Method for preparing silver nanowire in hydrophobic phase

A nanowire and hydrophobic phase technology, applied in nanotechnology and other directions, can solve the problem that silver nanowires cannot be uniformly dispersed, and achieve the effect of expanding the application field and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

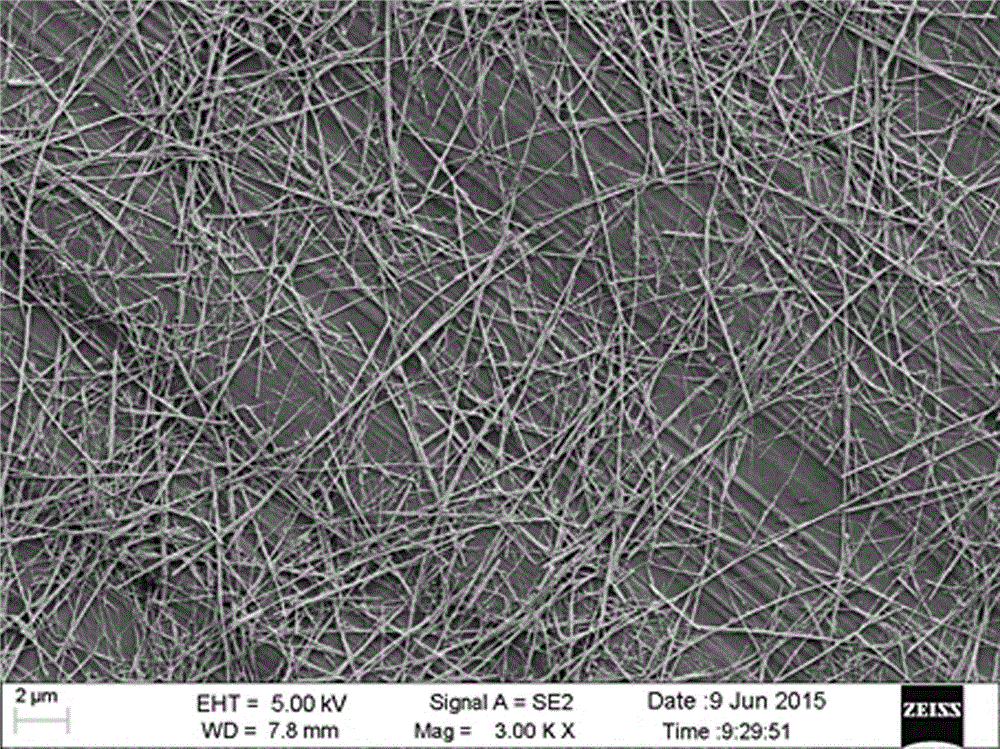

[0028] Example 1

[0029] At room temperature, mix 300 mg of silver bromide, 3 mg of cupric chloride and 30 g of oleylamine, stir and fully dissolve to obtain a mixed solution, raise the temperature of the mixed solution to 160°C for 6 hours, then cool to room temperature to obtain a reaction solution, and use Wash with cyclohexane, filter, and dry to obtain silver nanowires. The silver nanowire that present embodiment makes (see figure 1 ), with an average diameter of 60 nm and an average length of 10 μm.

Example Embodiment

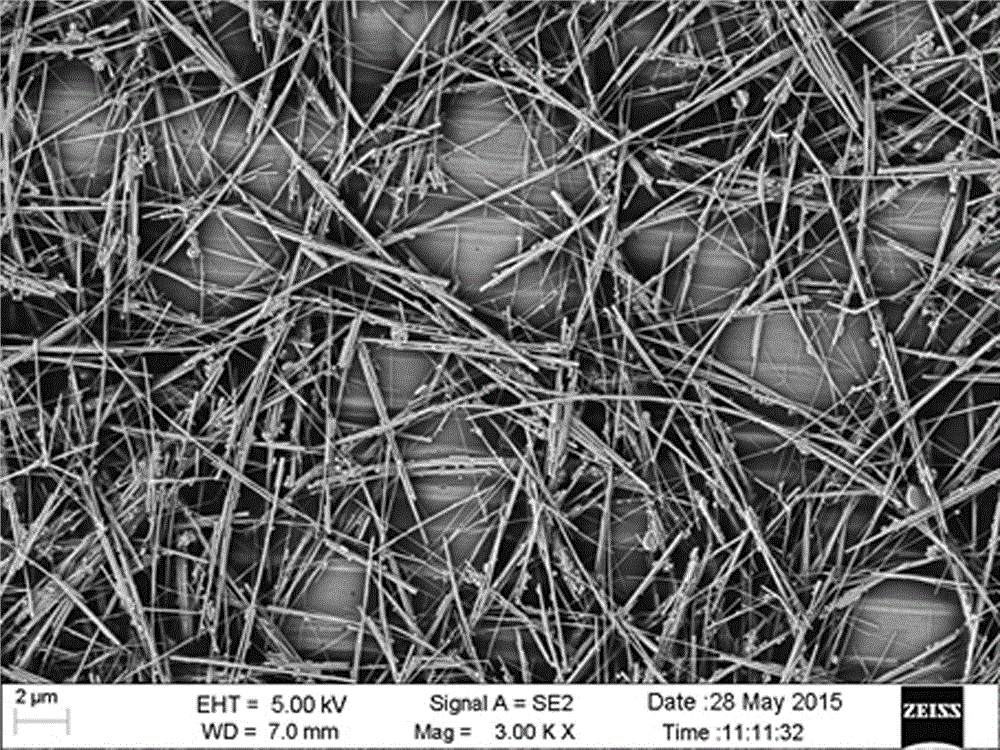

[0030] Example 2

[0031] At room temperature, mix 300 mg of silver bromide, 3 mg of copper sulfate and 30 g of oleylamine, stir to dissolve fully to obtain a mixed solution, raise the temperature of the mixed solution to 160°C for 6 h, then cool to room temperature to obtain a reaction solution, and use Wash with cyclohexane, filter, and dry to obtain silver nanowires. The silver nanowire that present embodiment makes (see figure 2 ), with an average diameter of 55 nm and an average length of 15 μm.

Example Embodiment

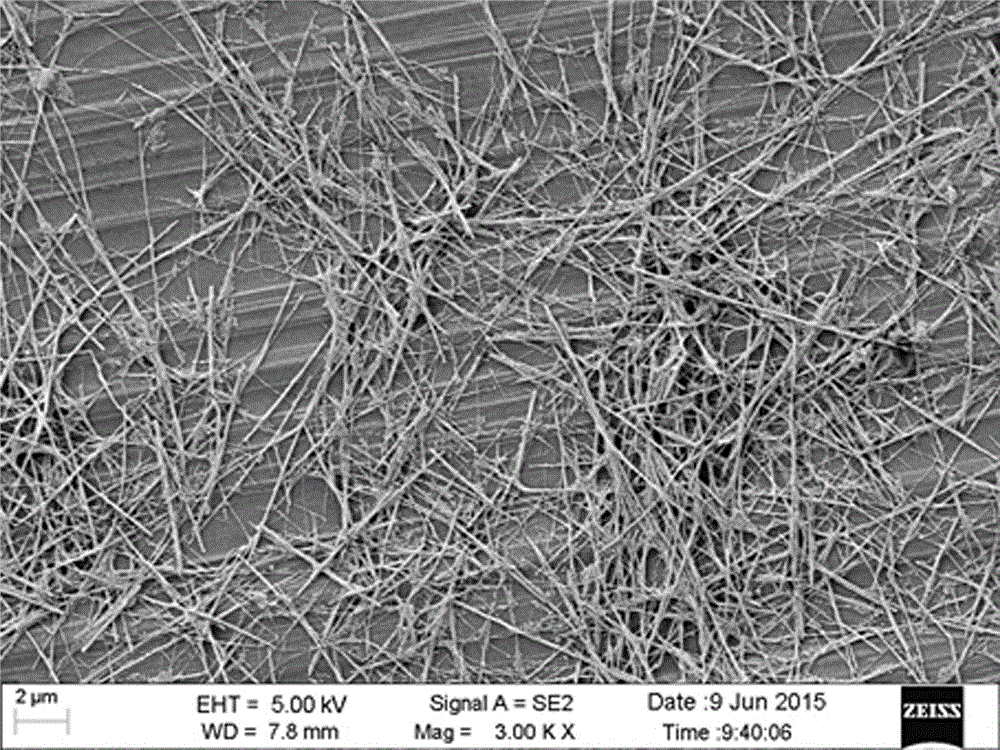

[0032] Example 3

[0033] At room temperature, mix 300 mg of silver bromide, 3 mg of copper oxide and 30 g of oleylamine, stir to dissolve fully to obtain a mixed solution, raise the temperature of the mixed solution to 160°C for 6 h, then cool to room temperature to obtain a reaction solution, and use Wash with cyclohexane, filter, and dry to obtain silver nanowires. The silver nanowire that present embodiment makes (see image 3 ), with an average diameter of 67 nm and an average length of 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap