Directional reconfigurable microelectromechanical antenna and preparation method thereof

A micro-electro-mechanical and directional technology, applied to antennas, microstructure devices composed of deformable elements, antenna components, etc., can solve the problems that cannot meet beamforming and fast scanning, and achieve light weight and process Fully Compatible, Low Power Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

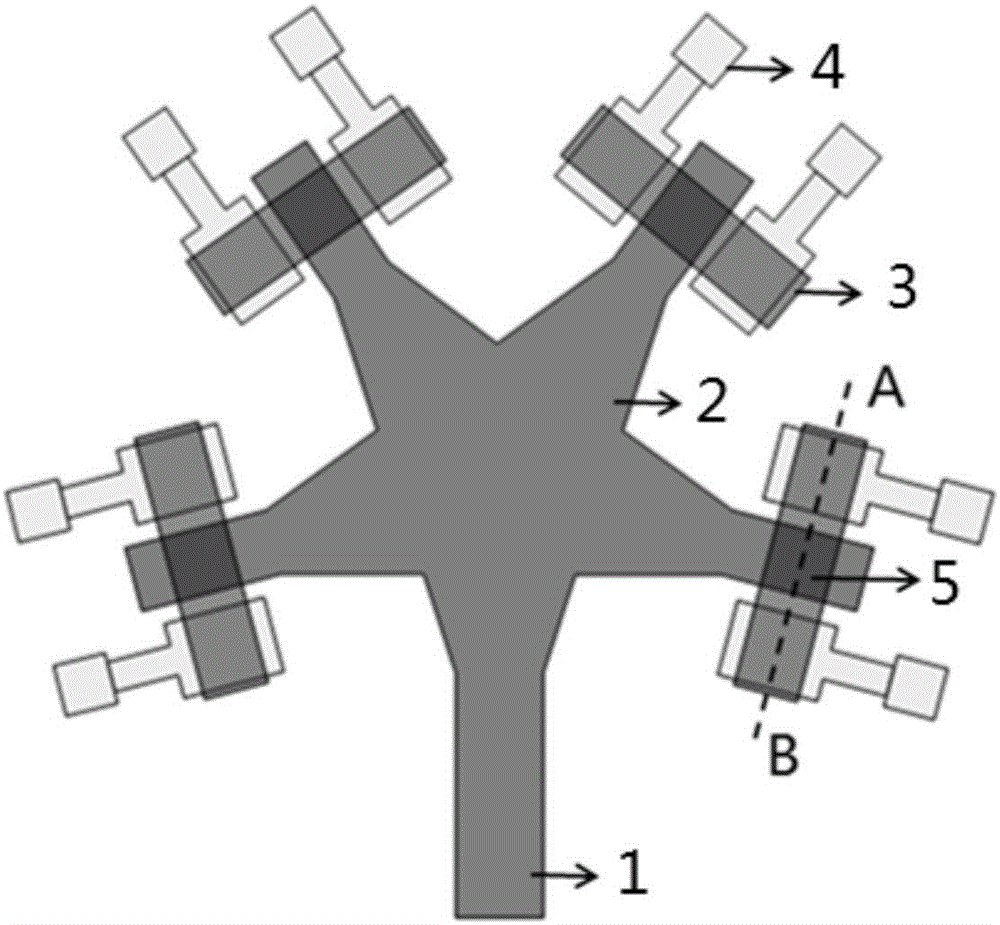

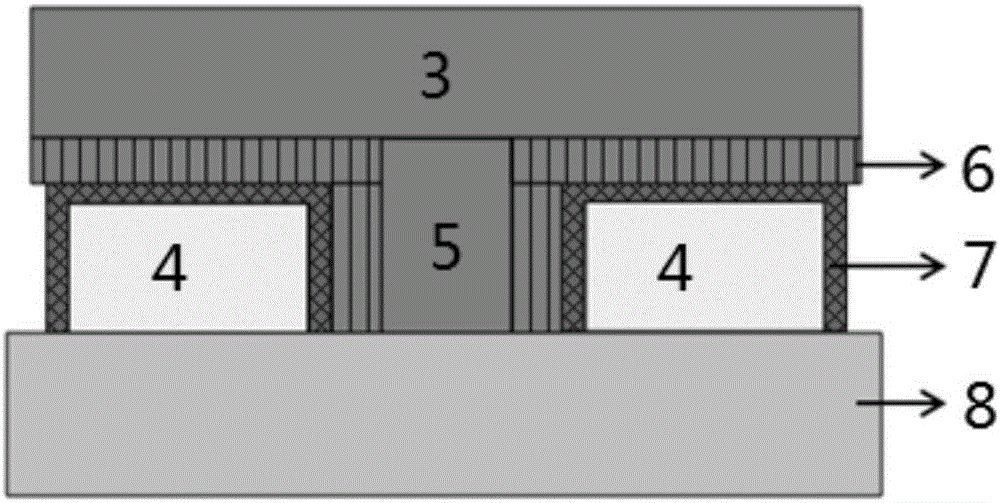

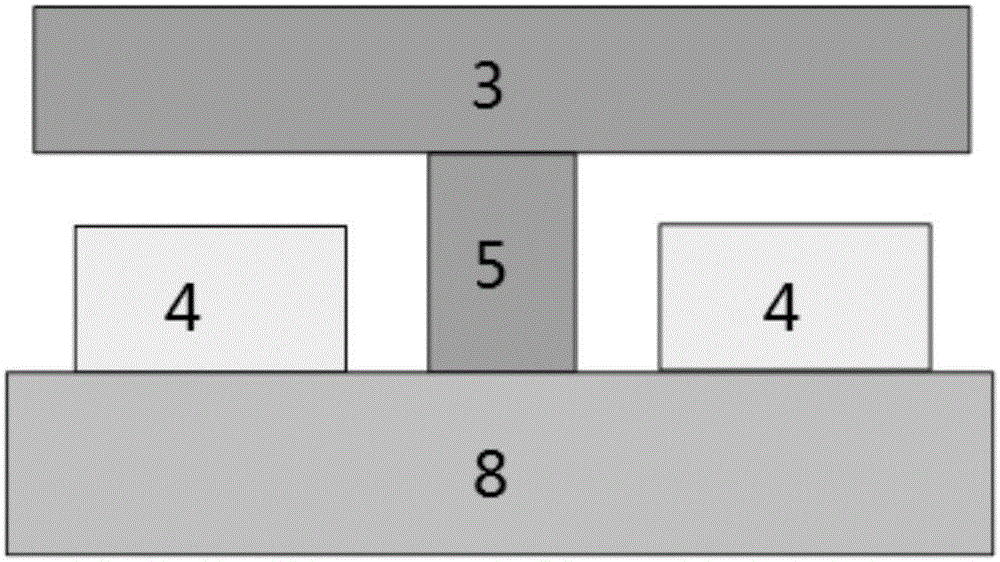

[0038] The directional reconfigurable microelectromechanical antenna of the present invention is a directional reconfigurable microwave antenna, with GaAs as the substrate, such as Figures 1 to 3 As shown, the microelectromechanical antenna uses gallium arsenide as a substrate 8, and on the substrate are provided a microstrip antenna feeder 1, a star-shaped structure microstrip antenna radiation element 2, a MEMS cantilever beam 3, a cantilever beam bridge pier 5, a cantilever Beam pull-down electrode 4, SiN dielectric layer 7 and polyimide sacrificial layer 6.

[0039] Any four radiation ends of the star-shaped microstrip antenna radiating element 2 are respectively connected to a cantilever beam pier 5, each cantilever beam pier 5 is connected to a MEMS cantilever beam 3, and the bottom of each MEMS cantilever beam 3 is on the cantilever beam A ca

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap