Cement-based composite restraint concrete compound column and manufacture method thereof

A composite material and composite material layer technology, which is applied in the field of cement-based composite material restrained concrete composite columns, can solve the problems of collapse and damage of buildings or structures, weak earthquake resistance, insufficient bearing capacity, etc., and achieves the improvement of ductility and energy dissipation capacity. , the effect of enhanced tensile properties, improved durability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

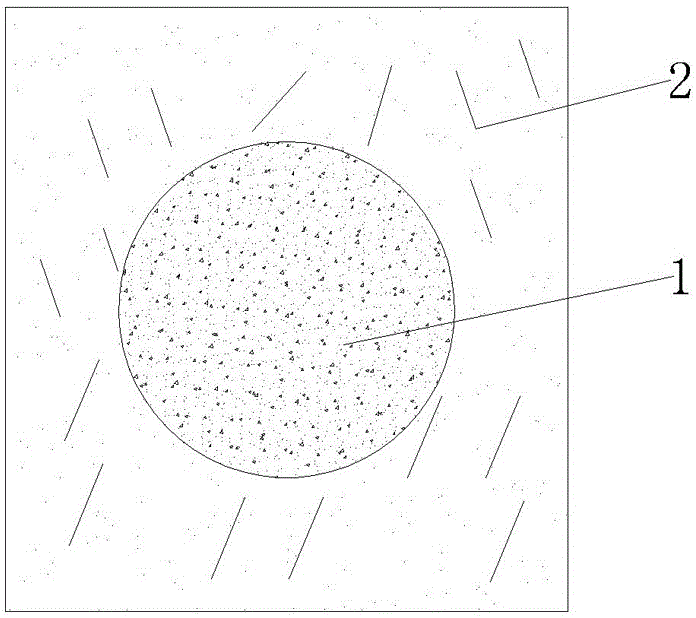

[0016] refer to figure 1 As shown, the cement-based composite material constrained concrete composite column provided by the first embodiment of the present invention includes a concrete inner core 1, a cement-based composite material layer 2 is wrapped around the concrete inner core, the concrete inner core is circular, and the column is in the shape of The square, cement-based composite material layer contains cement, sand and / or mineral admixtures, water, steel fibers and PVA fibers, wherein the mineral admixtures can be coal powder or silica fume, etc. Wherein the length of the steel fiber is greater than 6 mm and the diameter is greater than 0.12 mm, and the length of the PVA fiber is greater than 6 mm.

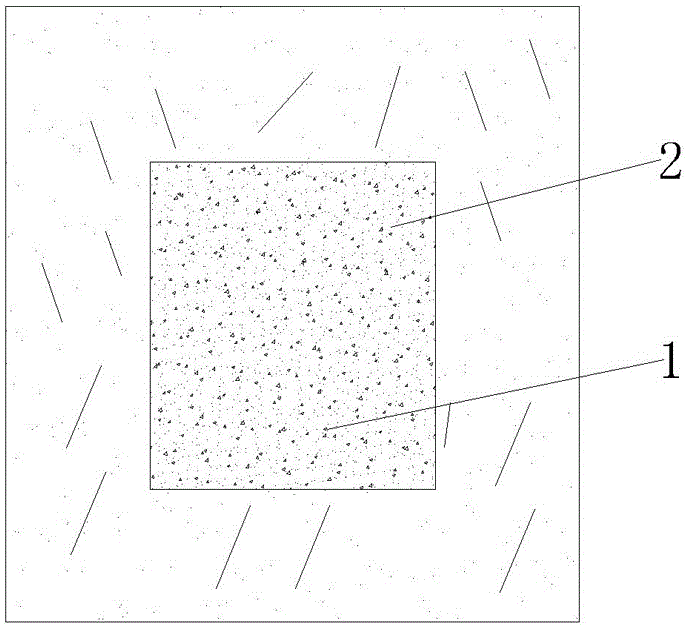

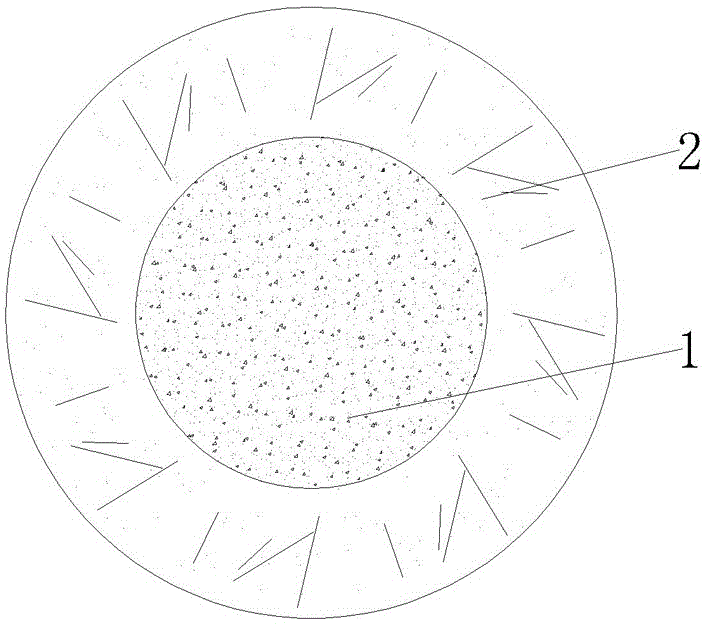

[0017] refer to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap