Method for making liquid metal waterproof shell

A technology of liquid metal and production method, which is applied in the direction of casing/cabinet/drawer parts, etc., which can solve the problems of electronic products not being waterproof, dustproof, shockproof, mobile phone frames are wide and thick, and poor adhesion and other issues, to achieve the effect of light weight, good visual effect and excellent electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0051] 1. Sapphire sheets can be processed by blanking, grinding, polishing, cleaning and other processes.

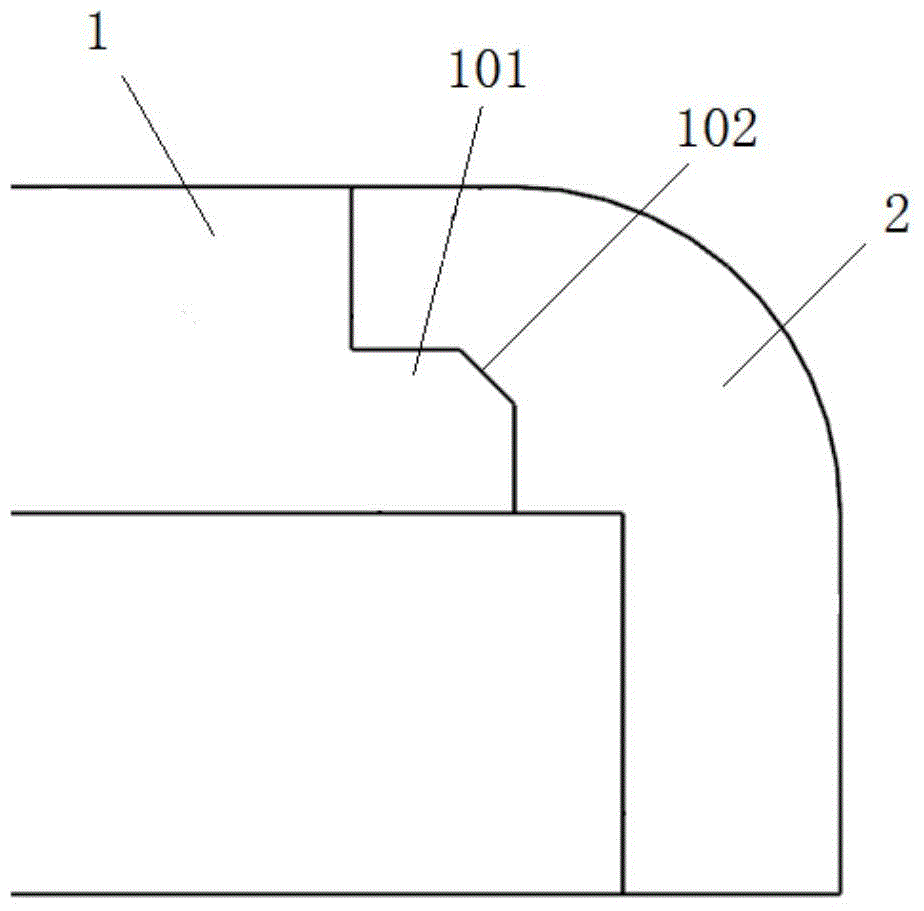

[0052] Oriented slicing is used when cutting the processed product, and cutting along a certain crystal direction can significantly reduce the phenomenon of large chipped corners when the product is cylindrically ground; the polishing pressure is 0.05Mpa to 0.21Mpa, and the surface of the product is polished with this range of pressure No defects, less scratches, increase product yield.

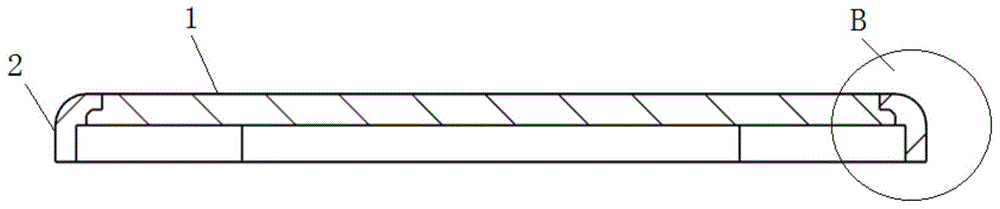

[0053] The uniform force applied during grinding can reduce the incidence of small chipped corners of the sapphire sheet; the grinding of the sapphire sheet is preferably carried out at a constant temperature. When grinding, the sapphire sheet 1 is first ground so that the outer side is higher and the inner side is lower, so that the product after grinding tends to be flat, and the yield rate of product grinding is increased. The thickness of the sapphire sheet 1 is 0.6mm-1.5mm.

[0054

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap