Cooker, making method thereof and cooking appliance

A pot and pot body technology, which is applied to special materials for cooking utensils, cooking utensils, kitchen utensils, etc., can solve the problem that pots do not have electromagnetic heating function, etc., and achieve excellent electromagnetic heating function, high electromagnetic heating efficiency, and expanded application. field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

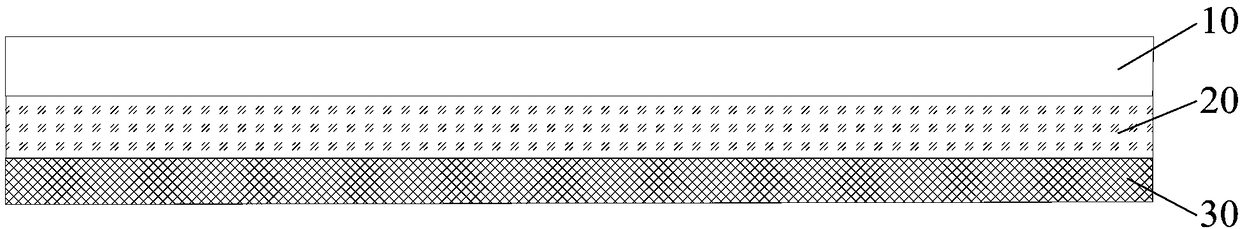

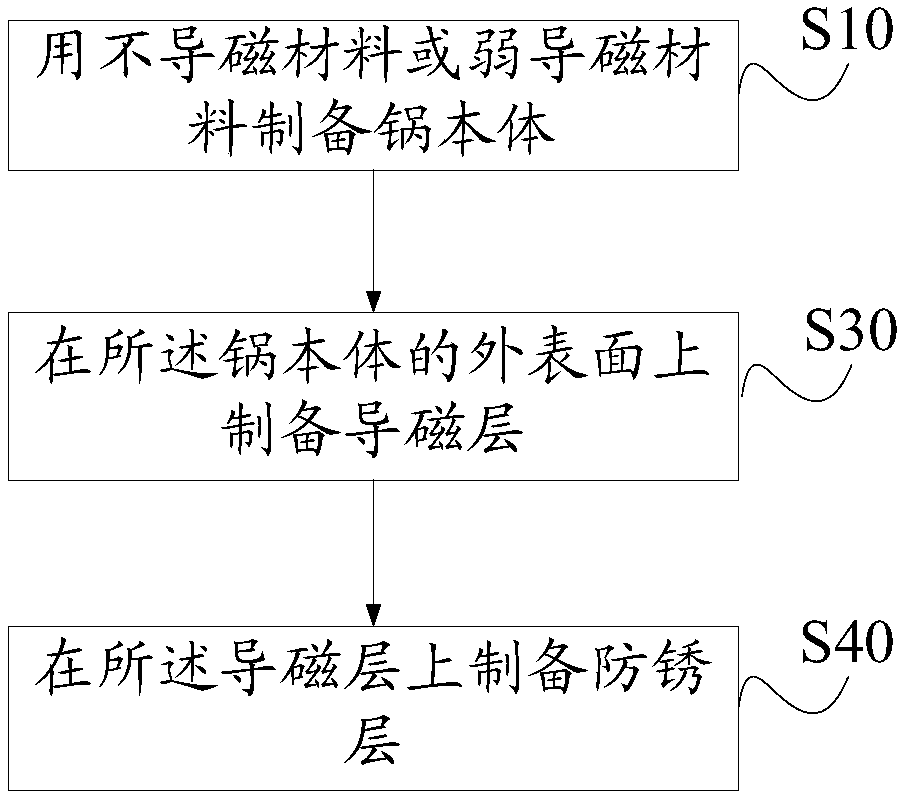

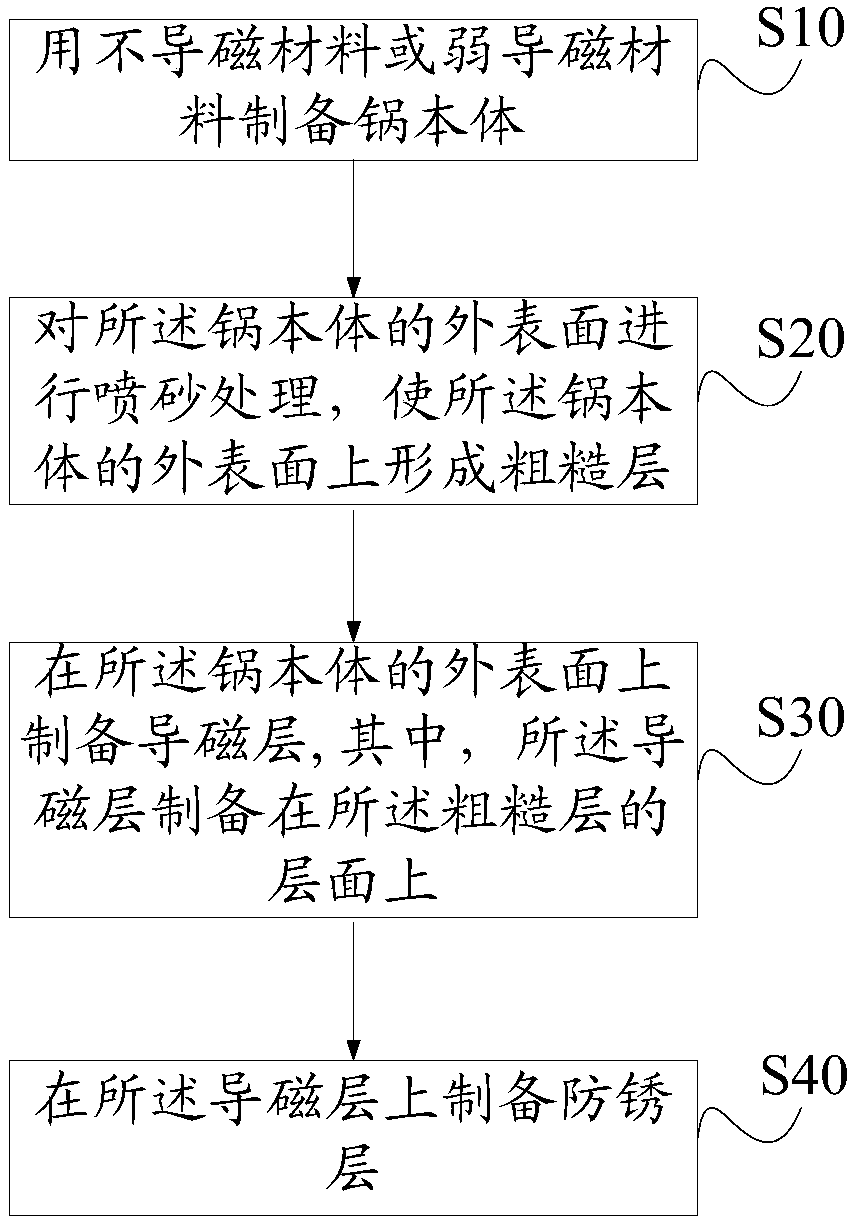

[0102] The preparation method of the cookware provided by the embodiment of the third aspect of the present invention, such as figure 2 As shown, for preparing the cookware of any one of the embodiments of the first aspect, comprising:

[0103] Step S10: preparing the pot body 10 with a non-magnetic or weakly magnetically conductive material;

[0104] Step S30: preparing the magnetic conductive layer 20 on the outer surface of the pot body 10;

[0105] Step S40 : preparing the anti-rust layer 30 on the magnetic conductive layer 20 .

[0106] In the method for preparing a cookware provided by the embodiment of the third aspect of the present invention, the cooker body 10 is first prepared with a non-magnetic or weakly magnetically conductive material, and then a conductive material containing magnetically conductive metal particles is prepared on the outer surface of the cooker body 10. The magnetic conductive layer 20 composed of magnetic materials, and then the anti-rust laye

Example Embodiment

[0134] Example 1

[0135] The pot body is made of aluminum, the magnetic conductive layer is a ferromagnetic coating, and the anti-rust layer is an aluminum oxide anti-rust layer. The specific preparation method of the pot is as follows:

[0136] The surface of the pot body to be sprayed is sandblasted with fine iron sand particles, and the position that does not need to be sprayed is covered with a fixture, so that the surface to be sprayed forms a surface with a certain roughness, that is, a rough layer (the roughness of the rough layer Ra is 60μm ~80μm), the surface after sanding is then blown off by high-pressure airflow to clean the fine powder particles remaining on the surface;

[0137] Use oxygen-acetylene flame to preheat the surface to be sprayed, the preheating temperature is 150℃, and the preheating time is 2min-3min;

[0138] On the preheating surface of the bottom of the pot, the magnetic coating is prepared in the area to be sprayed by high-pressure cold spraying

Example Embodiment

[0141] Embodiment 2

[0142] The pot body is made of aluminum, the magnetic conductive layer is an iron-nickel magnetic coating, and the anti-rust layer is a fluororesin anti-rust layer. The specific preparation method of the pot is as follows:

[0143] The surface of the pot body to be sprayed is sandblasted with fine iron sand particles, and the position that does not need to be sprayed is covered with a fixture, so that the surface to be sprayed forms a surface with a certain roughness, that is, a rough layer (the roughness of the rough layer Ra is 60μm ~80μm), the surface after sanding is then blown off by high-pressure airflow to clean the fine powder particles remaining on the surface;

[0144] On the preheated surface of the bottom of the pot, the magnetic coating is prepared in the area to be sprayed by high-pressure cold spraying technology. The spraying material is mixed powder of Fe and Ni. The specific process parameters are: the working gas is nitrogen, and the spray

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap