Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Air separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases. The most common method for air separation is fractional distillation. Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon. Other methods such as membrane, pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA) are commercially used to separate a single component from ordinary air. High purity oxygen, nitrogen, and argon used for semiconductor device fabrication requires cryogenic distillation. Similarly, the only viable source of the rare gases neon, krypton, and xenon is the distillation of air using at least two distillation columns.

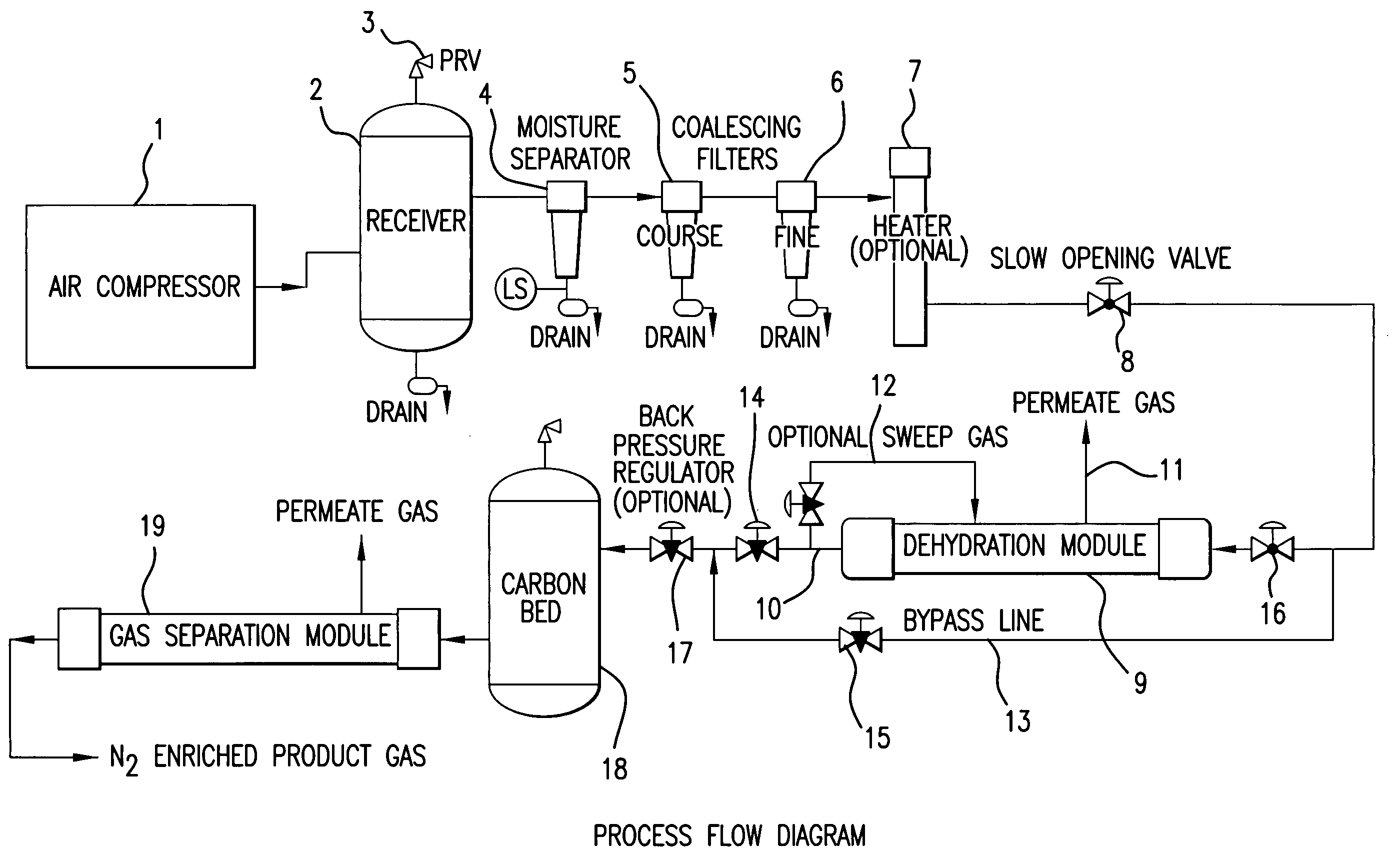

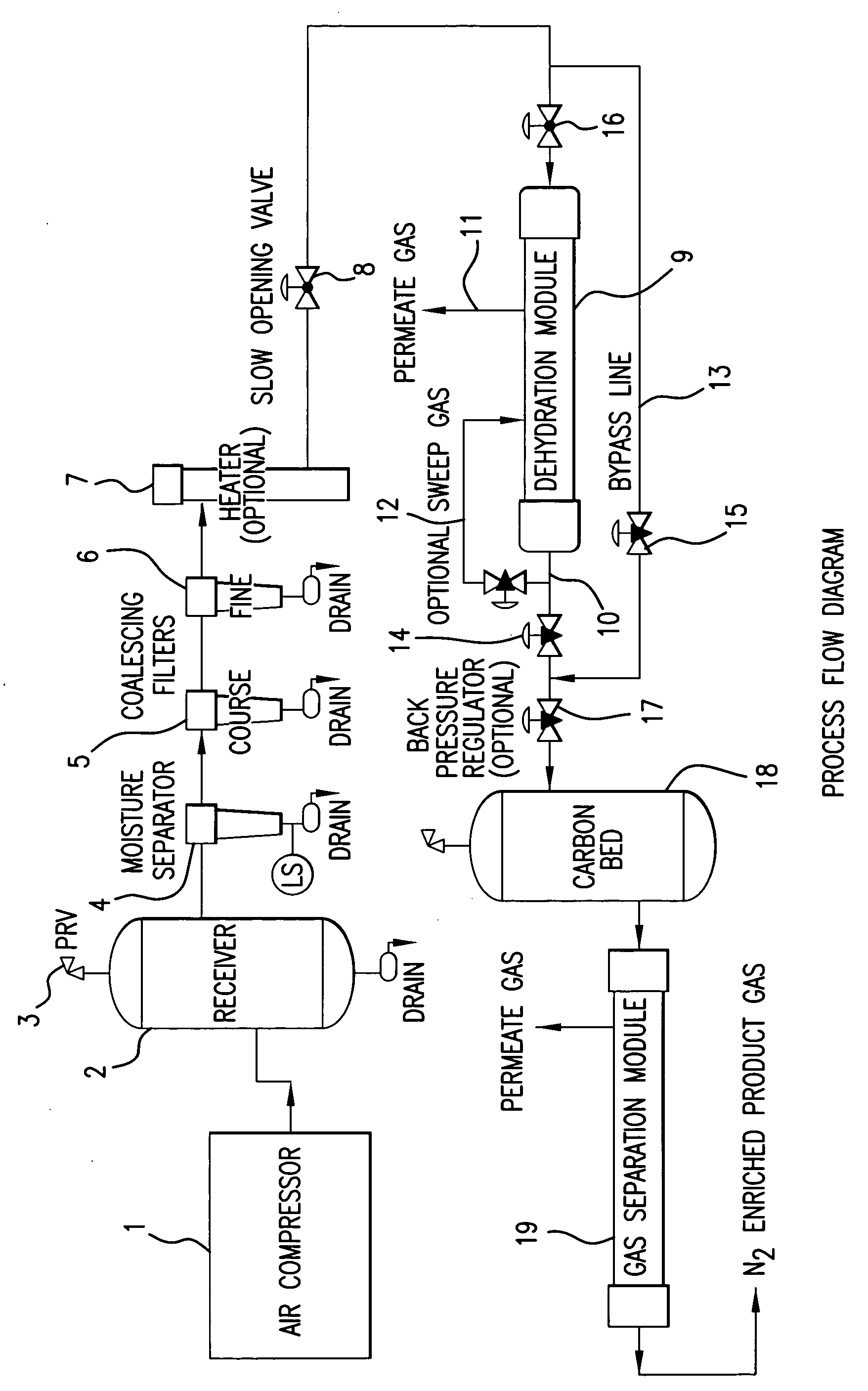

Air separation system using dehydration membrane for pretreatment of compressed air

Owner:GENERON IGS

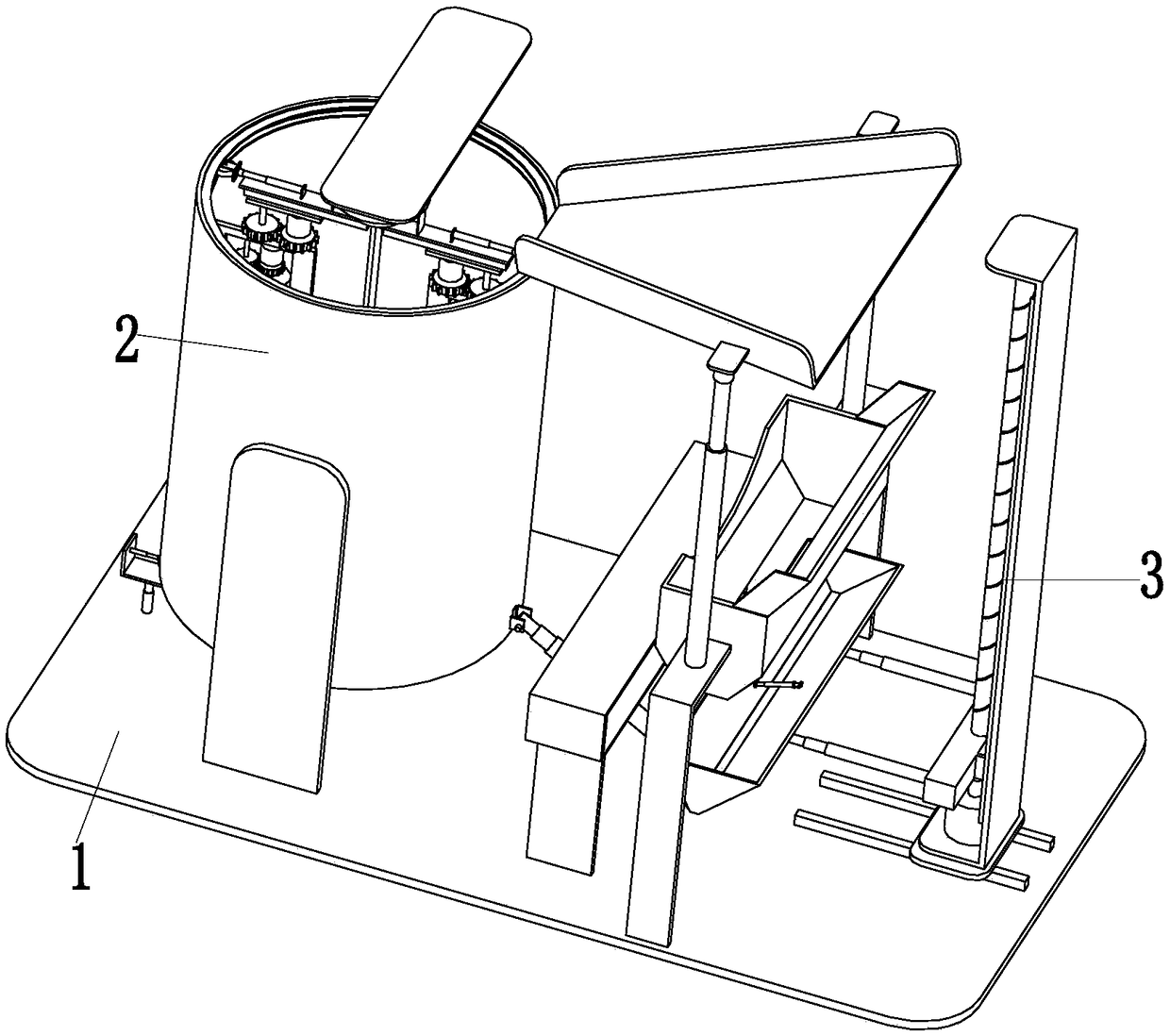

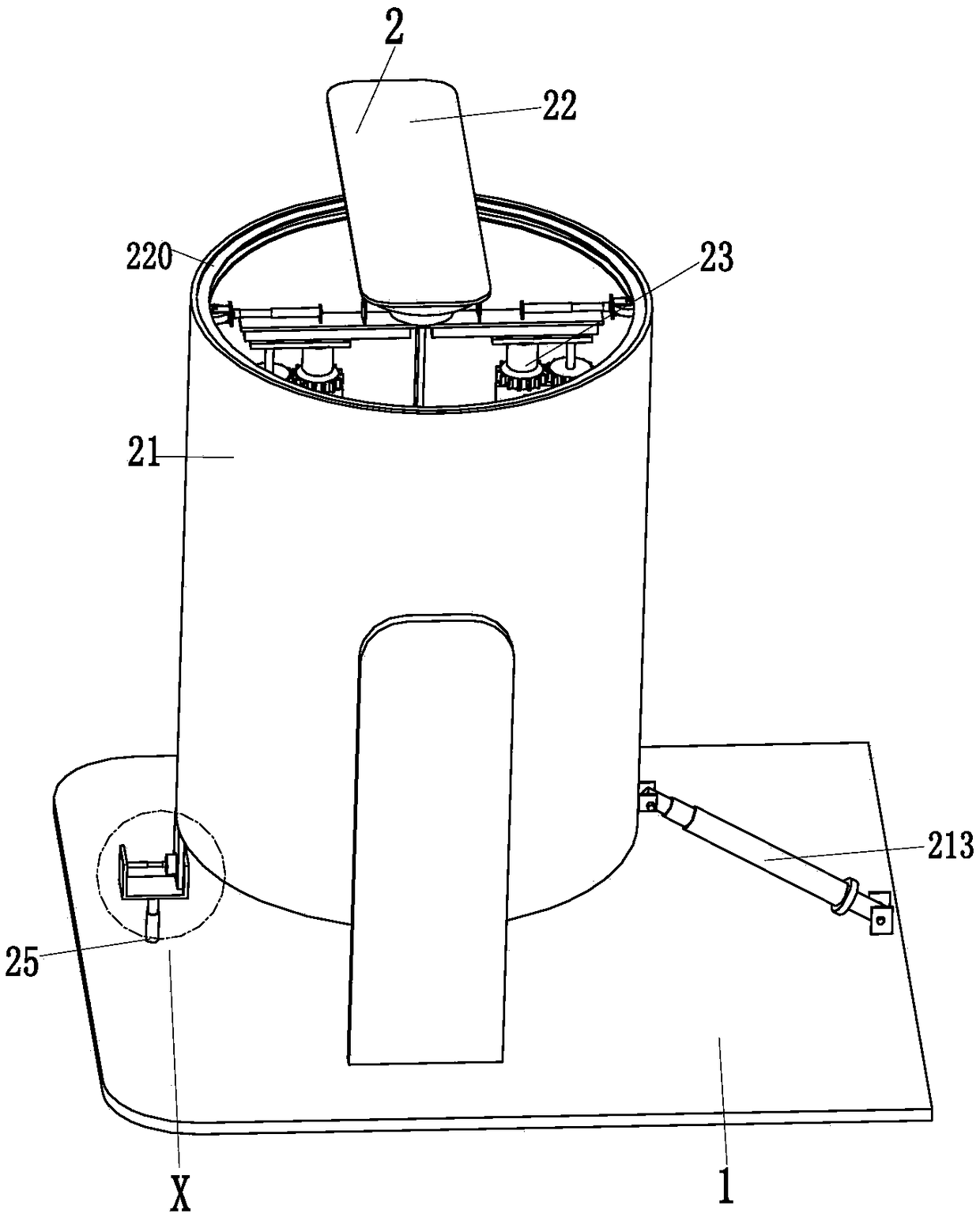

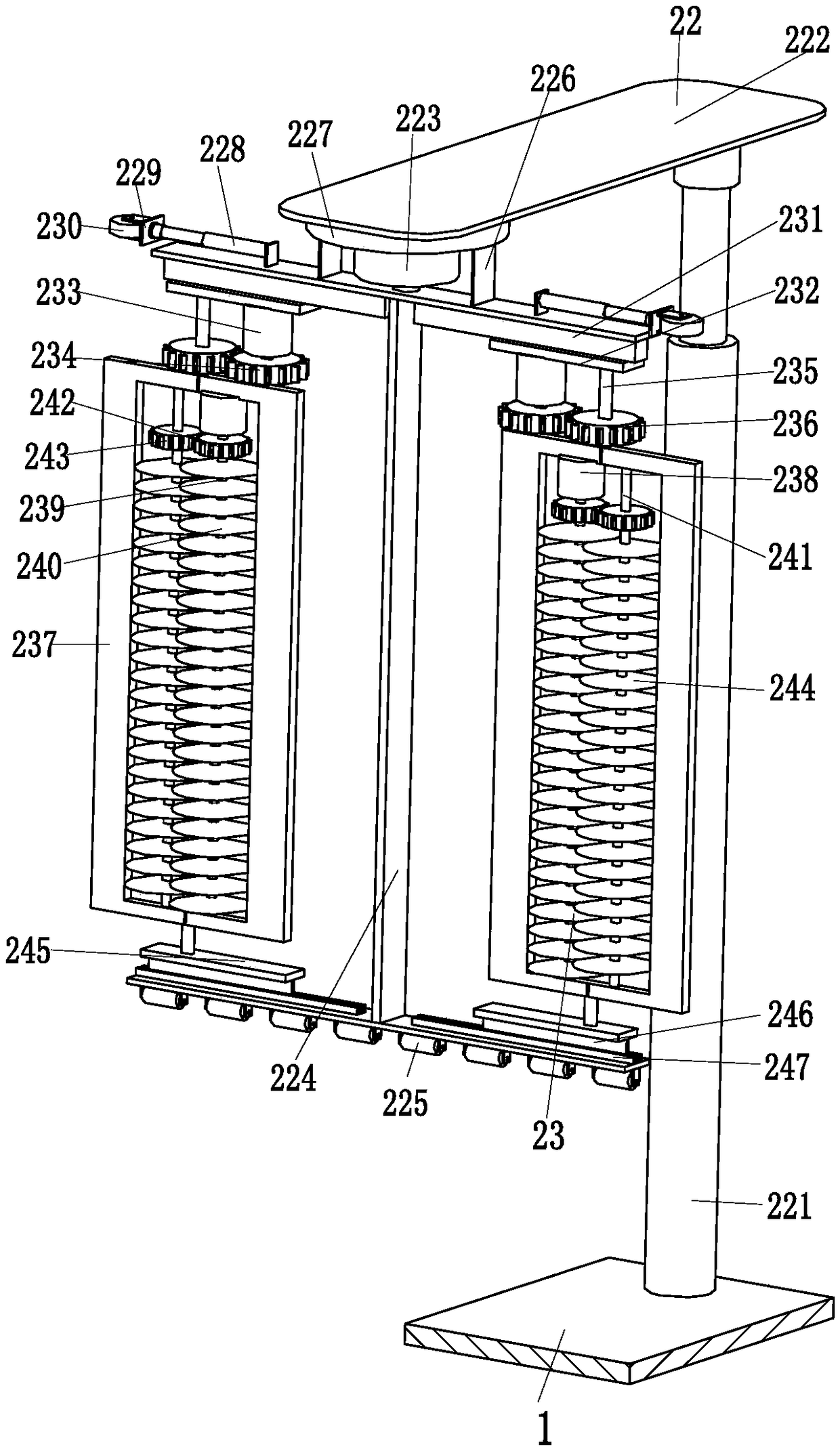

Air separation device and method of garbage

InactiveCN101823019AObvious superiorityImprove sorting efficiencyGas current separationWet separationAir volumeMagnetic separator

Owner:BEIJING HAOHAI TIANJI TECH +1

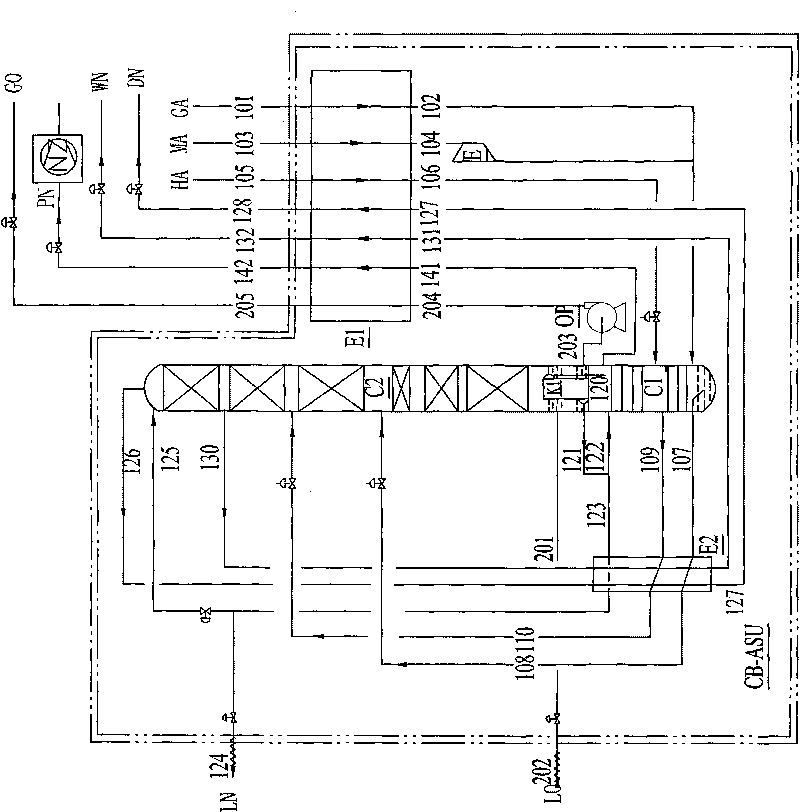

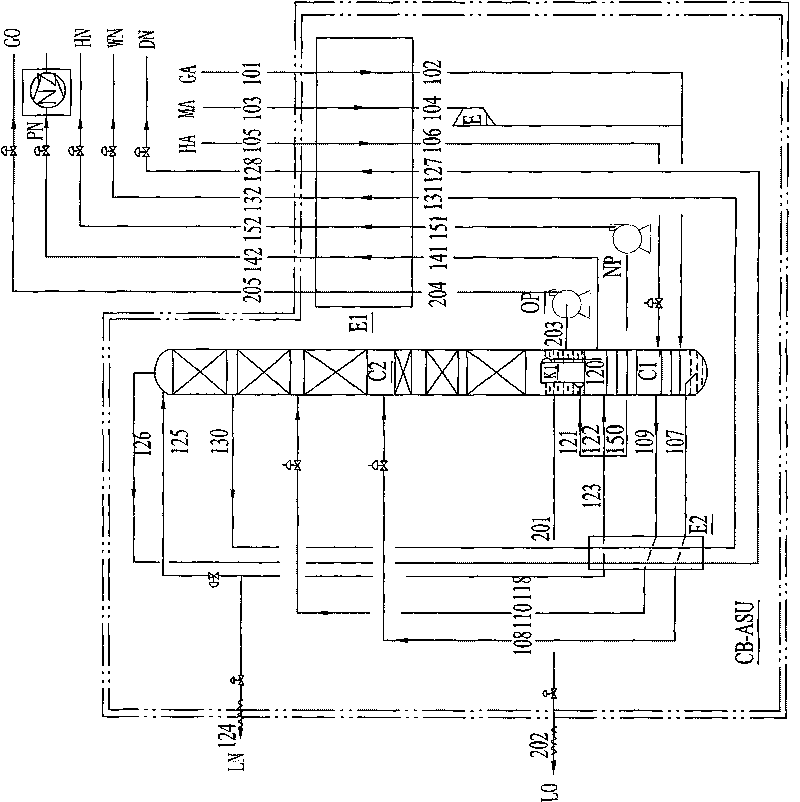

Method for reducing comprehensive energy consumption of air separation

Owner:四川空分设备(集团)有限责任公司

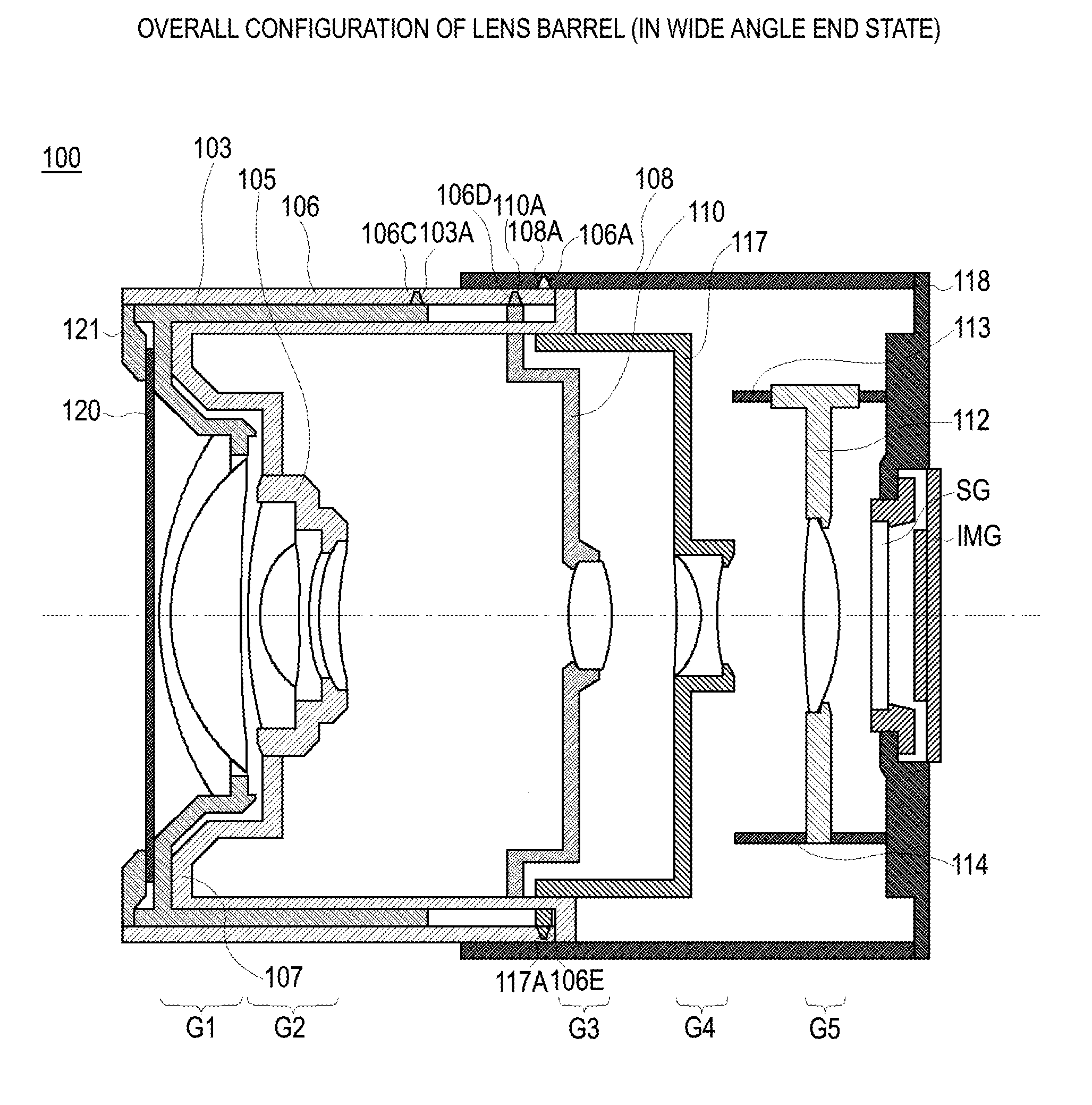

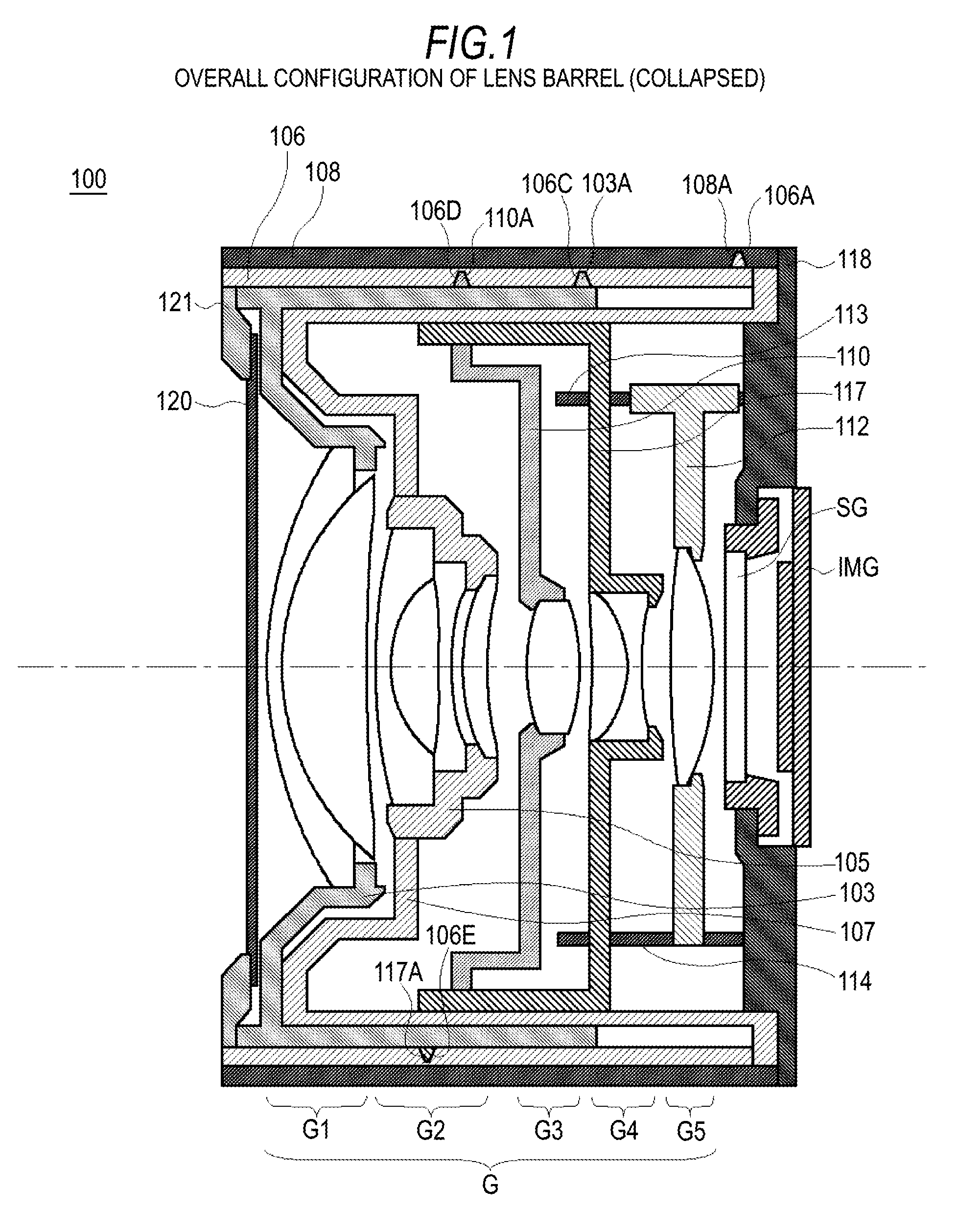

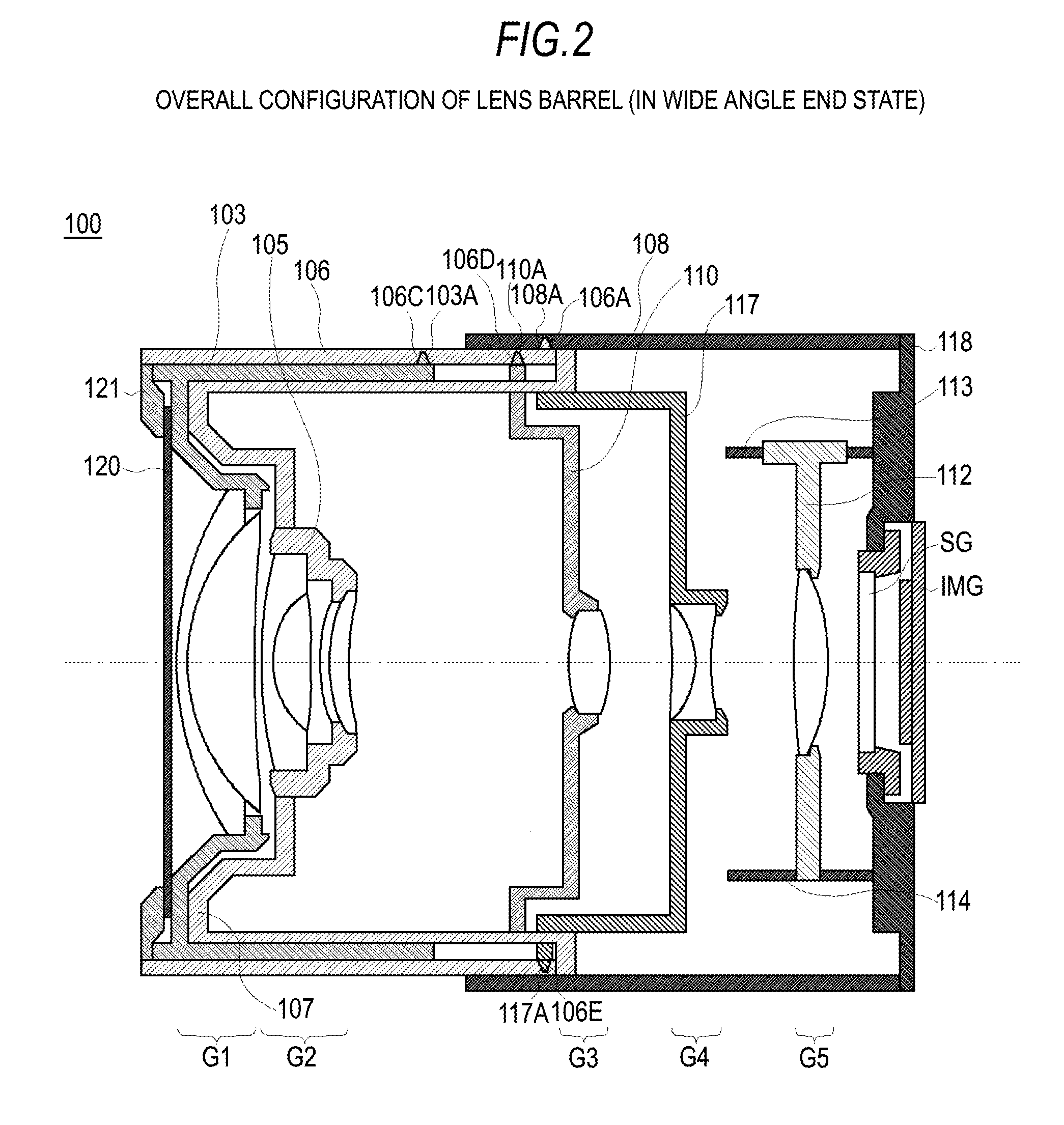

Lens barrel and imaging apparatus

InactiveUS20110157721A1High variable power ratioSimple configurationMountingsCamera body detailsPhysicsAir separation

Owner:SONY CORP

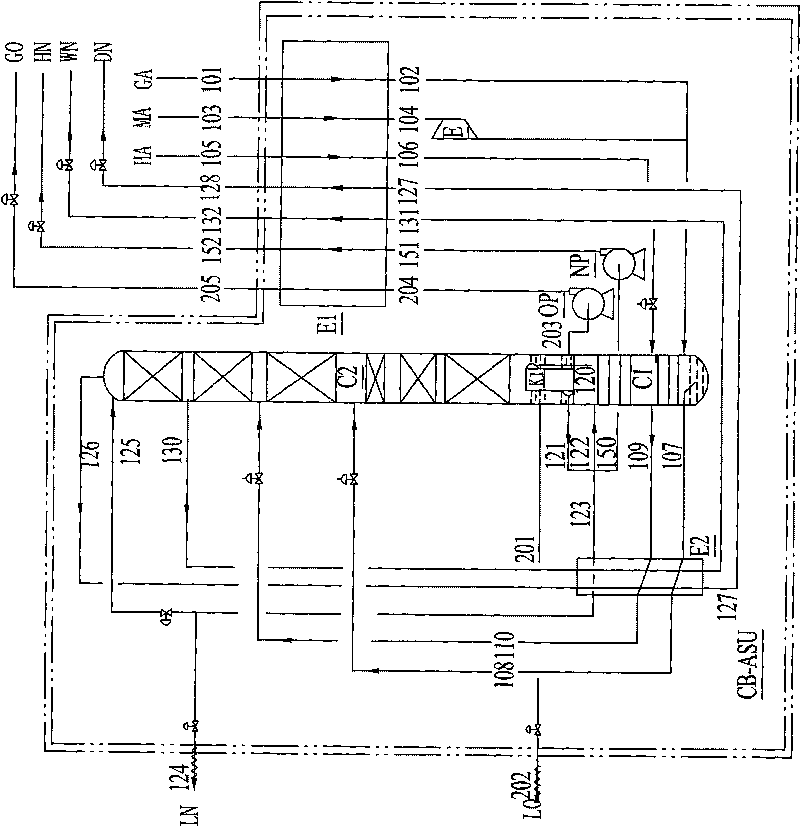

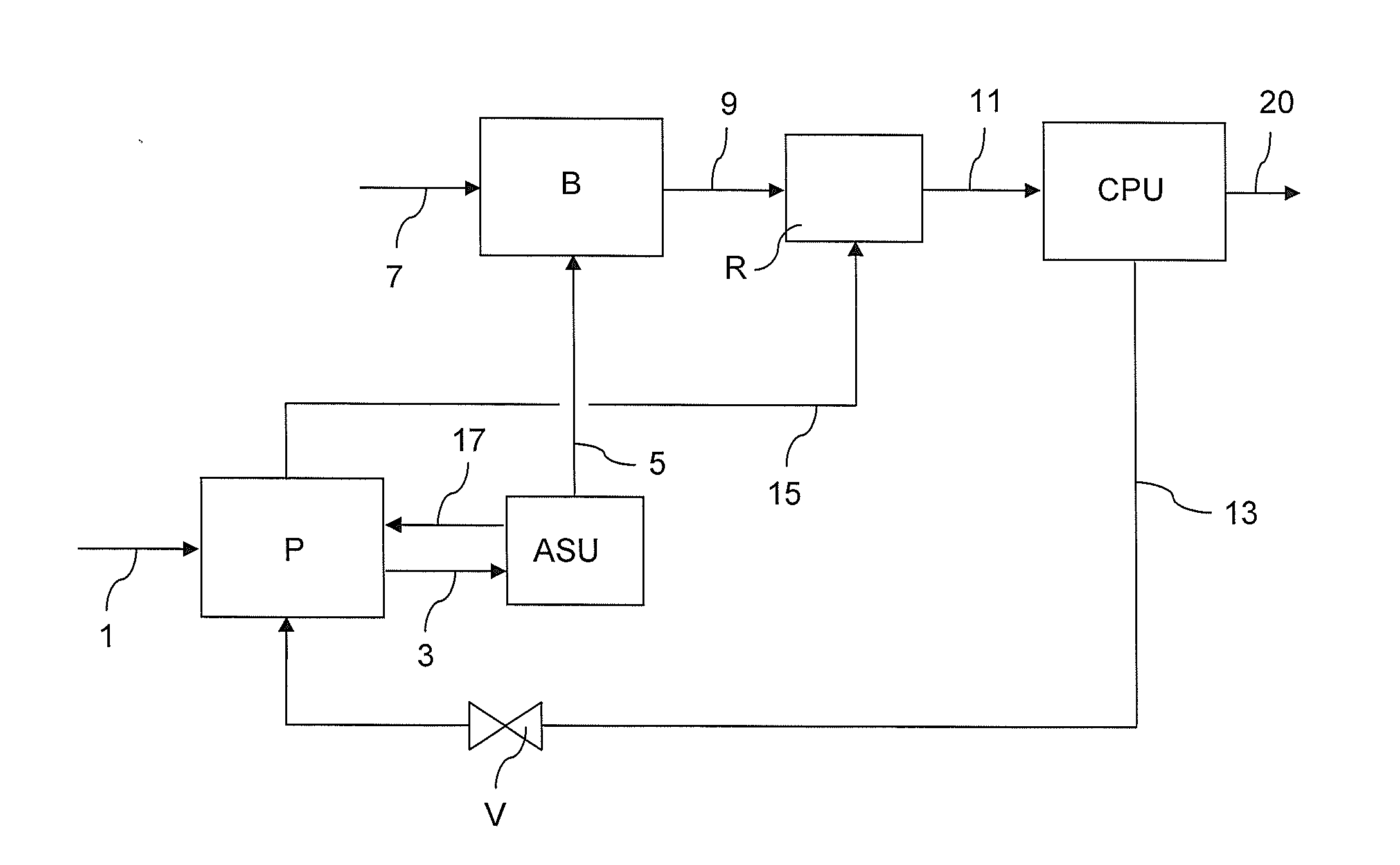

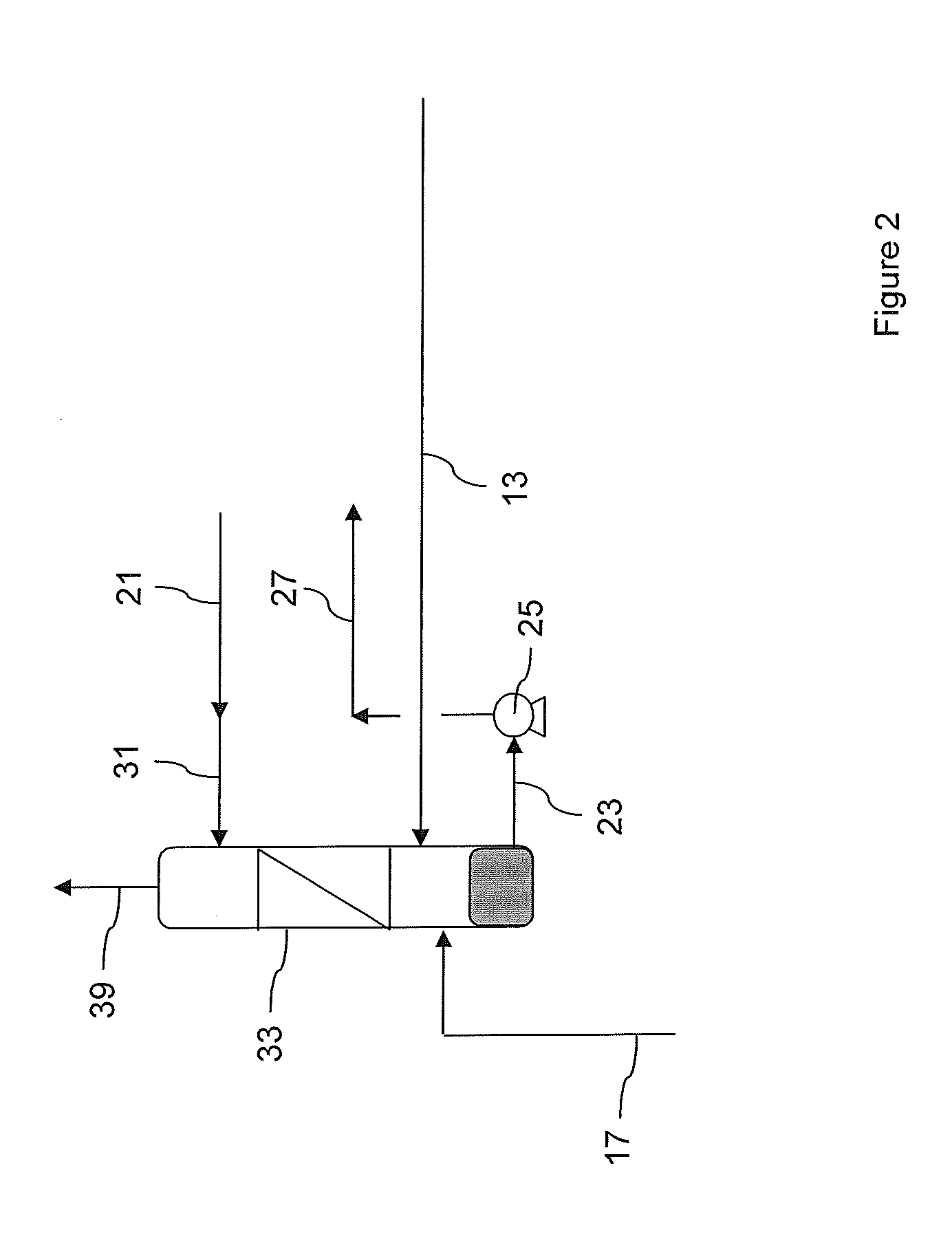

Apparatus and Integrated Process for Separating a Mixture of Carbon Dioxide and at Least One Other Gas and for Separating Air by Cryogenic Distillation

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Tea processing machine

ActiveCN109046631APre-extraction tea treatmentGrain treatmentsAir separationAgricultural engineering

Owner:安徽省万佛山农业综合开发有限公司

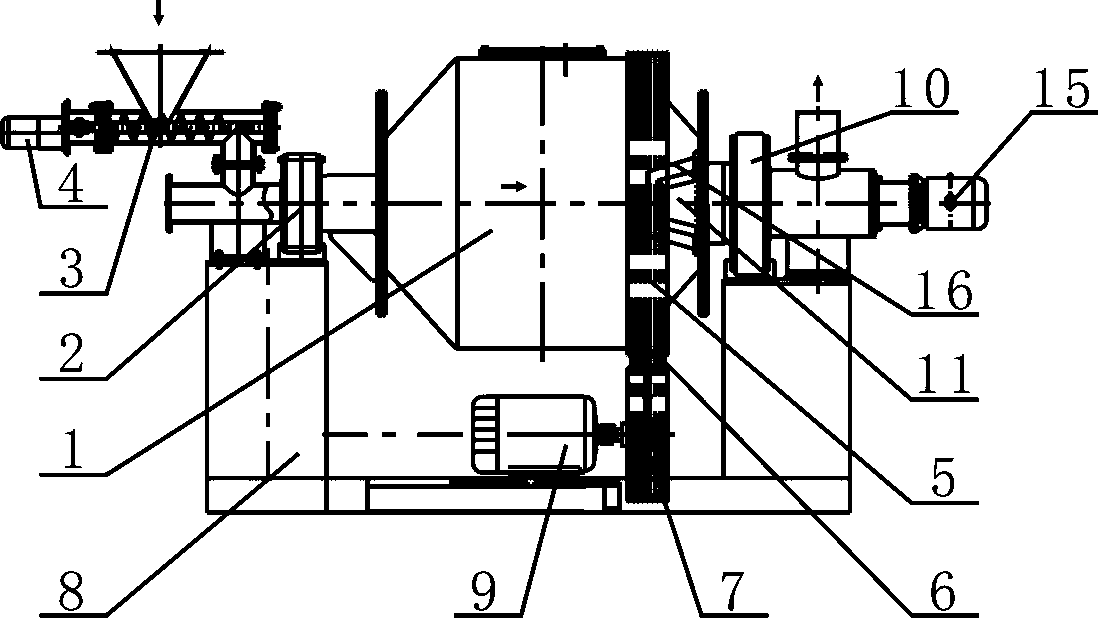

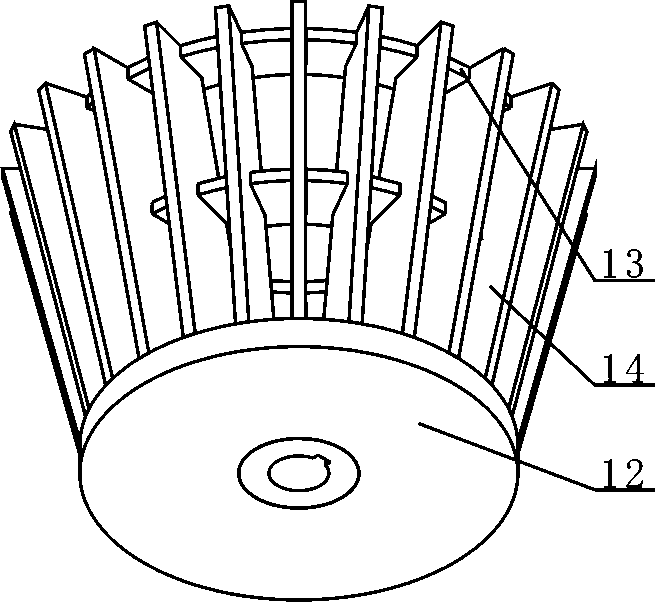

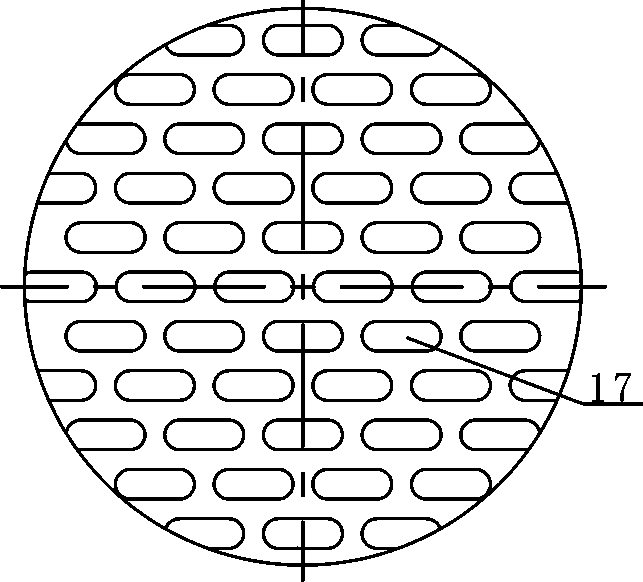

Continuous feeding air separation device

PendingCN108405089AIncrease productionImprove particle size uniformityGrain treatmentsEngineeringAir separation

Owner:LUOYANG SHENGYUAN HIGH TECH MATERIALS

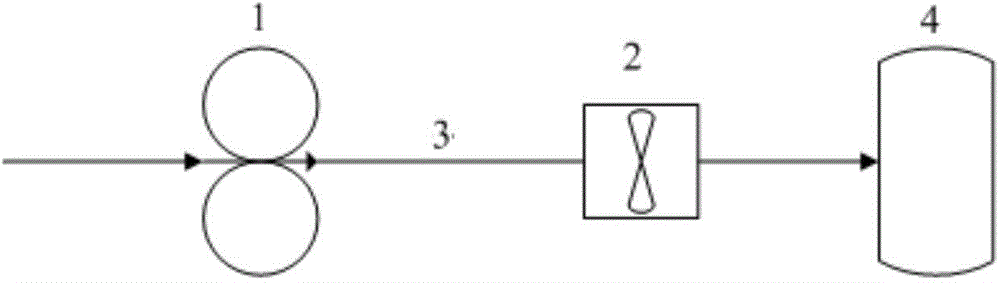

Oil-air separator driven by engine oil scavenging pump

InactiveCN104594976AReduce pollutionReduce consumptionMachines/enginesCrankcase ventillationAtmospheric airFuel tank

Owner:CHINA NORTH ENGINE INST TIANJIN

Ultra-fine fly ash light self-insulation wall plate and manufacturing method thereof

InactiveCN107780590ALow refractorinessReduce weightCeramic shaping plantsBuilding componentsAir separationUltra fine

Owner:SHANXI HUATONG LANTIAN ENVIRONMENTAL PROTECTION

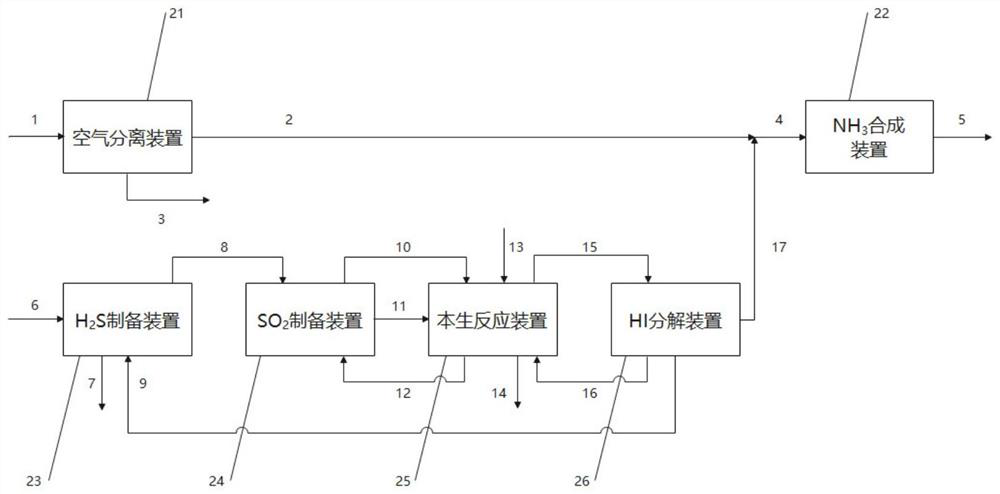

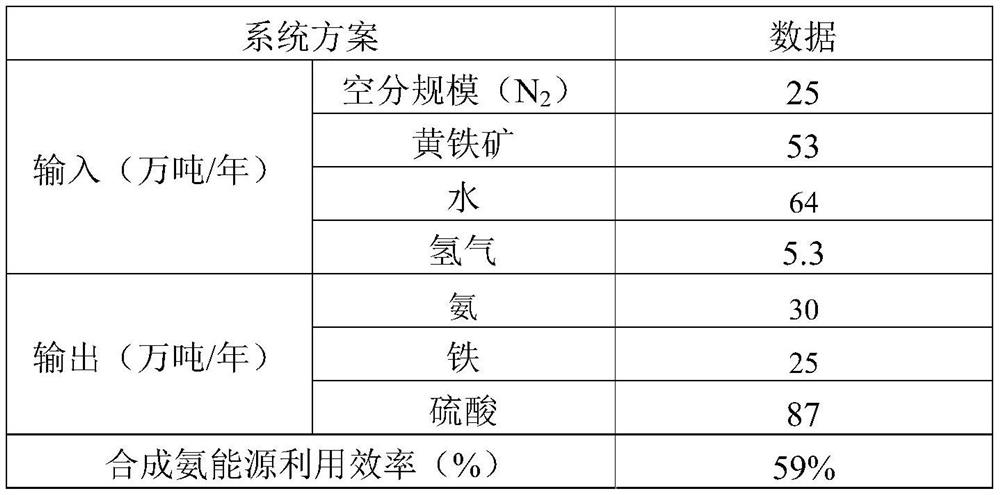

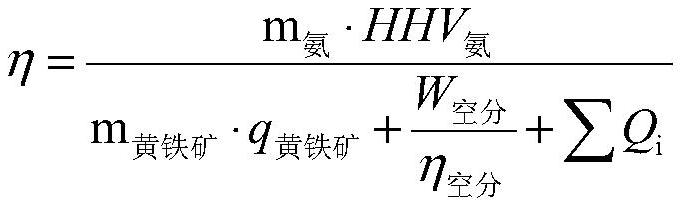

CO2 zero-emission ammonia synthesis system and method based on iodine-sulfur semi-open circulating hydrogen production and application of CO2 zero-emission ammonia synthesis system and method

ActiveCN113401920ASimple processLess investmentNitrogen purification/separationSulfur compoundsPhysical chemistryAir separation

Owner:国能经济技术研究院有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap