Multifunctional machining system and method for irregular workpieces

A processing system and irregular technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of increasing production cost and impact on production efficiency, reducing the floor space, improving production efficiency, and improving processing. The effect of precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

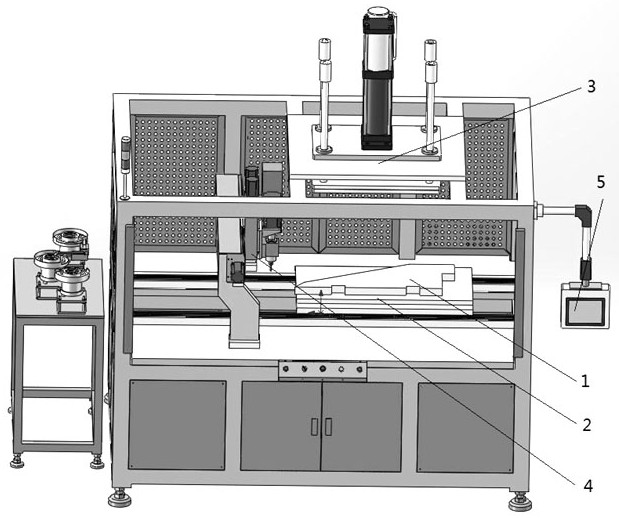

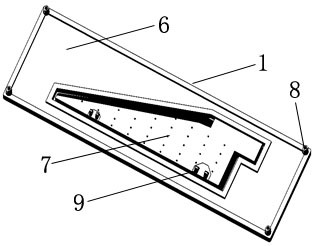

[0027] Such as figure 1 As shown, a multi-function processing system for irregular workpieces, including the accompanying tool 1, a pneumatic jig 2, an automatic drilling riveting machine 3, a CCD camera 4, a position sensor, and a control terminal 5, the accompanying tool 1 by a pneumatic clamp 2 is fixed to the machining platform of the automatic drilling riveting machine 3, the accompanying tool 1 includes an upper mounting plate 6 and a lower bottom plate 7, the lower bottom plate 7 center hollow, and the mounting plate 6 is provided with the lower bottom plate 7 square angle. The positioning device 8 is required to be processed, and the upper mounting plate 6 and the lower bottom plate 7 are fixed and positioned by the positioning device 8 after the center of the lower bottom plate 7 is placed. The CCD camera 4 and the position sensor are mounted in automatic drilling. On the spindle of the riveting machine 3, the control terminal 5 is connected between the au

Example Embodiment

[0033] Example 2

[0034] See Figure 4 The specific operation steps of the multi-function processing system for irregular workpieces are as follows:

[0035]Step S1. Put the workpiece into the accompanying storage 1, adjust the rotating screw 9 to fix the workpiece;

[0036] Step S2. Pack the assembled accompanying tool 1 with a pneumatic clamp 2 to fix the machining platform of the automatic drilling riveting machine 3;

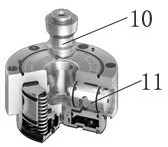

[0037] Step S3. The reference positioning is performed by the infrared identification sensor on the spoiler 11 and the automatic drilling riveting machine installed on the peer tool 1, and the automatic drilling riveting machine 3 main shaft is controlled by the positioning information of the human machine interaction interface feedback. Processing point;

[0038] Step S4. The PLC master unit automatically looks for processing points on the workpiece through the image information feedback of the CCD camera 4, and controls the automatic drilling riveting machine 3 t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap