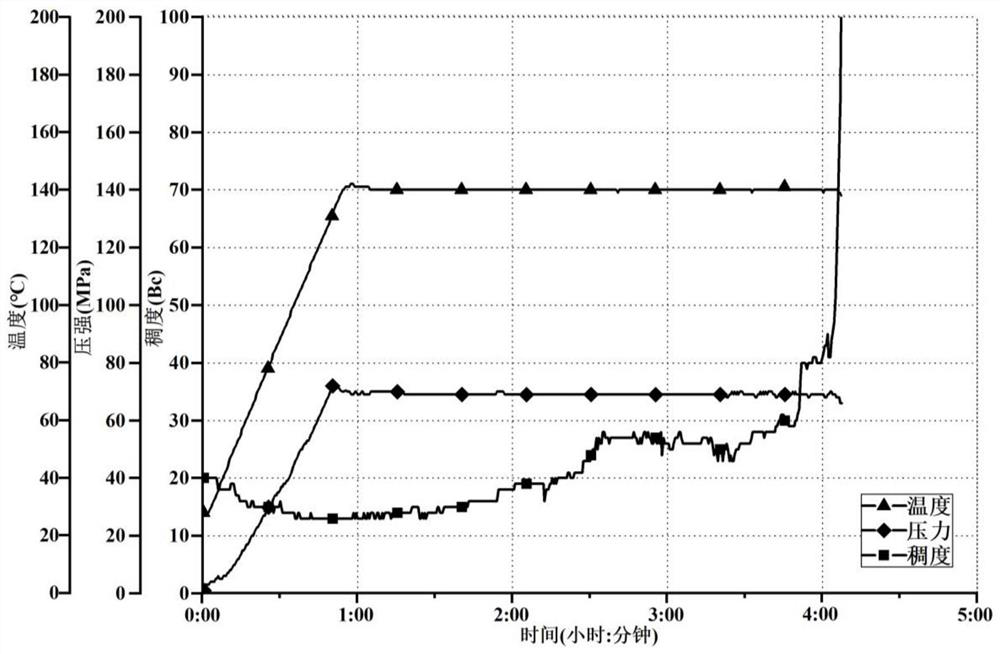

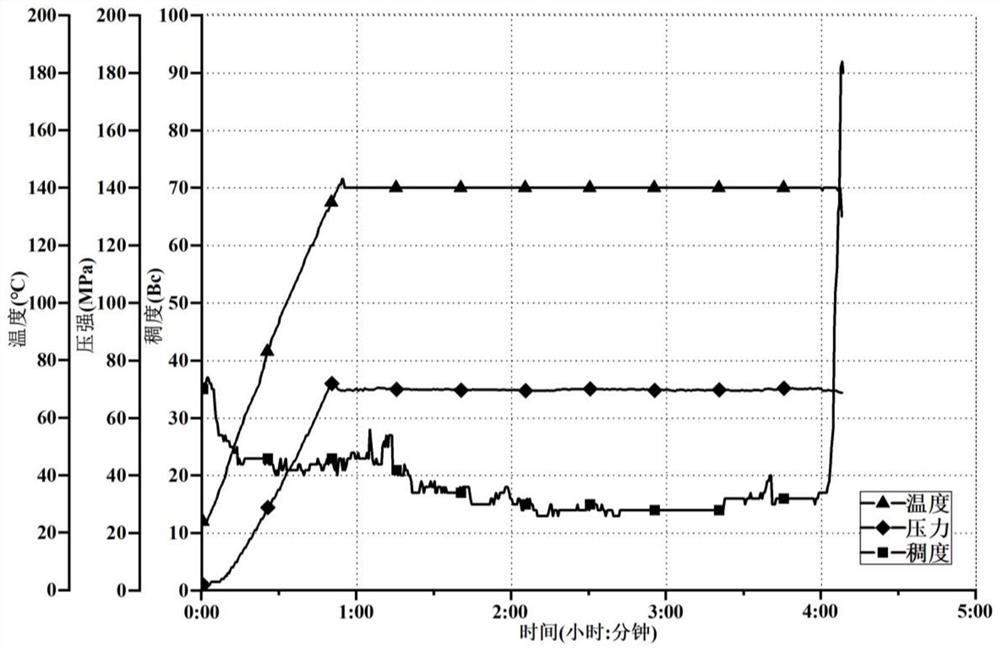

Weak gelling agent, preparation method of weak gelling agent, cement paste suspension stabilizer and application of cement paste suspension stabilizer

ActiveCN114716605AImprove rigidityEnhanced interactionSolid waste managementDrilling compositionMeth-Pyrrolidinones

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Production device and production process for cement kiln multifunctional necking hanging piece

PendingCN111136467AInnovative designHigh degree of automationOther manufacturing equipments/toolsProcess engineeringCement kiln

Owner:泰州华航精密铸造有限公司

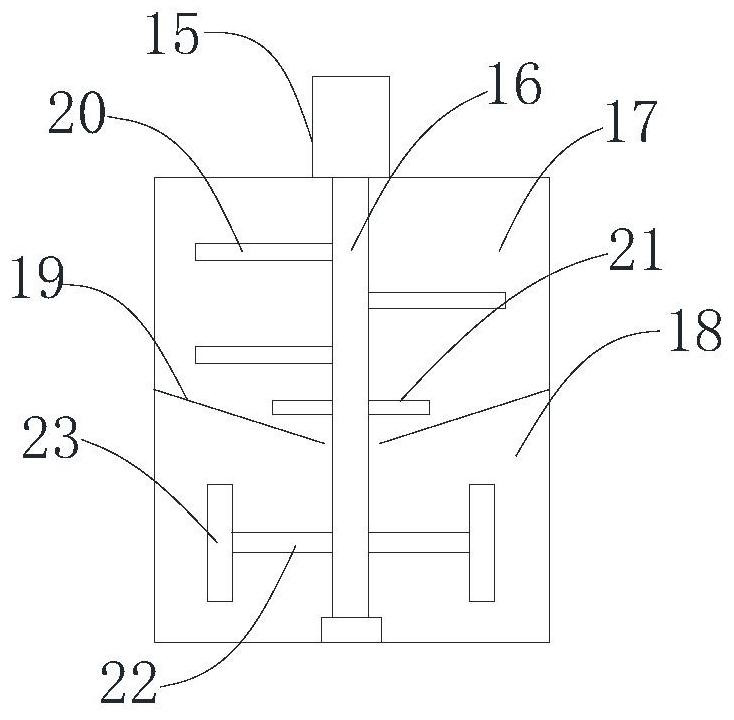

Cement-based slurry stirring system

PendingCN113263625AIncrease productivityMixing operation control apparatusIngredients weighing apparatusThermodynamicsProcess engineering

Owner:天长市汊涧建筑安装装璜有限公司

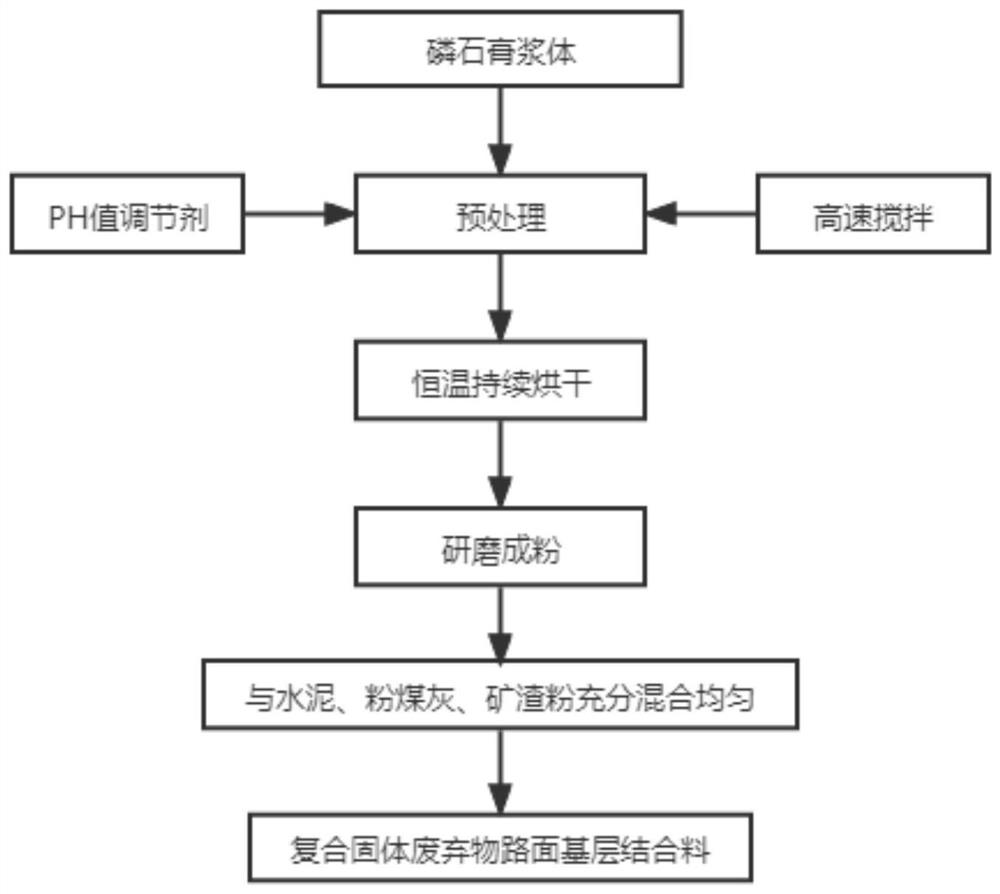

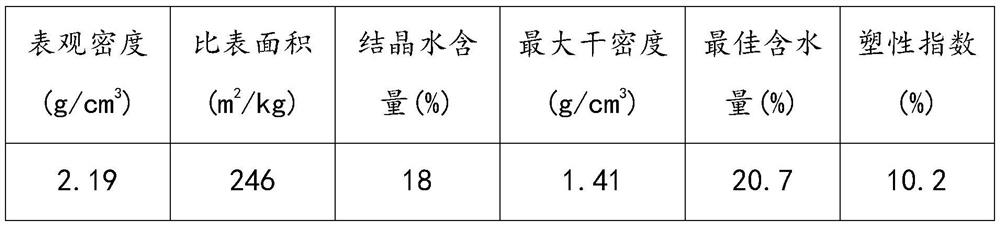

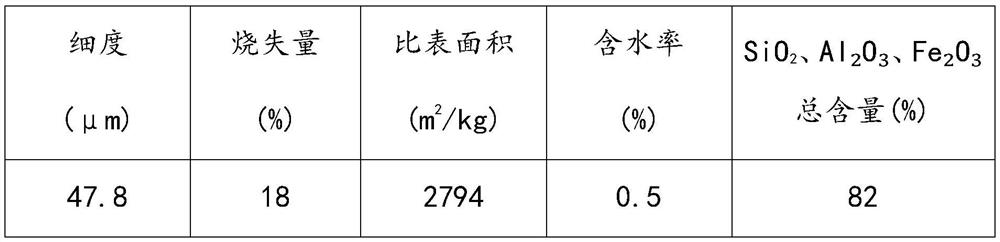

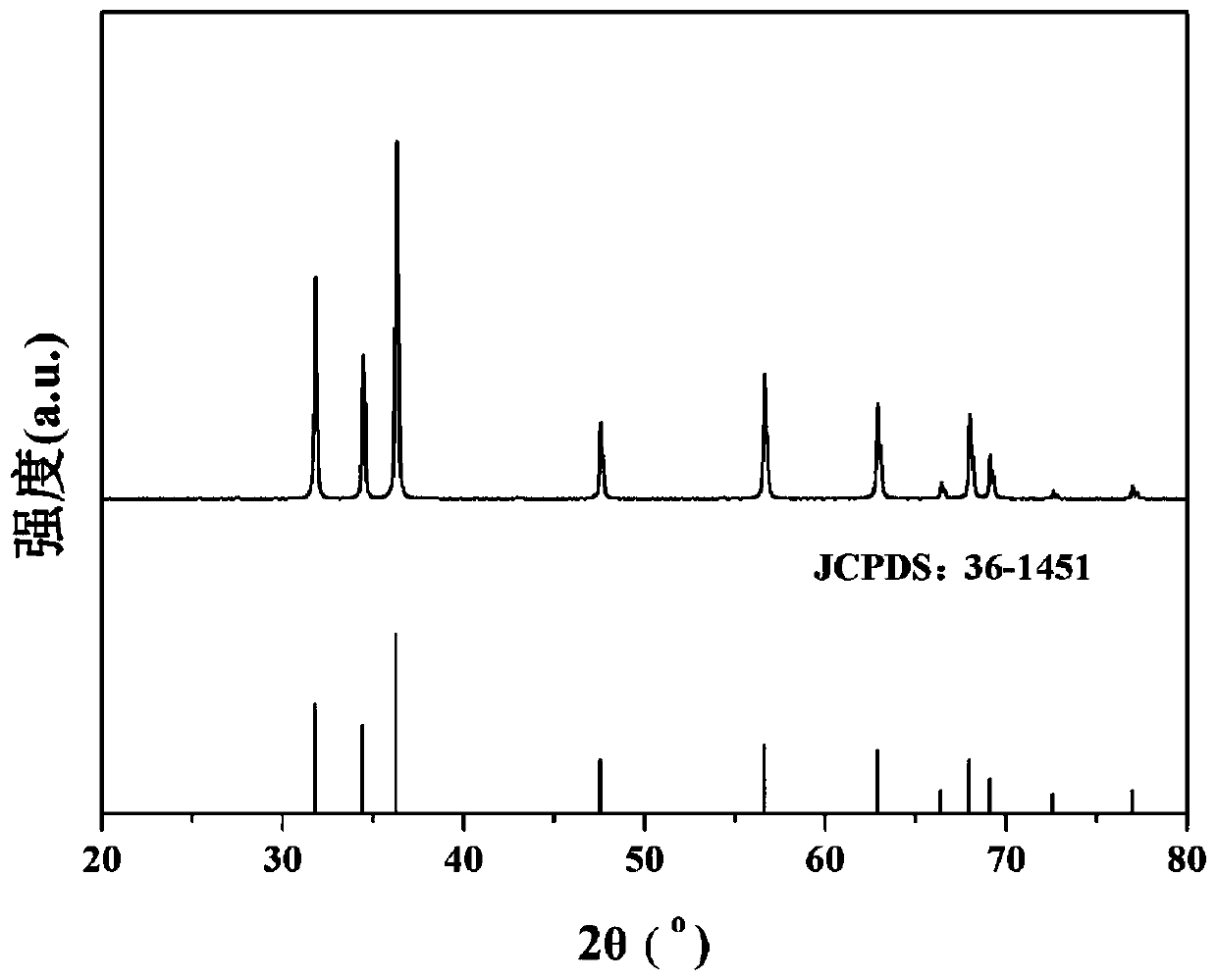

Composite solid waste pavement base binder and preparation method thereof

PendingCN114804773AAchieve recyclingAchieve environmental protectionShrinkage crackingRoad engineering

Owner:中路高科交通检测检验认证有限公司

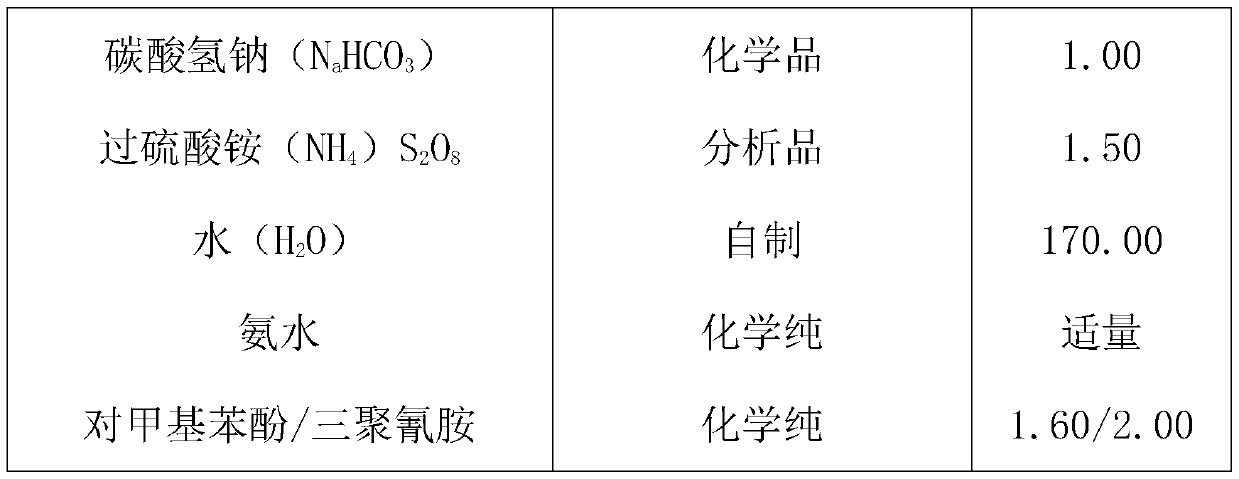

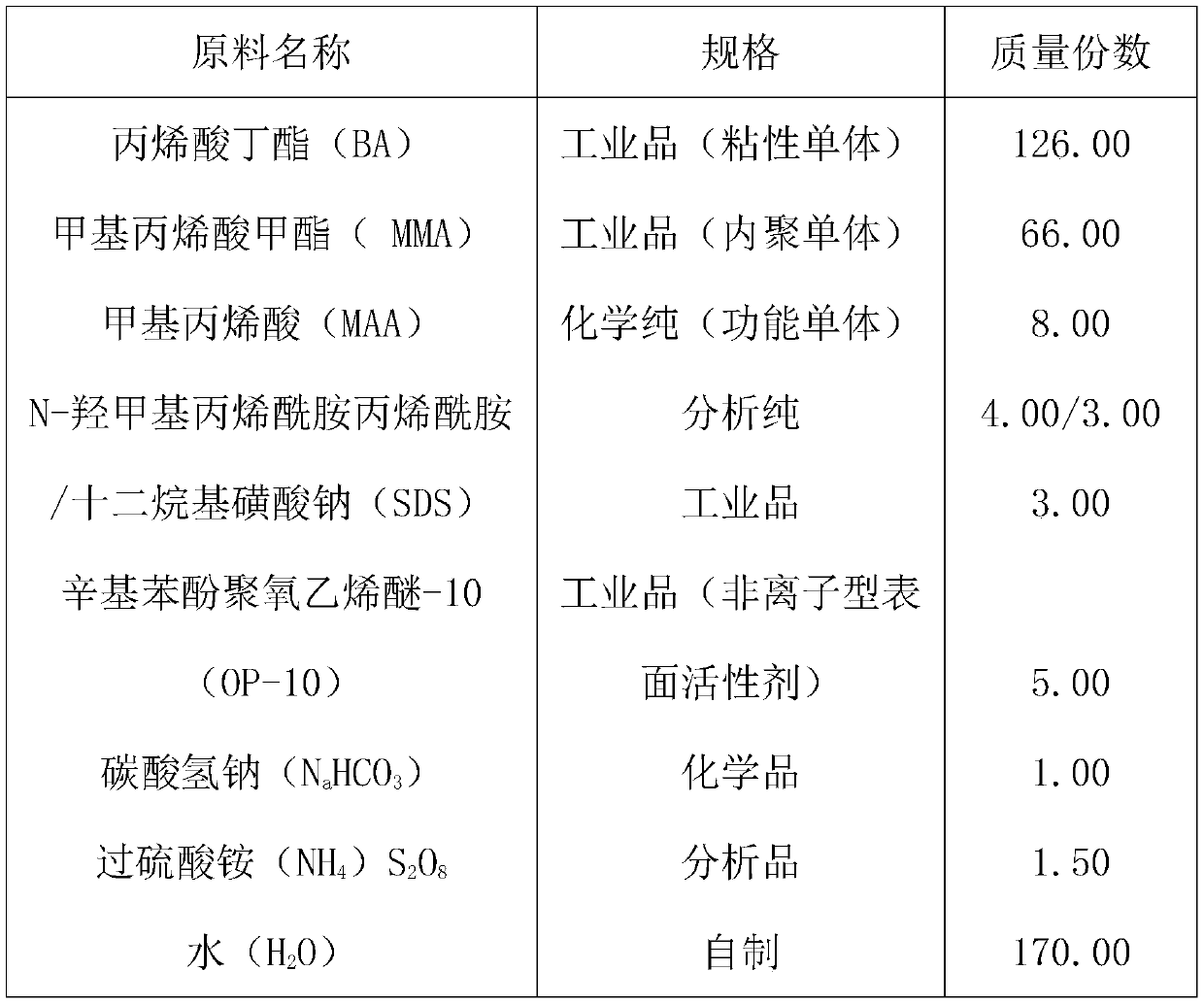

Concrete glue reducing agent and preparation method thereof

The invention relates to a concrete glue reducing agent and a preparation method thereof. The concrete glue reducing agent is prepared by adding a quaternary ammonium salt surfactant and silicone oilinto raw material components according to a proper proportion. During preparation, a methyl allyl polyoxyethylene ether polycarboxylic acid water reducing agent is added into water firstly, then organic amine and organic alcohol are added for a stirring reaction, cellulose ether is added, a stirring reaction is performed for certain time, a mixture of a quaternary ammonium salt surfactant and silicone oil is added, and a stirring mixing reaction is performed to finally prepare a concrete glue reducing agent. According to the invention, the concrete glue reducing agent is used for concrete, thehydration degree of the cement is enhanced, the cement consumption is lowered, the mechanical properties and compactness of the concrete are effectively enhanced, and the workability and the volume stability of the concrete are also improved; and according to the concrete glue reducing agent, the manufacturing cost can be effectively reduced, 30 kg of cement can be saved for each cubic meter of concrete with C30 or above, and the concrete glue reducing agent is compatible with a conventional additive and has no side effect.

Owner:BEIJING FURUILES TECH DEV CO LTD

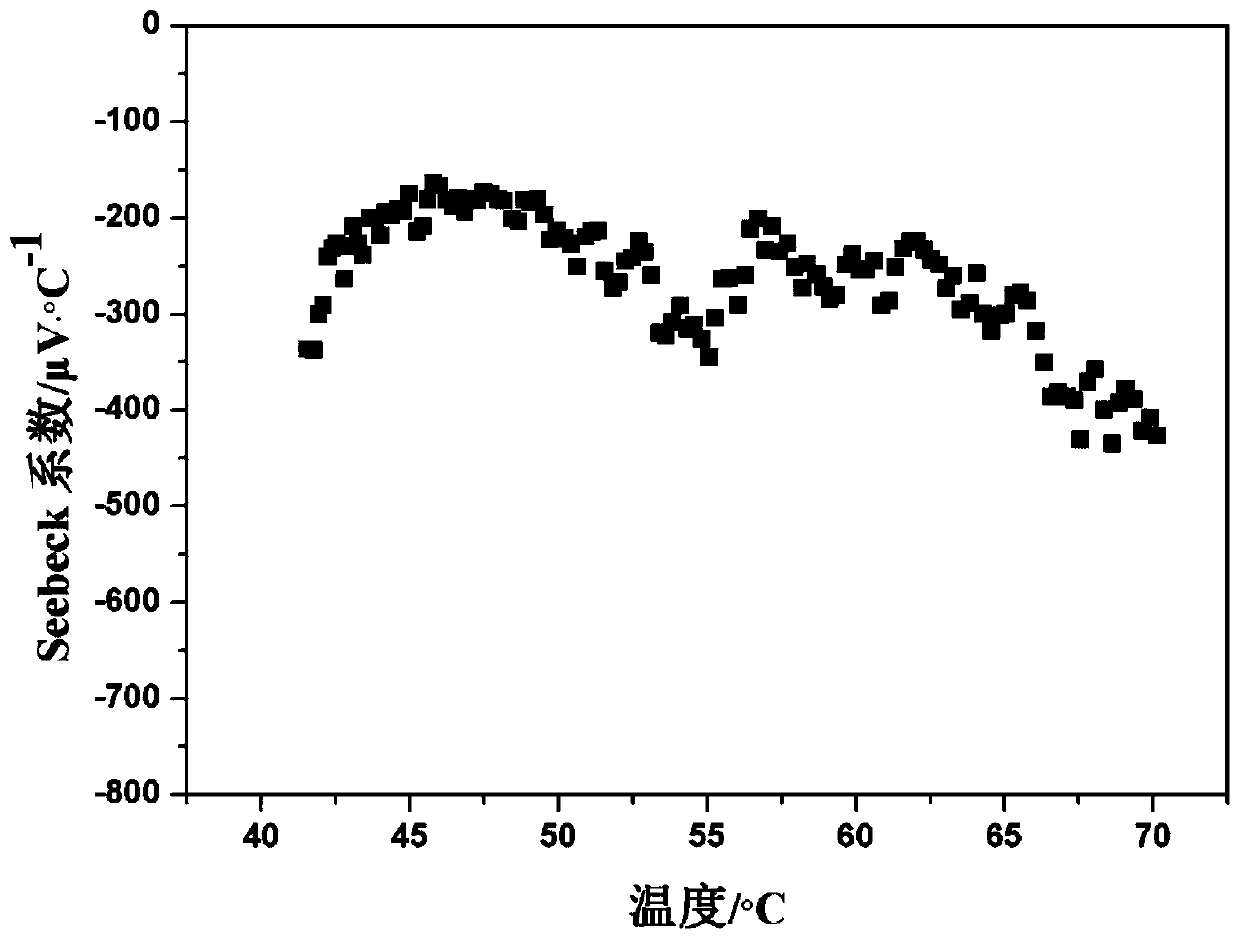

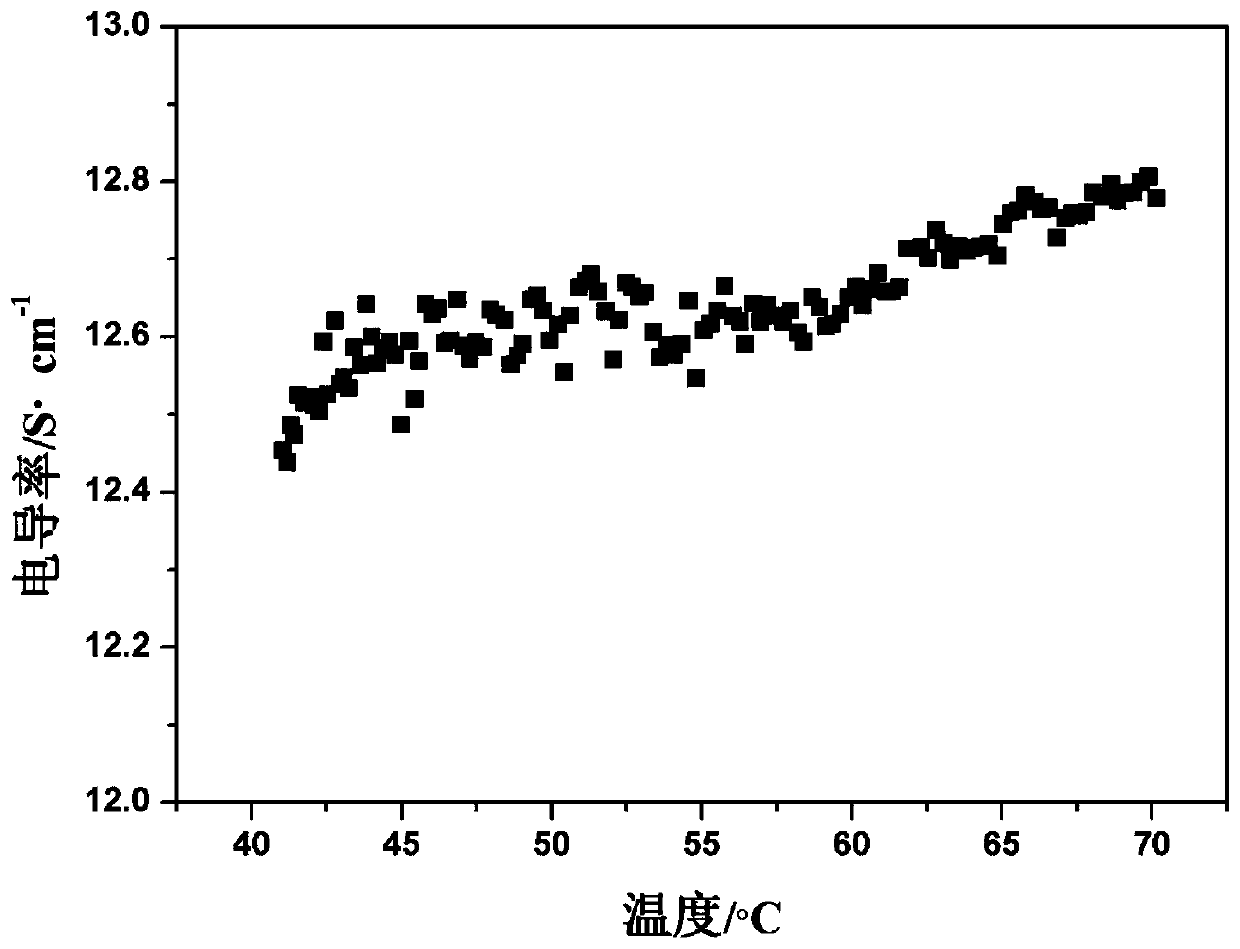

Method for improving power factor of cement-based composite material by pretreating zinc oxide

ActiveCN111302687AHigh thermoelectric power factorSuitable for application requirementsBall millHeat treated

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

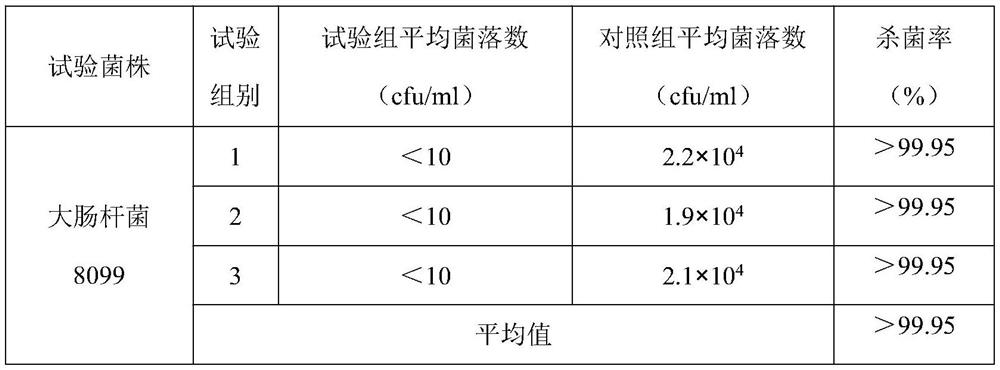

Preparation method of wormwood antibacterial coating

InactiveCN114133771AFacilitated releaseNo pollution in the processAntifouling/underwater paintsPaints with biocidesBiotechnologyCellulose

Owner:韩惠来

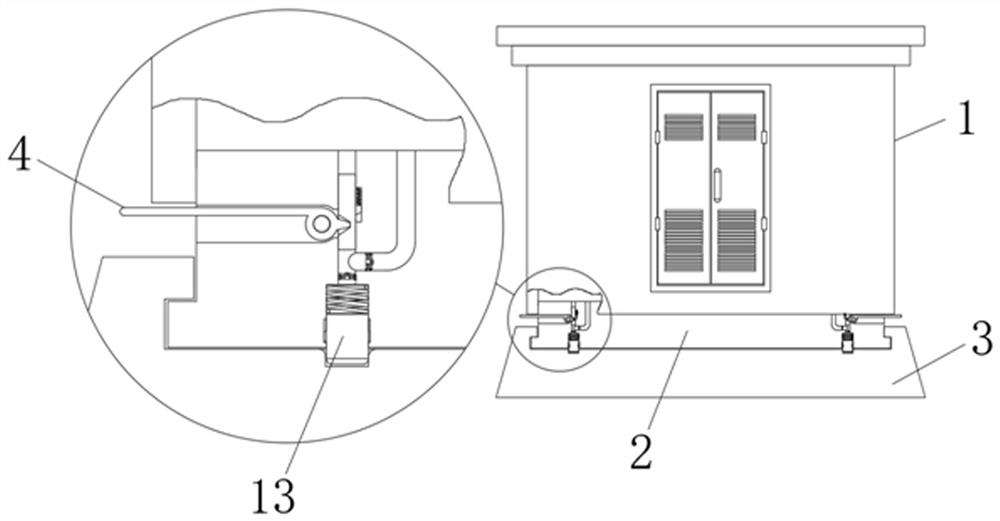

Sliding quick-connection type outdoor large transformer cabinet

PendingCN114551034AEasy to controlQuick installationTransformers/reacts mounting/support/suspensionTransformers/inductances casingsPlate pressureTransformer

Owner:XIANGTAN SHUANGHUAN MACHINERY DEV

Nano densified polymer-based waterproof coating and preparation method thereof

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Energy-saving environment-friendly high-strength fast permeable concrete and preparation method thereof

PendingCN114230242ASimple structureIncrease usage intensityCement productionCeramicwareStructural engineeringHoneycomb like

Owner:扬州通惠系统集成科技有限公司

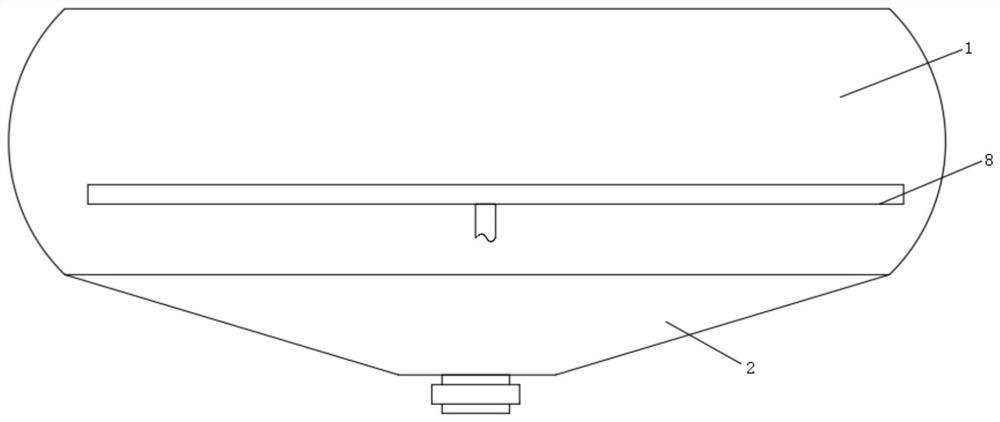

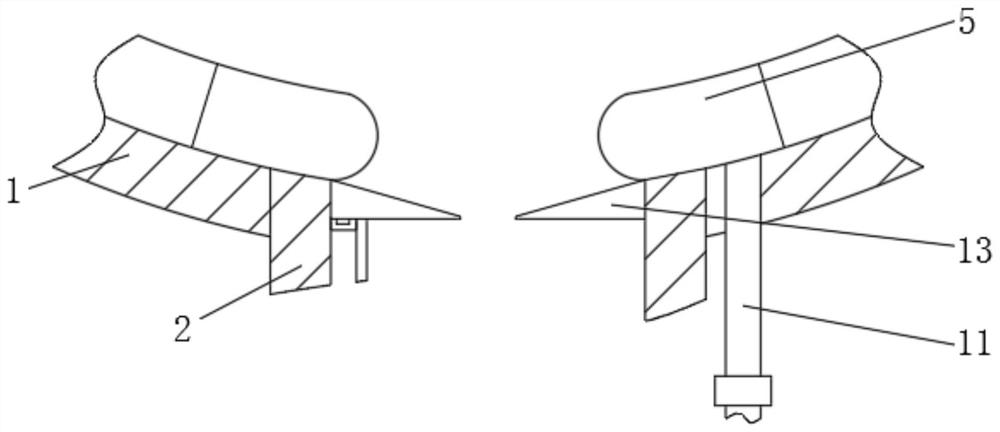

Fluidized bed assembly of bulk cement tanker

Owner:东莞市永强汽车制造有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap