Enhanced heat dissipation control method of electric vehicle

A control method and technology for electric vehicles, applied to electrochemical generators, circuits, electrical components, etc., can solve the problems of reducing the volume of the battery box, the inability to guarantee temperature uniformity and reliability, and reducing the distance between batteries, so as to improve the The effect of cooling efficiency, improving safety and stability, and reducing structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

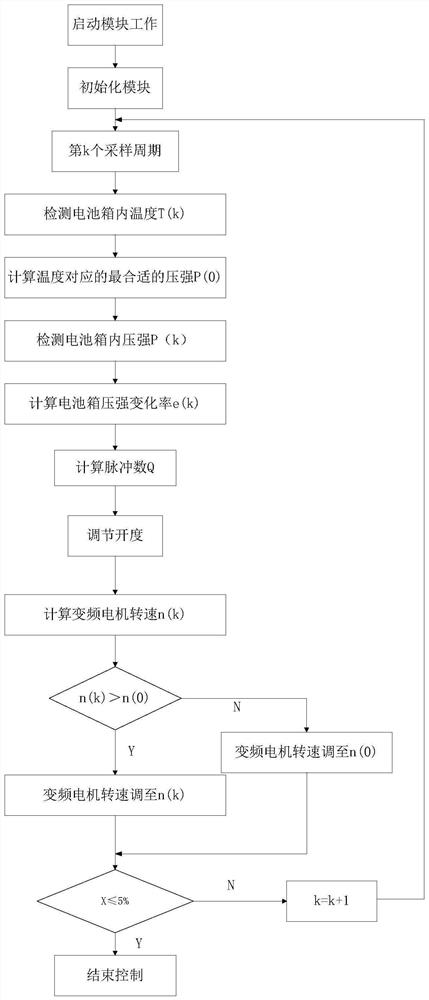

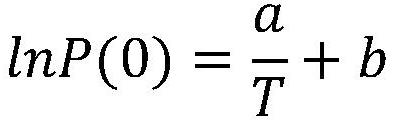

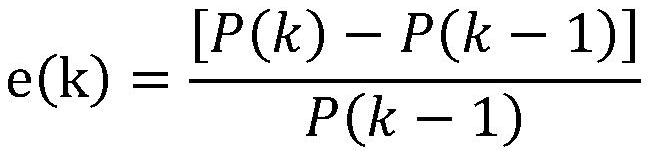

[0035] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a method for strengthening heat dissipation control of an electric vehicle, including:

[0036] S1: Detect the real-time temperature T and pressure P inside the battery box through the battery box temperature and pressure detection module 100 .

[0037] The temperature and pressure detection module 100 of the battery box in this embodiment is a temperature sensor and a pressure sensor. The temperature sensor is installed in the middle of the reinforced heat dissipation plate in the battery box, and the pressure sensor is installed at the air inlet of the battery box cover. Communication; when the temperature sensor and pressure sensor collect temperature T and pressure P, the temperature sensor and pressure sensor signals are collected through the analog input module of PLC, and the temperature T(k) and pressure P(k) are obtained through analog-to-digital conversion ).

Embodiment 2

[0061] In order to verify and explain the technical effect adopted in this method, this embodiment compares the energy consumption before and after frequency conversion, and compares the test results by means of scientific demonstration, so as to verify the real effect of this method.

[0062] In the pumping of the battery box, in order to obtain the maximum suction volume and a certain degree of vacuum, the motor of the vacuum pump is always at the maximum speed. When the vacuum degree in the battery box is low, long-term full-load operation will generate a lot of useless work. Cause waste of electric energy; in the step-by-step control of this method, if it is detected that the vacuum is low, first reduce the opening of the electric control valve, and then reduce the speed of the vacuum pump to reduce the suction volume at this time, so as to maintain the vacuum in the battery box. In a certain range of vacuum degree, the control module 400 can effectively save electric energy b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap