Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cutting force is a fundamental physics concept that describes the amount of force used in a specific amount of area. This "force per area" relationship is used to derive the amount of stress applied to an object that is being cut. When the stress overcomes the strength of the material it is being applied to,...

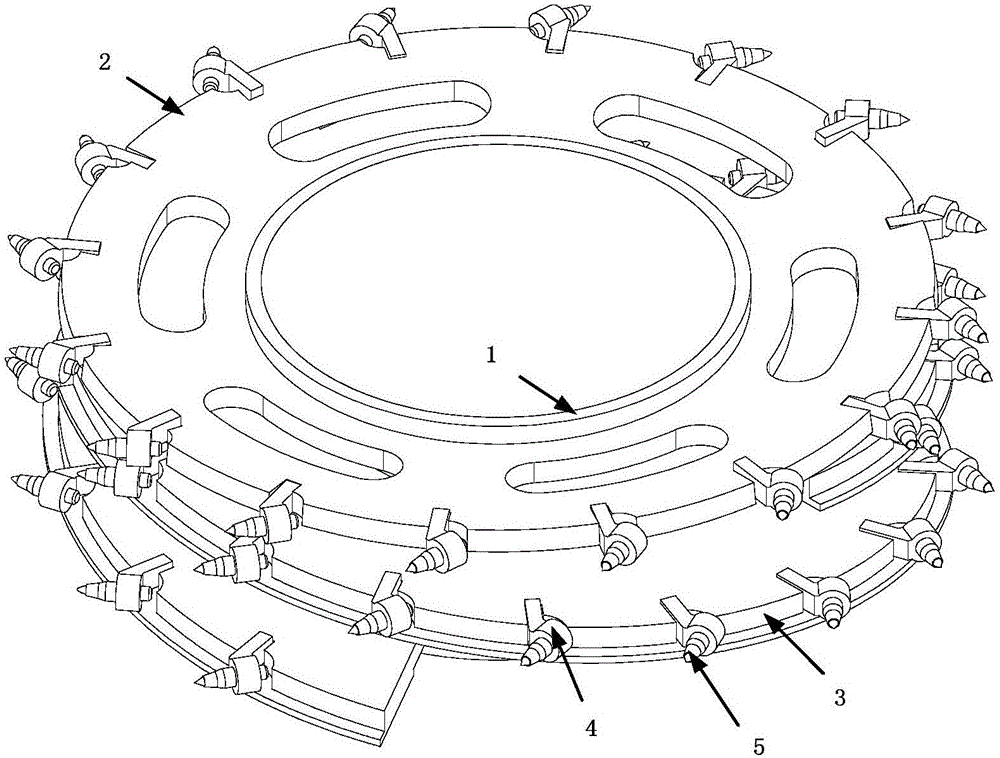

Method for extracting drum load spectrum of cutting unit of drum shearer

InactiveCN105956243AThe contrast effect is obviousHigh simulationSpecial data processing applicationsEngineeringRock sample

Owner:NORTHEASTERN UNIV

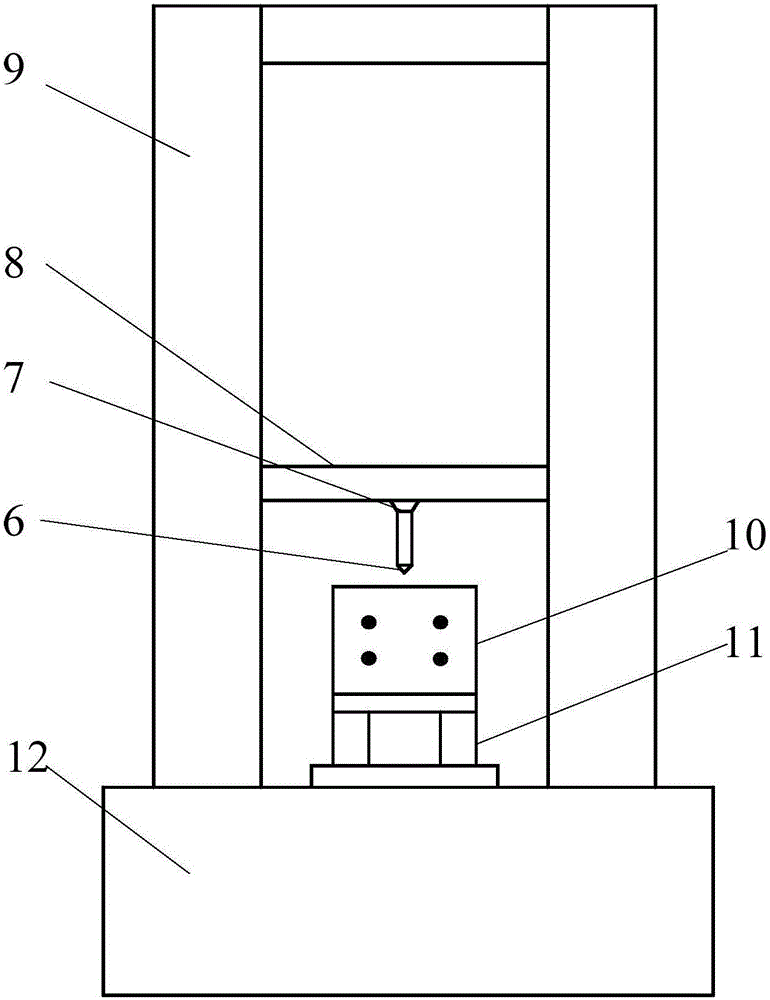

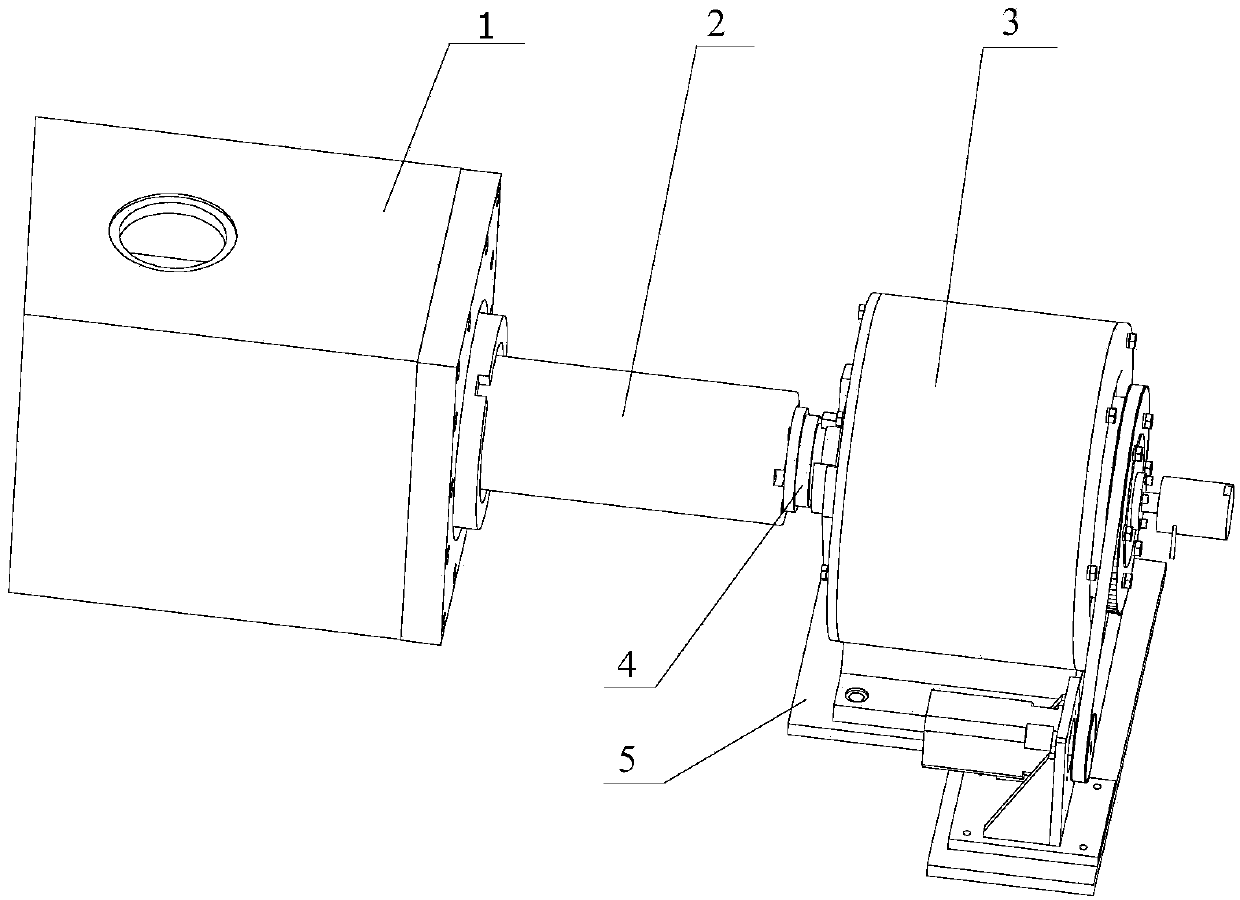

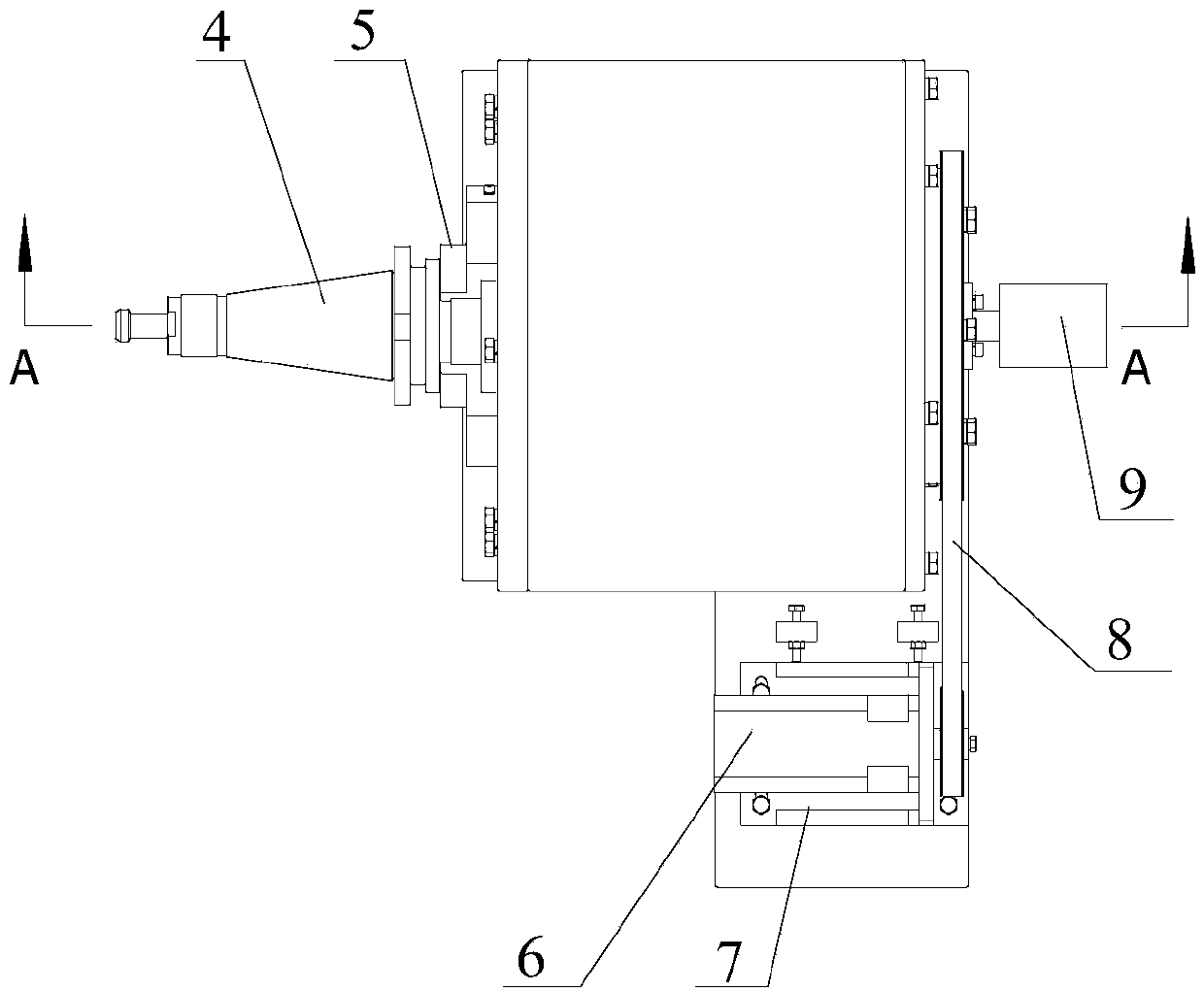

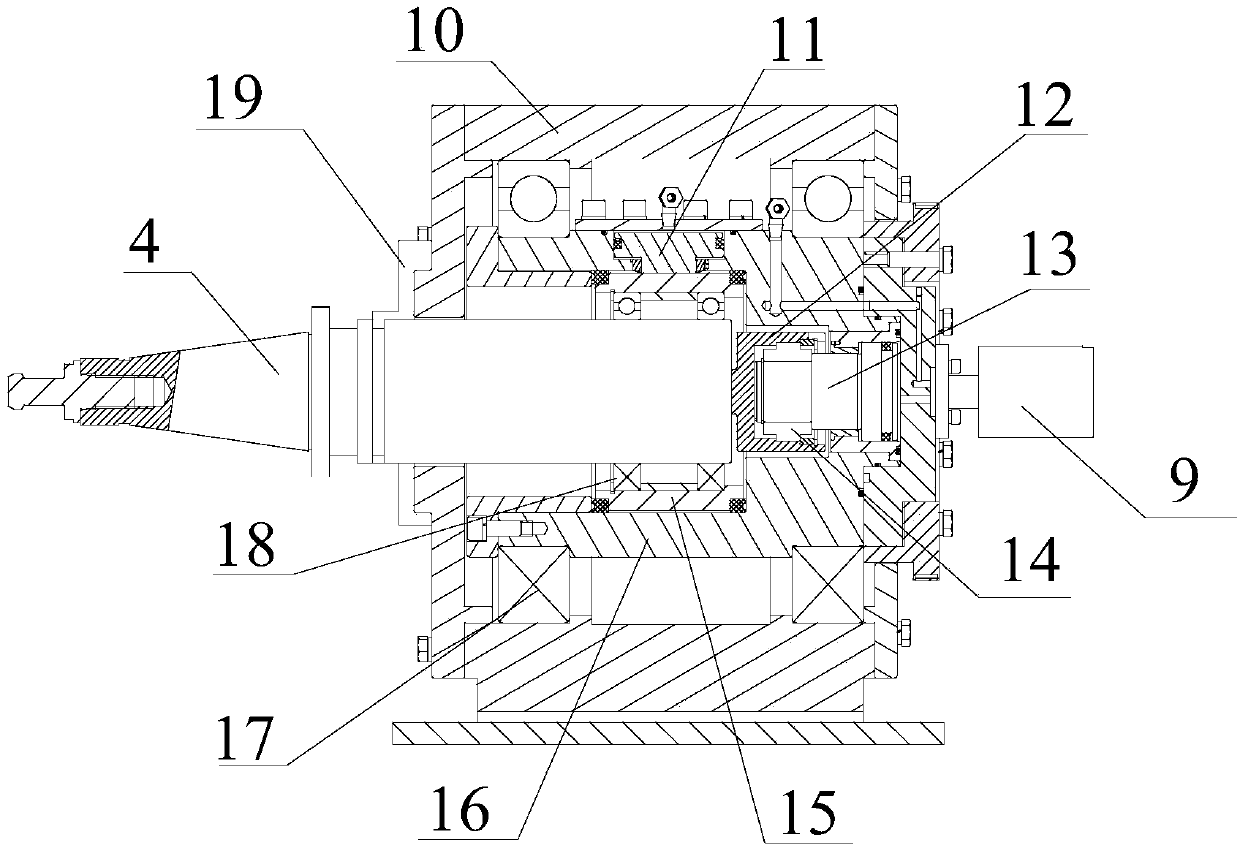

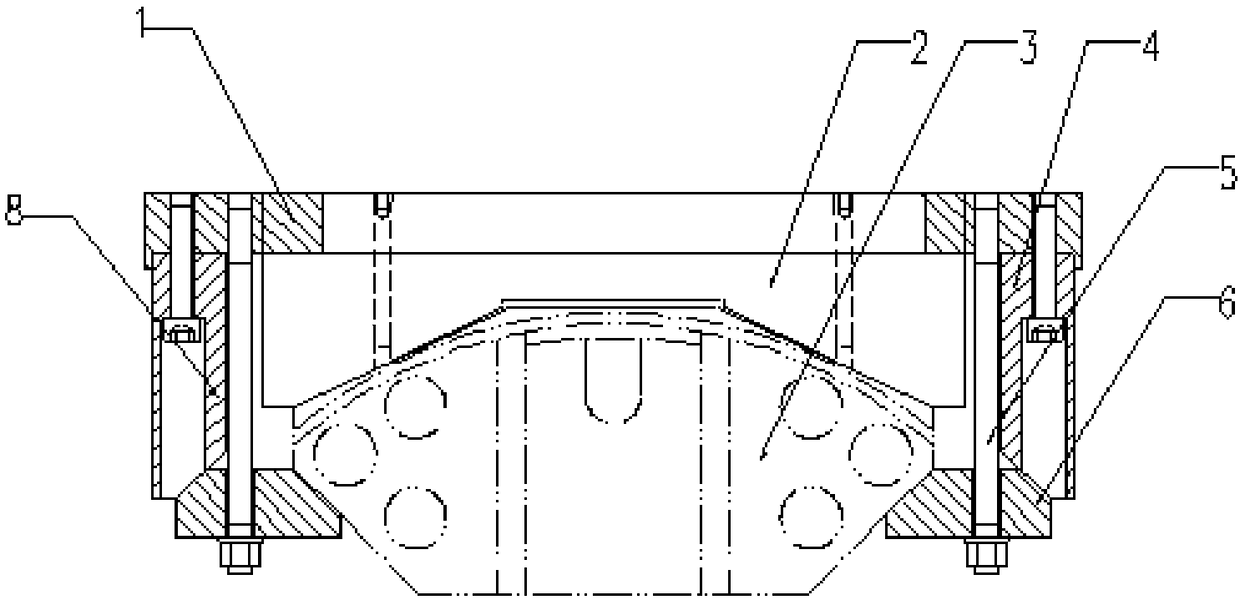

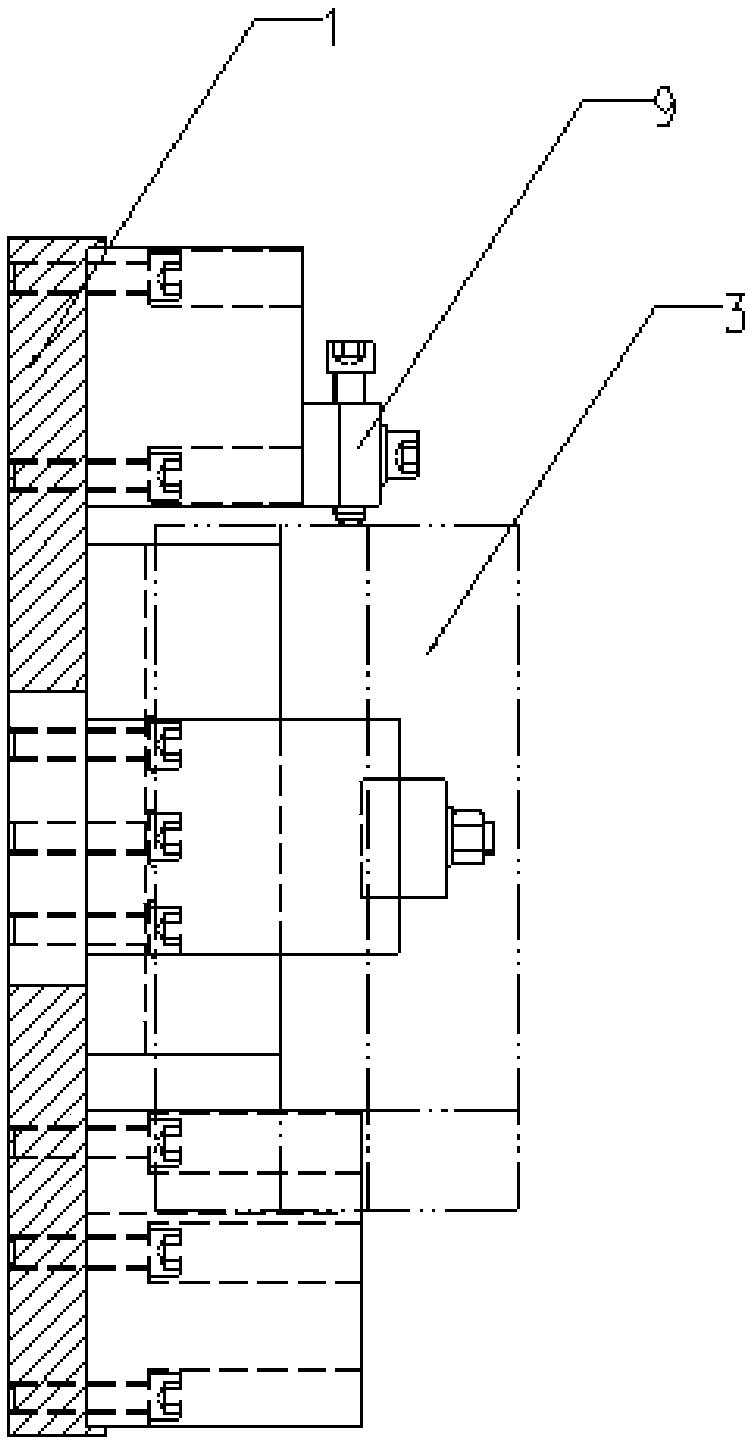

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

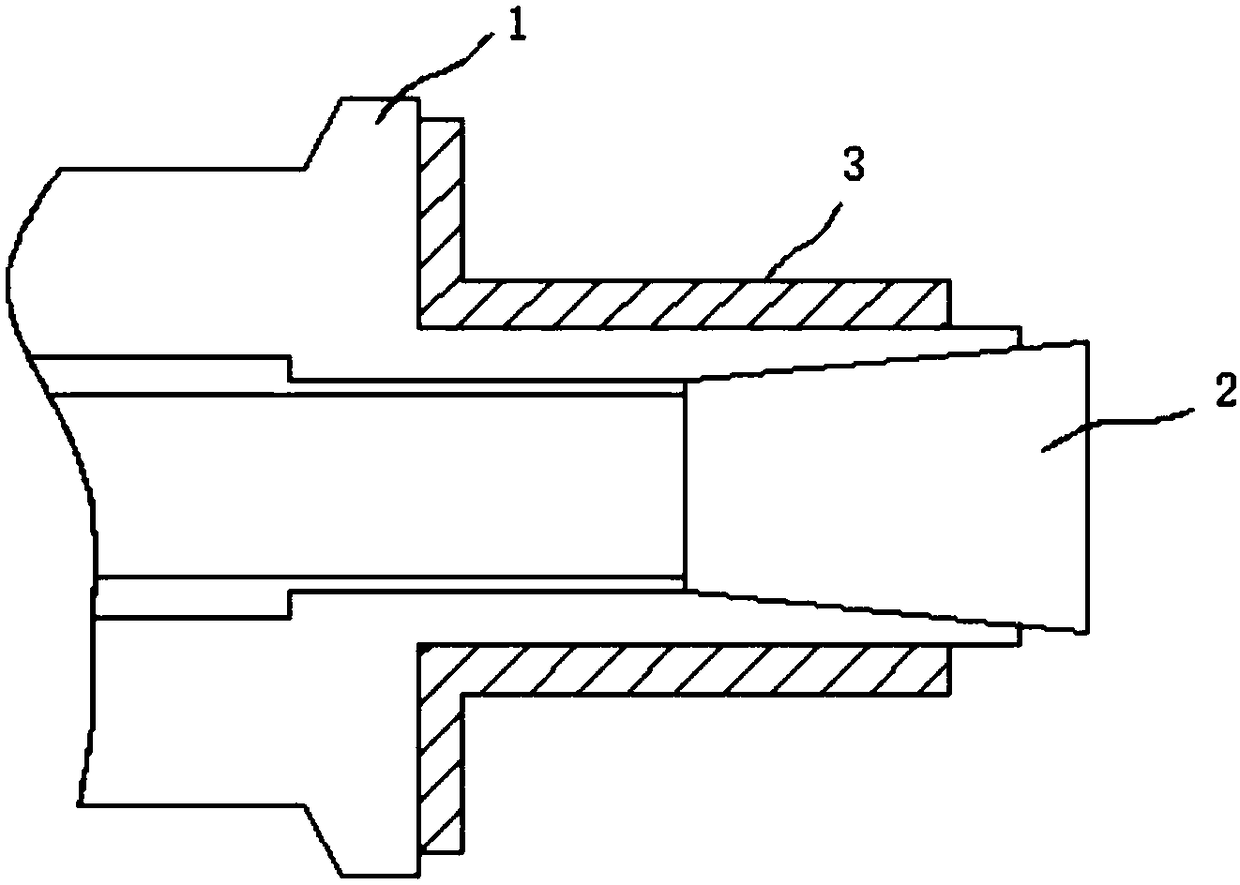

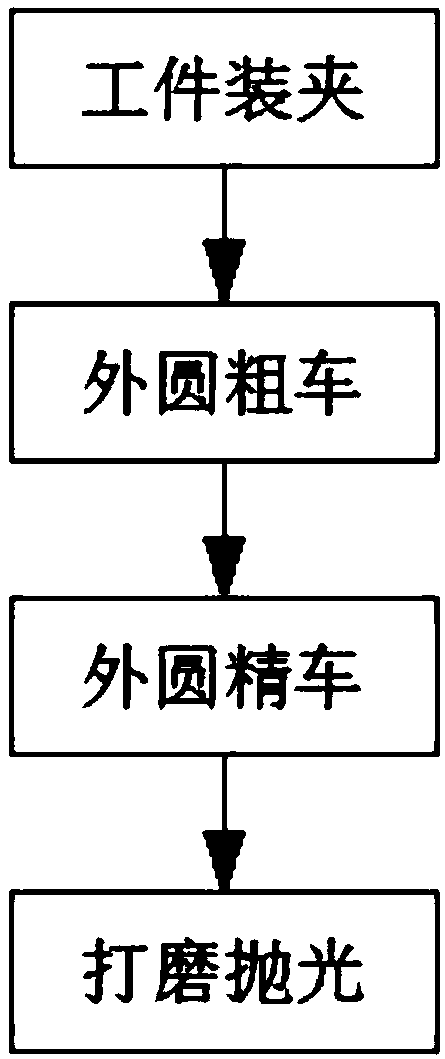

Finish turning method for external circular surface of thin-walled gear ring

InactiveCN108127128AEliminate cutting heatReduce radial forceRadial stressSurface roughness

Owner:JIANGYIN YONGXING MACHINERY MFG

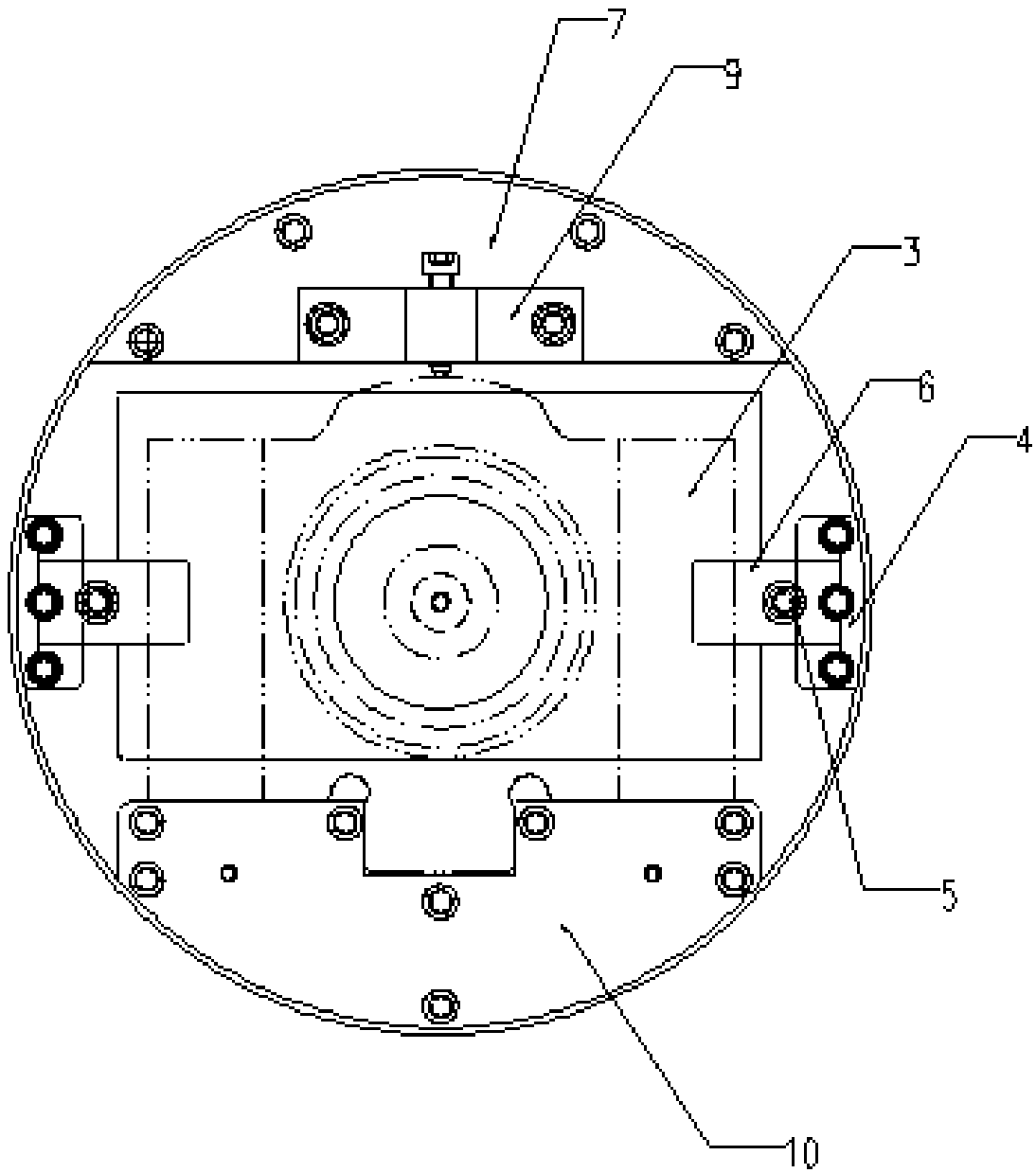

Turning and grinding tool for inner holes of bearing seat

Owner:无锡市万向联轴器有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap