Nano high-resilience composite material for children's toys and preparation method thereof

A technology for composite materials and children's toys, which is applied in the field of nanometer high-resilience composite materials for children's toys and its preparation, can solve the problems of unsatisfactory mechanical properties and poor resilience, and achieves good synergy and high foaming ratio. , the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

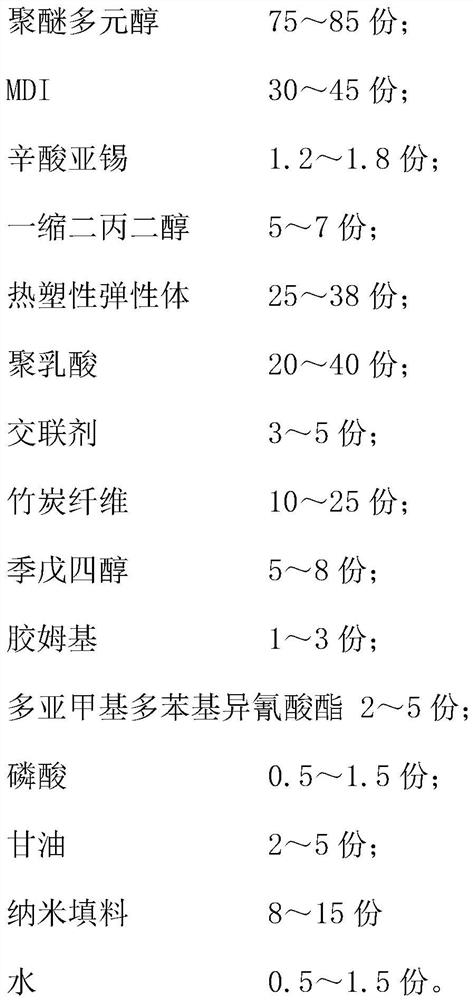

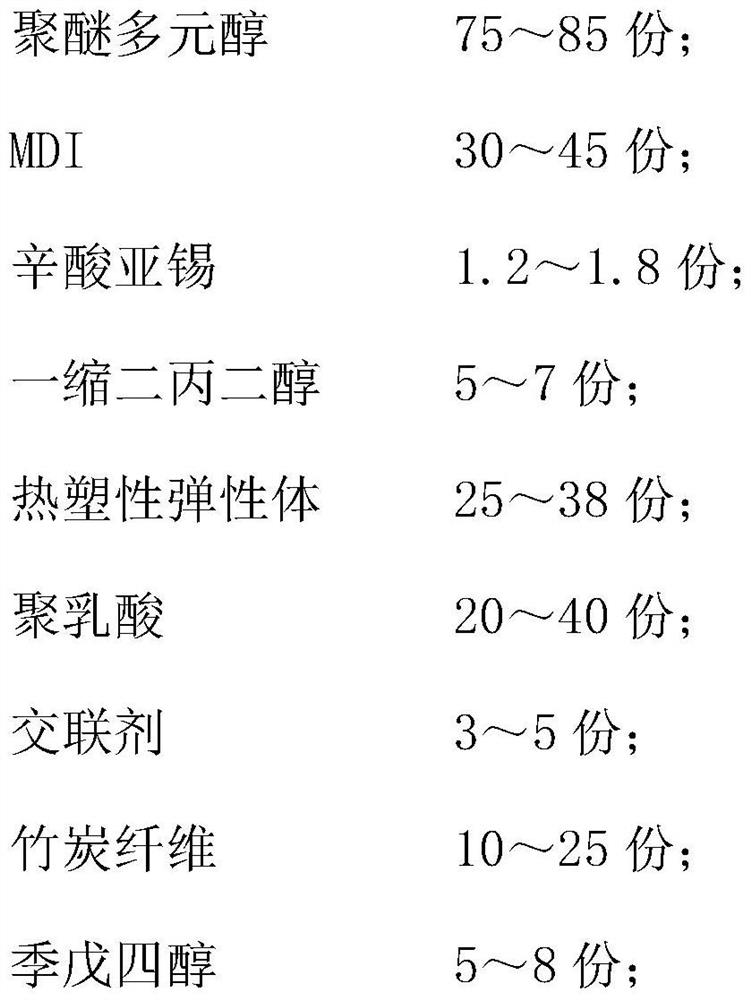

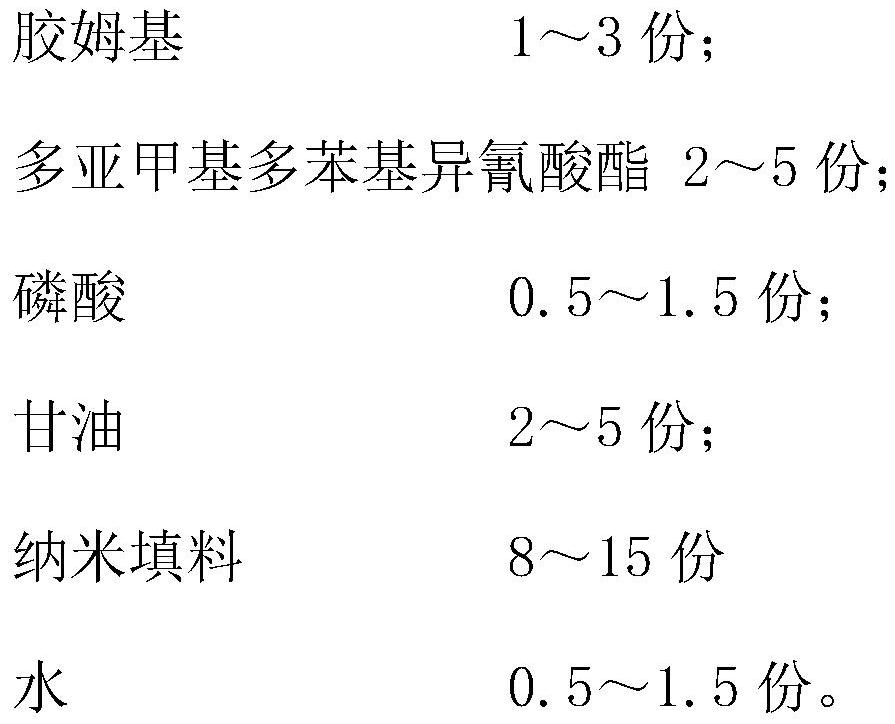

[0024] A nanometer high resilience composite material for children's toys, comprising the following raw materials in parts by weight: 80 parts of polyether polyol, 35 parts of MDI, 1.5 parts of stannous octoate, 6 parts of dipropylene glycol, 35 parts of thermoplastic elastomer, polylactic acid 30 parts, 5 parts of di-tert-butyl hydroperoxide, 20 parts of bamboo charcoal fiber, 6 parts of pentaerythritol, 2 parts of gum base, 4 parts of polymethylene polyphenyl isocyanate, 1.2 parts of phosphoric acid, 4 parts of glycerin, nano filler ( It is a mixture composed of nano-polypropylene / montmorillonite composite material, nano-calcium carbonate, nano-zinc oxide and nano-silicon oxide. The weight ratio of the three is 2:4:4) 12 parts, and water 1.0 part.

[0025] Among them, the thermoplastic elastomer includes the following raw materials in parts by weight: 25 parts of expanded polystyrene, 40 parts of hydrogenated styrene-butadiene block copolymer, 25 parts of monoethyl itaconate,

Embodiment 2

[0027] A nano high resilience composite material for children's toys, comprising the following raw materials in parts by weight: 75 parts of polyether polyol, 45 parts of MDI, 1.2 parts of stannous octoate, 7 parts of dipropylene glycol, 38 parts of thermoplastic elastomer, polylactic acid 20 parts, 3 parts of di-tert-butyl hydroperoxide, 25 parts of bamboo charcoal fiber, 8 parts of pentaerythritol, 3 parts of gum base, 2 parts of polymethylene polyphenyl isocyanate, 0.5 parts of phosphoric acid, 5 parts of glycerin, nano filler ( It is a mixture composed of nano-polypropylene / montmorillonite composite material, nano-calcium carbonate, nano-zinc oxide and nano-silicon oxide. The weight ratio of the three is 3:3:4) 10 parts, and water 0.5 parts.

[0028] Wherein, the preparation of the thermoplastic elastomer is the same as in Example 1.

Embodiment 3

[0030] A nano high resilience composite material for children's toys, comprising the following raw materials in parts by weight: 85 parts of polyether polyol, 40 parts of MDI, 1.8 parts of stannous octoate, 6 parts of dipropylene glycol, 25 parts of thermoplastic elastomer, polylactic acid 40 parts, 4 parts of di-tert-butyl hydroperoxide, 20 parts of bamboo charcoal fiber, 5 parts of pentaerythritol, 1 part of gum base, 5 parts of polymethylene polyphenyl isocyanate, 1.5 parts of phosphoric acid, 4 parts of glycerin, nano filler ( It is a mixture composed of nano-calcium carbonate, nano-zinc oxide and nano-silicon carbide, and the weight ratio of the three is 3:1:1) 15 parts and water 1.0 part.

[0031] Wherein, the thermoplastic elastomer comprises the following raw materials in parts by weight: 30 parts of expanded polystyrene, 35 parts of hydrogenated styrene-butadiene block copolymer, monomethyl itaconate and clothing with a mass ratio of 1:1 20 parts of a mixture composed of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap