Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Fused quartz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fused quartz or fused silica is glass consisting of silica in amorphous (non-crystalline) form. It differs from traditional glasses in containing no other ingredients, which are typically added to glass to lower the melt temperature. Fused silica, therefore, has high working and melting temperatures. Although the terms fused quartz and fused silica are used interchangeably, the optical and thermal properties of fused silica are superior to those of fused quartz and other types of glass due to its purity. For these reasons, it finds use in situations such as semiconductor fabrication and laboratory equipment. It transmits ultraviolet better than other glasses, so is used to make lenses and optics for the ultraviolet spectrum. The low coefficient of thermal expansion of fused quartz makes it a useful material for precision mirror substrates.

Capillary open tubular column based on silicon dioxide zeolite nanoparticles as well as preparation and application thereof

InactiveCN108318611AEfficient fillingIncrease the areaComponent separationSolid sorbent liquid separationWater bathsSolvent

The invention discloses a preparation method of a capillary open tubular column based on silicon dioxide zeolite nanoparticles. The preparation method comprises the following steps: mixing a silicon source, an alkali source and water according to certain proportion, stirring, clarifying, removing ethanol through water bath, and performing hydrothermal crystallization to obtain silicalite-1 silicondioxide zeolite nanoparticles; dispersing the prepared silicon dioxide zeolite nanoparticles into a solvent, adding into a bare fused quartz capillary, sealing the two ends of the capillary, and sintering at high temperature to prepare the capillary open tubular column based on the silicon dioxide zeolite nanoparticles. A capillary electrochromatography of the capillary open tubular column basedon the silicon dioxide zeolite nanoparticles is combined with an amperometric detection system, separation and analysis of homologous compounds and multiple groups of isomers such as branched chain isomerism, position isomerism and conformation isomerism can be realized. The capillary open tubular column is simple in preparation process, good in separation effect and low in analysis cost; by adoption of an amperometric detection technology, the detection sensitivity of the capillary electrochromatography technology can be further improved.

Owner:EAST CHINA NORMAL UNIV

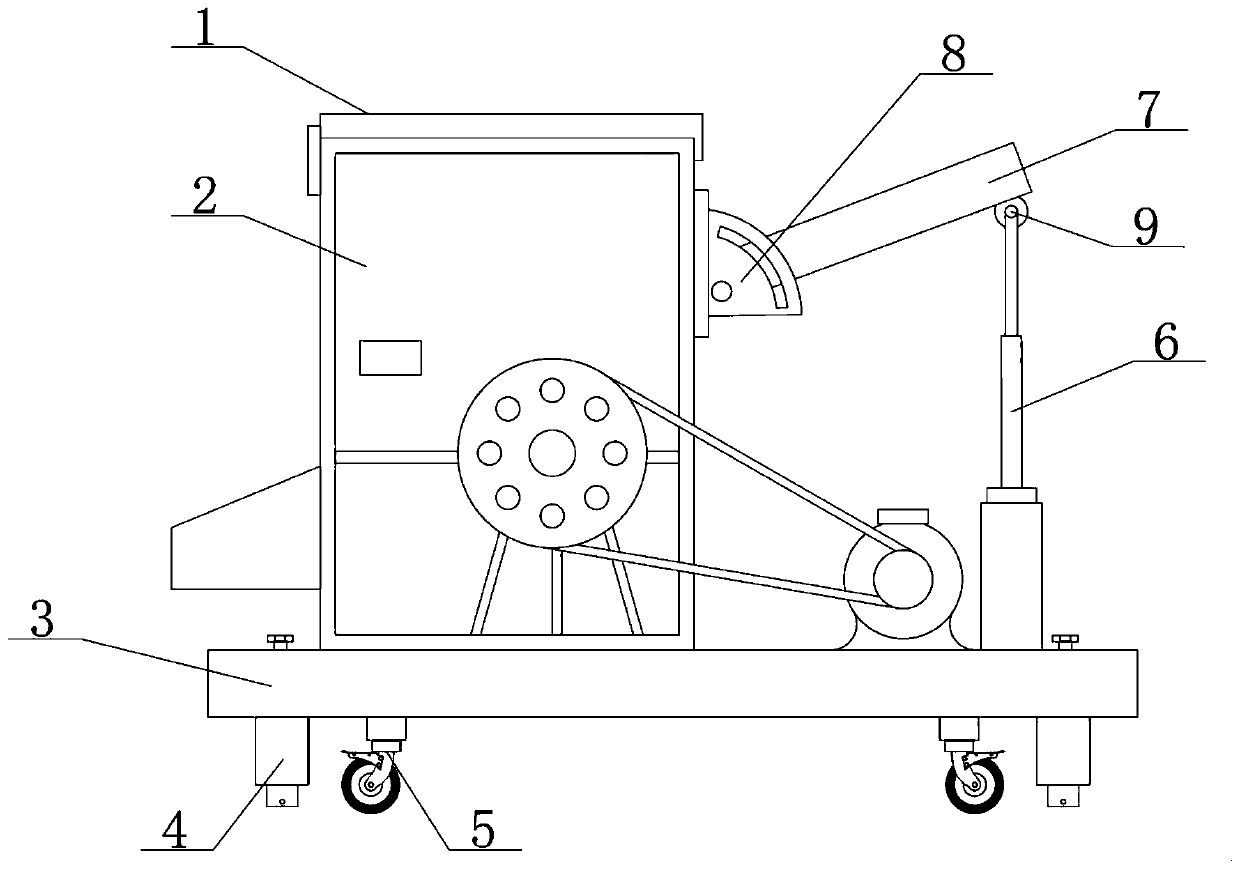

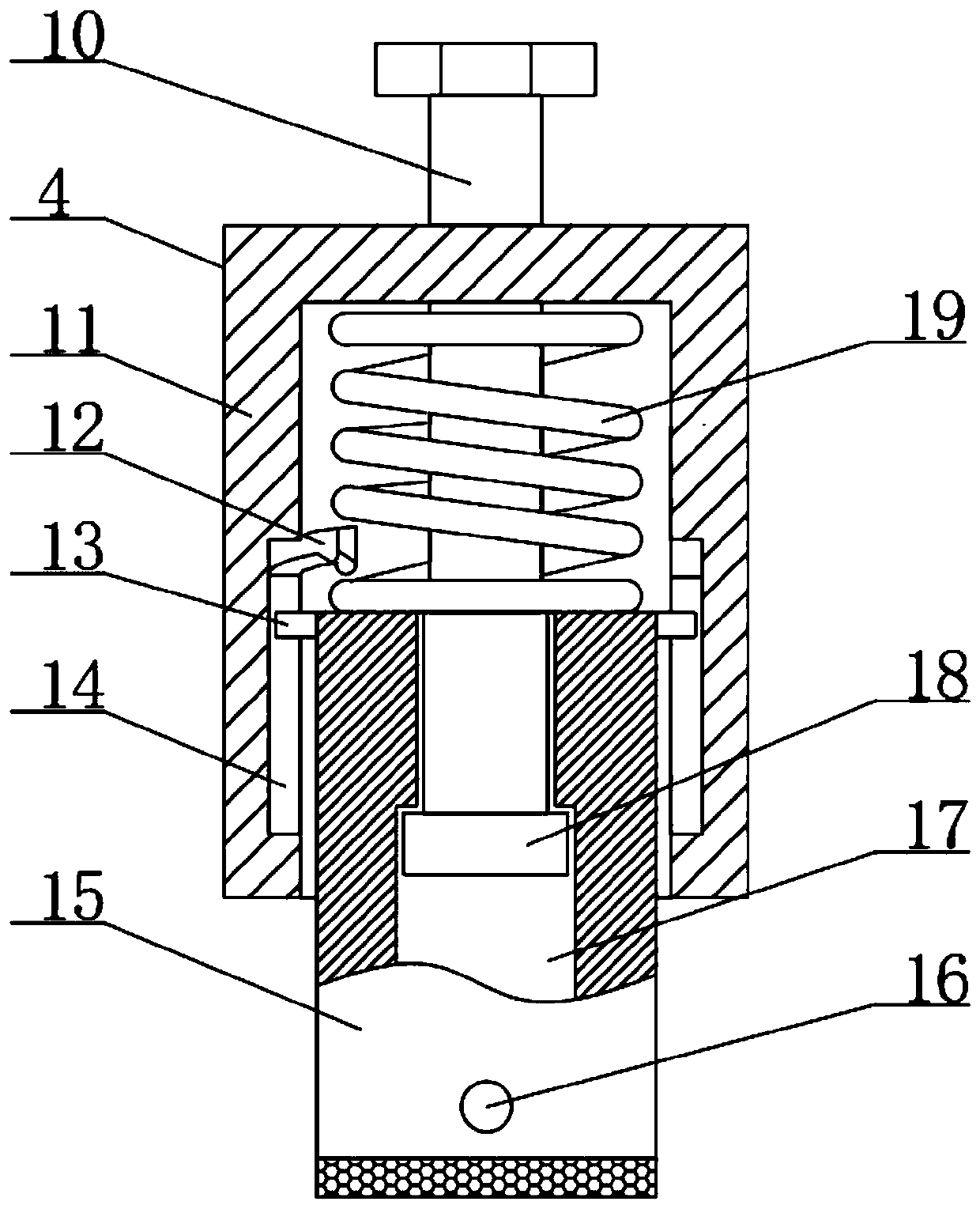

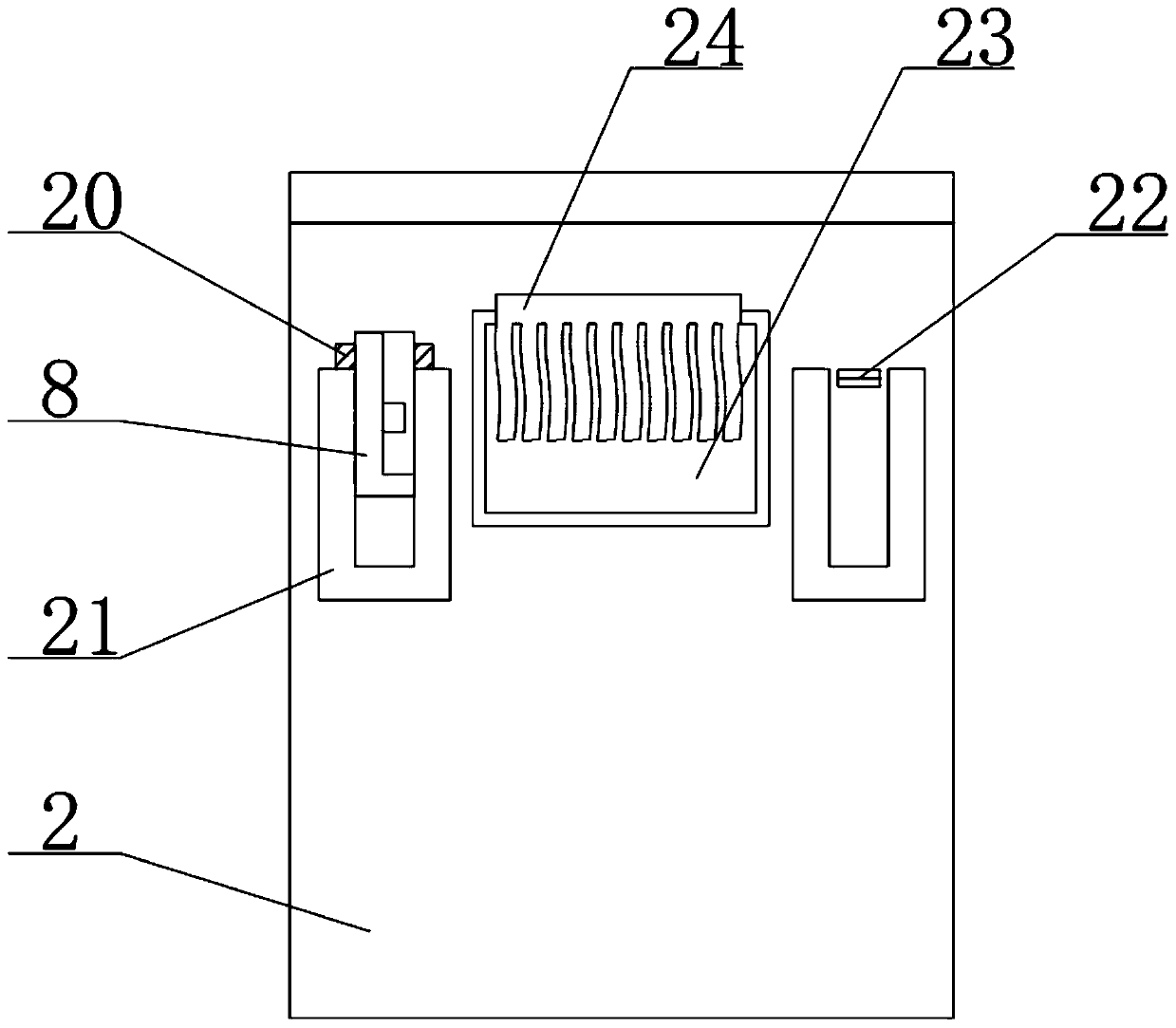

Quick-dismounted crushing device for high-purity fused quartz production

PendingCN110116042AEasy to moveMobile does not affectNon-rotating vibration suppressionGrain treatmentsMaterial resourcesEngineering

Owner:新沂市引河石英材料有限公司

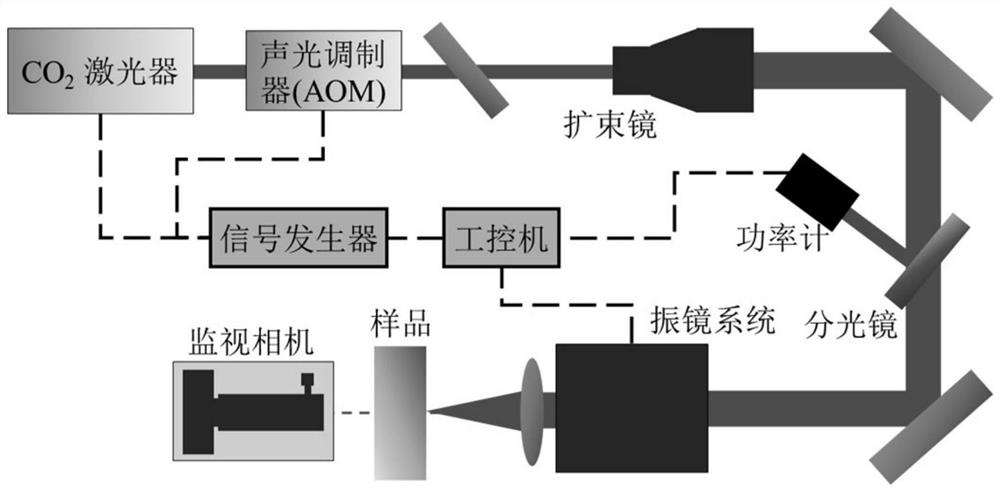

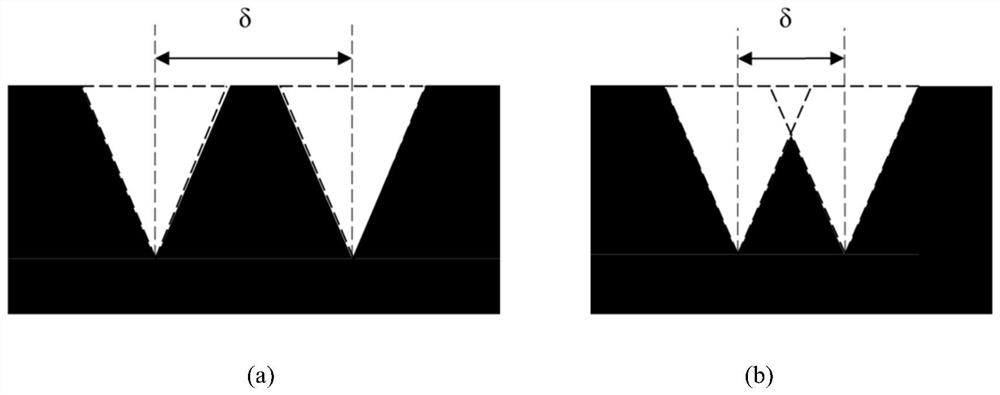

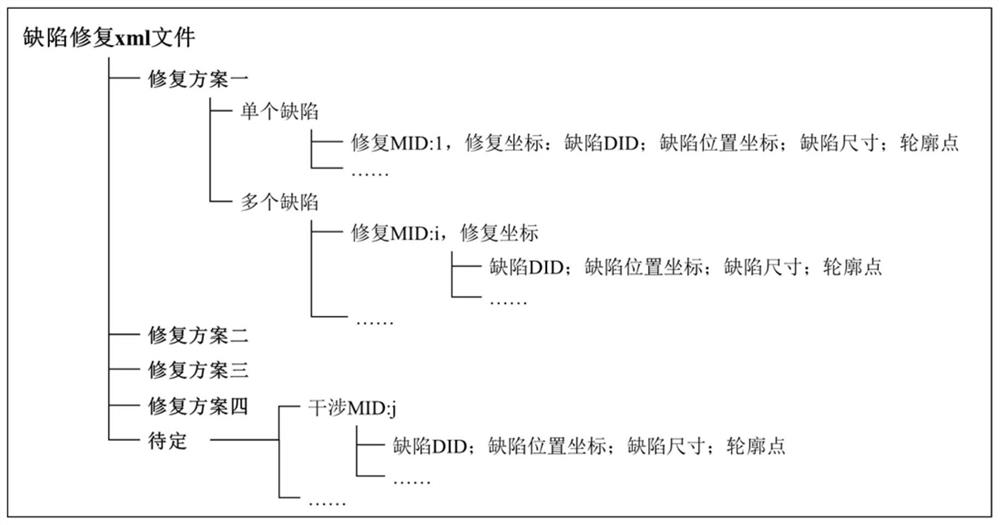

Automatic laser repairing method for surface microdefects of large-diameter fused quartz optical element

PendingCN114113111AEasy to analyzeReduce the number of adjustmentsOptically investigating flaws/contaminationEngineeringMechanical engineering

Owner:HARBIN INST OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap