Functional slurry and application thereof

A functional and slurry technology, applied in the field of sensors, can solve problems such as poor transmission performance, high equipment dependence, and technical difficulty, and achieve excellent electrical output performance, improved sensitivity, and high biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

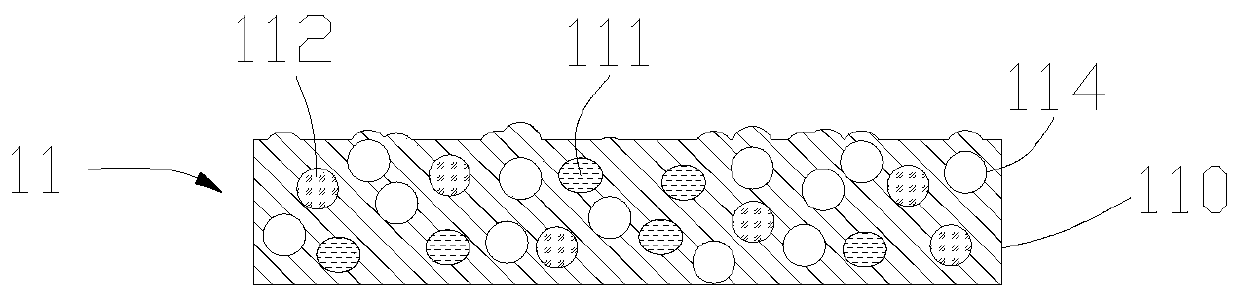

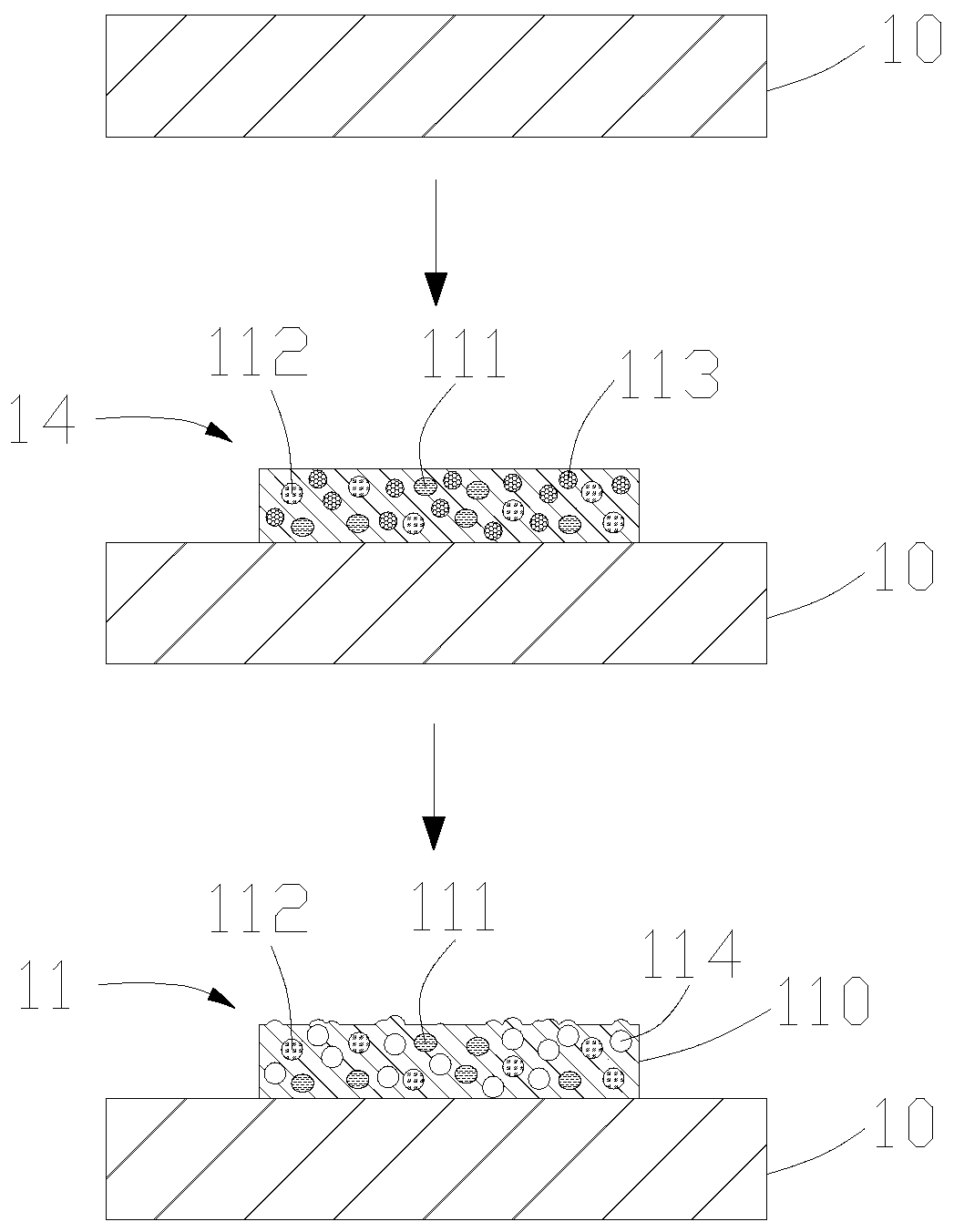

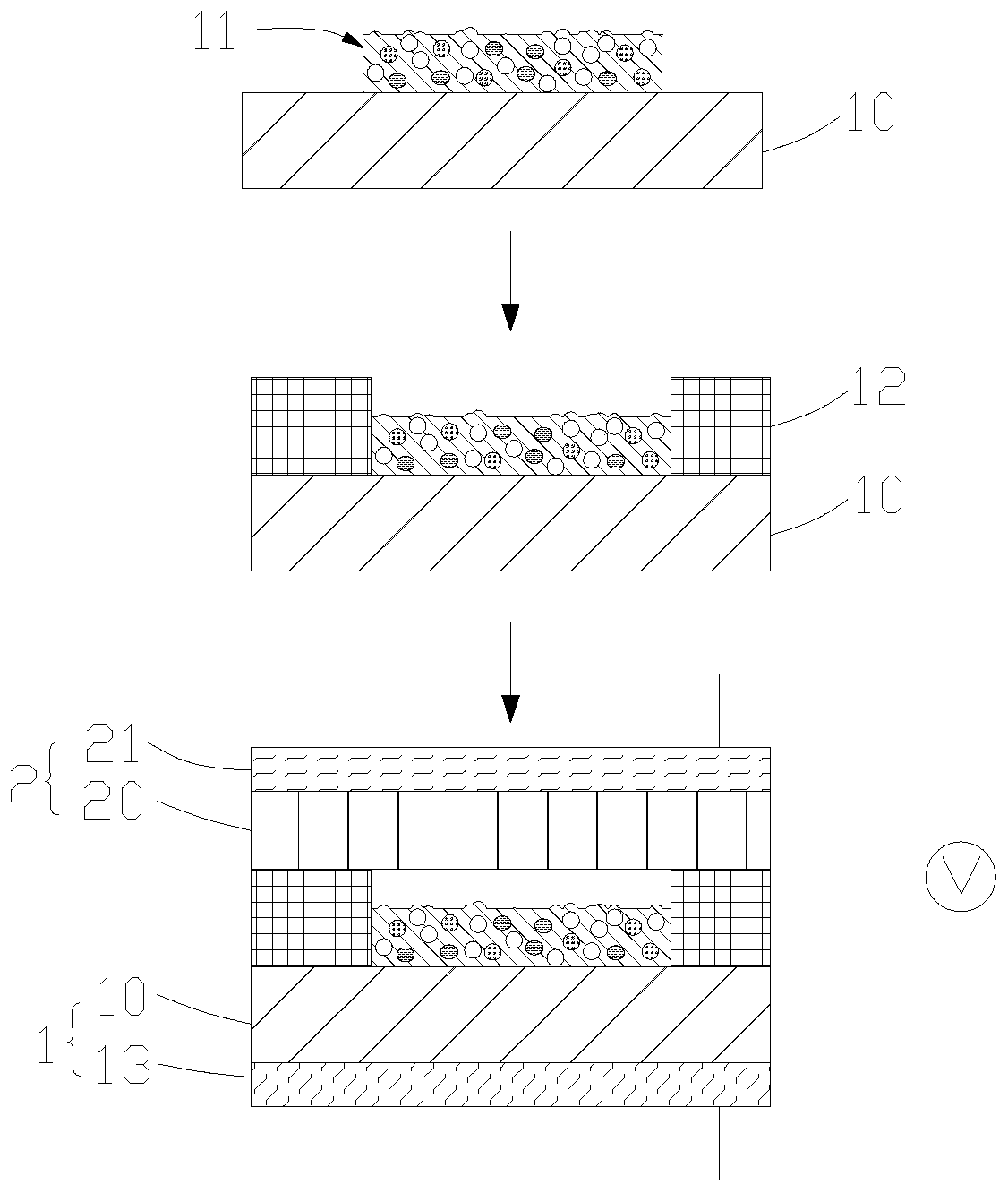

[0062] Such as figure 2 Shown, the preparation method for the functional thin film provided by the present invention comprises:

[0063] S1, providing the functional slurry and the first flexible film 10;

[0064] S2, coating the functional slurry on one surface of the first flexible film 10 to form a prefabricated layer 14;

[0065] S3, heating and curing the first flexible film 10 with the prefabricated layer 14, so that the carbonate particles 113 in the prefabricated layer 14 are decomposed to form cells 114, and a functional film including the functional layer 11 is obtained.

[0066] In step S1, the material of the first flexible film 10 includes polydimethylsiloxane (PDMS), polyethylene terephthalate (PET), polybutylene terephthalate (PBT) at least one of the Wherein, considering that PDMS has the best biocompatibility and thermal stability, the material of the first flexible film 10 is preferably PDMS.

[0067] In step S2, the method of coating the surface of the fir

Embodiment 1

[0097] Weigh 5g of carbon black and 1g of silver nanoparticles in a beaker, then add 50mL of ethanol to the beaker and stir evenly, add 0.1g of silane coupling agent KH550 to the beaker, stir for 1h, and then clean it with deionized water. Drying for 2 hours under the condition of ℃ for later use, to obtain a mixture of carbon black with aminopropyl groups attached to the surface and silver nanoparticles with aminopropyl groups attached to the surface.

[0098] Add 10 g of polyurethane elastomer (TPU) particles into 100 mL of N,N-dimethylformamide (DMF) solution, and stir for 30 min to completely dissolve the elastomer particles to obtain a first mixed solution. Then the mixture that is equivalent to 5% of the mass fraction of the elastomer particles is added to the first mixed solution, and stirred for 30 minutes so that the carbon black with aminopropyl groups on the surface and the silver nanoparticles with aminopropyl groups on the surface are evenly distributed, and the secon

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap