Supplying and correcting system and method for COG (Chip on Glass) preformer

A technology of pre-pressing machine and camera, applied in IC supply and correction mechanism, COG pre-press IC supply and correction field, can solve the problems of complex structure of COG process equipment, inability to guarantee accuracy, low production efficiency, etc., and achieve simple structure , improve the yield, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

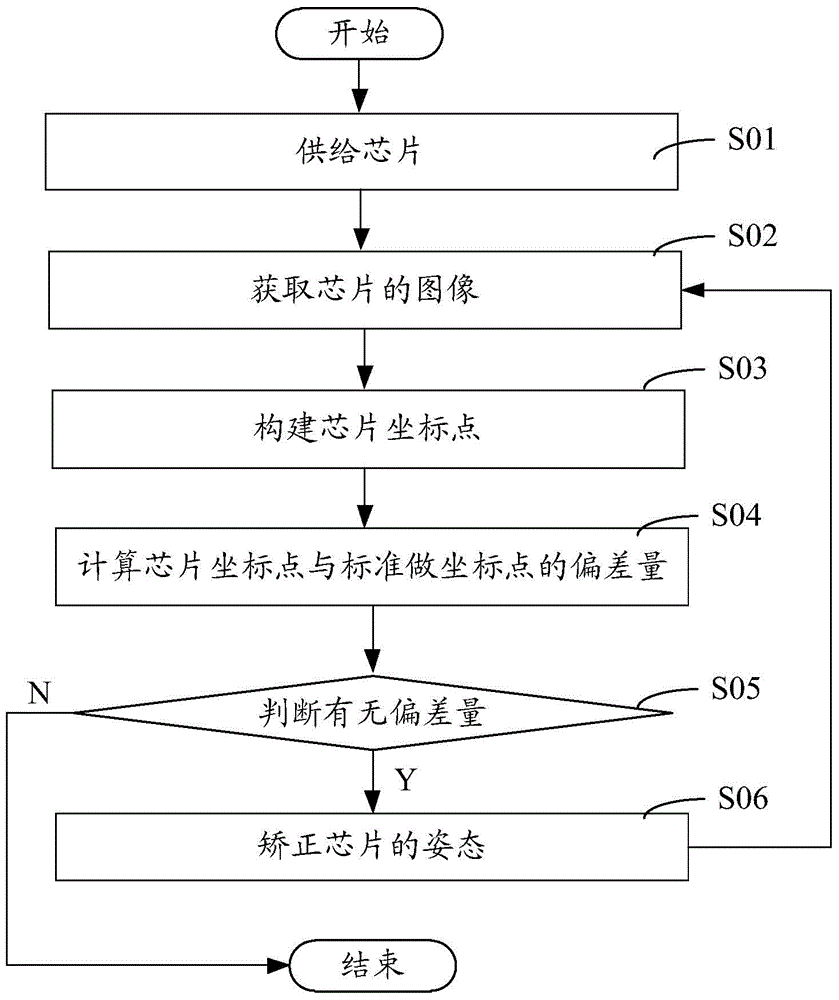

[0024] The supply and correction system of the COG pre-pressing machine cooperates with the COG pre-pressing machine. The supply and correction system can provide the chip to the vacuum suction head of the COG pre-pressing machine, and then the supply and correction system corrects the posture of the chip. After accurate correction, pre-pressing can be performed action.

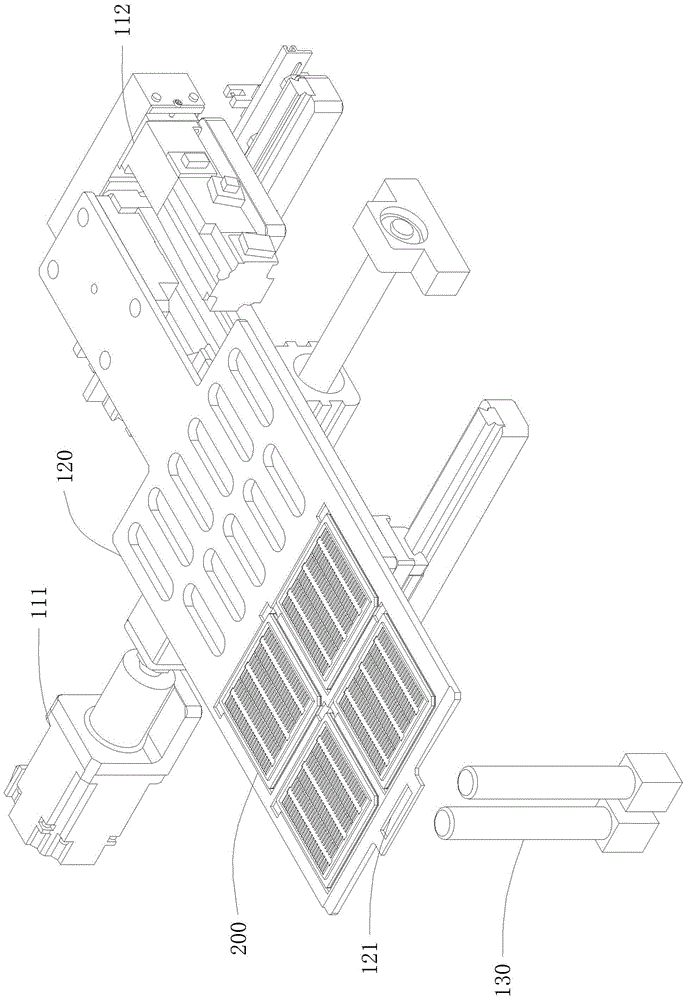

[0025] Please refer to figure 1 , The supply and correction system of the COG pre-pressing machine includes a drive mechanism, a supply tray 120, an image system 130, and a control system.

[0026] The driving mechanism includes an X-axis motor 111, a Y-axis motor 112, and a driving platform. The X-axis motor 111 and the Y-axis motor 112 respectively drive the driving platform to move in the X-axis direction and the Y-axis direction. The supply tray 120 is arranged on the driving platform, and the chip 200 is placed on the supply tray 120, and the chip 200 is used for pre-pressing with the glass substrate. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap