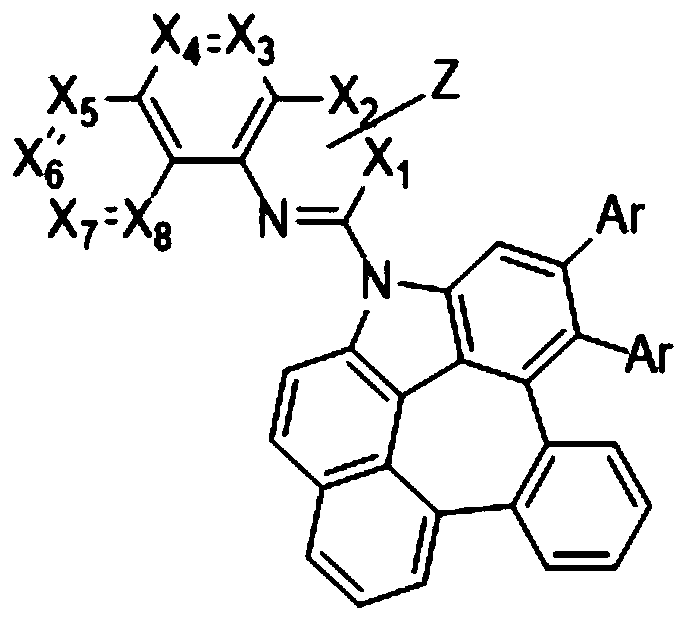

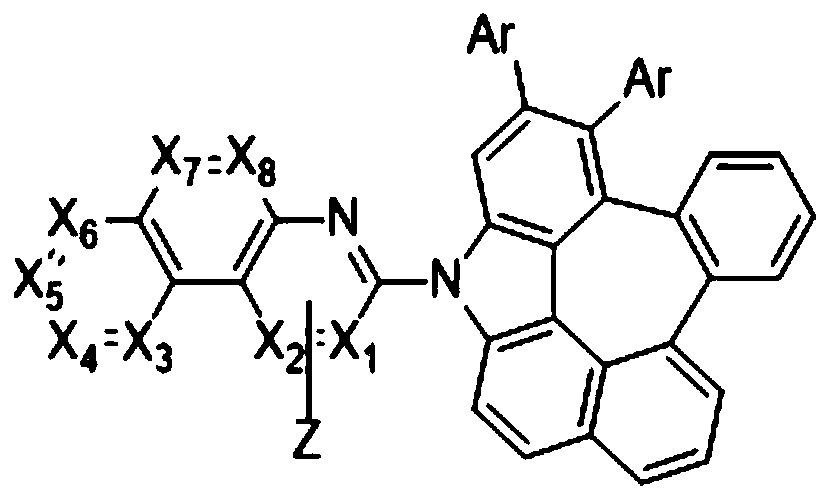

Phosphorescent compound and organic luminescent device employing same

A compound and phosphorescent technology, which is applied in the field of organic light-emitting devices and phosphorescent compounds, can solve problems such as low process efficiency, increased production cost, and complicated manufacturing process, and achieve the effects of improving the brightness of the light source, increasing the current efficiency, and improving the power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 approach

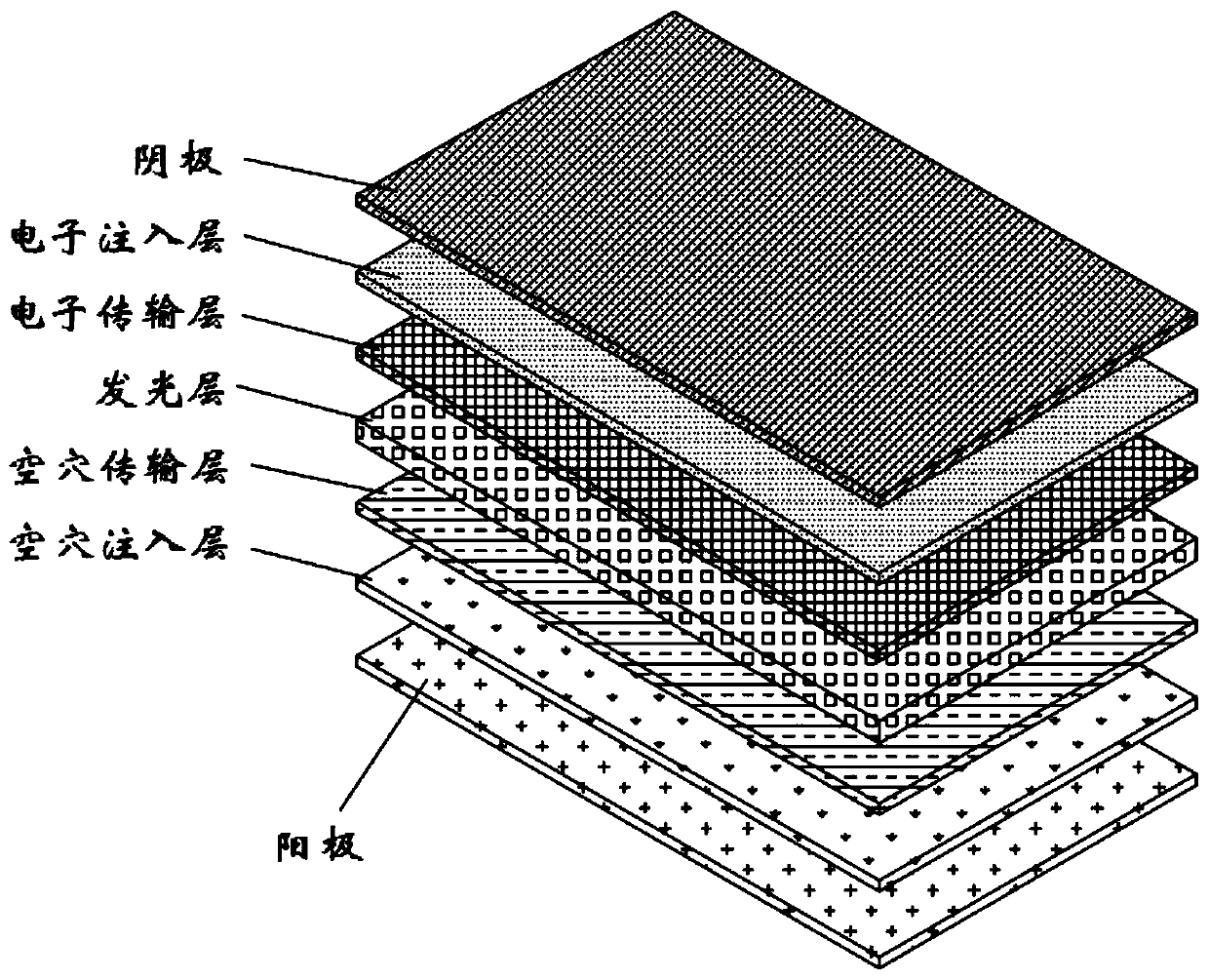

[0108] The ITO glass substrate was patterned to have a light emitting area of 3 mm x 3 mm. Then, the patterned ITO glass substrate was washed.

[0109] The substrate is then placed in a vacuum chamber. The standard pressure is set at 1×10-6 Torr. Thereafter, on the ITO substrate with CuPc NPB RH-001+(btp)2Ir(acac)((5%) Alq3 LiF and Al The sequence forms layers of organic matter.

[0110] At 0.9mA, the brightness is equal to 1227d / m2 (6.0V). At this time, CIEx=0.659, y=0.329.

no. 2 approach

[0112] The ITO glass substrate was patterned to have a light emitting area of 3 mm x 3 mm. Then, the patterned ITO glass substrate was washed.

[0113] The substrate is then placed in a vacuum chamber. The standard pressure is set at 1×10-6 Torr. Thereafter, on the ITO substrate with CuPc NPB RH-007+(btp)2Ir(acac)(5%) Alq3 LiF and Al The sequence forms layers of organic matter.

[0114] At 0.9mA, the brightness is equal to 1098cd / m2 (6.3V). At this time, CIEx=0.659y=0.330.

no. 3 approach

[0116] The ITO glass substrate was patterned to have a light emitting area of 3 mm x 3 mm. Then, the patterned ITO glass substrate was washed.

[0117] The substrate is then placed in a vacuum chamber. The standard pressure is set at 1×10-6 Torr. Thereafter, on the ITO substrate with CuPc NPB RH-073+(btp)2Ir(acac)(5%) Alq3 LiF and Al The sequence forms layers of organic matter.

[0118] At 0.9mA, the brightness is equal to 1232cd / m2 (6.1V). At this time, CIEx=0.659, y=0.329.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap