Plant fiber reinforced calcium silicate board and preparation method thereof

A technology of calcium silicate board and plant fiber, applied in the field of calcium silicate board, can solve the problems of increasing the financial burden of consumers, reducing the strength of calcium silicate board, difficult to degrade construction waste, etc. Pulp energy consumption and the effect of improving flexural strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

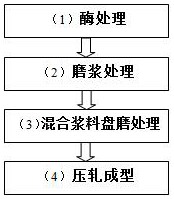

Method used

Image

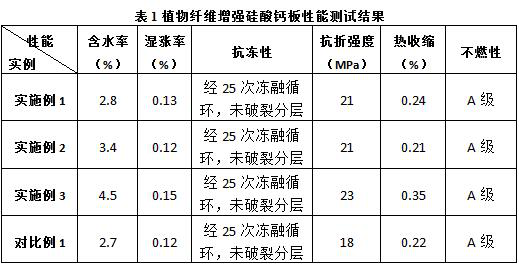

Examples

Embodiment 1

[0032] The preparation method of the preferred plant fiber reinforced calcium silicate board of the present embodiment is characterized in that: comprising the steps:

[0033] Step (1) Enzyme treatment, the coniferous wood pulp is decomposed by a fiber deflattering machine, and then a certain amount of decomposed coniferous wood pulp is taken, an appropriate amount of water is added to make the pulp concentration of the coniferous wood pulp 3%, and a mixed enzyme solution is added Obtain the mixed slurry, the softwood pulp is calculated as the absolute dry slurry, and according to the quality of the softwood pulp, the consumption of the mixed enzyme solution is controlled to be 7IU / g, and then the mixed slurry is placed in a magnetic stirring water bath, and the stirring speed is 300rpm, stirring The temperature is 45°C, after 1 hour of heat preservation, the temperature is raised to 95°C and heat preservation for 20 minutes for inactivation treatment, then the mixed pulp is tak

Embodiment 2

[0038] This example is similar to Example 1, except that: in step (1) enzyme treatment, the amount of mixed enzyme solution is controlled to be 10 IU / g.

Embodiment 3

[0040] This embodiment is similar to embodiment 1, except that: in the mixed pulp disc grinding treatment, the weight part of the wood pulp fiber after pulping is 7 parts.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap