Assembling module for floor or wall coverings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

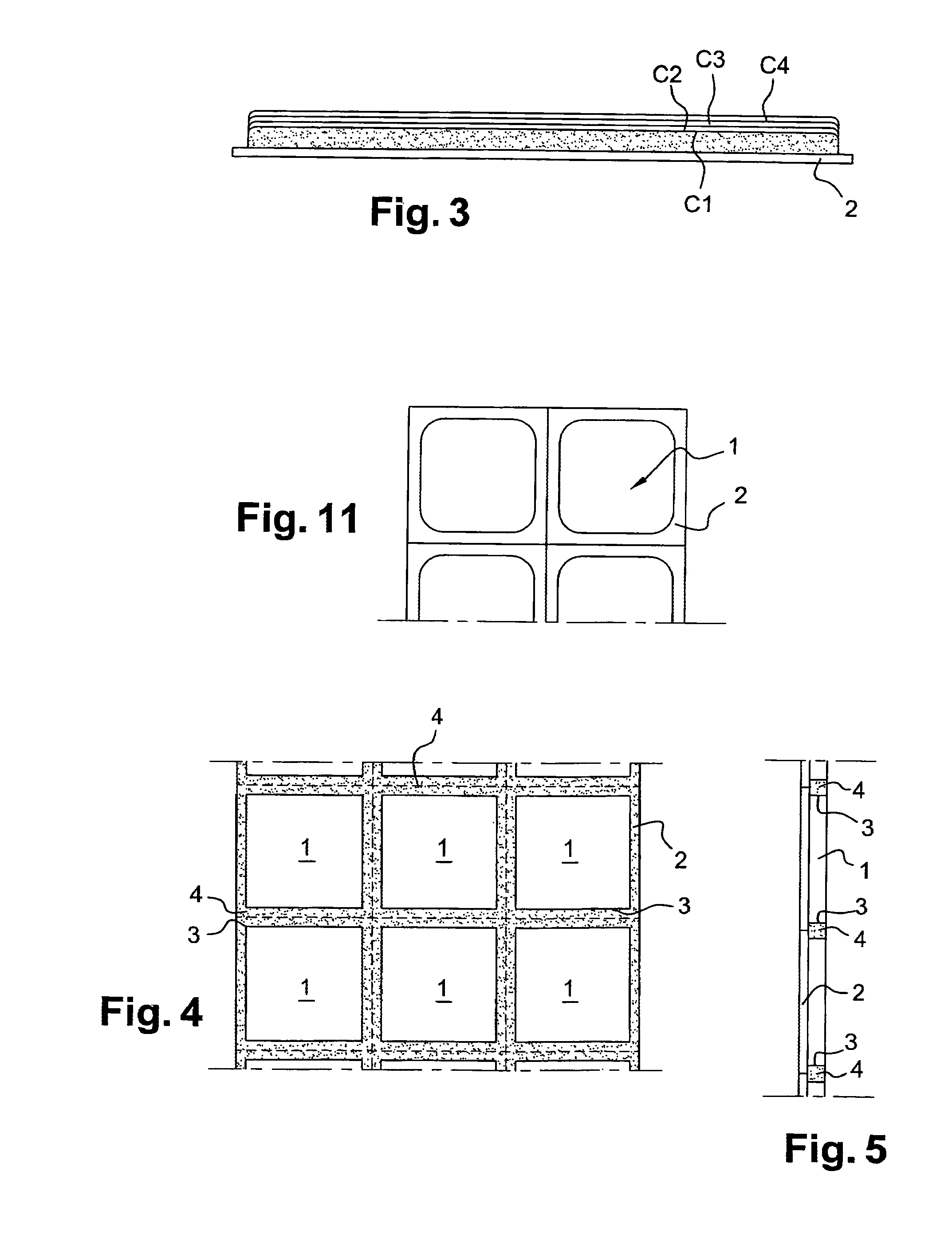

[0035]To give a clearer idea of the subject of the invention, preferred embodiment will now be described in a non-limiting manner with the figures of the drawings.

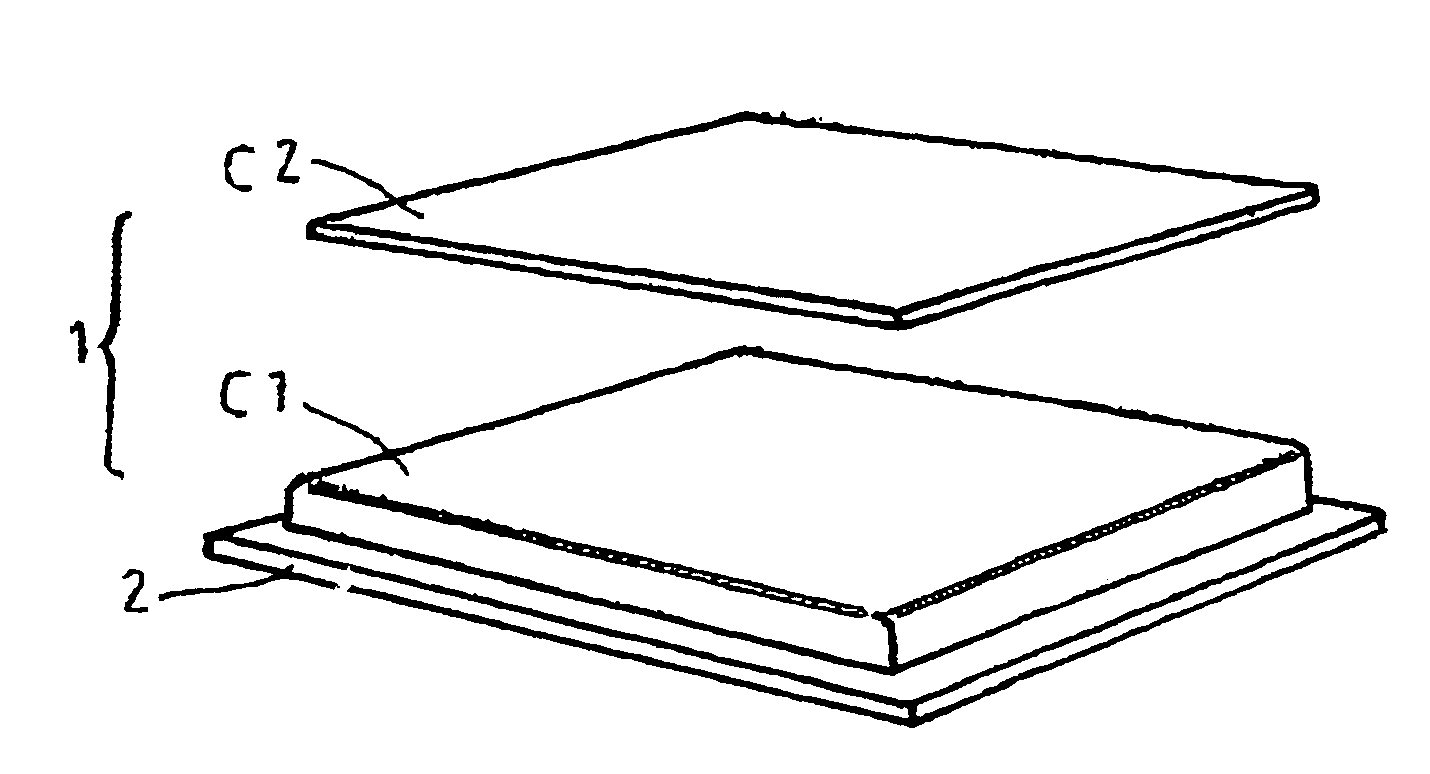

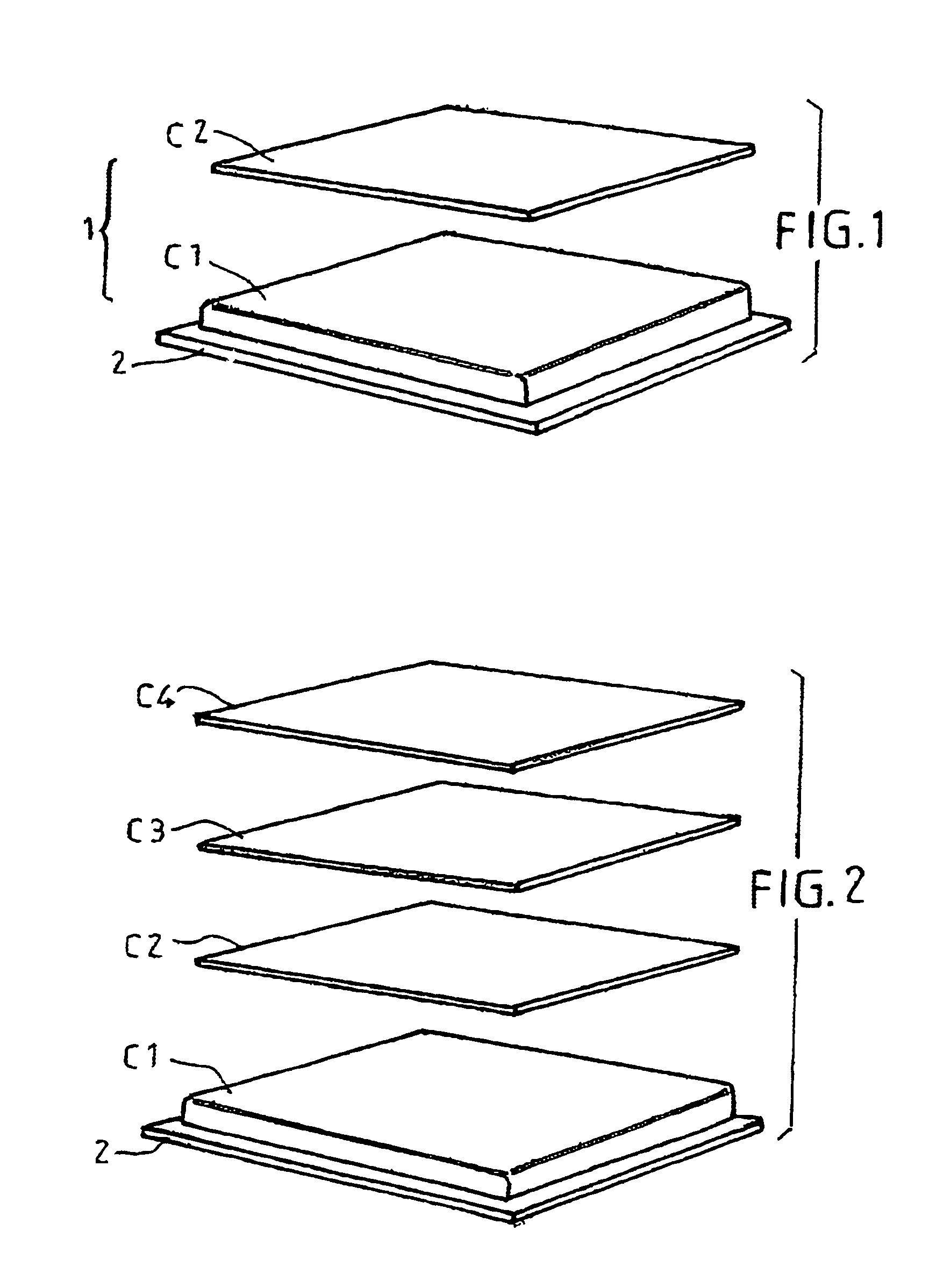

[0036]The assembly module for wall and floor coverings according to the invention bears the general reference (1). It may be made in the form of a square tile, in the form of a rectangular strip, or in other forms. It is a thick, rigid tile, shown in a first non-limiting example in a square format, of variable dimensions which may be, by way of non-limiting example, of the order of 300 to 500 millimeters each side. The module is made in the form of a multilayer structure with at least two layers (Cl) (C2). The first layer is the bottom base layer intended to come into contact with the floor and / or wall surface, and it is made of polymer highly loaded with mineral fillers. This first layer is associated on its upper face with a second layer (C2), defined by a printed polymer film, contributing to the decorative part of the m

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap