Flow control valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

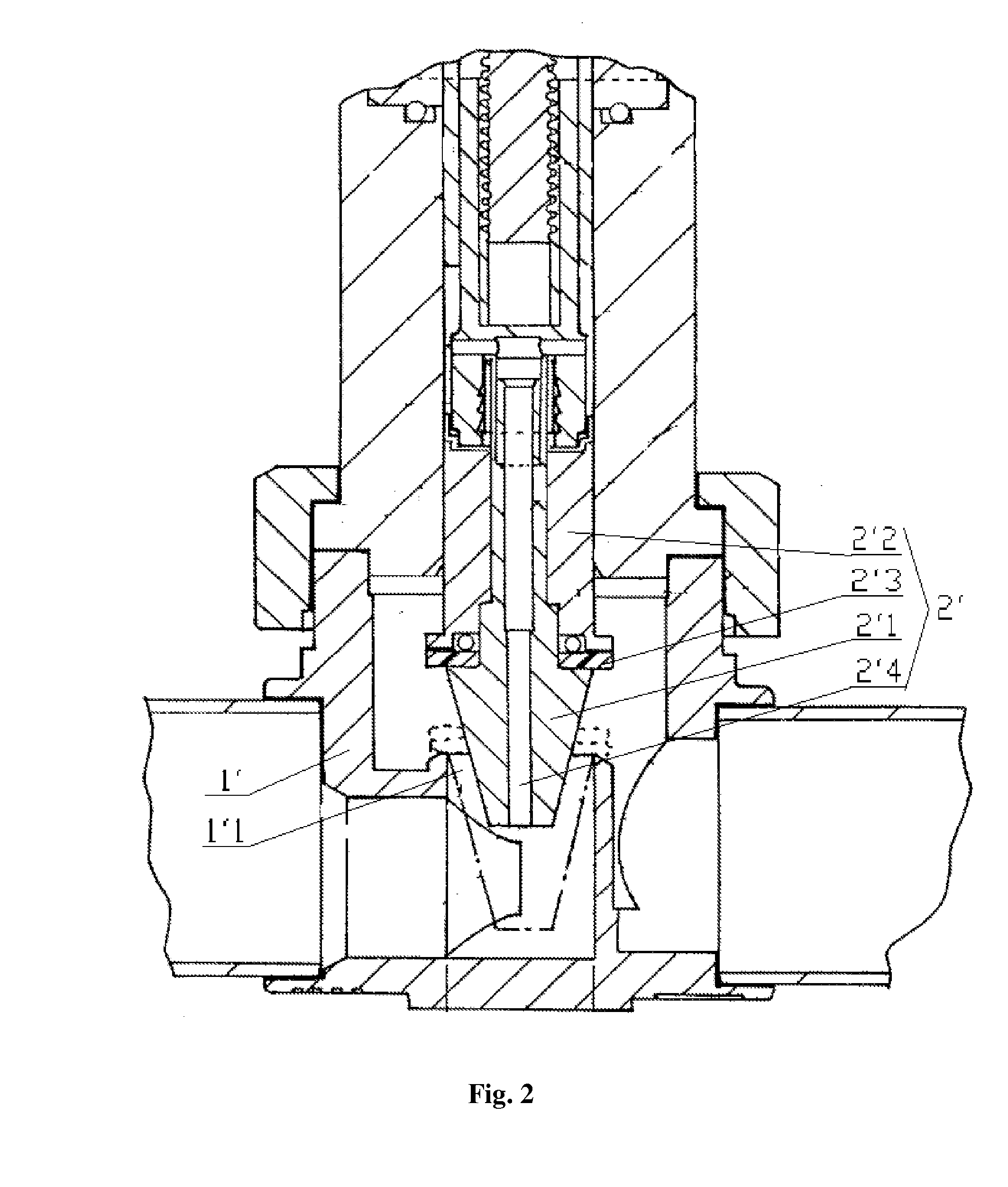

[0057]A spirit of the present application is to provide a flow adjusting valve, with the structural design of the flow adjusting valve, pressures exerted by the refrigerant on the valve rod in the axial direction can be balanced while ensuring that the required flow curve can be obtained.

[0058]In order that those skilled in the art can better understand technical solutions of the present application, the present application is described in detail hereinafter in conjunction with the accompanying drawings and the embodiments.

[0059]Referring to FIG. 4, FIG. 4 is a structural schematic view of a flow adjusting valve according to an embodiment of the present application.

[0060]The electronic expansion valve according to the present application is configured for adjusting the flow of the refrigerant. As shown in FIG. 4, the electronic expansion valve includes a motor shell 52 in which a motor 5 is provided. The output shaft 51 of the motor 5 is in transmission connection with the screw rod 61

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap