Hemp fiber crusher

A technology of crusher and hemp fiber, which is applied in the direction of grain processing, etc., can solve the problems of maintaining high-quality cutting and the difficulty of high-efficiency and meeting the requirements of hemp fiber cutting treatment, so as to optimize the cavity structure layout, make it difficult to collect, and reduce difficult cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that any combination among the following embodiments is possible.

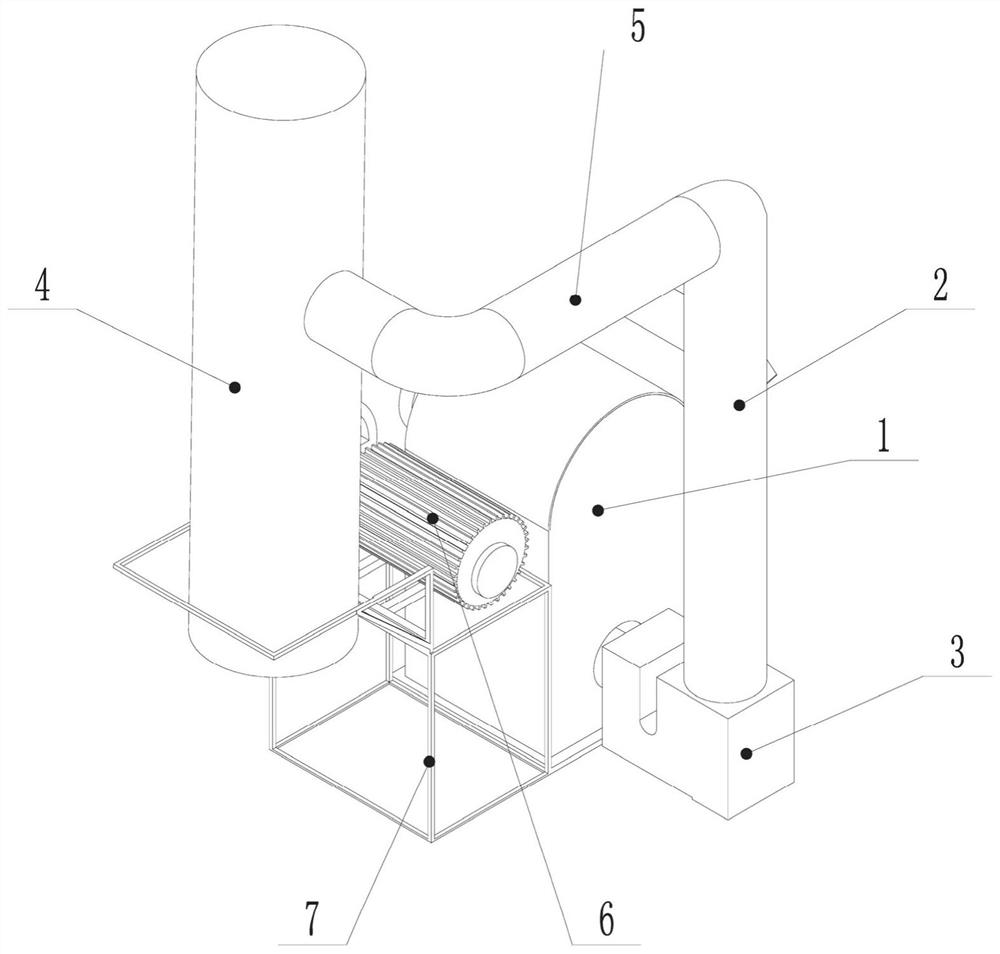

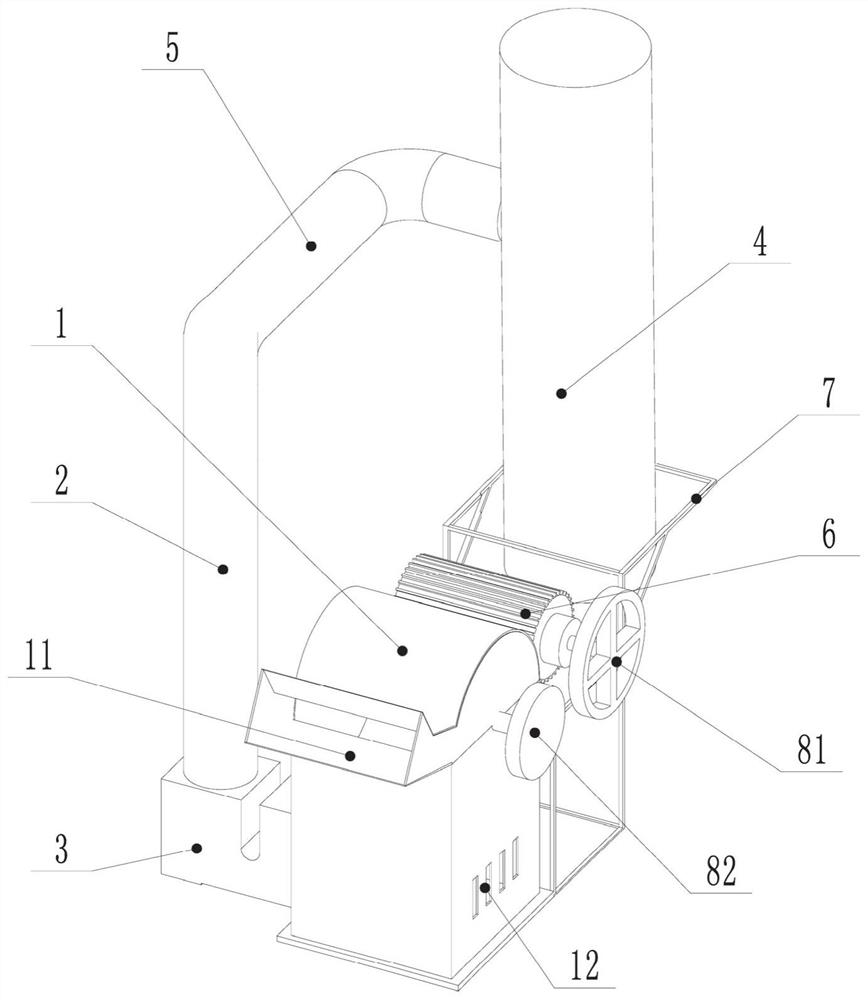

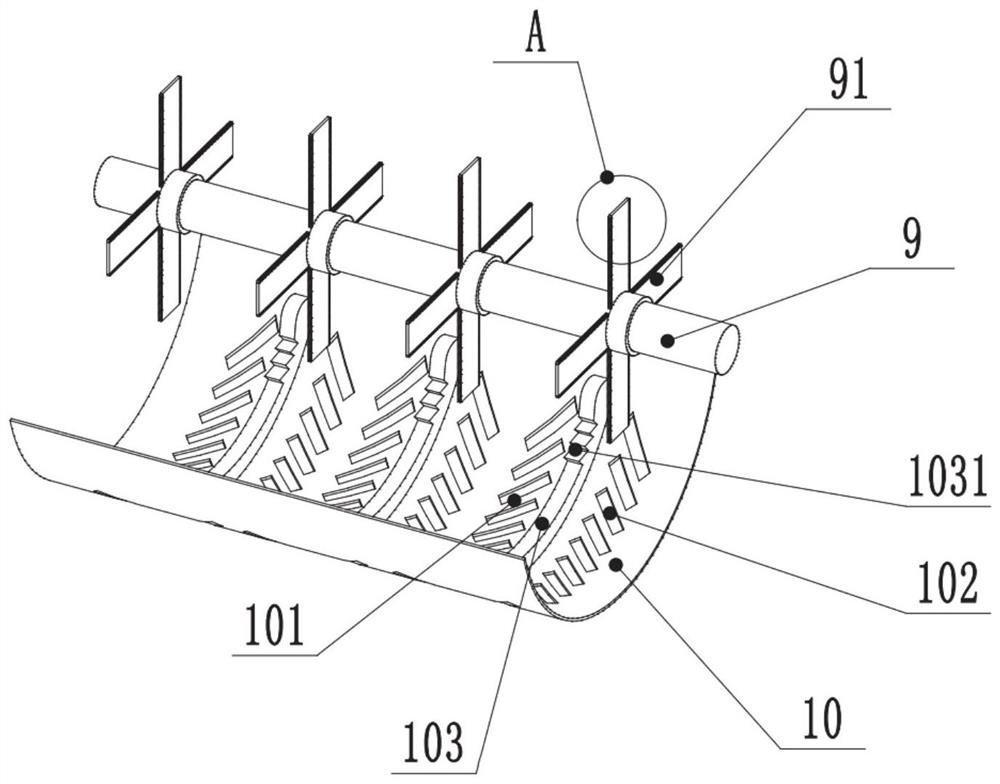

[0031] In a typical implementation of the present invention, this embodiment discloses a hemp fiber crusher. The hemp fiber crusher in this embodiment is used to crush the hemp fiber until the length of the hemp fiber is 6-7mm. The hemp fiber that is the short bunch shape enters in a container through suction; body and the second cavity, a partition drain plate 10 is provided between the first cavity and the second cavity, and the shell 1 is provided with an inlet 11 and an outlet, the inlet 11 is connected to the first cavity, the outlet is connected to the second cavity, and the second cavity is connected to the second cavity. A rotating shaft 9 is arranged in a cavity, and the rotating shaft 9 is connected to a plurality of blades 91, and the rotating shaft 9 is also connected to a power source; the second cavity is also connected to a suction mechanism; the edges on both sides of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap