Full-automatic packing machine

A fully automatic, body-based technology, which is applied in the direction of paper product packaging, transportation and packaging, and the type of packaged items. It can solve the problems of affecting the appearance, not meeting the force requirements of the cardboard, and the cable ties cannot be adjusted accurately, so as to achieve a convenient packaging position. , high degree of automation, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiment represented by accompanying drawing:

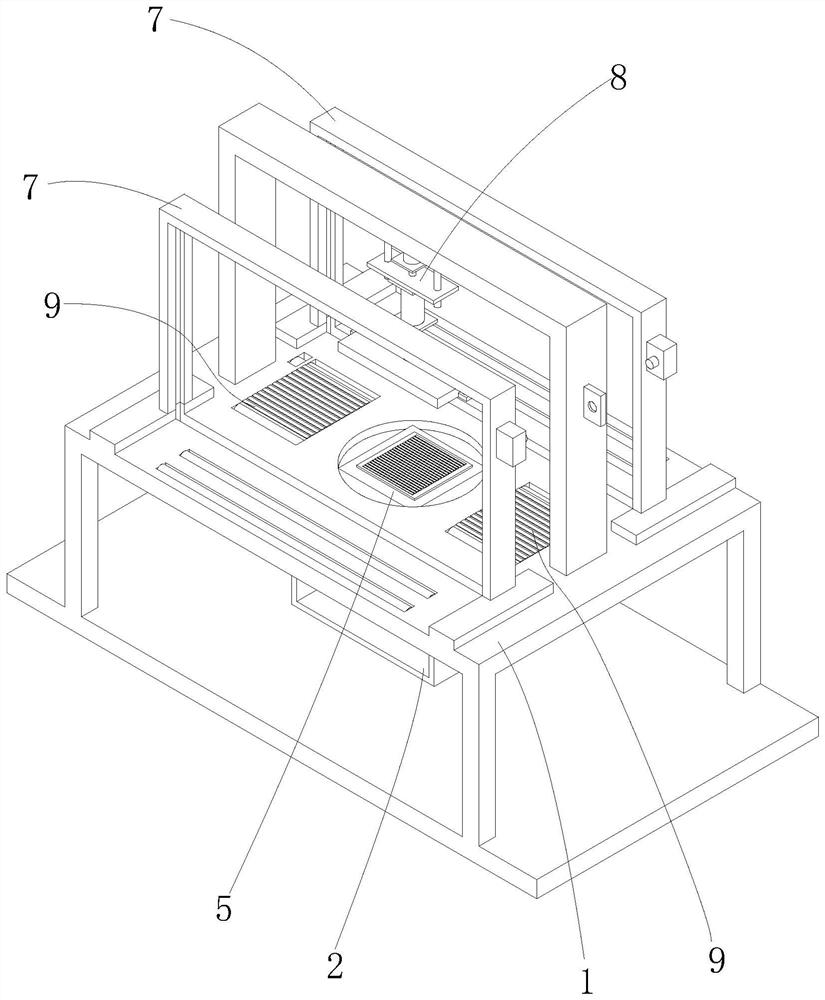

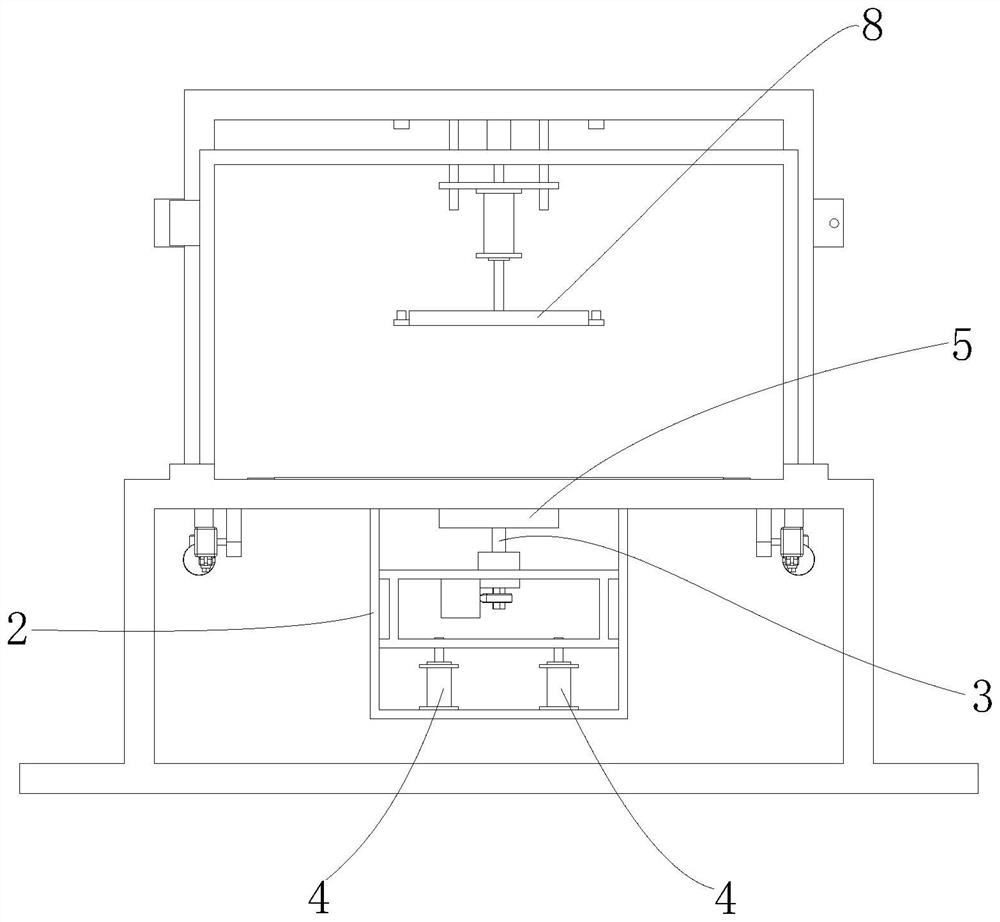

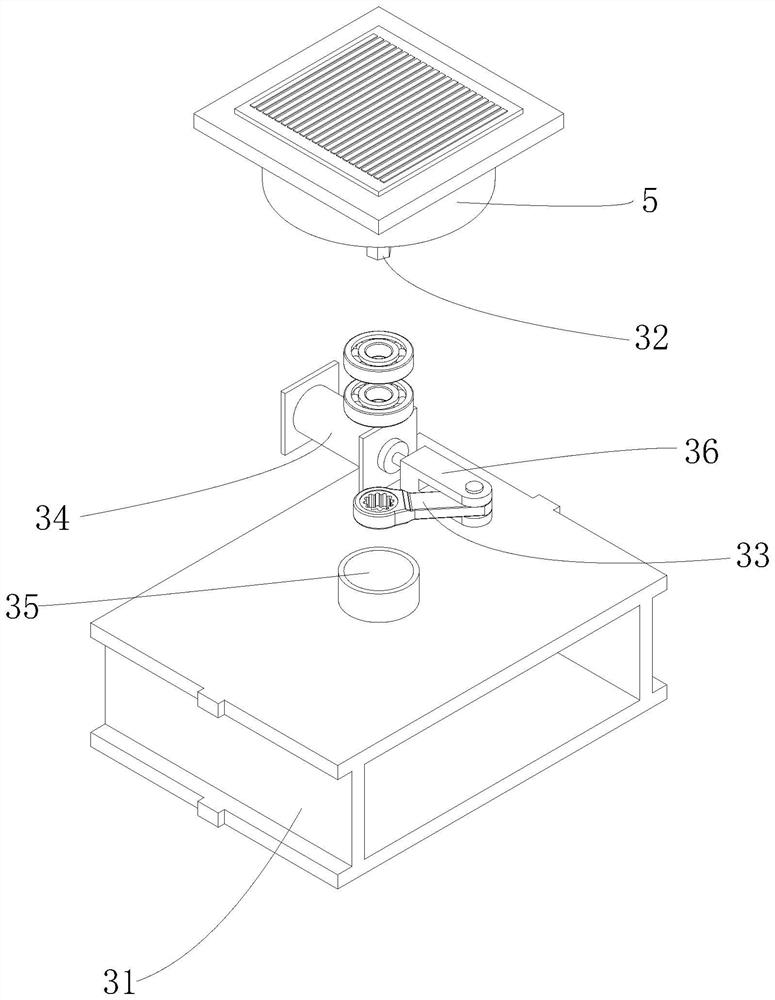

[0035] like Figure 1 to Figure 9 As shown, this embodiment discloses a fully automatic packing machine, including a fuselage platform 1, the lower end surface of the fuselage platform 1 is provided with a mounting frame 2, and the mounting frame 2 is provided with a The rotary assembly 3, the bottom of the installation frame 2 is provided with a first cylinder 4 for controlling the vertical movement of the rotary assembly 3; the top of the rotary assembly 3 is provided with a turntable assembly 5 that rotates synchronously with it and is used to place cardboard; The turntable assembly 5 includes a placement plate 51. The turntable assembly 5 is provided with a swing assembly 6 for driving the placement plate 51 to move reciprocatingly and linearly relative to the fuselage platform 1. The upper end surface of the fuselage platform 1 is along the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap