Machining unit multi-tool-magazine linkage configuration method

A configuration method and processing unit technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unreasonable allocation of cutting tools, complex structure of parts, high processing cost, etc., to reduce inventory waste, reduce etc. Time, the effect of increasing resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

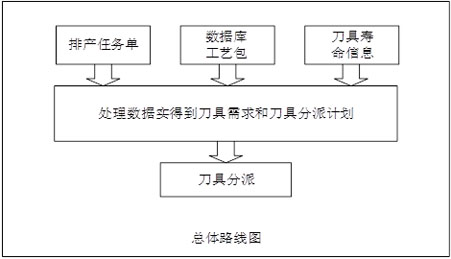

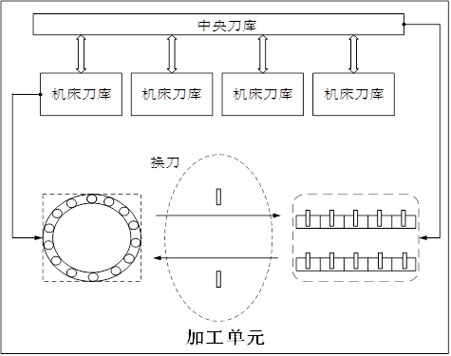

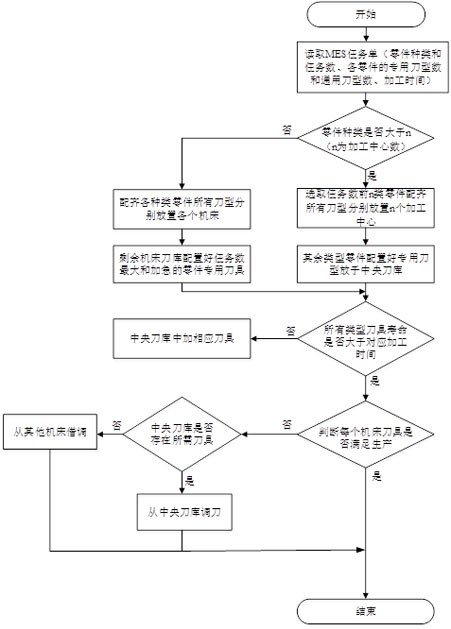

[0029] Such as figure 2 As shown, a hydraulic servo parts intelligent processing unit includes a central tool magazine and four CNC machine tool magazines. The feature of this processing unit is that each machine tool is processing the current workpiece process, and at the same time, it realizes the release and delivery of the borrowed tool required for the next process to be processed in the input buffer zone. Therefore, based on this, preparing the tool before processing starts, and transporting it to the corresponding tool position by the manipulator according to the handle number can reduce the number of tool adjustments in subsequent production, which is of great help to improve production efficiency. First, the production order is obtained based on intelligent scheduling. When a batch of production order is received in the production of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap