Solar cell panel system convenient for forming gas film

A technology of solar panels and air film, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve problems such as uneven temperature of panels, difficulty in melting snow, conduction, etc., to improve the ability to resist strong winds, The effect of accelerating gas flow and suppressing dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

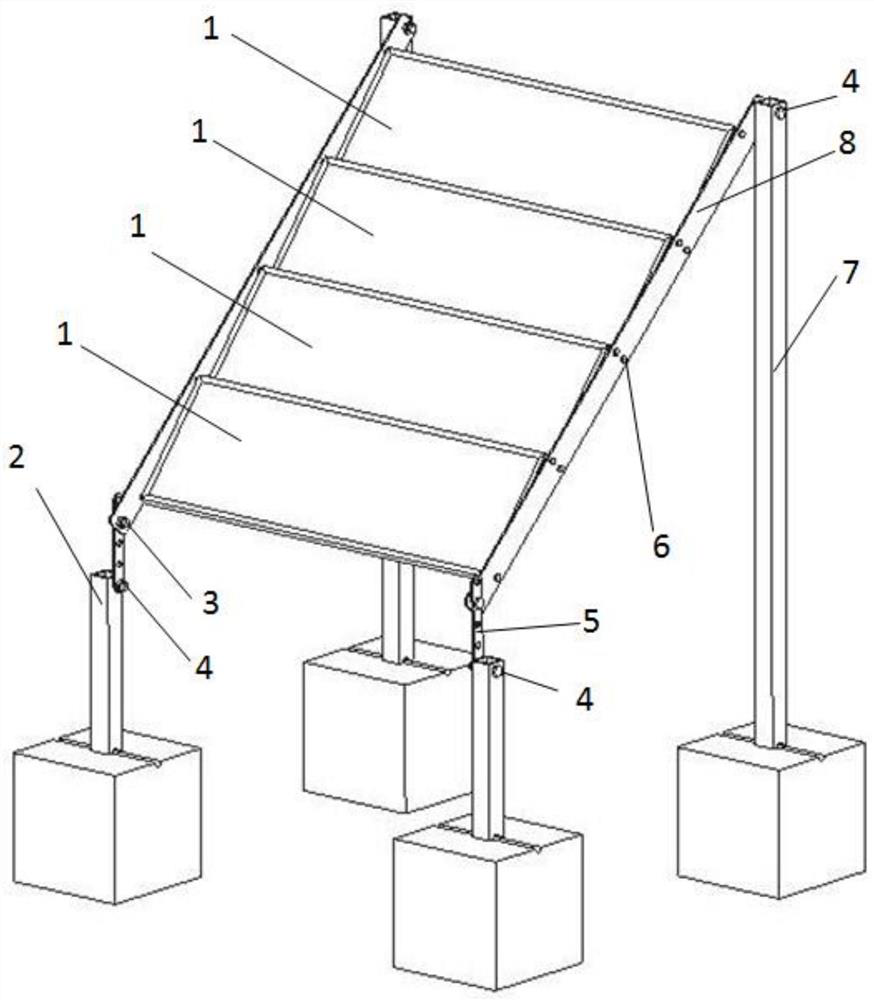

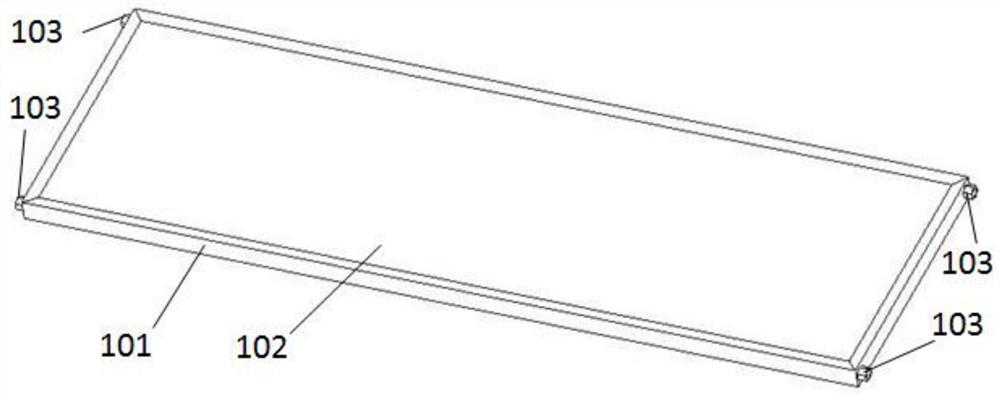

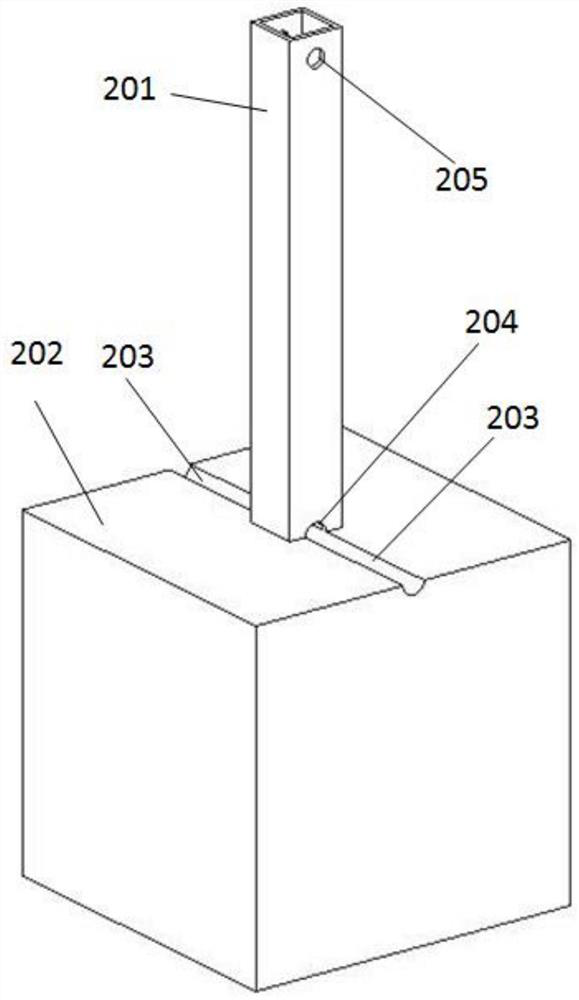

[0043] according to the above Figure 1-9 As shown, a solar panel system that facilitates the formation of an air film is prepared, wherein the specification of the screw 6 is M10, the specification of the bolt A3 is M16, the specification of the bolt B4 is M20, the screw 6 is equipped with an anti-loosening washer, and the specification of the bolt A3 is M16. Both bolts and bolts B4 are equipped with anti-loosening washers and nuts; the number of mounting holes B802 set in the middle of side plate 8 is 8; the adjustment connecting rod 5 is provided with 5 connecting holes 501; the width of gap 9 is 10 mm; the solar cell The length and width of the plate 1 are 300 millimeters and 1000 millimeters; the multi-piece solar panel 1 is 4 solar panel 1; the connection hole 501 participating in the assembly on the adjustment connecting rod 5 is selected with reference to the sunlight irradiation angle, and is selected as the second and the fifth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap