METHOD OF PRODUCING SiC SINGLE CRYSTAL INGOT

a single crystal, sic single crystal technology, applied in the direction of single crystal growth, polycrystalline material growth, after-treatment, etc., can solve the problem of low throughput of the method of producing a single crystal ingot of sic single crystal in document 1, and achieve the effect of improving the temperature uniformity of raw materials and effectively using raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Hereinafter, embodiments of the present invention will be appropriately described in detail with reference to the drawings. In the drawings used in the following description, in order to facilitate understanding of features of the present invention, feature parts are enlarged for convenience of illustration in some cases, and size ratios and the like of components may be different from actual components. Materials, sizes, and the like exemplified in the following description are examples, the present invention is not limited thereto, and they can be appropriately changed and implemented without departing from the spirit and scope of the invention.

“Method of Producing a SiC Single Crystal Ingot”

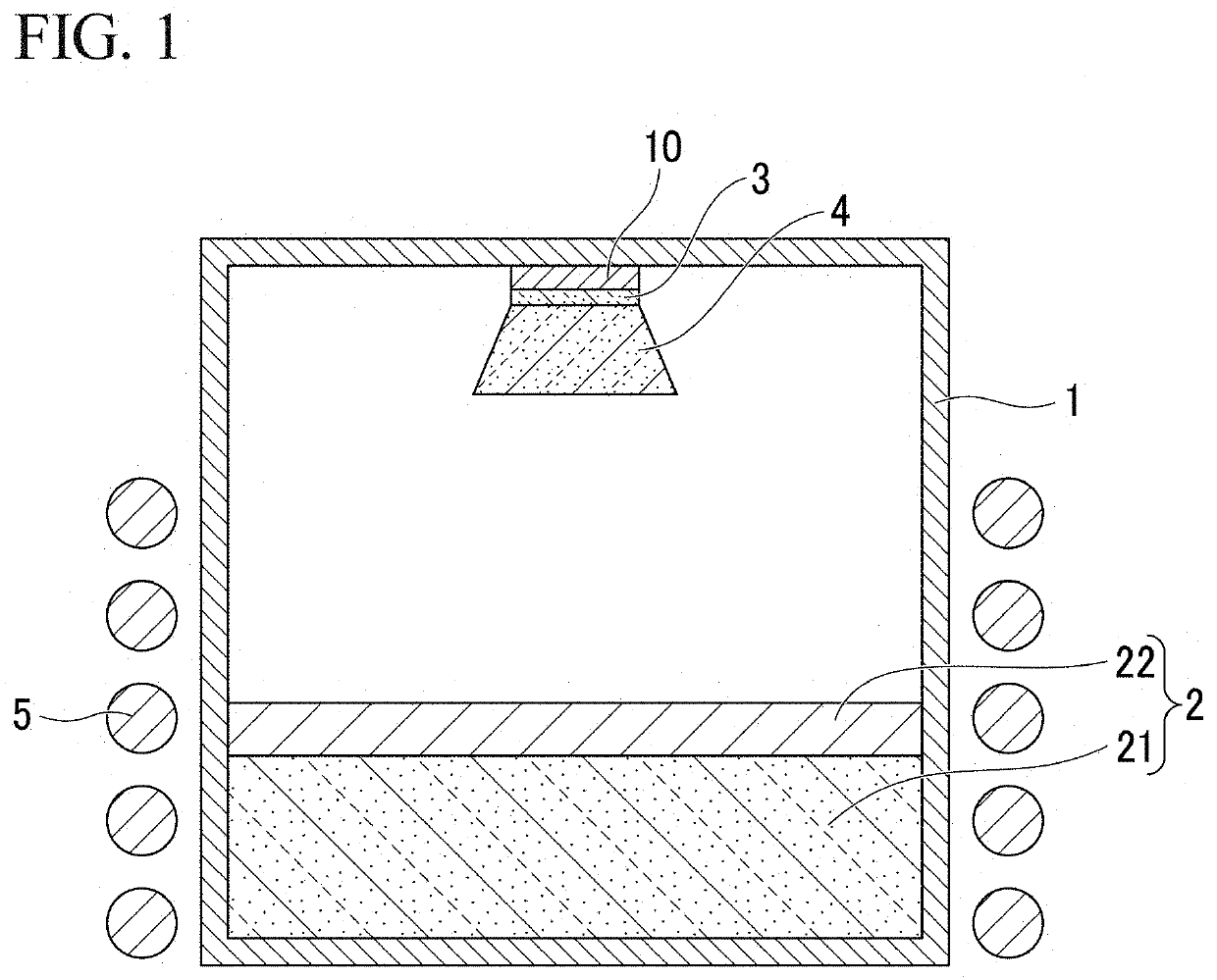

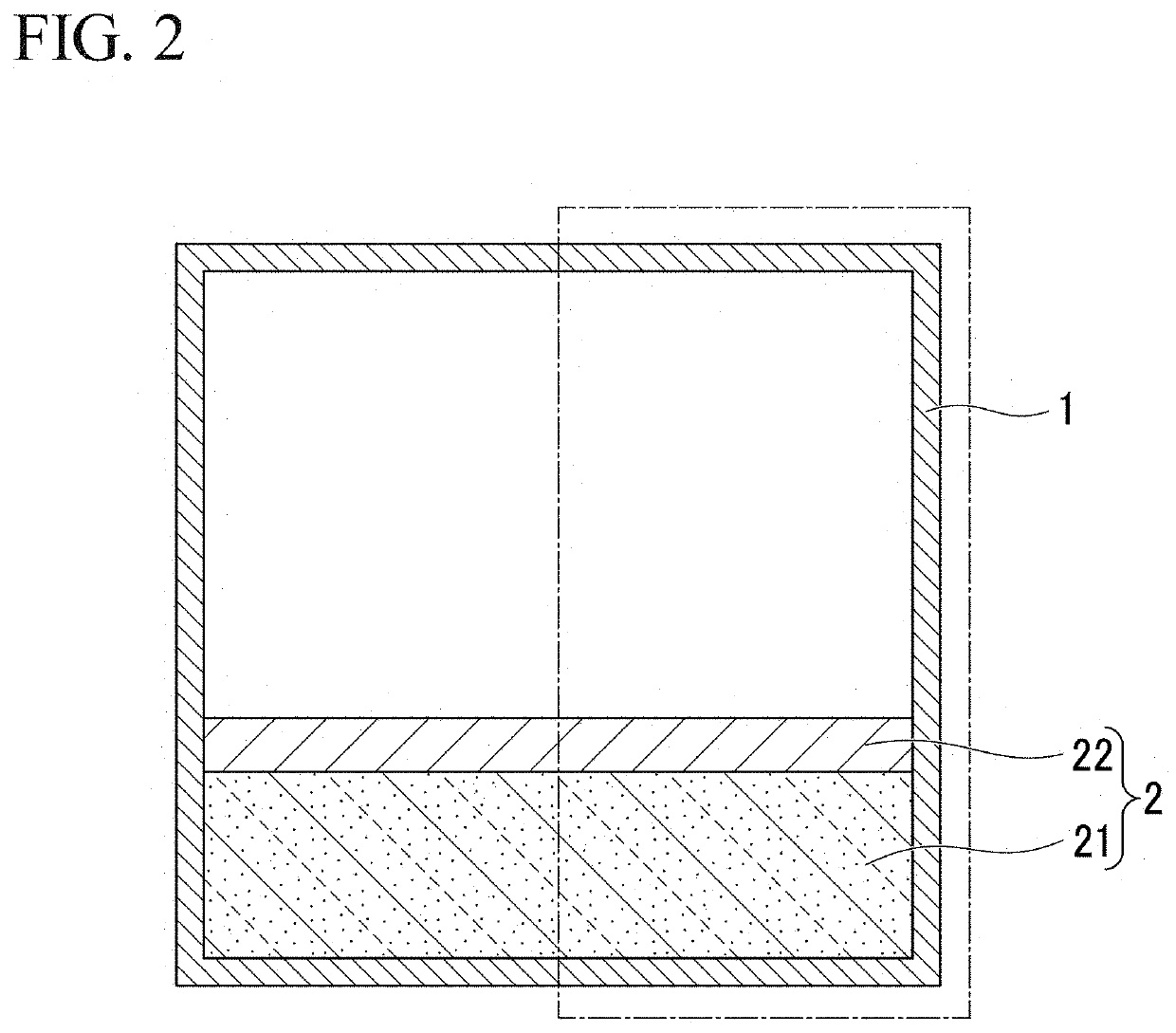

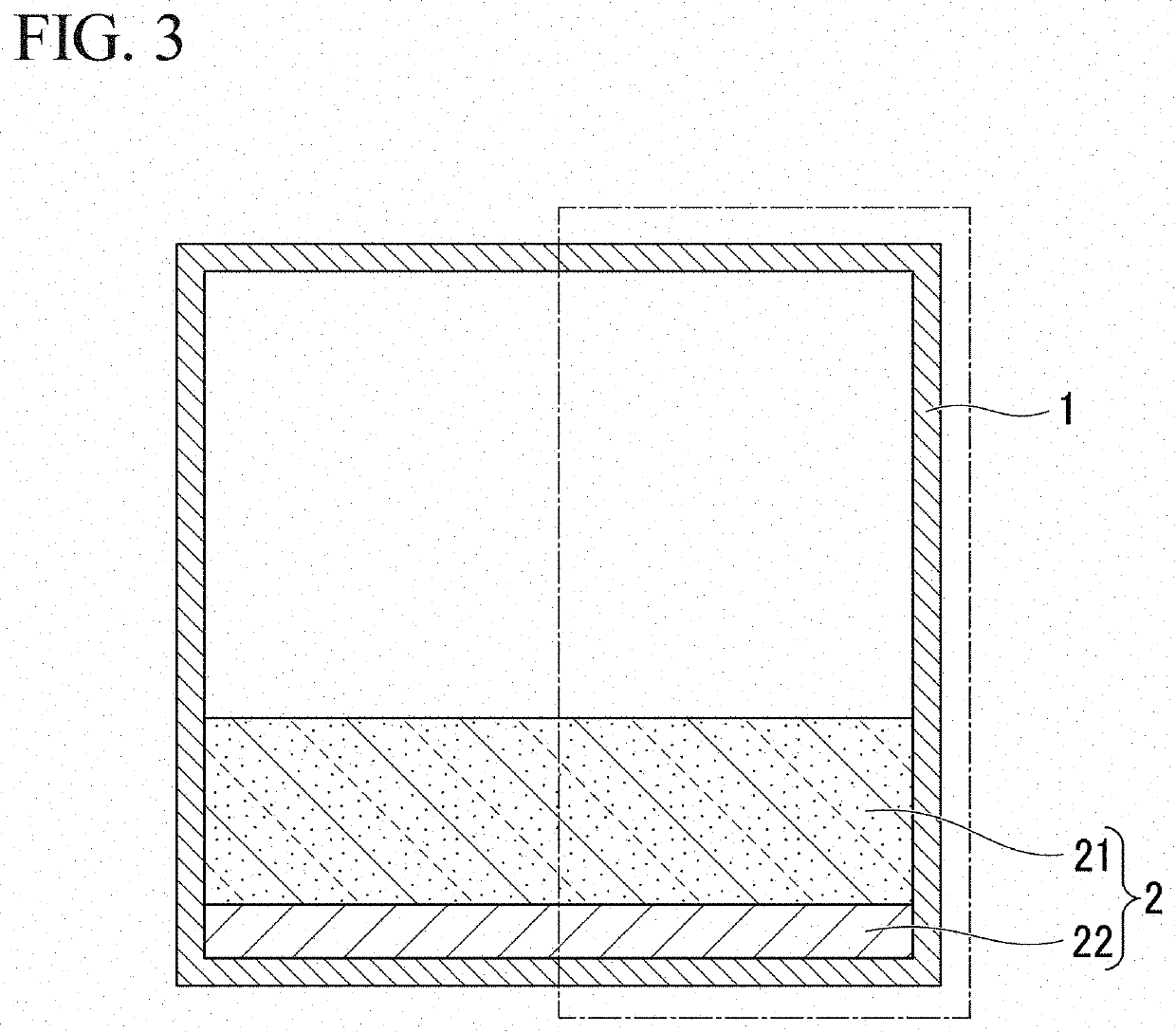

[0023]The method of producing a SiC single crystal ingot according to the present embodiment is a method of producing a SiC single crystal ingot using a sublimation method in which, in a lower part of a crucible, a high thermal conductivity raw material layer containing a high thermal condu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap