Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Characterization methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are two types of characterization: direct and indirect. Direct characterization explicitly tells the reader what a character's qualities are. Indirect characterization uses five different methods that combine different elements to reveal a character's personality.

Characterization method for ionic liquid dissolvability

InactiveCN101470063AImprove solubilityReliable dataWeighing by absorbing componentSolubilityDissolution

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

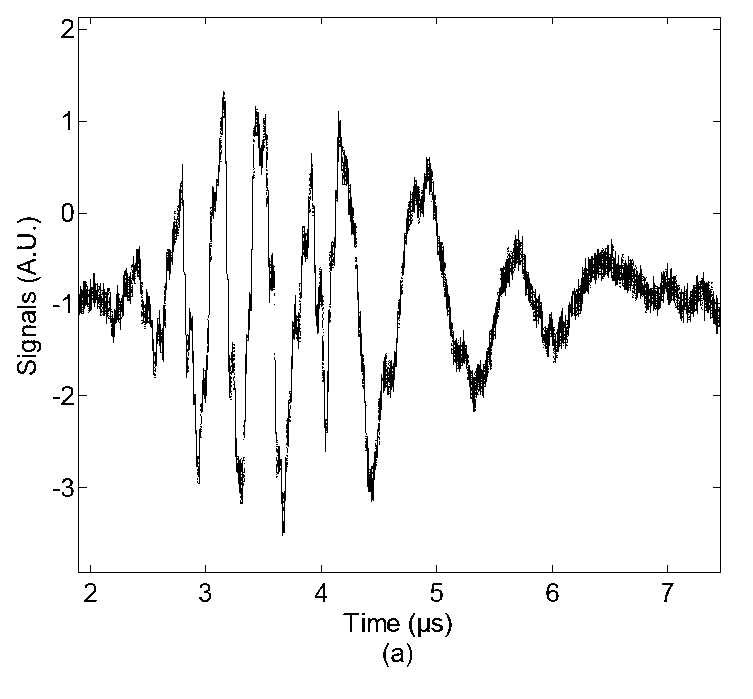

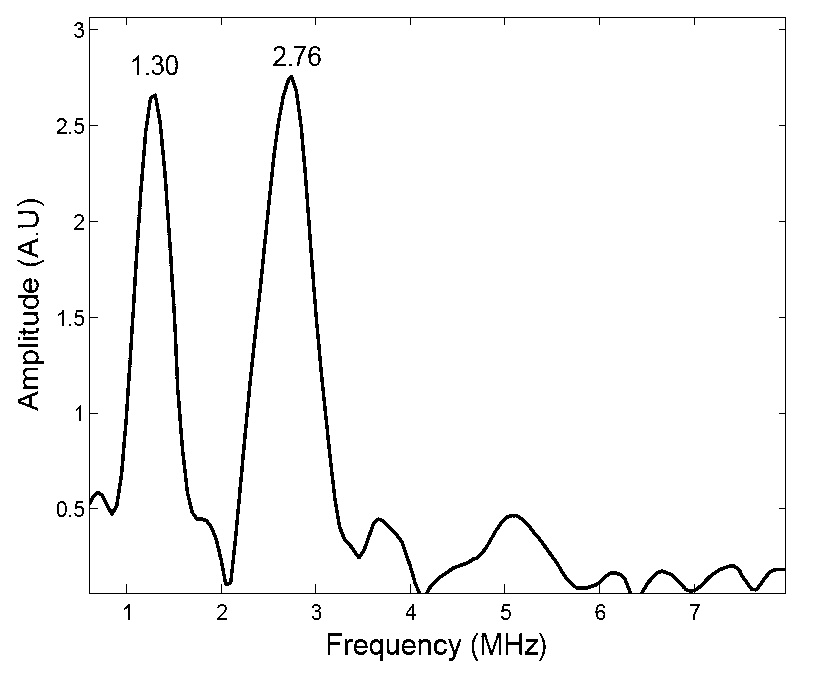

Soft matter mechanical property measurement method and system

InactiveCN105865923AImprove test accuracyImprove test efficiencyMaterial strength using tensile/compressive forcesComputer control systemAcoustics

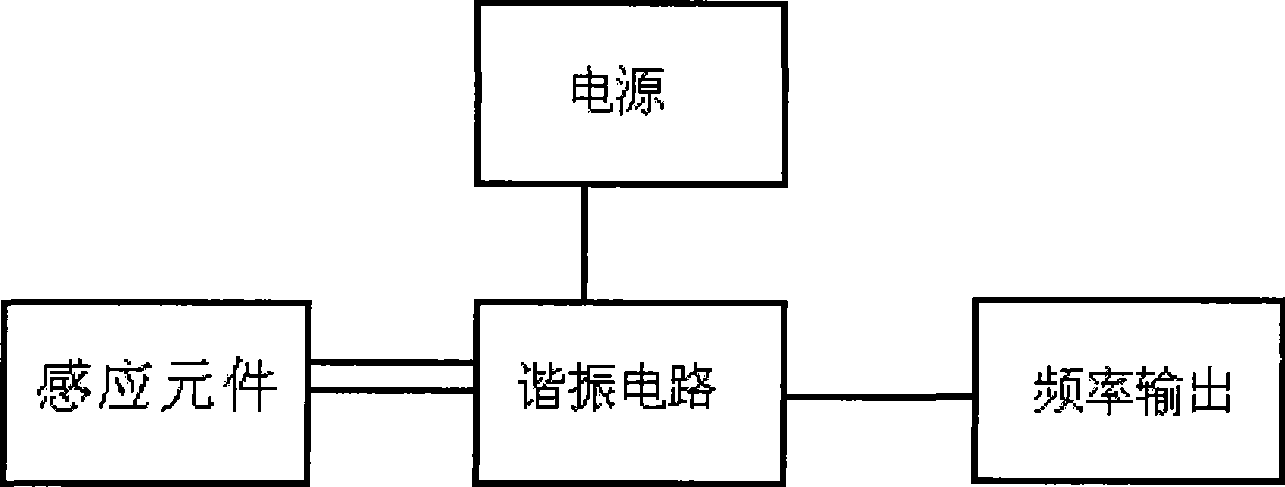

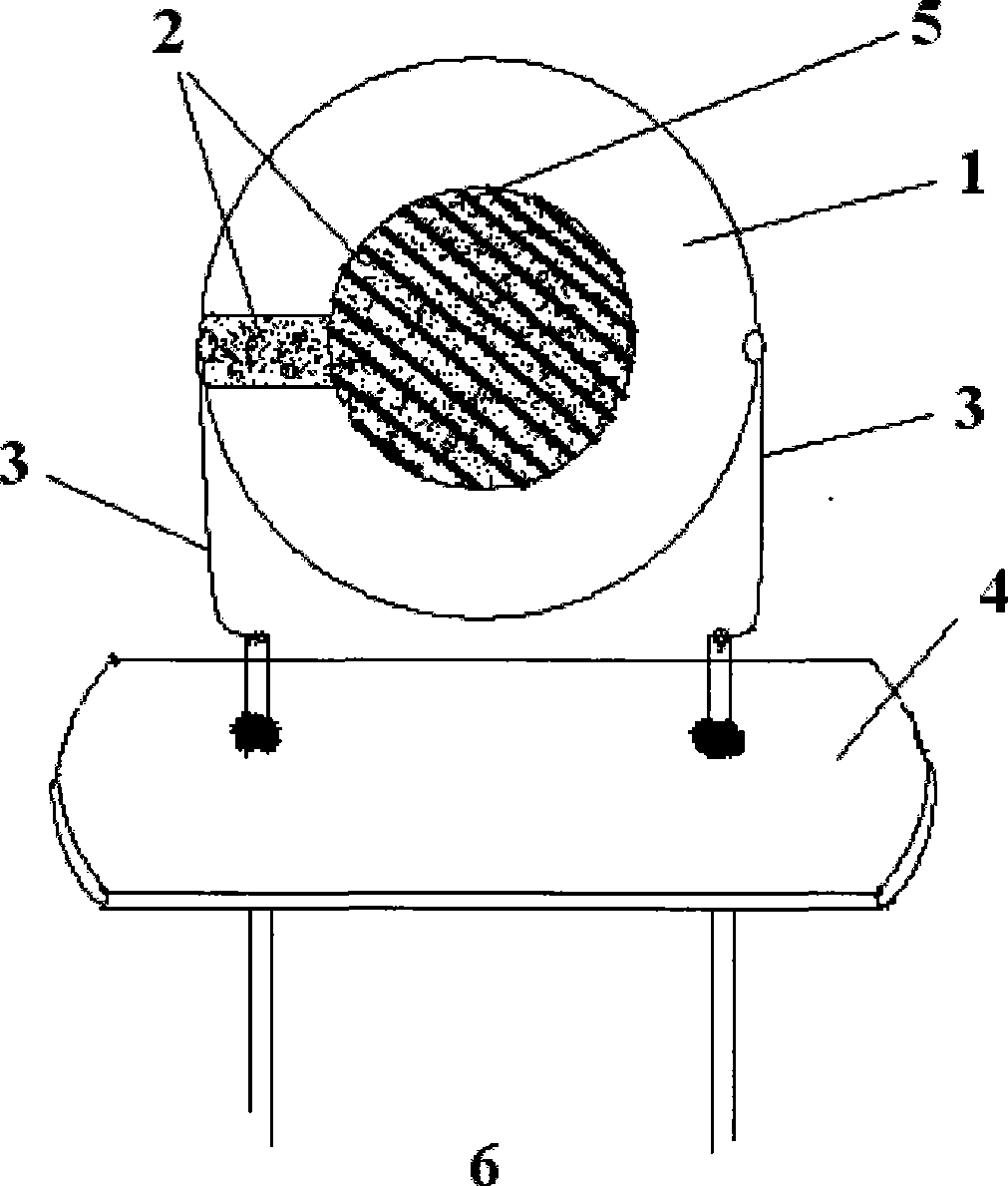

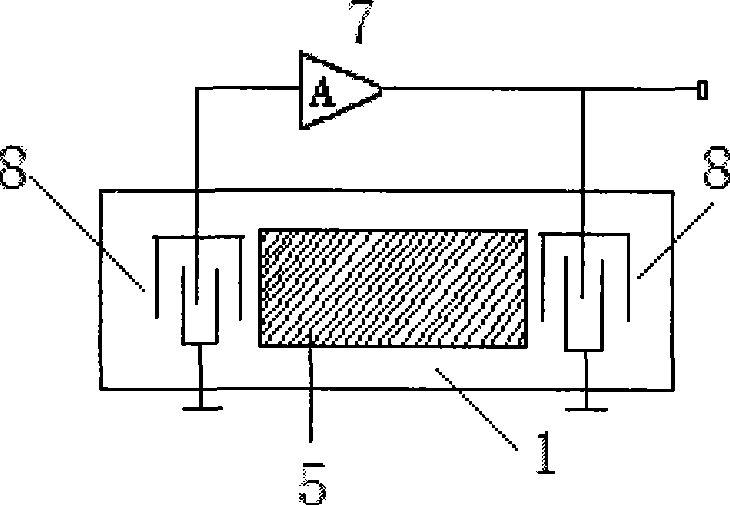

The invention discloses a soft matter mechanical property measurement method and system. The measurement system comprises a piezoelectric bimorph beam, an electric hoisting platform, an impedance analyzer, a strain gauge and a computer control system. The measurement of a characterization method of a plurality of types of mechanical properties can be finished through one-time loading, and different mechanical properties of a sample to be detected are obtained, so that the testing accuracy and the testing efficiency can be improved; a change rule that the mechanical properties of the sample to be detected can be changed along pressing depth can be obtained, and influences on a measurement result, caused by factors including the end part abrasion of a pressed needle tip and the surface effect of the sample to be detected and the like are eliminated, so that a relatively accurate result is provided; a beam type loading system is adopted, is a flexible loading system and is applicable to measurement of soft matters; and the piezoelectric bimorph beam is used for amplifying a pressing signal by utilizing bending deformation in a pressing process, so that the sensitivity of a testing process is relatively high when amplification is carried out.

Owner:PEKING UNIV

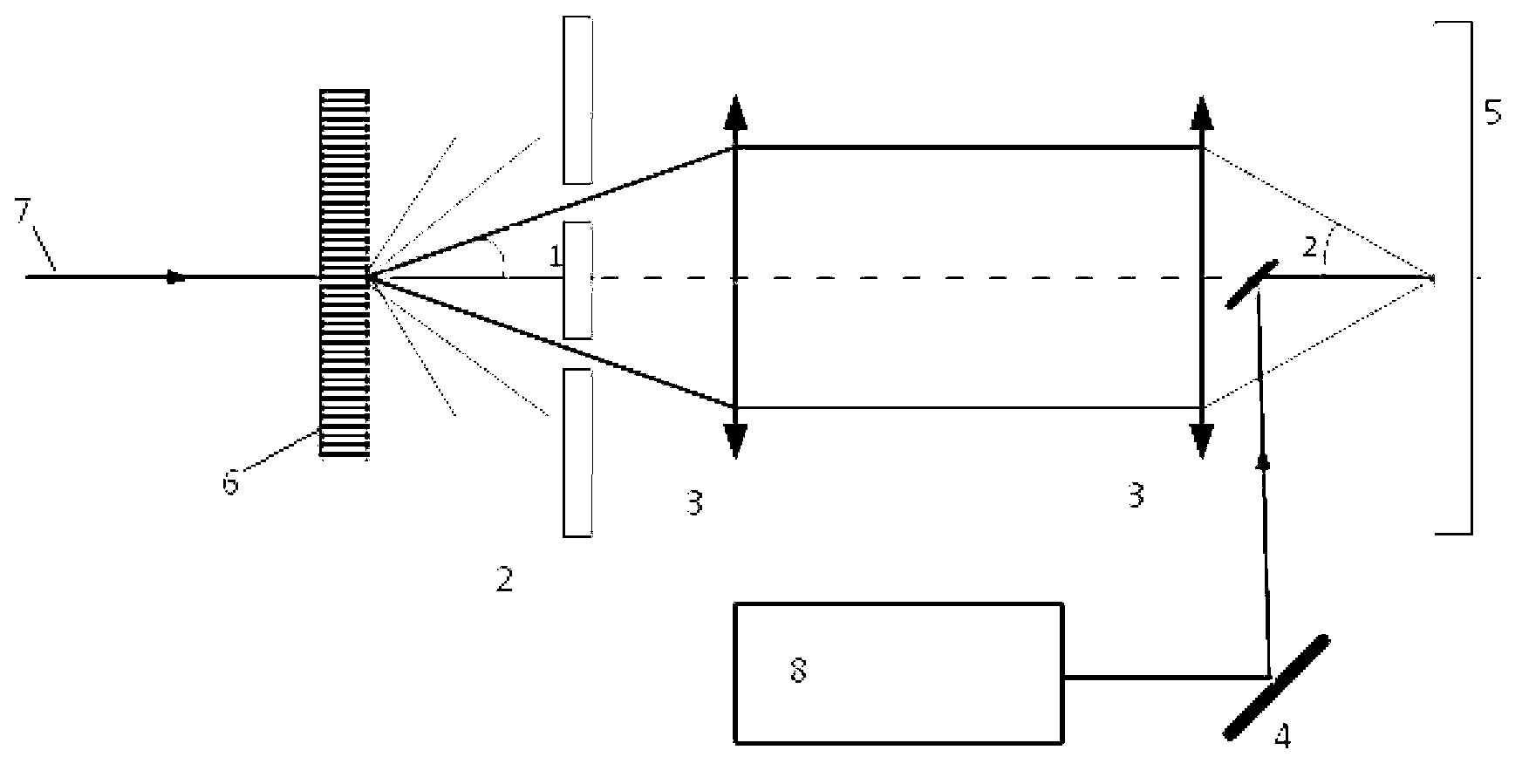

Non-contact detection method for detecting elastic parameter uniformity of material on line

InactiveCN103018170ARealize online characterizationImprove real-time performanceMaterial analysis by optical meansGratingNanosecond

Owner:NANJING BAISISHENG NEW MATERIAL TECH

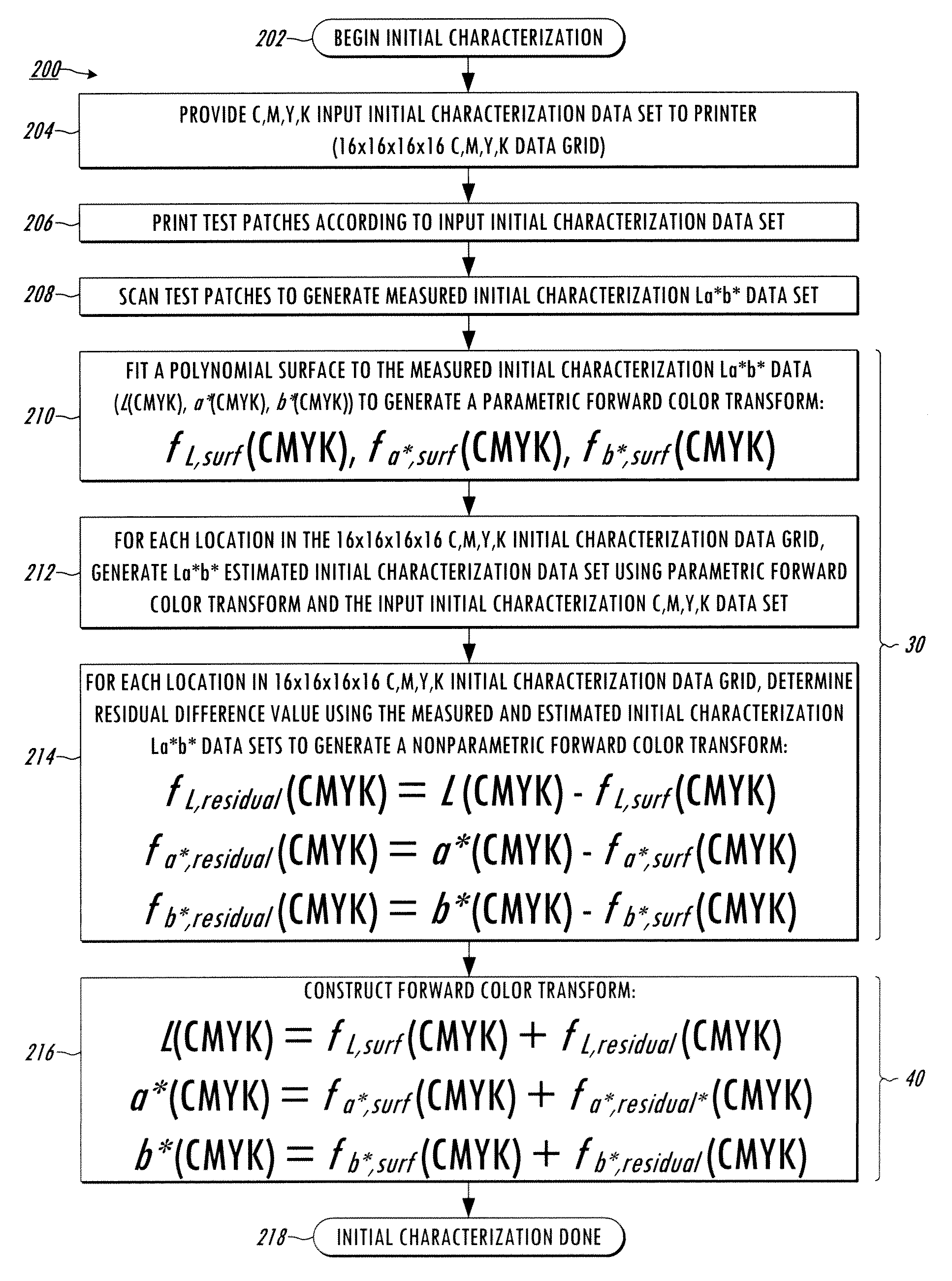

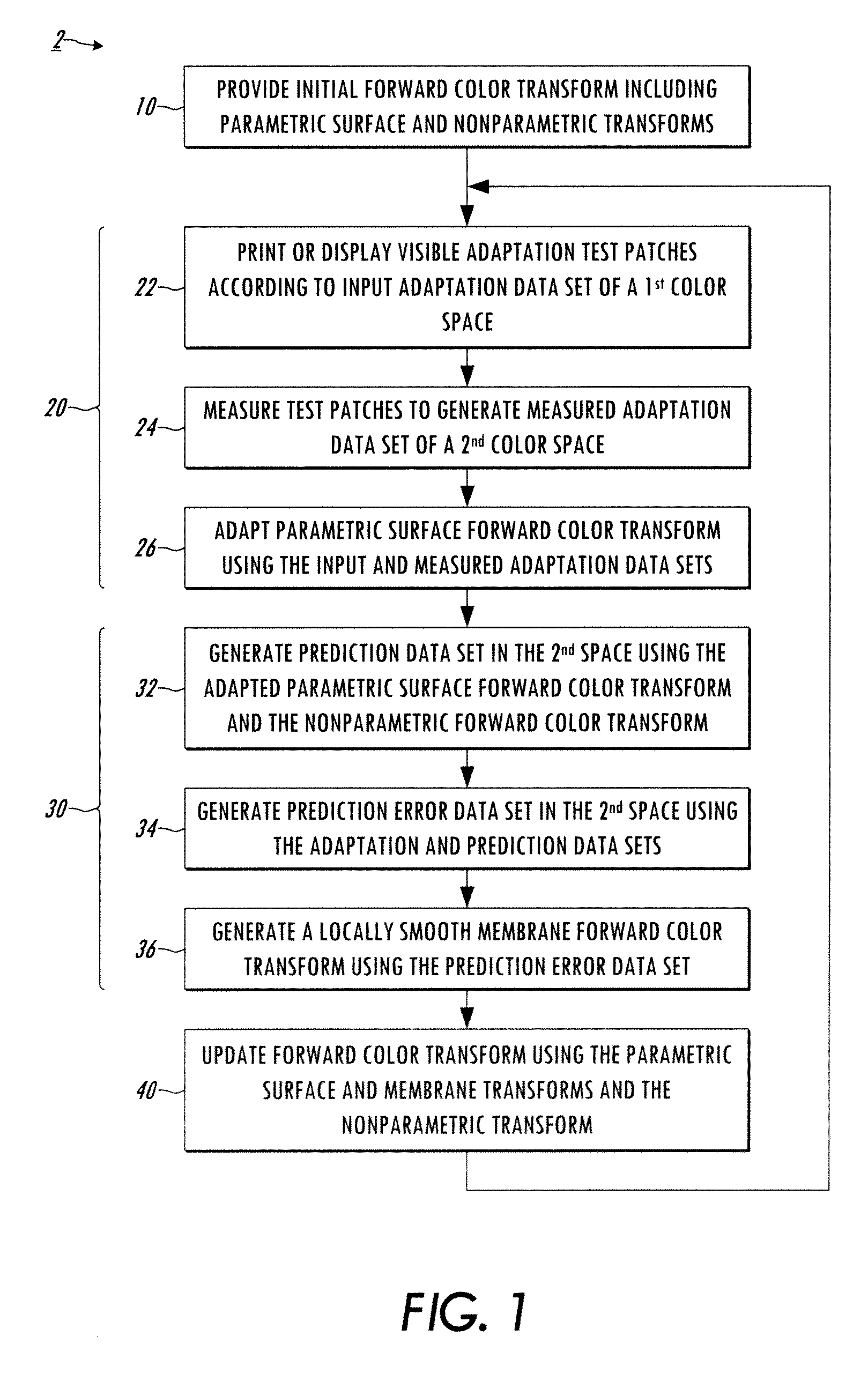

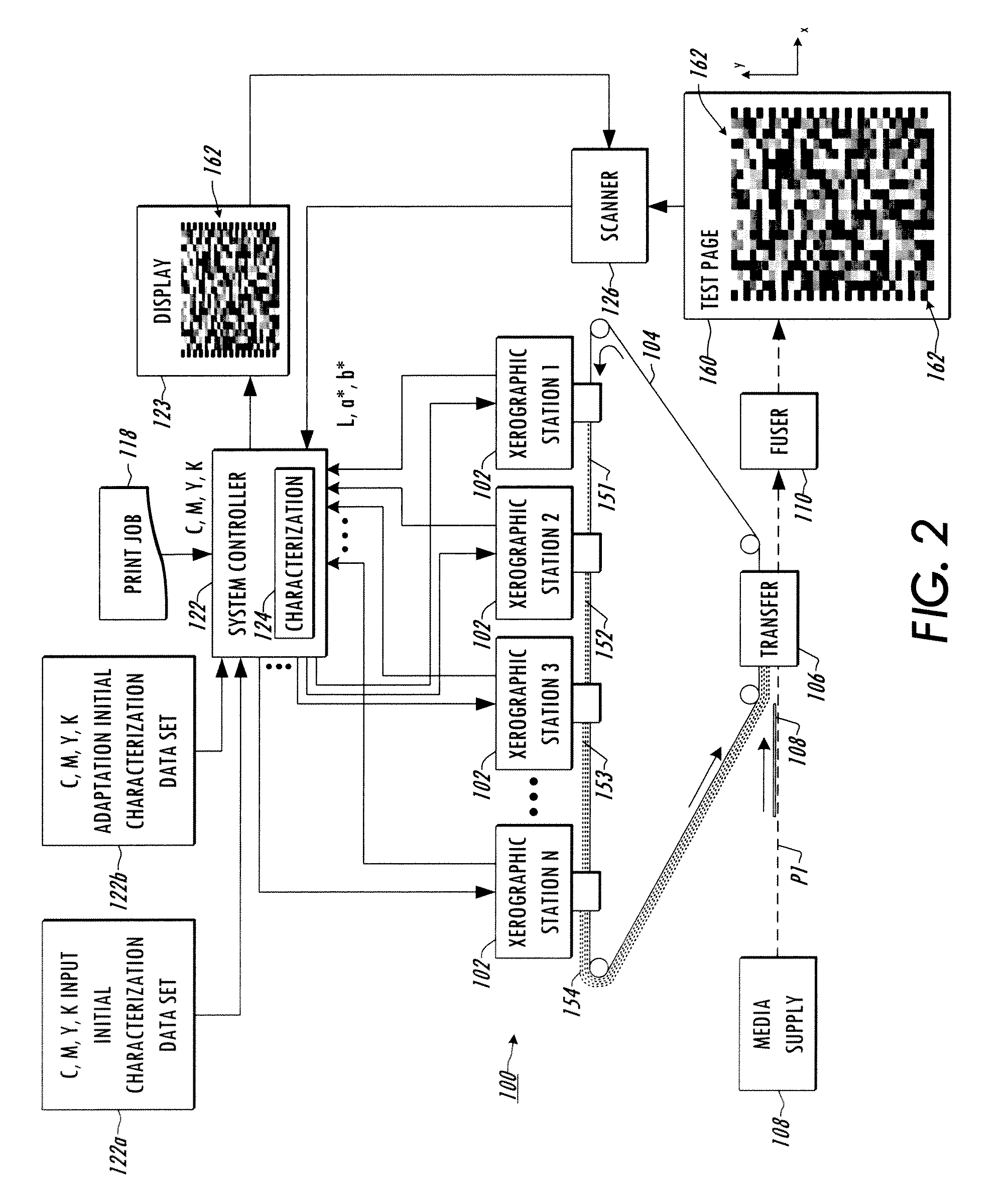

Membrane-based methods and system for color characterization

ActiveUS20110063698A1Lack capabilitySurfaceColor television with pulse code modulationColor television with bandwidth reductionMembrane configurationCharacterization methods

Owner:PALO ALTO RES CENT INC

Characterization method for strengthening phase of ferromagnetic alloy block and/or film

ActiveCN108827991AAchieve separationAchieve representationMaterial analysis using wave/particle radiationElectron microscopeAlloy

Owner:CENT SOUTH UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap