Organic solar cell based on self-assembled compound modified anode and preparation method thereof

A solar cell and self-assembly technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of simple preparation process, simple molecular structure, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

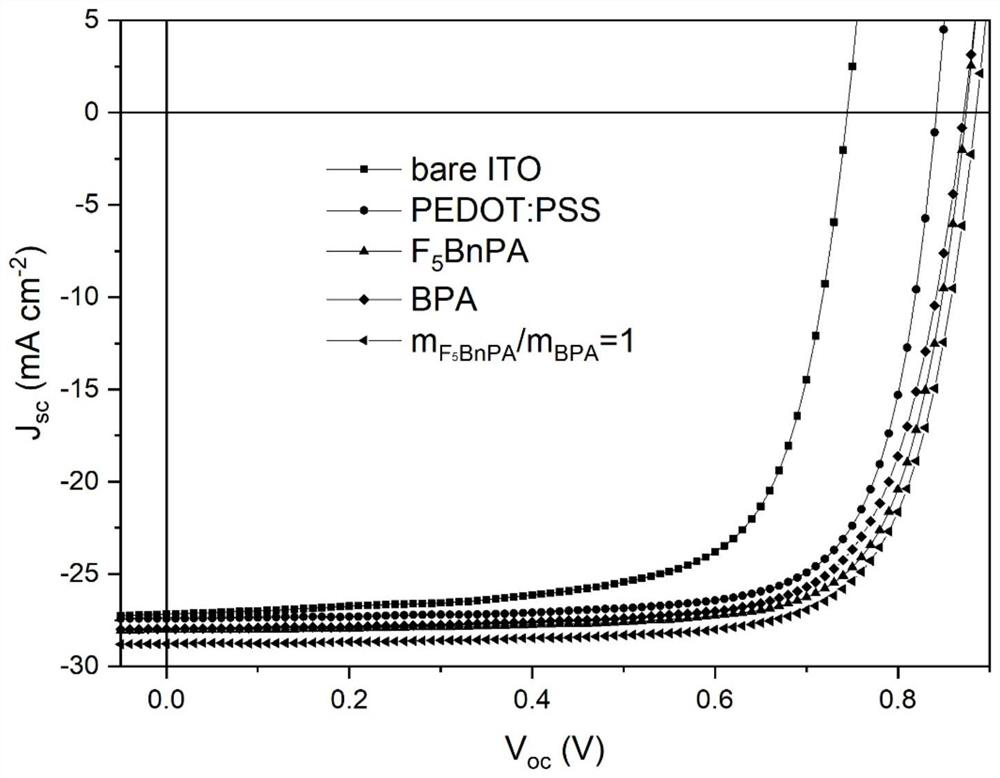

Embodiment 1

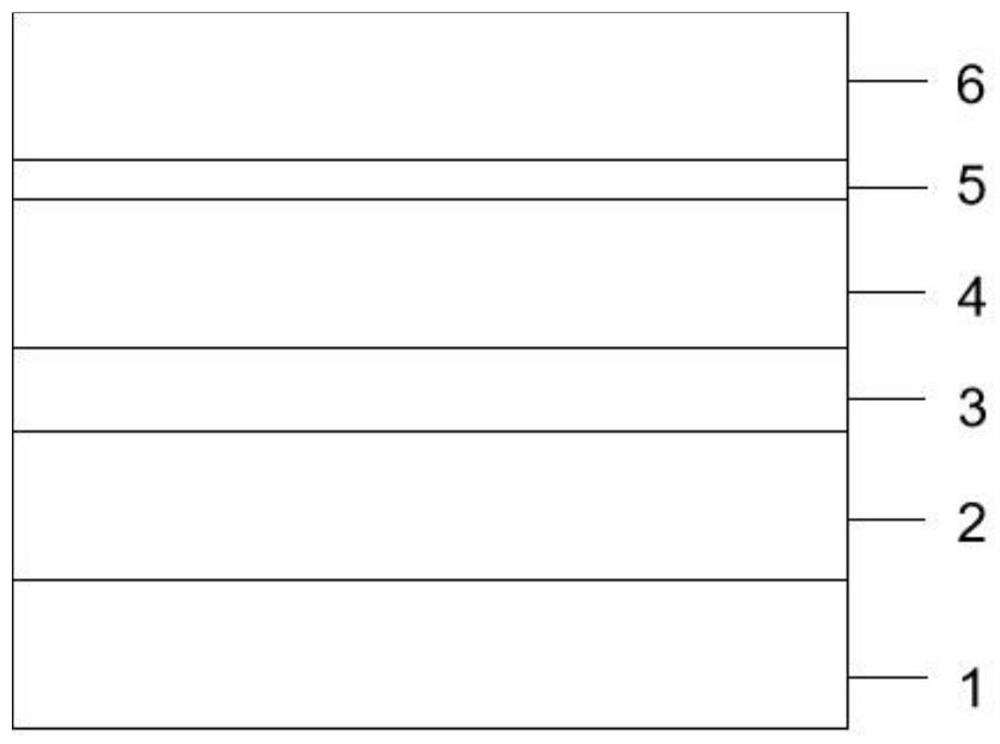

[0043] In the organic solar cell structure without anode buffer layer in this embodiment, the device structure includes a glass substrate, an anode layer, a photoactive layer, a cathode buffer layer and a cathode layer from bottom to top, and the specific preparation method is as follows:

[0044] 1. Cleaning of anode-containing glass substrates: The glass substrates coated with ITO are sonicated in an ultrasonic cleaner for 15 minutes with cleaning agent, deionized water, acetone, absolute ethanol, and isopropanol in sequence, and then vacuumized at 70-80 °C. The anode substrate with clean surface required for the experiment can be obtained by drying in a drying oven.

[0045] 2. Preparation of active layer: The cleaned and dried ITO-plated glass substrate was subjected to ultraviolet ozone treatment for 20 minutes. Dissolve PM6 and BO-4Cl in chloroform at a mass ratio of 1:1.2 to prepare a solution with a concentration of 17.6 mg / mL, and then add the additive DIO to the solut

Embodiment 2

[0050] In this embodiment, based on the organic solar cell structure with PEDOT:PSS as the anode buffer layer, the device structure includes an anode layer, an anode buffer layer, a photoactive layer, a cathode buffer layer and a cathode layer from bottom to top, and the specific preparation method is as follows:

[0051] 1. Cleaning of the anode-containing glass substrate: the same as in Example 1.

[0052] 2. Preparation of anode buffer layer: The cleaned and dried ITO-coated glass substrate was subjected to ultraviolet ozone treatment for 20 minutes. The PEDOT:PSS solution was spin-coated on the ITO surface at 3500 rpm, and then annealed at 150 °C for 15 min to form a PEDOT:PSS-based anode buffer layer with a thickness of 30 nm.

[0053] 3. Preparation of active layer: Dissolve PM6 and BO-4Cl in chloroform at a mass ratio of 1:1.2 to form a solution with a concentration of 17.6 mg / mL, and then add the additive DIO to the solution at a volume ratio of 99.5:0.5 to obtain Acti

Embodiment 3

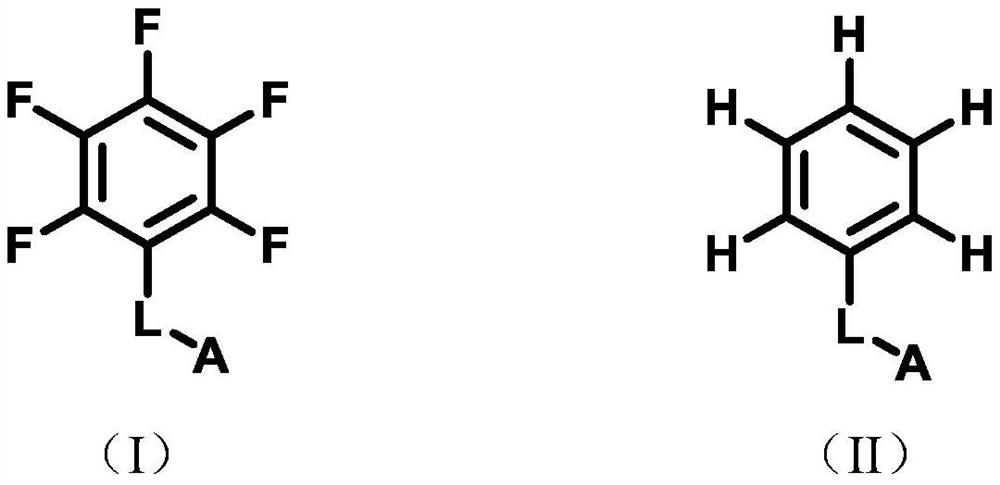

[0058] In this embodiment, based on the organic solar cell structure in which the self-assembled compound is the anode buffer layer, the device structure includes an anode layer, an anode buffer layer, a photoactive layer, a cathode buffer layer and a cathode layer from bottom to top, and the specific preparation method is as follows:

[0059] 1. Cleaning of the anode-containing glass substrate: the same as in Example 2.

[0060] 2. Preparation of anode buffer layer: The cleaned and dried ITO-coated glass substrate was subjected to ultraviolet ozone treatment for 20 minutes. 10 mg of benzylphosphoric acid was dissolved in 10 mL of anhydrous methanol and stirred at room temperature for 12 hours under nitrogen atmosphere. After fully dissolving, the self-assembly solution was spin-coated on the surface of the treated anode layer at 8000 rpm, annealed at 80 °C for 10 minutes in a nitrogen atmosphere, and then washed with methanol for three times to form an anode buffer layer.

[00

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap