Doped type triethanolamine benzoate concrete reinforcing bar corrosion inhibitor

A technology of triethanolamine grease and concrete steel bars, which is applied in the field of building materials, can solve problems such as insufficient bearing capacity, increase in reinforced concrete structure maintenance, maintenance costs, economic losses, etc., and achieve the effects of reducing corrosion, slowing down corrosion, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

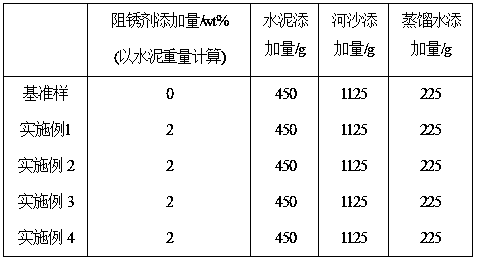

[0028] Example 1

[0029] Weigh 15kg of benzoic acid triethanolamine, 15kg of trisodium phosphate, 10kg of triethanolamine and 60kg of water, stir, dissolve, and mix uniformly to prepare the concrete steel rust inhibitor of the present invention.

Example Embodiment

[0030] Example 2

[0031] Weigh 30 kg of benzoic acid triethanolamine resin, 15 kg of ammonium phosphate, and 5 kg of glycerol, mix them evenly, add 50 kg of water, stir and dissolve evenly to prepare the concrete steel reinforcement rust inhibitor of the present invention.

Example Embodiment

[0032] Example 3

[0033] Weigh 30kg of benzoic acid triethanolamine, 10kg of ammonium phosphate, 5kg of isoprene glycol, add 55kg of water, stir and dissolve uniformly to obtain the concrete steel rust inhibitor of the present invention.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap