Novel vertical motor cooling system

A vertical motor and cooling system technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as high hot air temperature, increased motor operating costs and maintenance complexity, and reduced cooler heat transfer effect. Achieve sufficient heat exchange, improve stability, and increase cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

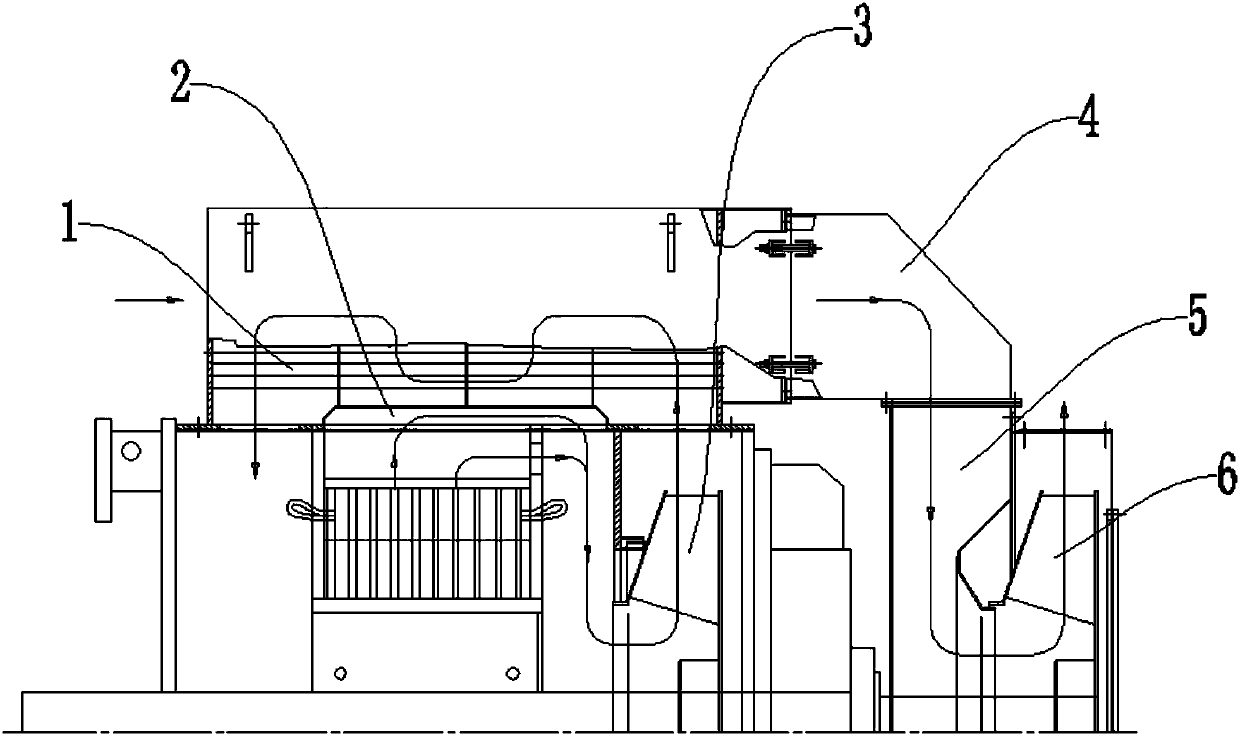

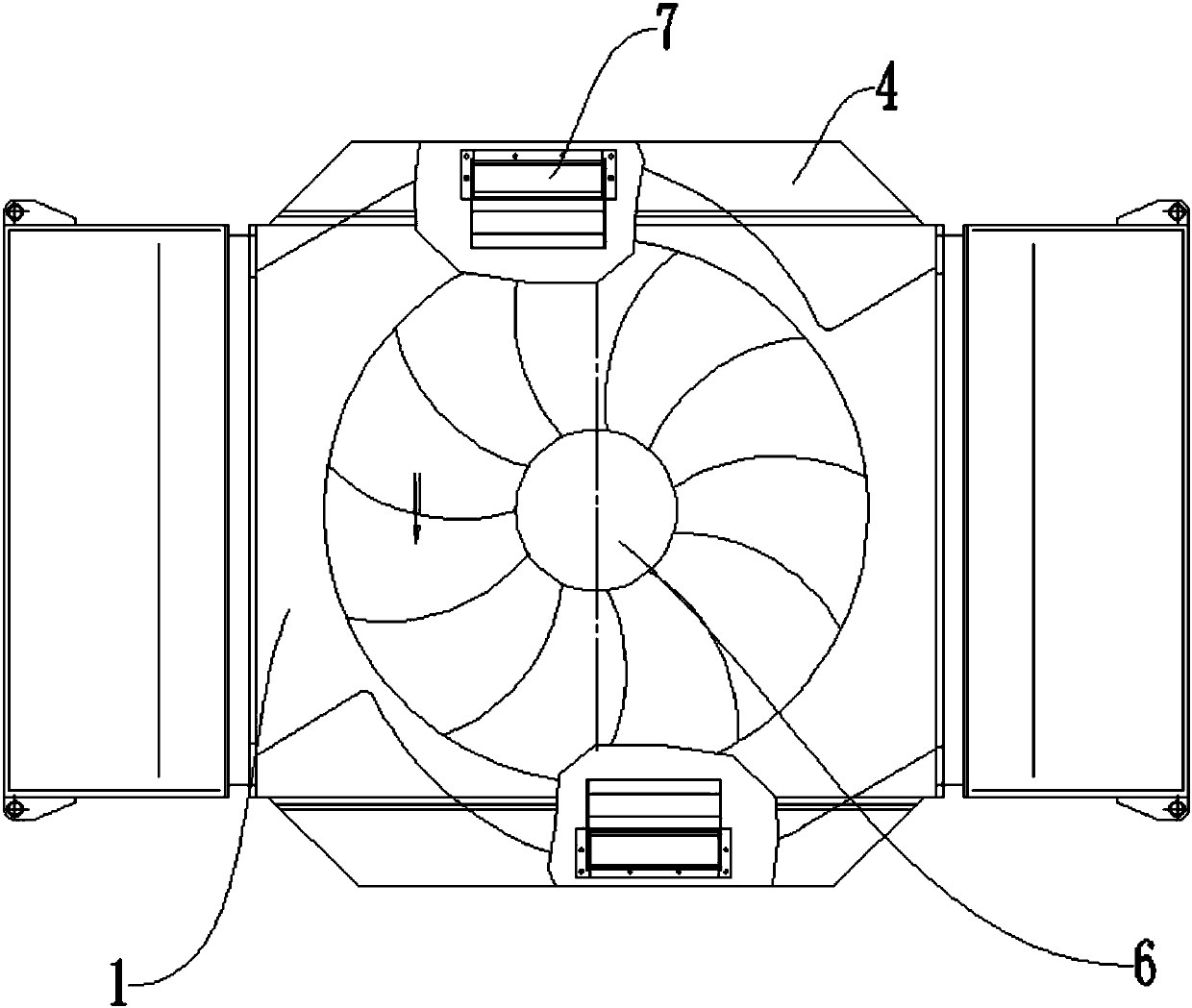

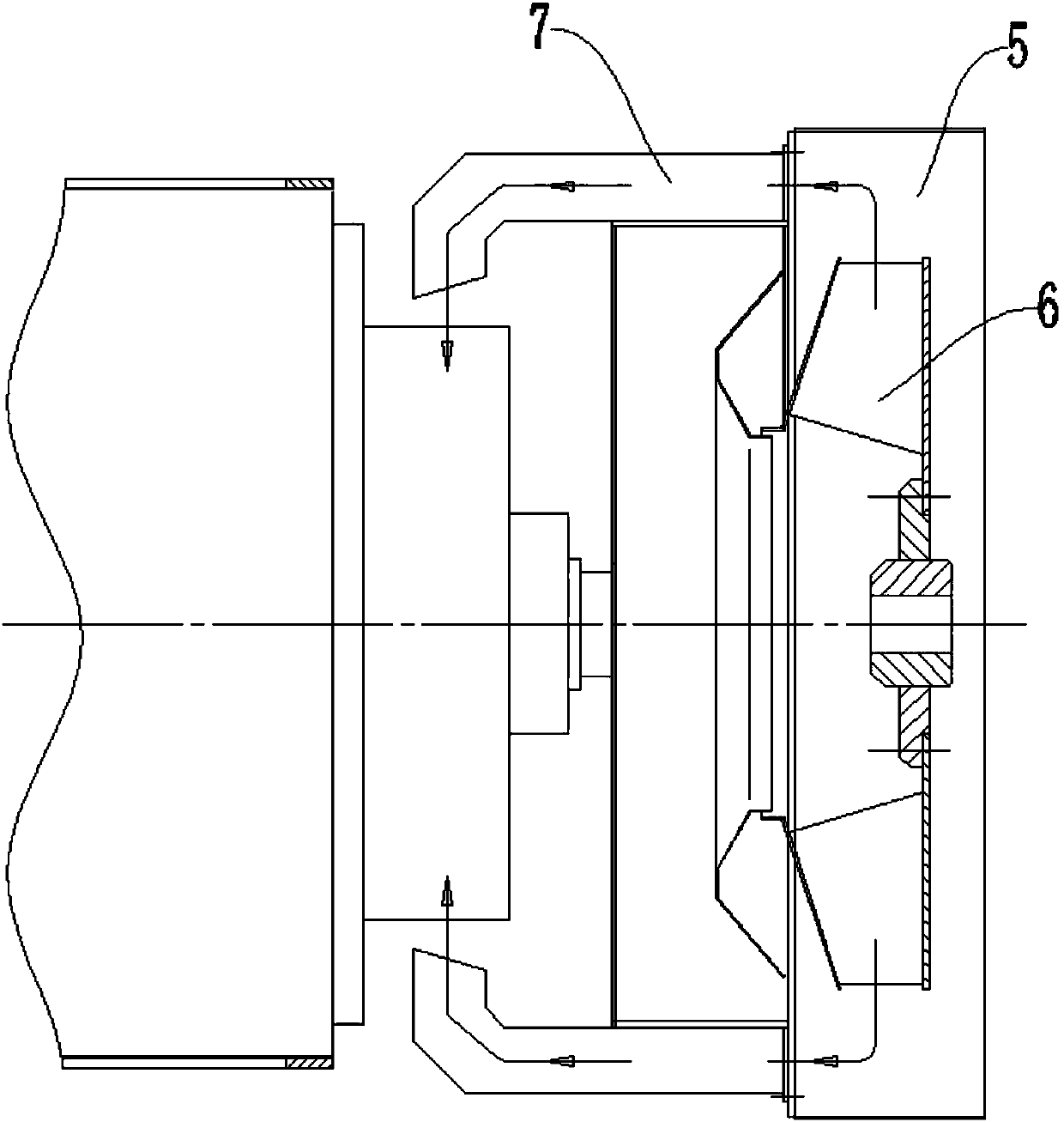

[0018] like figure 1 , figure 2 and image 3 As shown, this specific embodiment adopts the following technical solutions: it includes a cooler main body 1, an inner air path expansion compartment 2, an inner fan 3, a main air duct 4, a fan cover 5, an outer fan 6, and a counseling air duct 7. The inner motor casing at the lower end of the main body 1 is provided with an inner air passage expansion chamber 2, an inner fan 3 is arranged above the inner air passage extension chamber 2, an outer fan 6 is arranged at the upper end of the cooler main body 1, and an outer fan 6 is arranged outside the outer fan 6. The fan cover 5 is provided with a leading air cylinder 4 outside the fan cover 5, and a tutoring air cylinder 7 is arranged in the leading air cylinder 4.

[0019] Wherein, the inner air path expansion compartment 2 is fixed on the inner side of the cooler main body 1 by screws, and the outer side of the inner air path expansion compartment 2 is provided with a cooling pip

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap