Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Round bar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

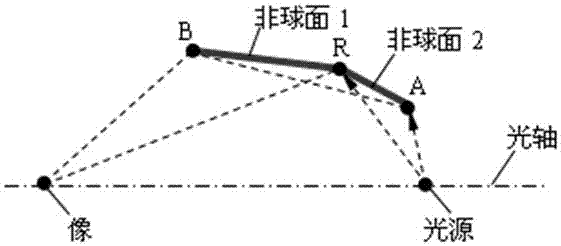

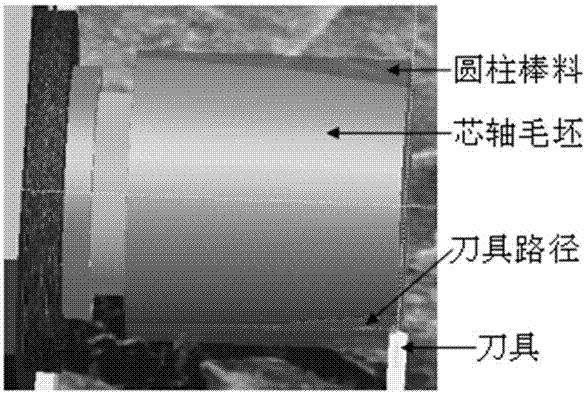

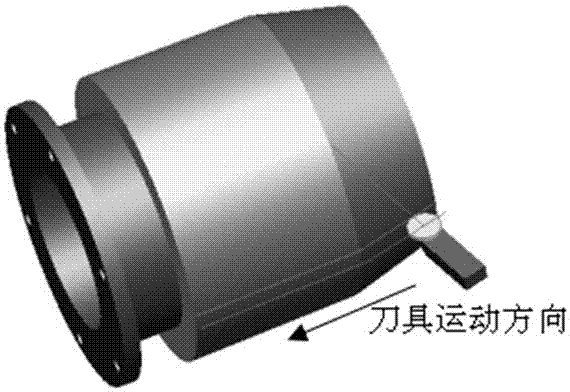

Manufacturing technology of Wolter-I type precision core shaft

ActiveCN107570967ARound barChemical plating

Owner:HARBIN INST OF TECH

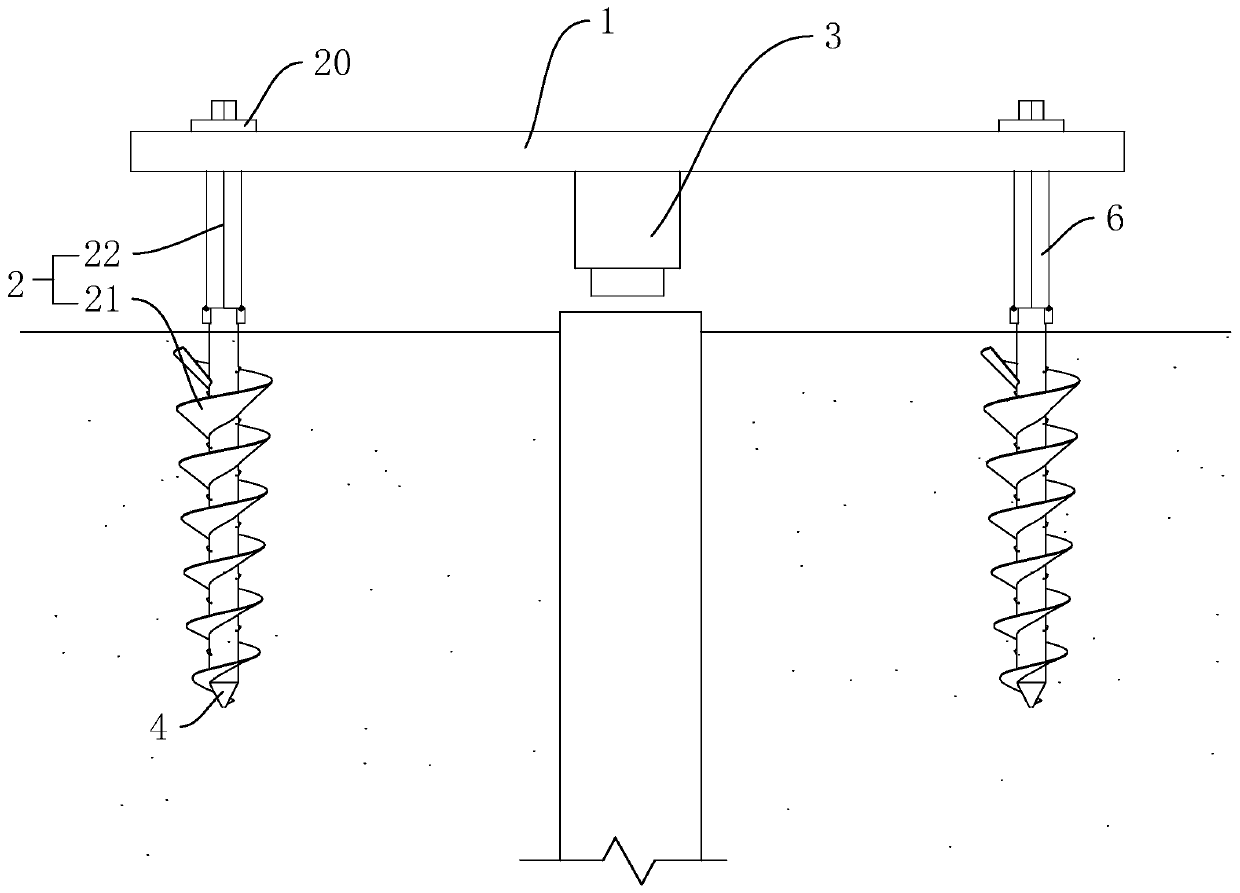

Pile foundation static load compression resistance testing device

ActiveCN111119255AAvoid reinforcementAvoid processing powerFoundation testingRound barTest rig

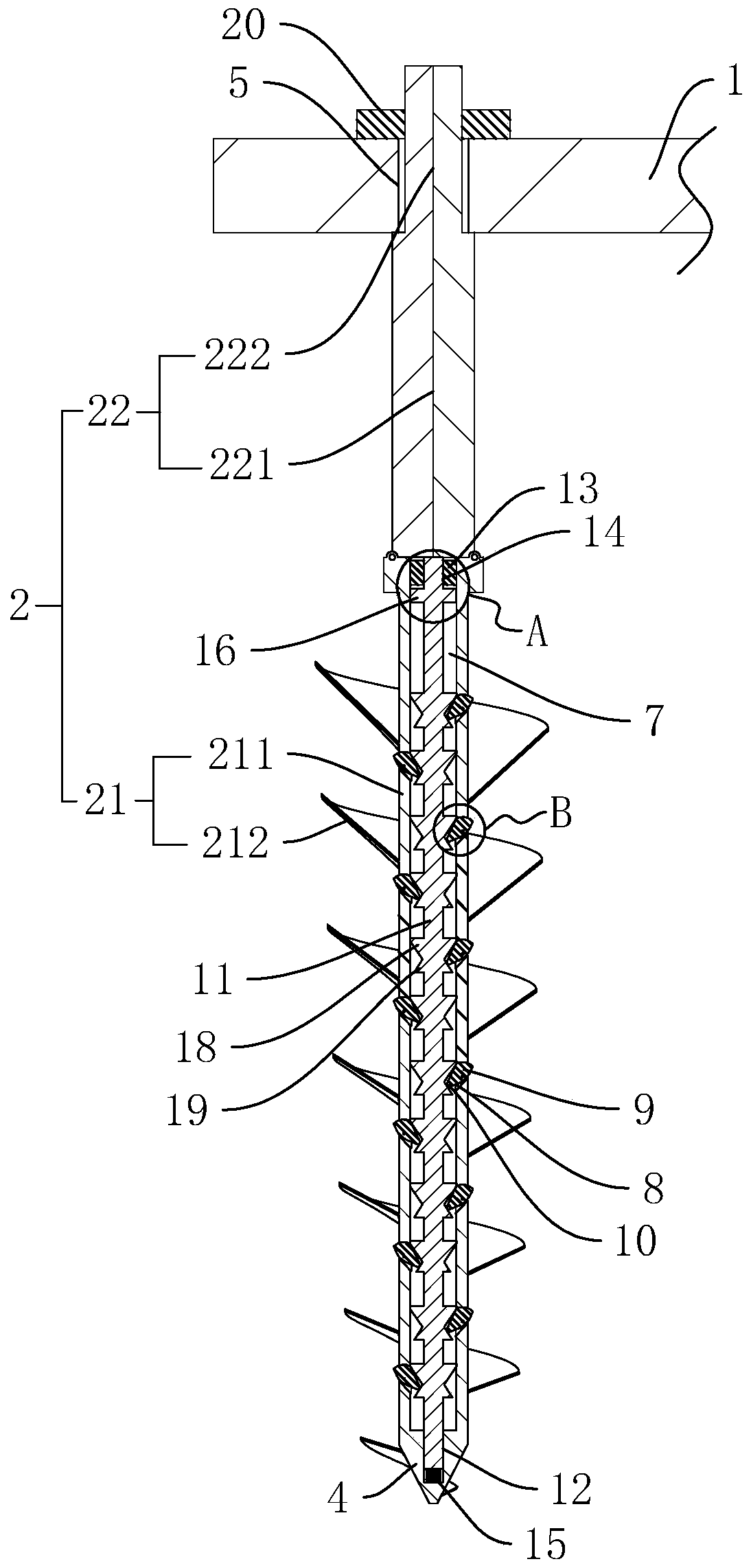

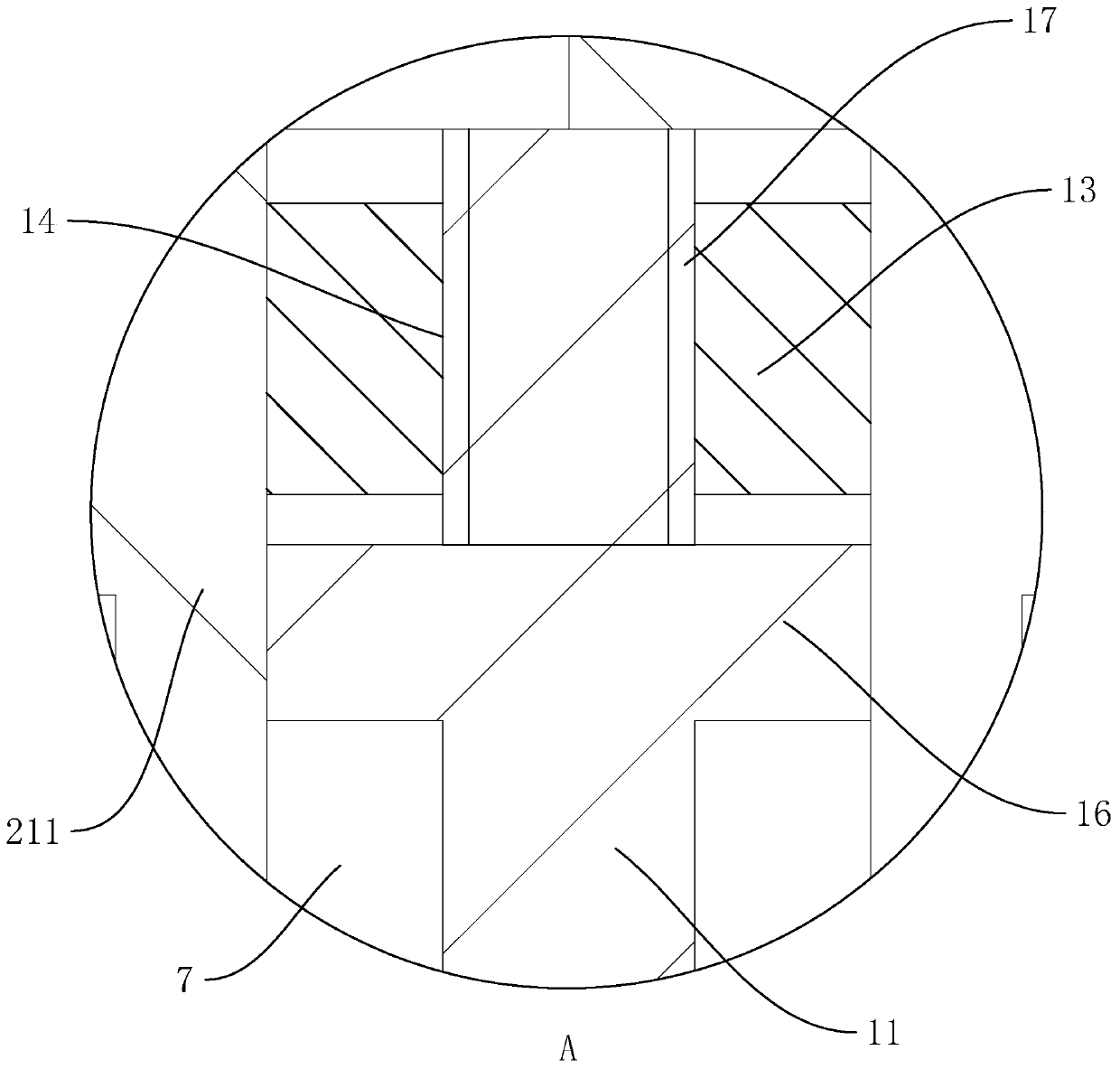

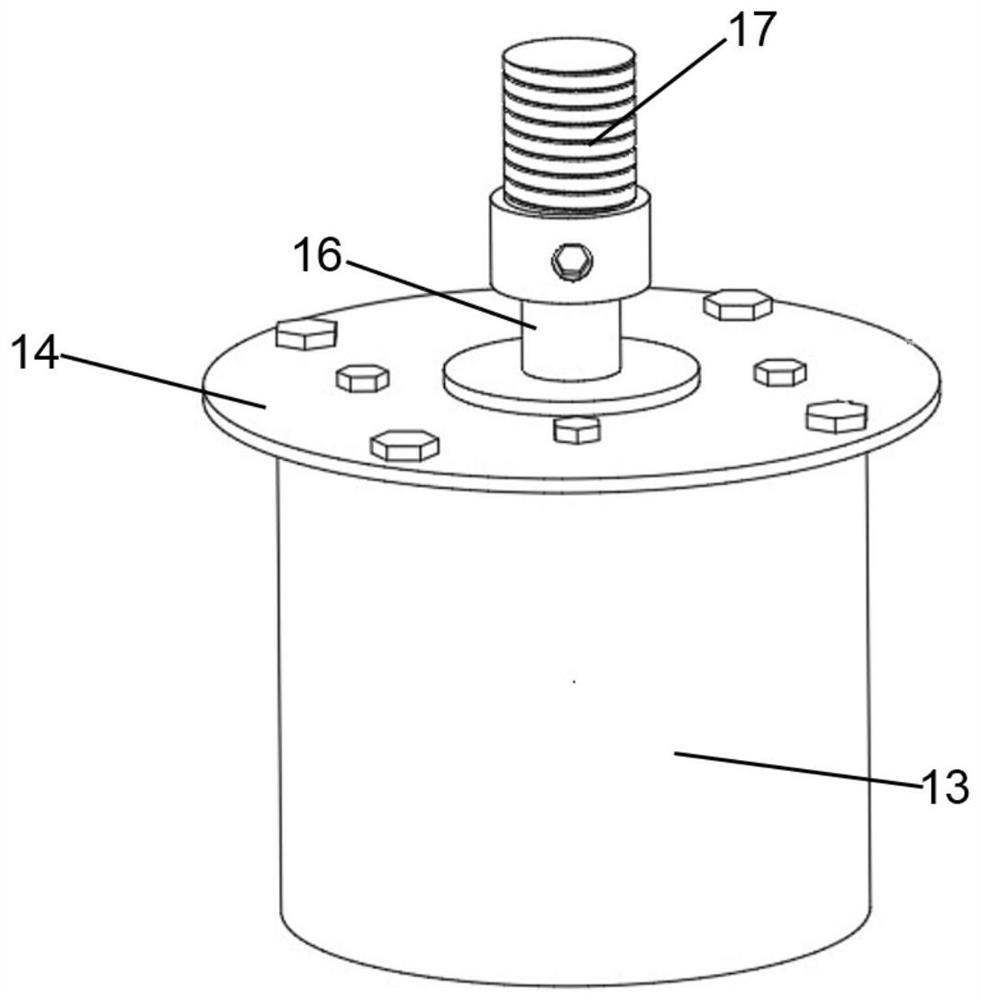

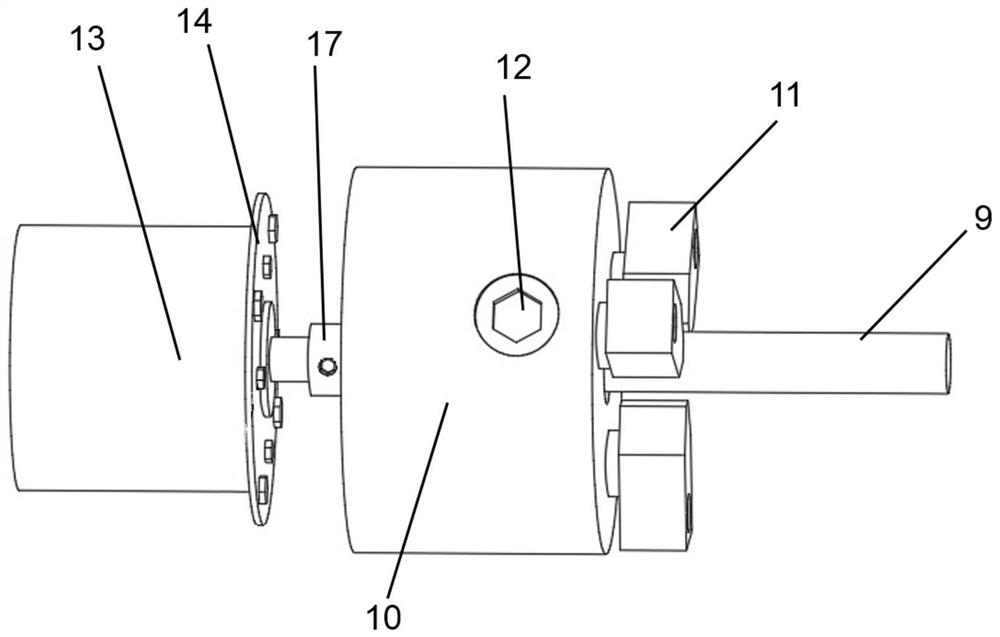

The invention discloses a pile foundation static load compression resistance testing device, and relates to the technical field of building detection. The pile foundation static load compression resistance testing device comprises a main beam used for being arranged at the position above a to-be-tested pile foundation. A hydraulic cylinder is arranged at the lower end of the main beam. The main beam is further provided with two supporting assemblies used for supporting the main beam. The two supporting assemblies are located on the two sides of the to-be-tested pile foundation correspondingly.Each supporting assembly comprises a fixing part used for being inserted into the ground for fixation and a connecting part which is arranged above the corresponding fixing part and further connectedwith the main beam. Each fixing part comprises a round bar and a screw sheet which is spirally and fixedly connected to the outer side wall of the round bar in the axial direction of the round bar. Guiding parts are formed at the ends, far away from the connecting parts, of the fixing parts. Due to arrangement of the supporting assemblies, the fixing parts of the supporting assemblies and the ground are fixed to form large supporting force, the trouble of ground stabilization or filling replacement treatment is saved, and the pile foundation static load compression resistance testing device is made more convenient to use on the whole. In addition, the weight requirement for the main beam is greatly lowered, the number of heavy objects above is smaller, risks caused by heavy object hoisting are reduced and the overall testing safety is made better.

Owner:台州市椒江建设工程质量检测中心有限公司

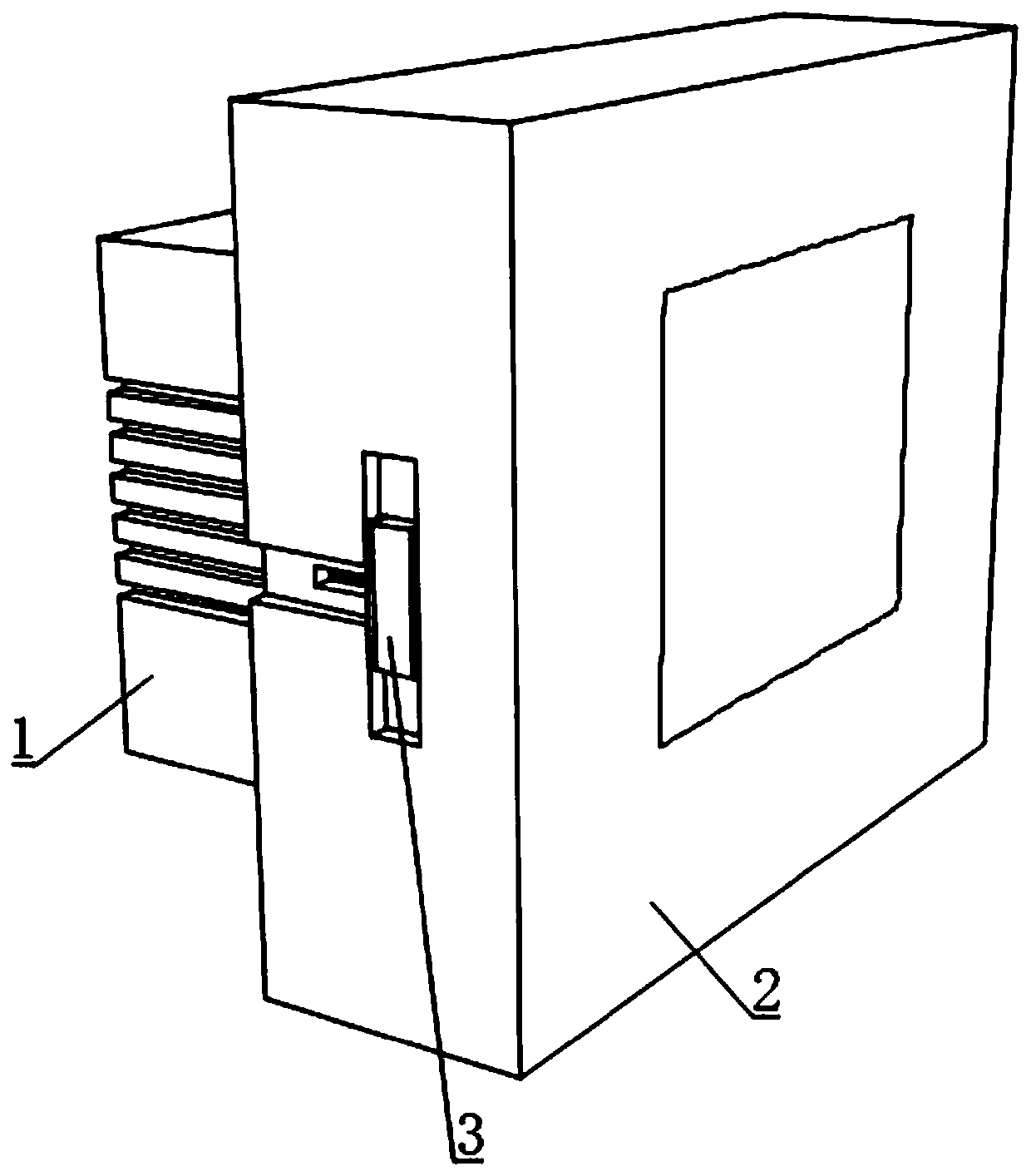

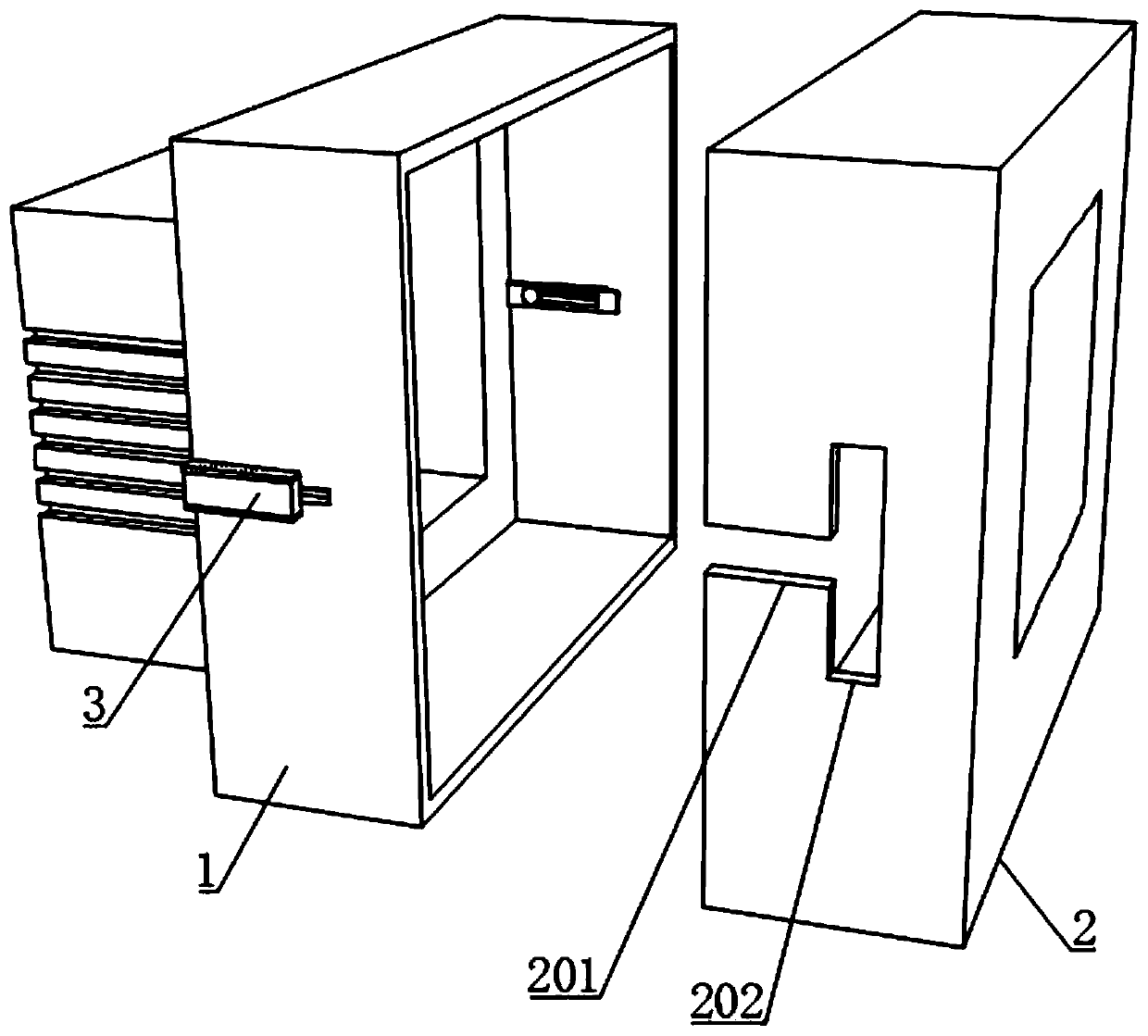

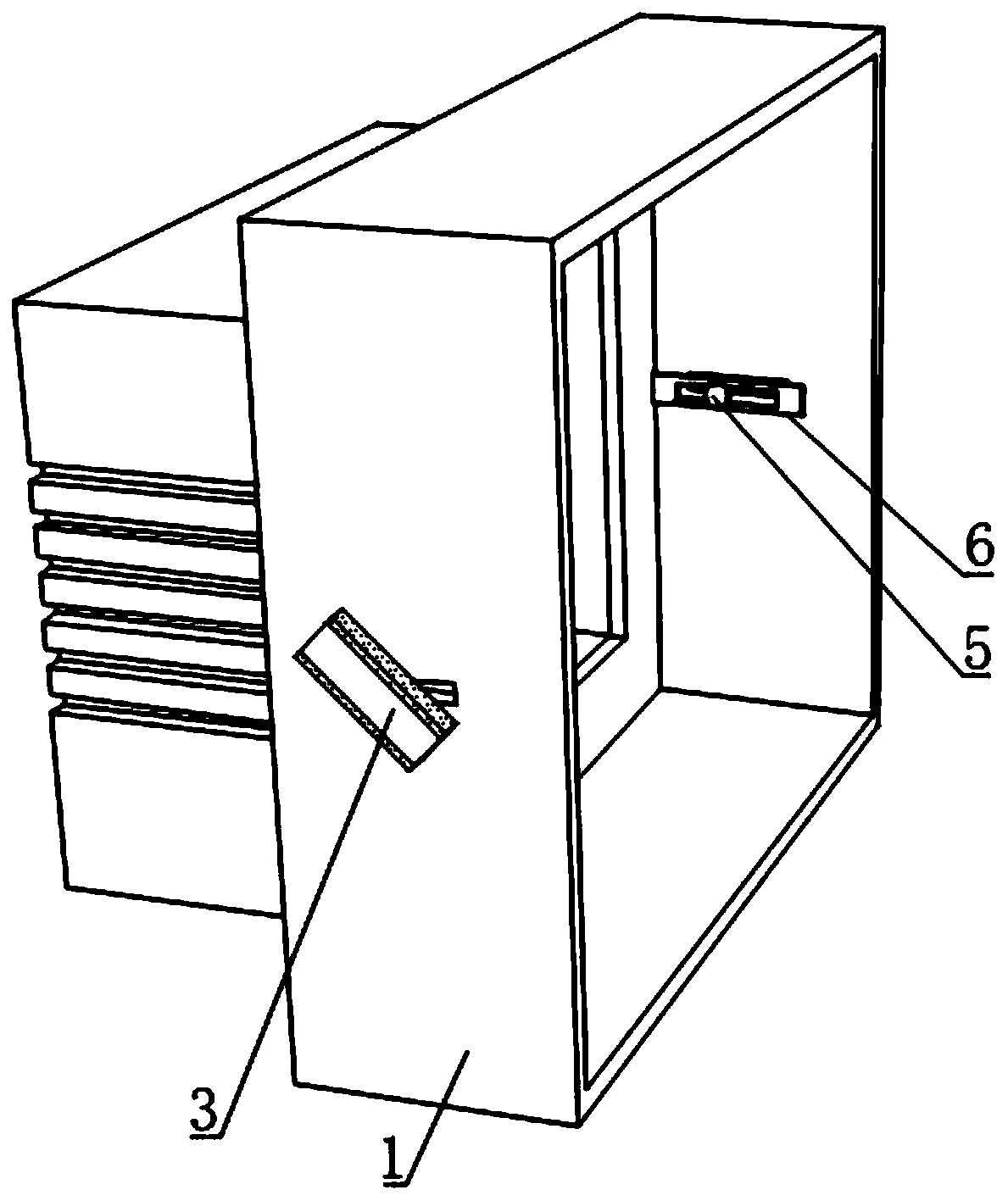

Intelligent 5G switch with shell convenient to disassemble and assemble

Owner:WENZHOU GUANGTAI ELECTRICAL APPLIANCE

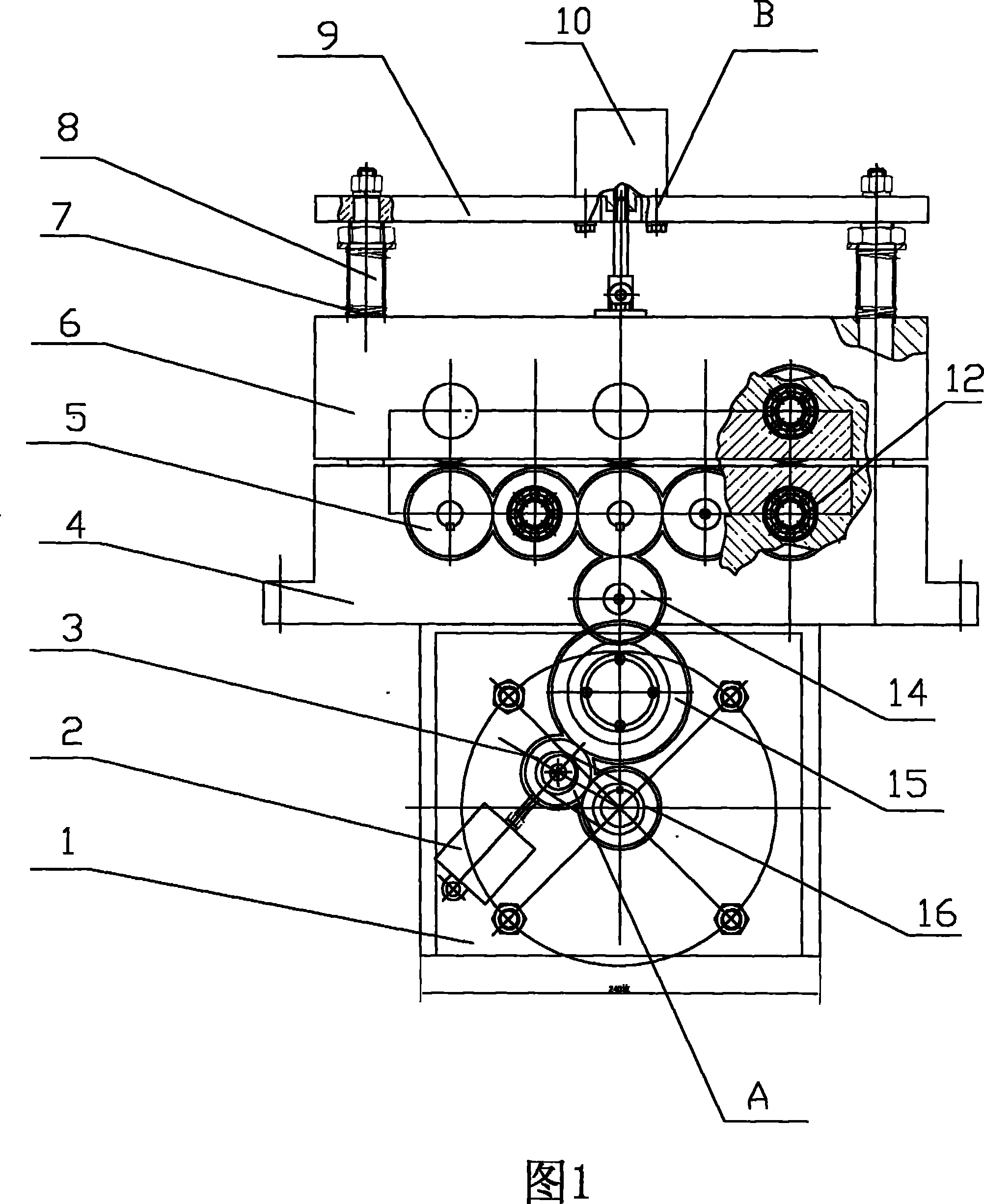

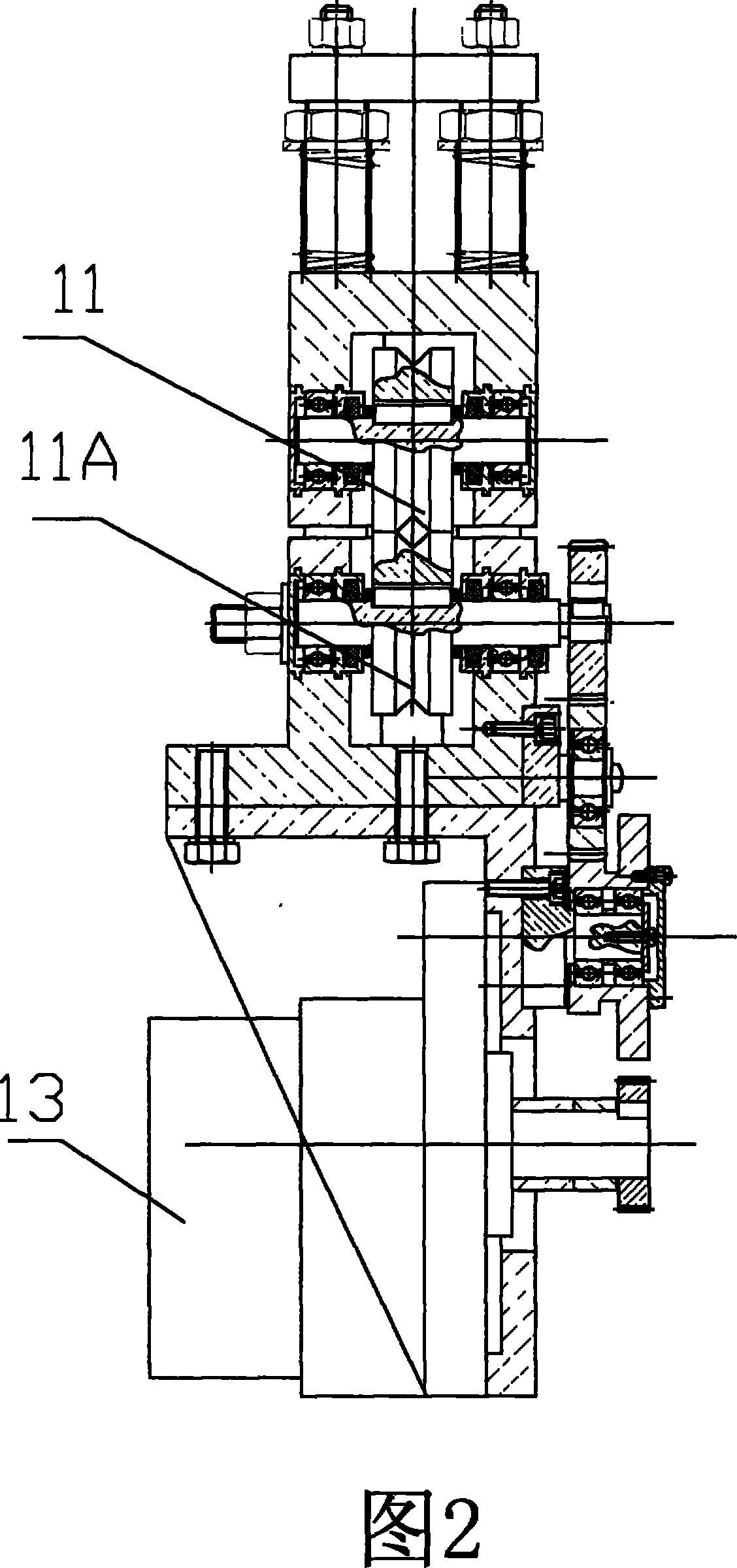

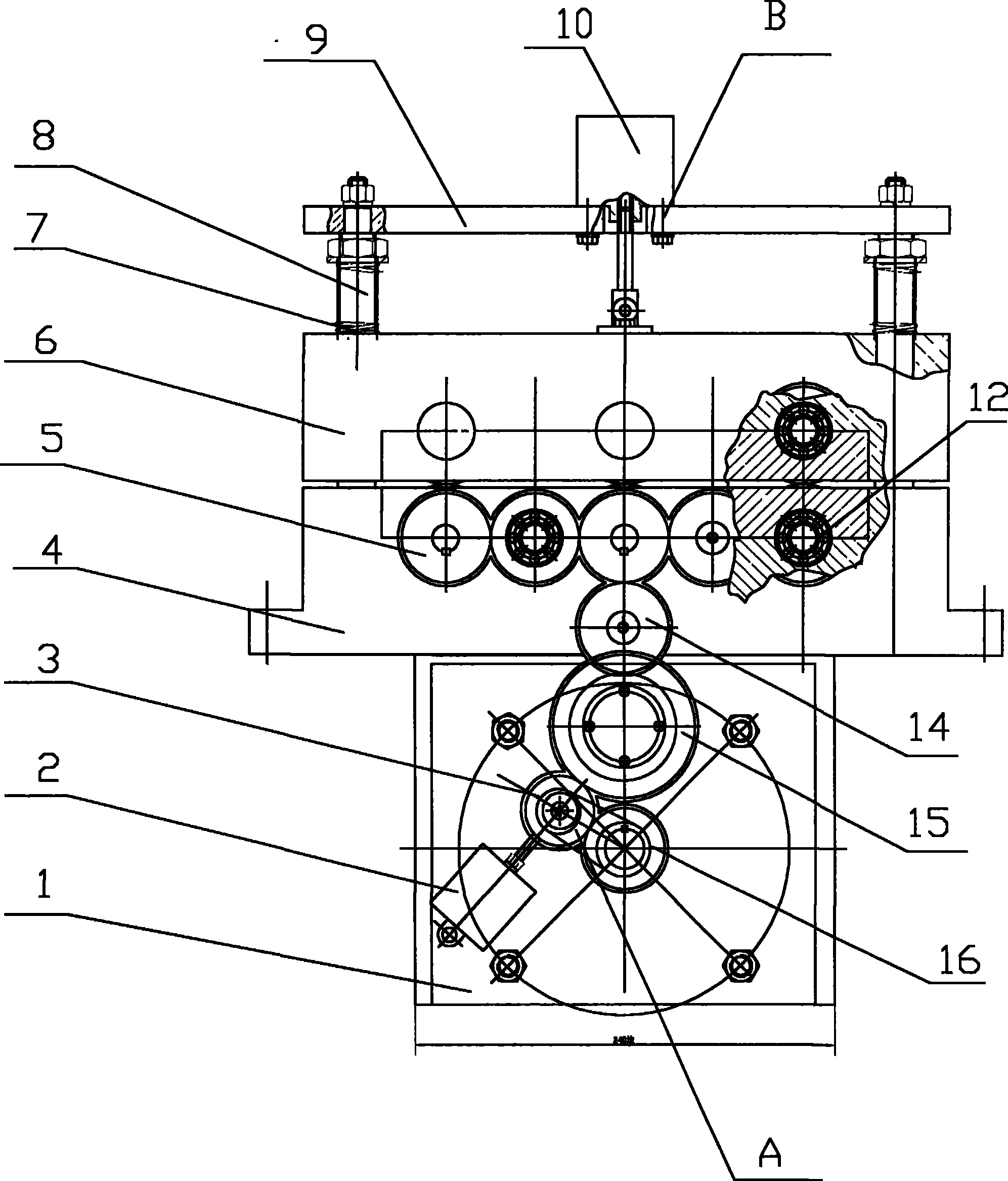

Traction engine

Owner:GUANGDONG UNIV OF TECH

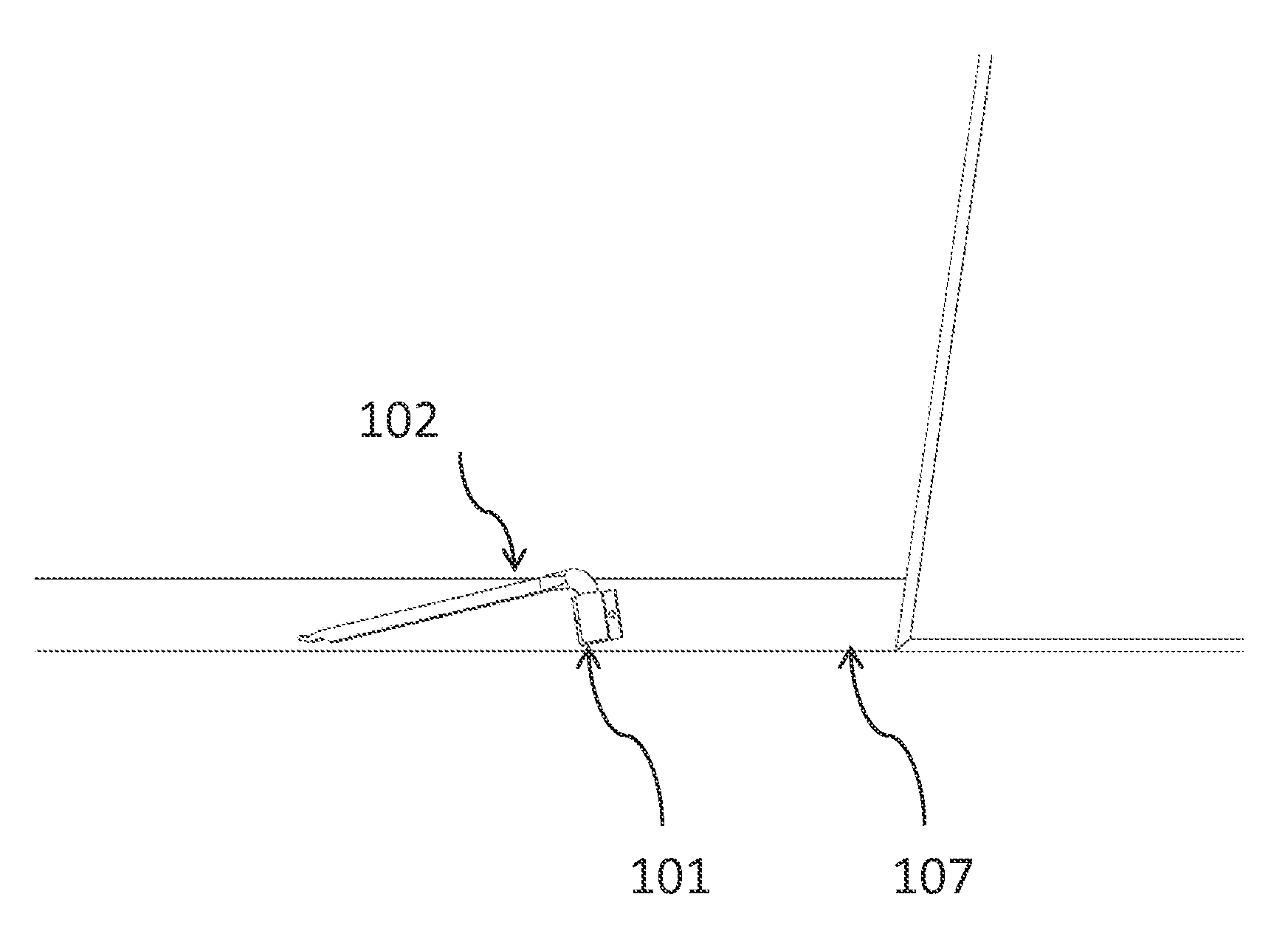

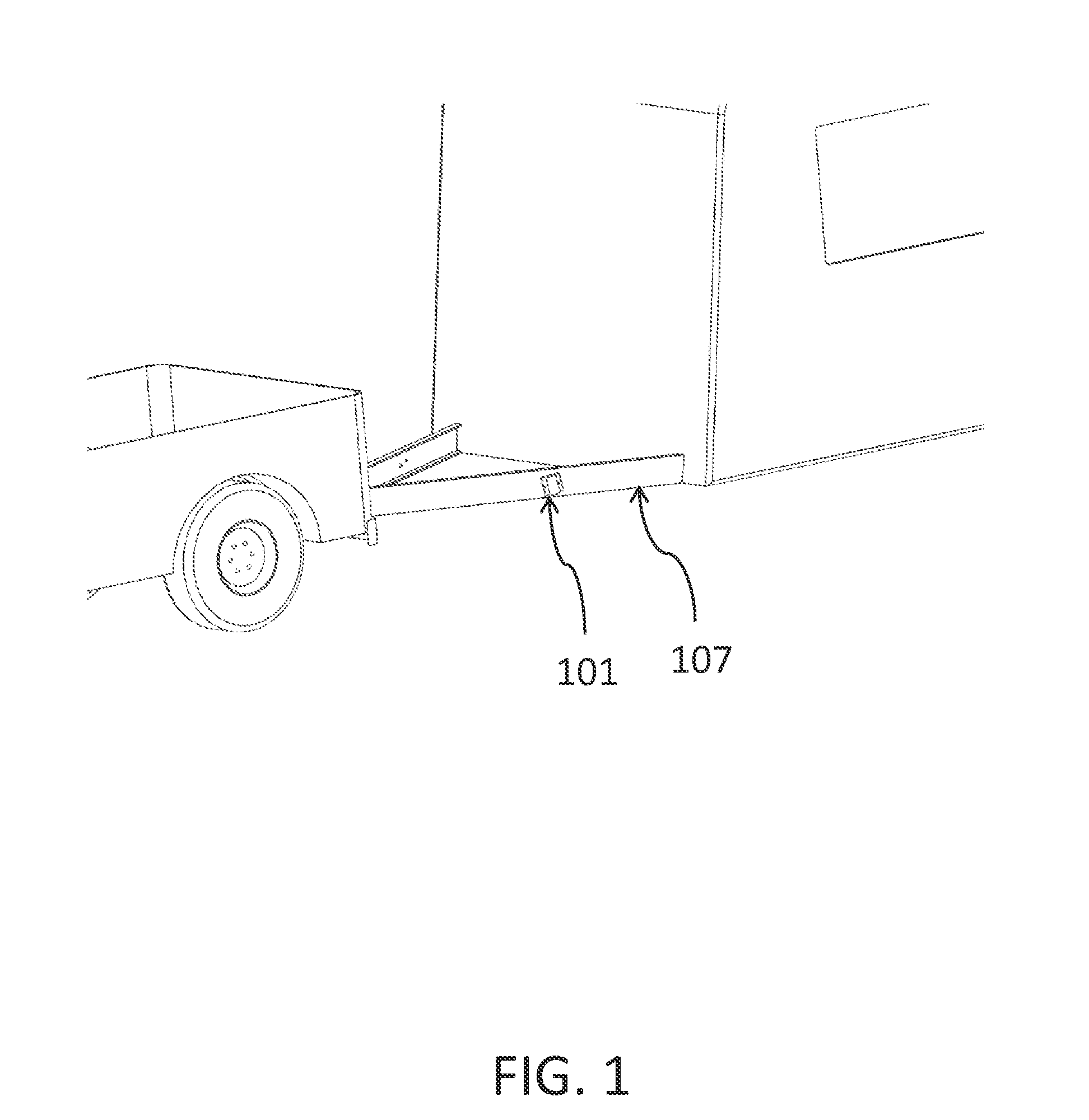

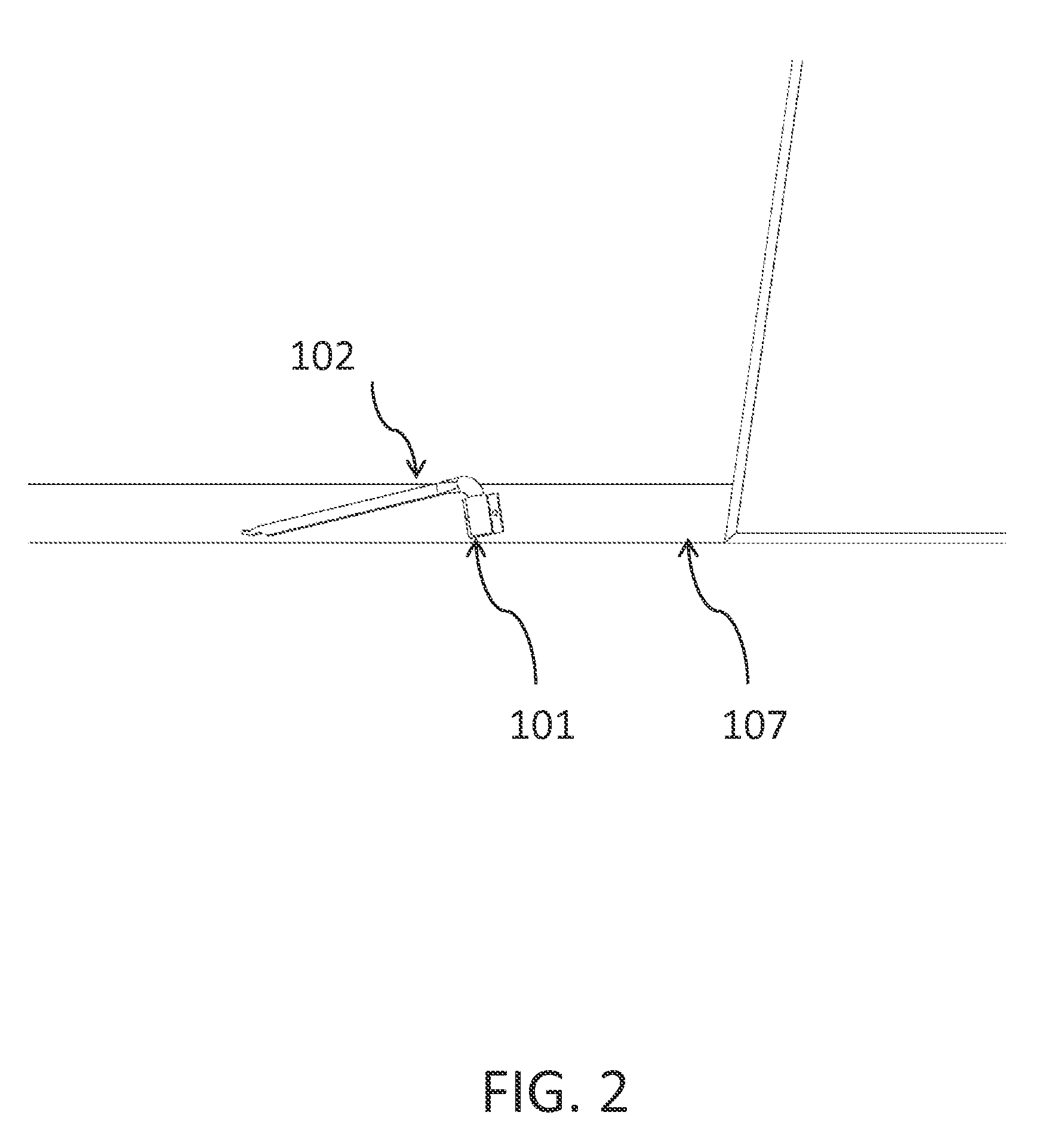

Weight Distribution System Round Bar Storage Bracket System

Owner:CRAMER MICHAEL +1

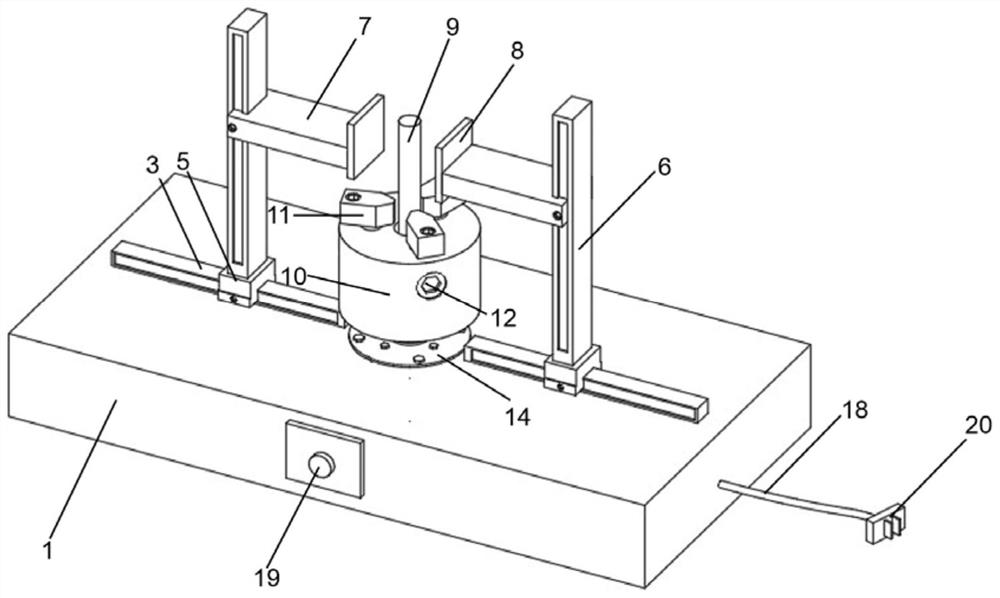

Simple round bar sample surface treatment device

The invention discloses a simple round bar sample surface treatment device, and belongs to the technical field of sample surface treatment equipment. The simple round bar sample surface treatment device comprises a fixing table, wherein two symmetrically-arranged fixing bottom plates are installed on the fixing table, first sliding blocks are arranged on the fixing bottom plates, vertical beams are fixedly installed at the upper ends of the first sliding blocks, second sliding blocks are installed on the vertical beams, and fixing plates are arranged at the outer ends of the second sliding blocks; and a high-speed motor is arranged in the fixing table and located between the two fixing bottom plates, and a three-jaw chuck is arranged on the upper portion of the high-speed motor. The three-jaw chuck is arranged, so that a round bar sample is conveniently and quickly fixed, and the required surface of a sample is polished by adjusting the position of the round bar and the position of thefixing plate; and the motor is controlled to be started and stopped through the arranged control button, the use safety is improved, the motor rotates to drive the round bar to move to rub with abrasive paper pasted to the fixing plate, and therefore manpower is saved, the work efficiency is improved, and the machining cost is greatly reduced.

Owner:ZHEJIANG UNIV OF TECH

Nano-rare earth permanent magnetic material and method for preparing the same

InactiveCN101154490BNo crackMeet the needs of engineering applicationsInorganic material magnetismMagnetic phaseMetallurgy

Owner:NINGBO UNIV

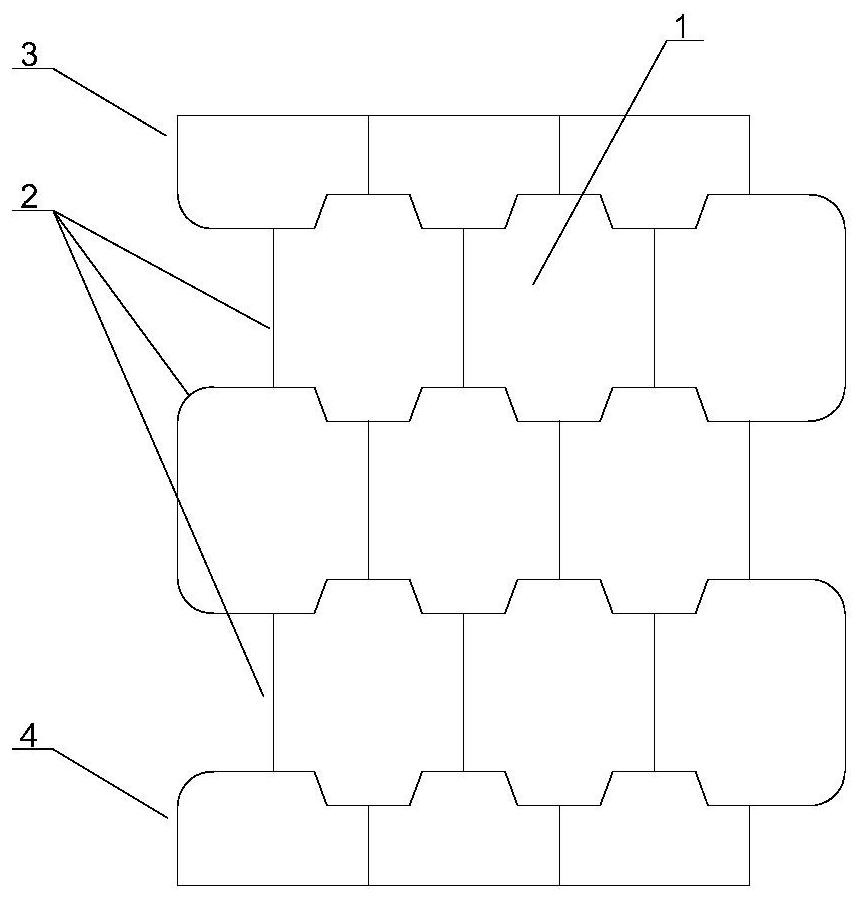

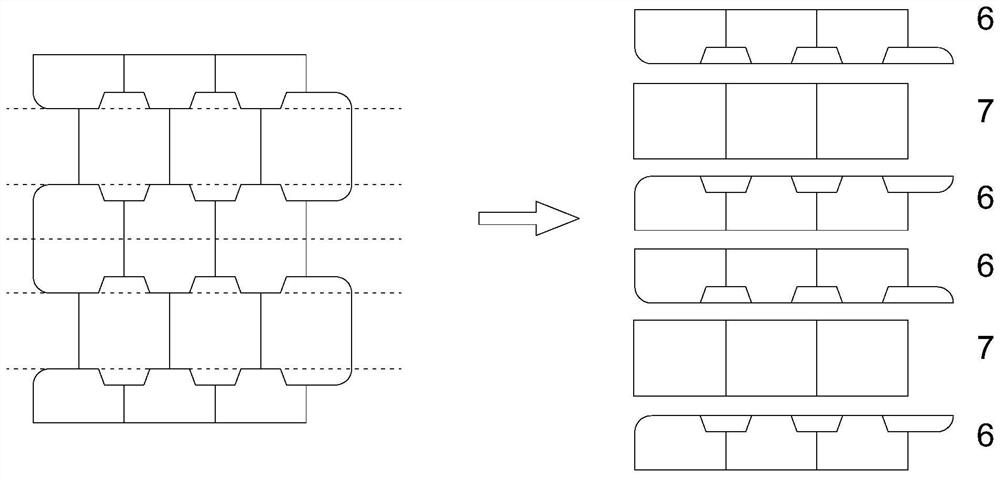

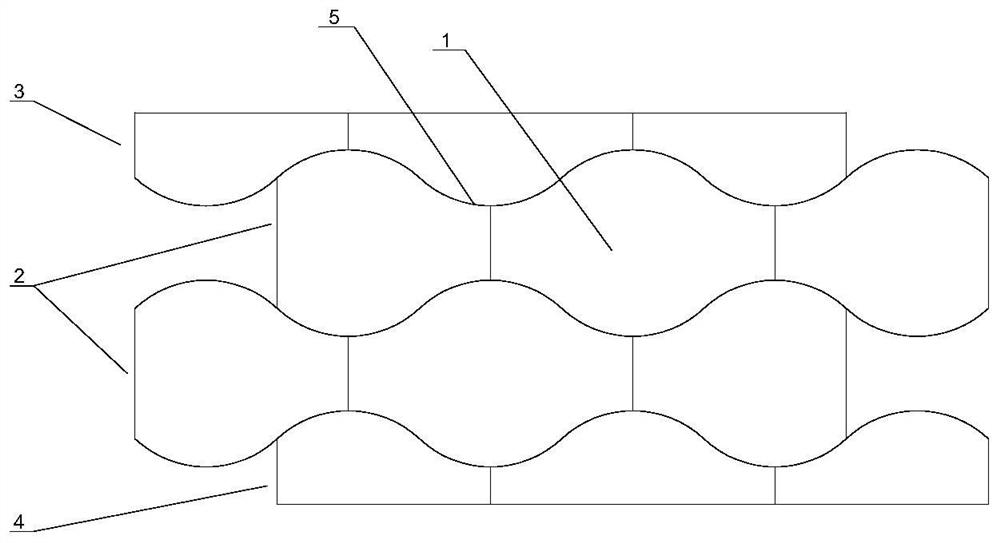

Batten splicing structure

Owner:刘康元

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap