Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Ultrasonic device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

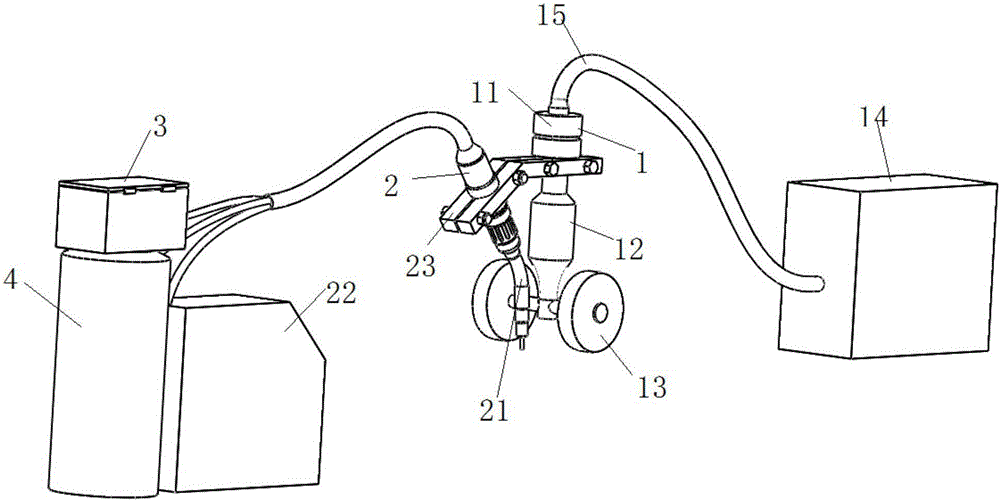

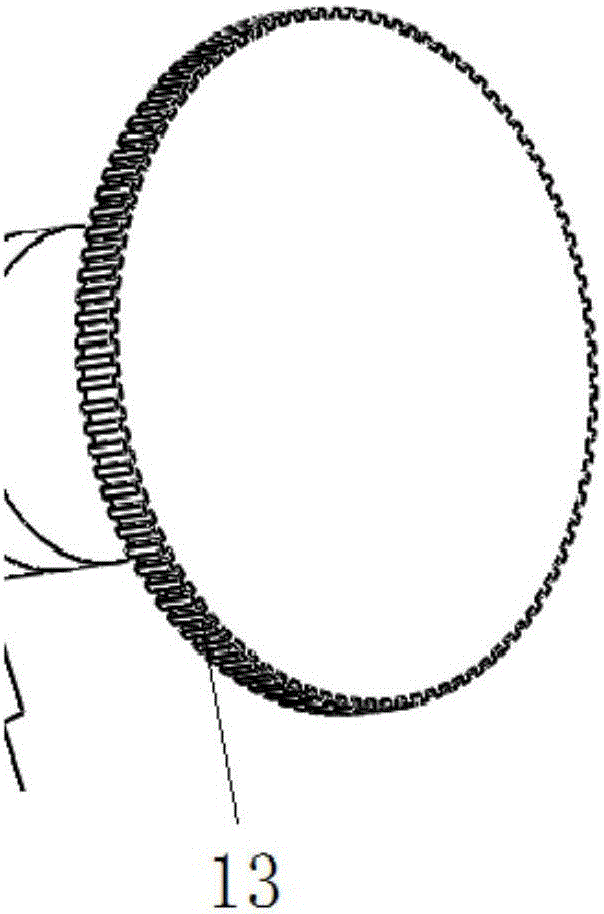

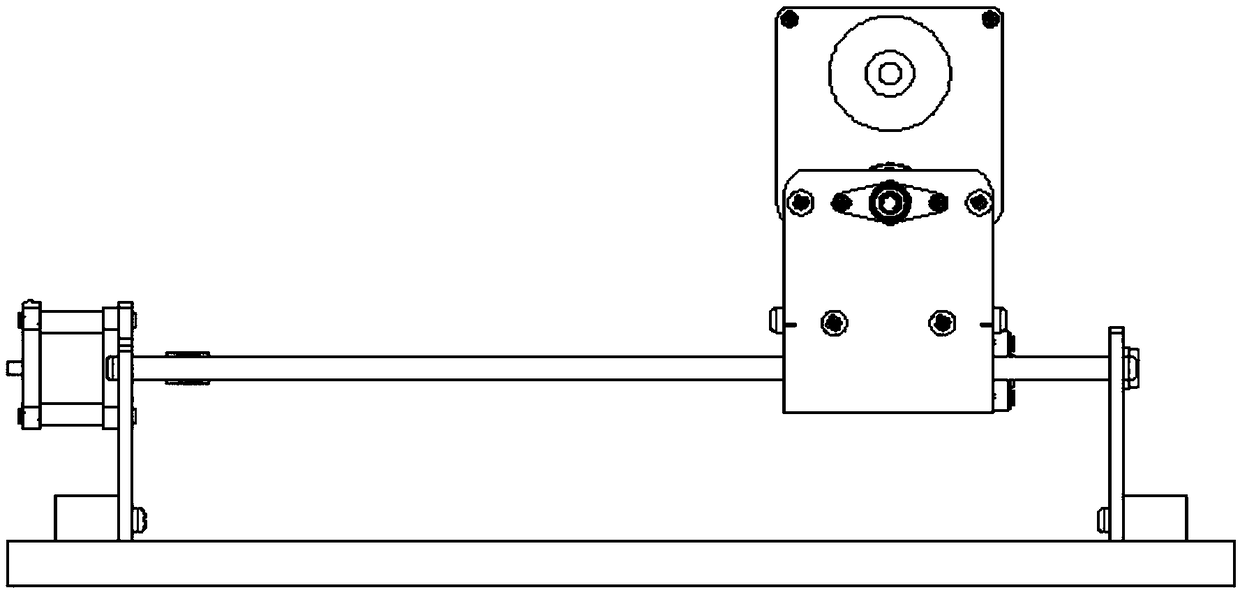

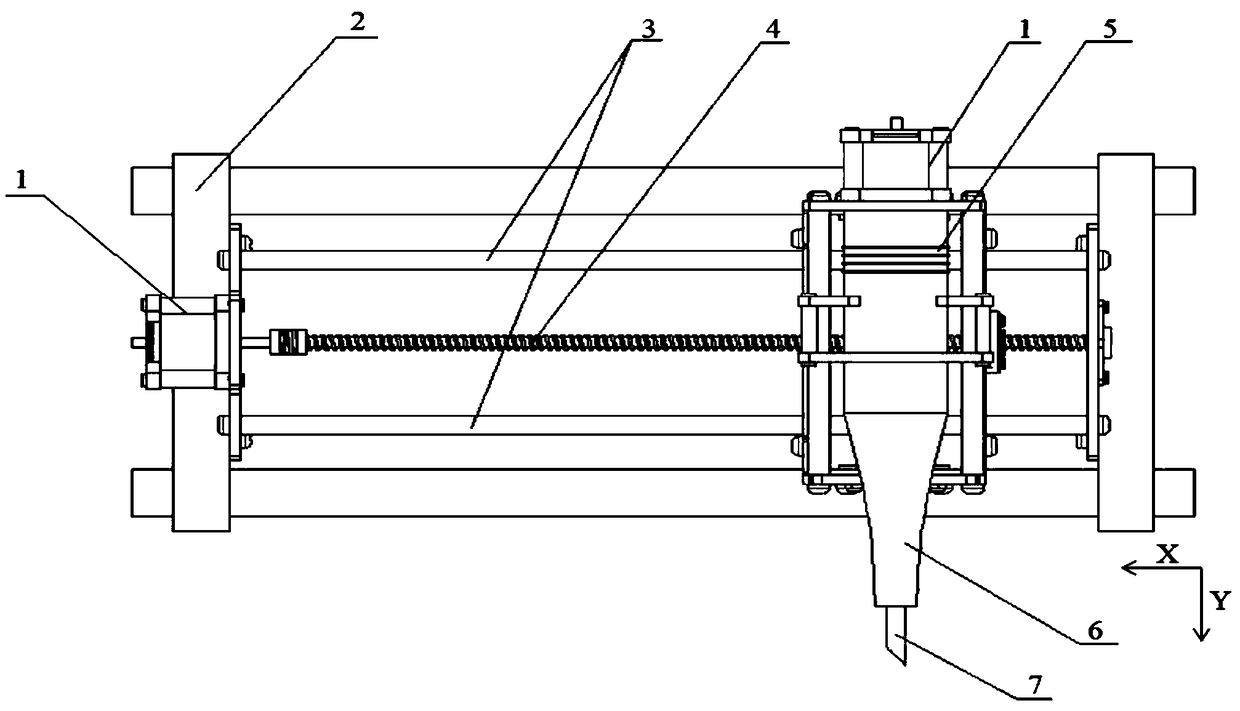

Rolling type ultrasonic arc composite welding device

PendingCN106624401AGrain refinementImprove weld structureWelding apparatusMechanical propertyHigh frequency vibration

Owner:GUANGDONG INST OF INTELLIGENT MFG

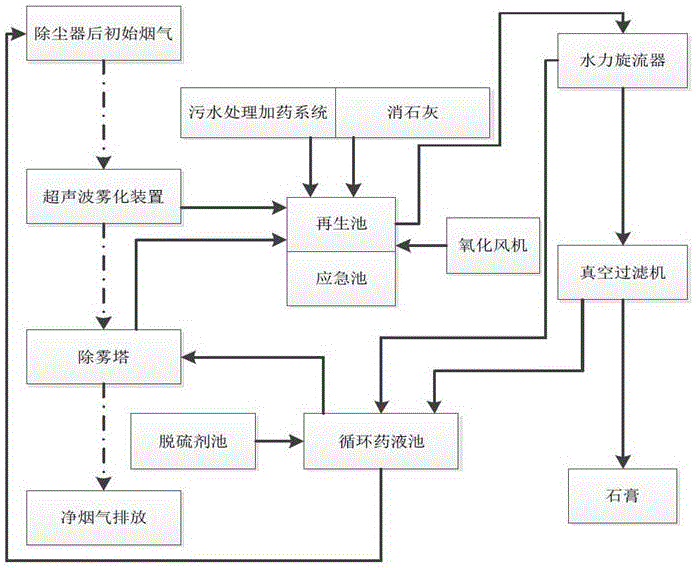

Thermal power plant ultrasonic atomization desulfurization-dust removal-ammonia escape prevention integrated system

InactiveCN107433115ALow concentration of sulfur dioxideReduce dust contentCombination devicesGas treatmentAutomatic controlEngineering

Owner:陈佐会

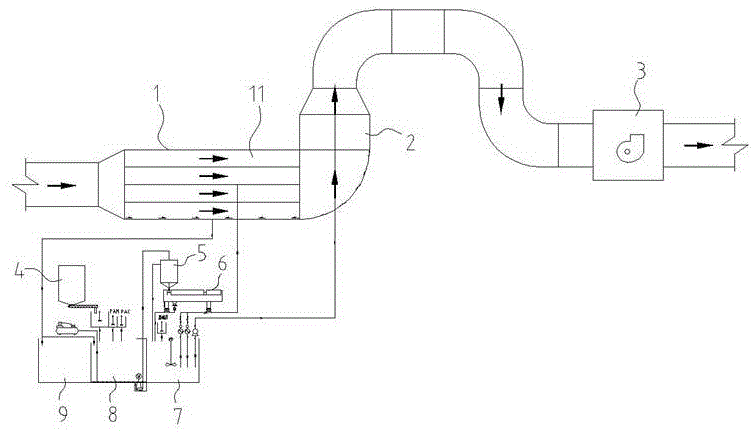

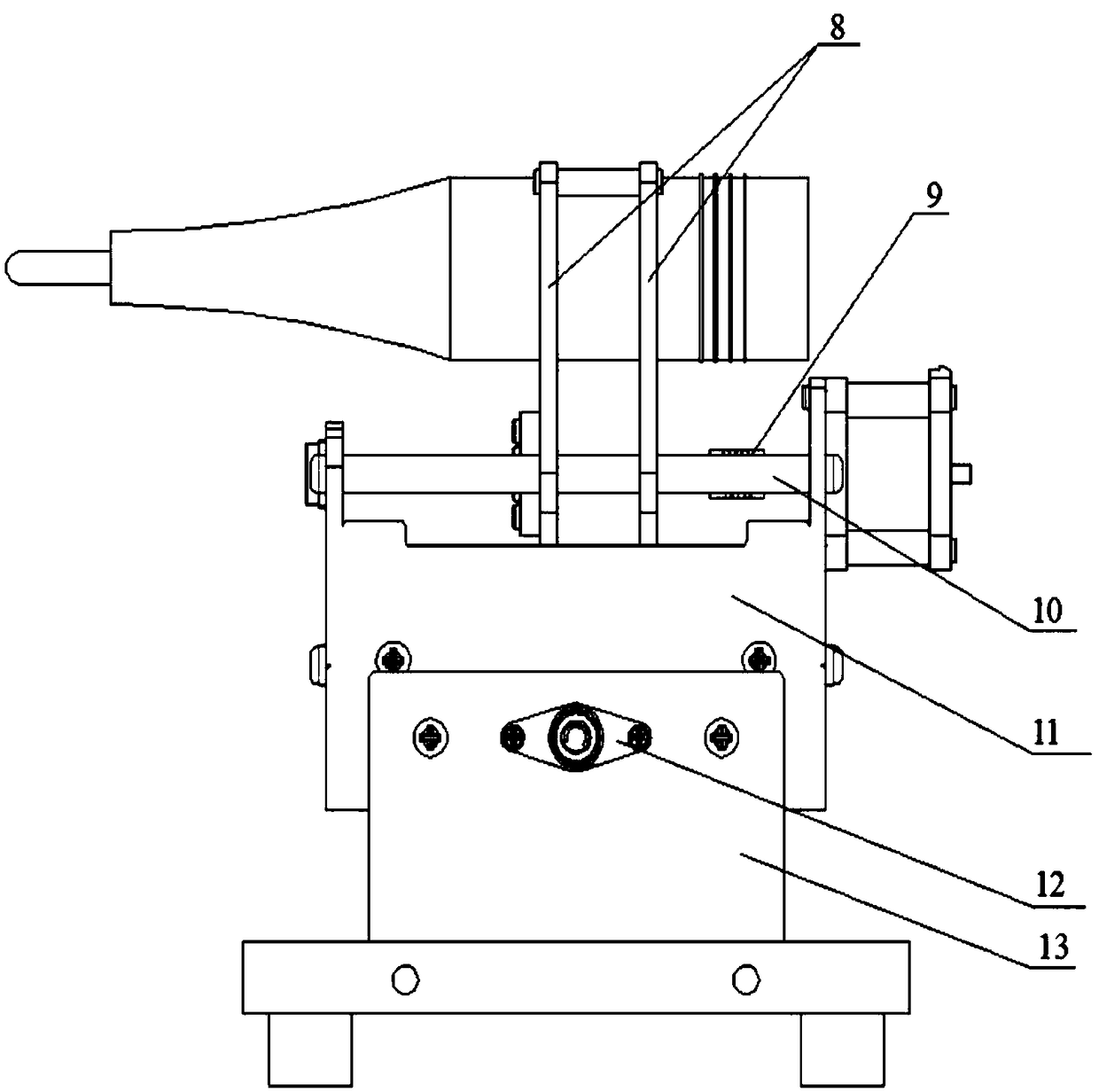

Device for on-line ultrasonic dressing of coarse-grained superhard abrasive grinding wheel

PendingCN108772782AImprove processing qualityEasy to replaceGrinding feed controlAbrasive surface conditioning devicesCamera lensEngineering

Owner:HUAQIAO UNIVERSITY

Method for ultrasonic self-cleaning arsenic removal in waste acid

ActiveCN112010390ANo change in pHRapid formation of precipitatesWater contaminantsWater/sewage treatment with mechanical oscillationsEnvironmental engineeringPollution

The invention relates to a method for ultrasonic self-cleaning arsenic removal in waste acid. According to the method, the purpose of efficiently removing arsenic can be achieved only by carrying outultrasonic enhancing treatment on the contaminated acid by utilizing an independently-developed ultrasonic device without adding any reagent, and the method comprises the following specific steps: adding ultrasonic waves into the contaminated acid for enhancement, reacting for a certain time, generating precipitate, carrying out solid-liquid separation, and obtaining a filtered solution and precipitate impurities. According to the arsenic removal method, arsenic impurities in the contaminated acid can be efficiently removed, the process is simple, the cost is greatly reduced, and meanwhile, the treated acid and water can be reused in a zinc oxide smoke dust recovery section so that the pollution to the environment is reduced; meanwhile, waste of a large amount of acid and water in waste acid is avoided, any arsenic removal reagent is not added, the treatment cost is reduced, other impurities are not introduced, energy is saved, and the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH +1

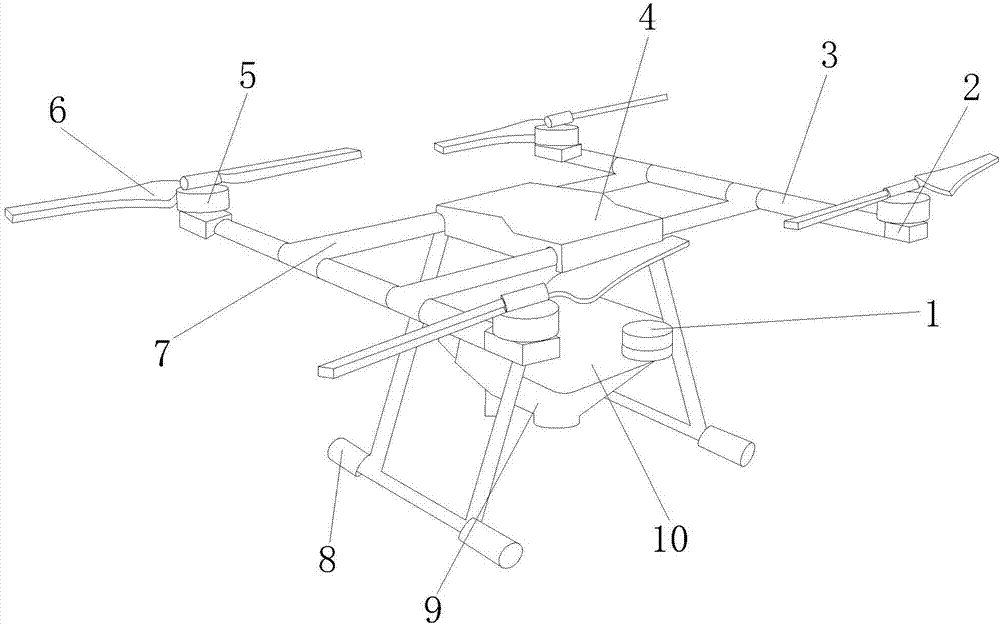

Unmanned spraying plane for agriculture

InactiveCN107333743AShorten the timeImprove spraying efficiencyInsect catchers and killersInterference fitEngineering

Owner:广州市妙伊莲科技有限公司

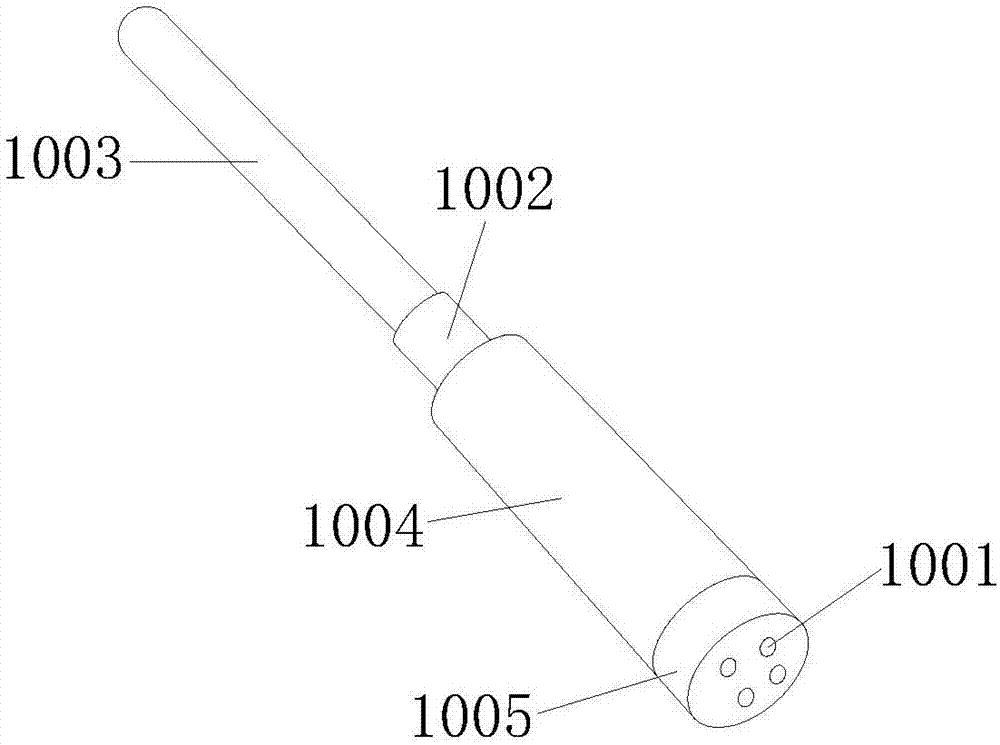

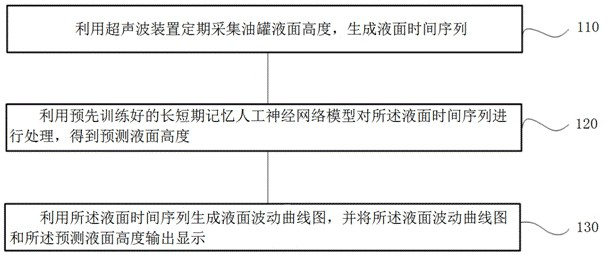

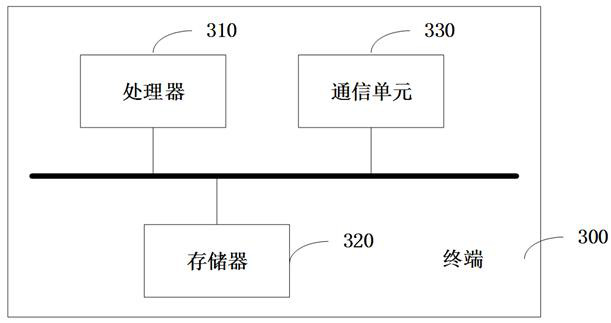

Oil tank liquid level ultrasonic measurement method and system based on LSTM, terminal and storage medium

InactiveCN113566929AImprove accuracyReliable design principleMachines/enginesLevel indicatorsEngineeringComputational physics

Owner:SHANDONG XIWANG FOOD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap