Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Weld zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weld Zone. Zone comprising the weld line and the heat-affected areas on either side of the weld line caused by the friction welding and subsequent heat-treatment processes.

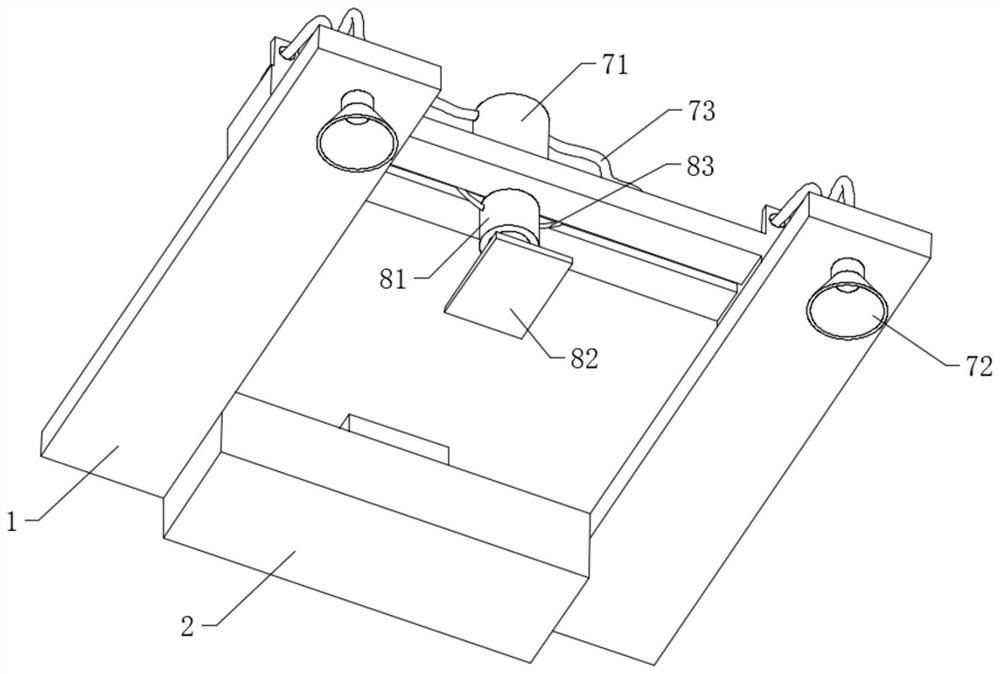

Method for reducing welding hollows of LTCC substrate and metal base plate and LTCC substrate structure

ActiveCN104093271AElectrical connection printed elementsSolder pasteWeld zone

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

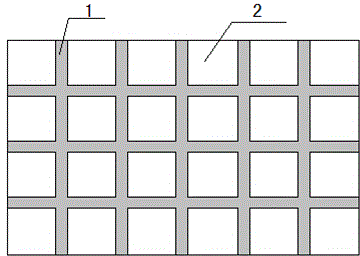

Flexible circuit board, manufacturing method thereof and display device

ActiveCN113645758AImprove welding qualityImprove welding yieldPrinted circuit assemblingElectrical connection printed elementsFlexible circuitsDisplay device

The invention provides a flexible circuit board, a manufacturing method thereof and a display device. The flexible circuit board comprises a main board and a small board, the main board is provided with at least one first welding area for exposing a part of a first conductive layer, the small board is provided with at least one second welding area for exposing a part of a second conductive layer, the second welding area comprises a welding hole, the orthographic projection of the second welding area on the mainboard is at least partially overlapped with the first welding area, and the first conductive layer and the second conductive layer are connected through a welding structure. The welding structure comprises: a first layer of welding flux which is located on the first conductive layer part exposed by the first welding area; a second layer of welding flux which is located on the part, exposed out of the second welding area, of the second conducting layer, wherein at least part of the second layer of welding flux is welded and fixed to the first layer of welding flux through the welding hole; and a high-melting-point connecting piece, wherein one end of the high-melting-point connecting piece is located in the first layer of welding flux, the other end of the high-melting-point connecting piece is located in the second layer of welding flux in the welding hole, and the melting point of the high-melting-point connecting piece is higher than that of the first layer of welding flux and that of the second layer of welding flux. According to the flexible circuit board, the manufacturing method thereof and the display device, the welding quality and the welding yield of the circuit board can be improved.

Owner:BOE TECH GRP CO LTD +1

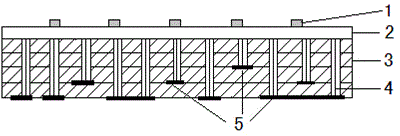

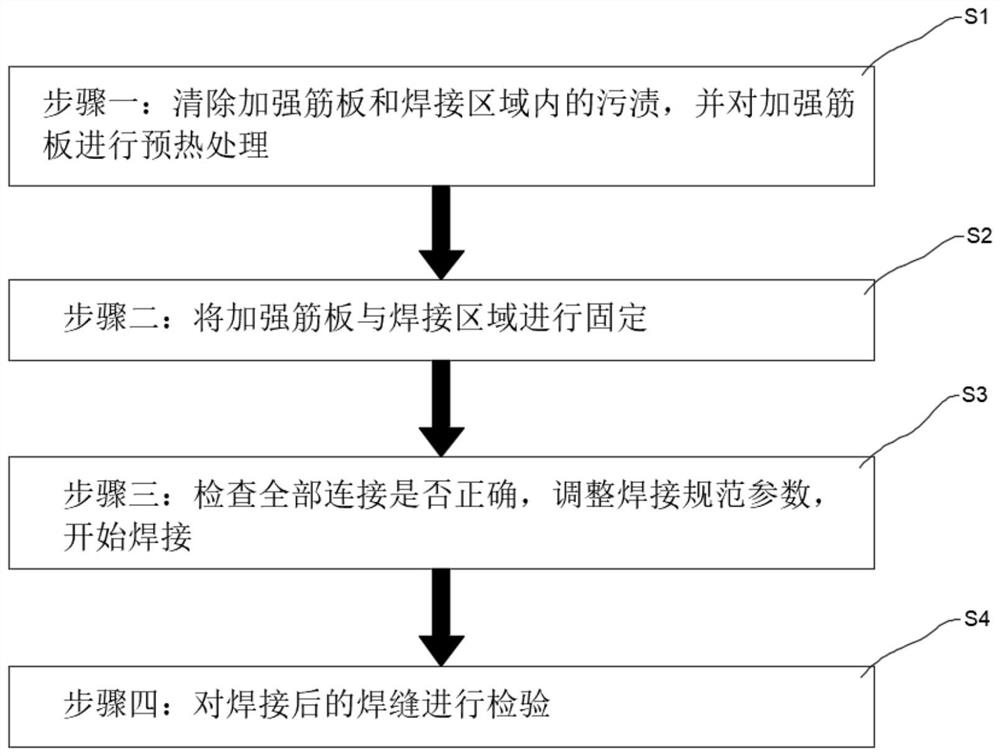

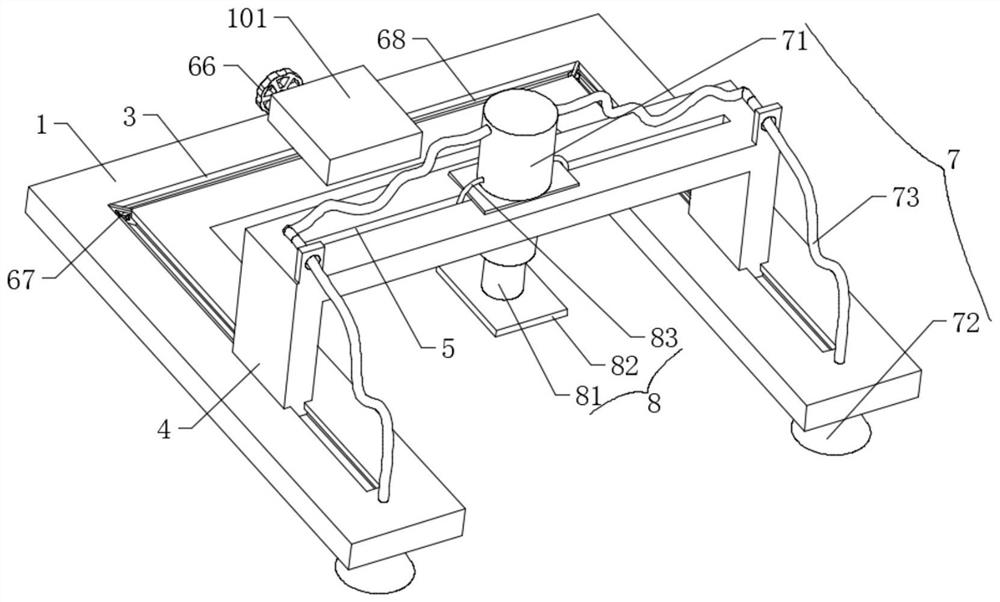

Reinforcing rib plate welding process and welding equipment thereof

ActiveCN114226914AImprove stabilityGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesSuction forceButt joint

Owner:河北邯峰发电有限责任公司

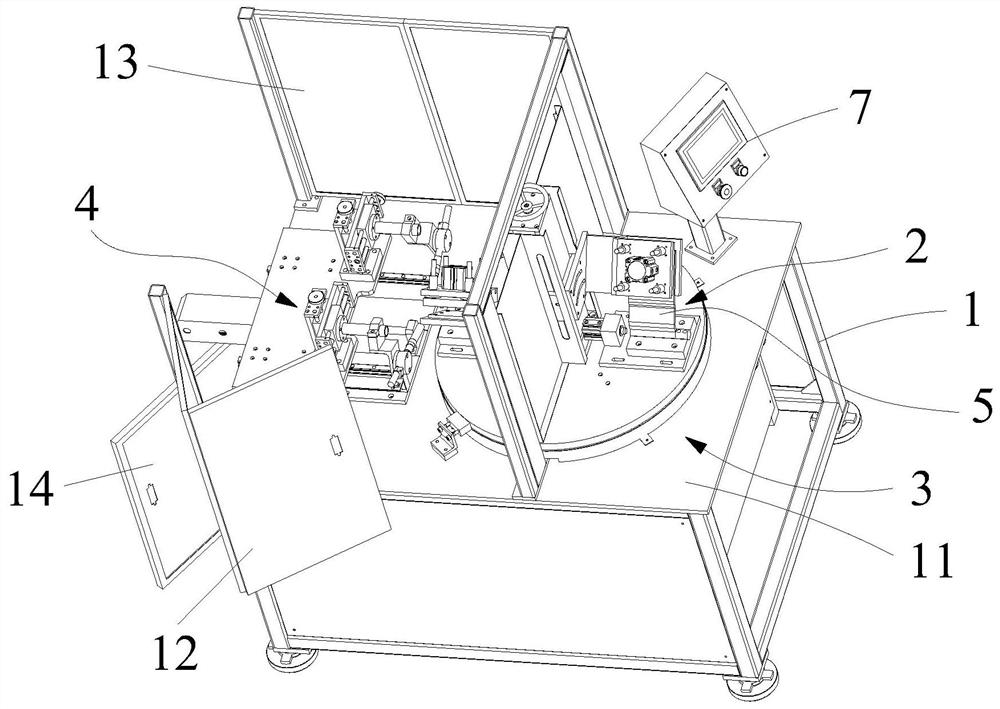

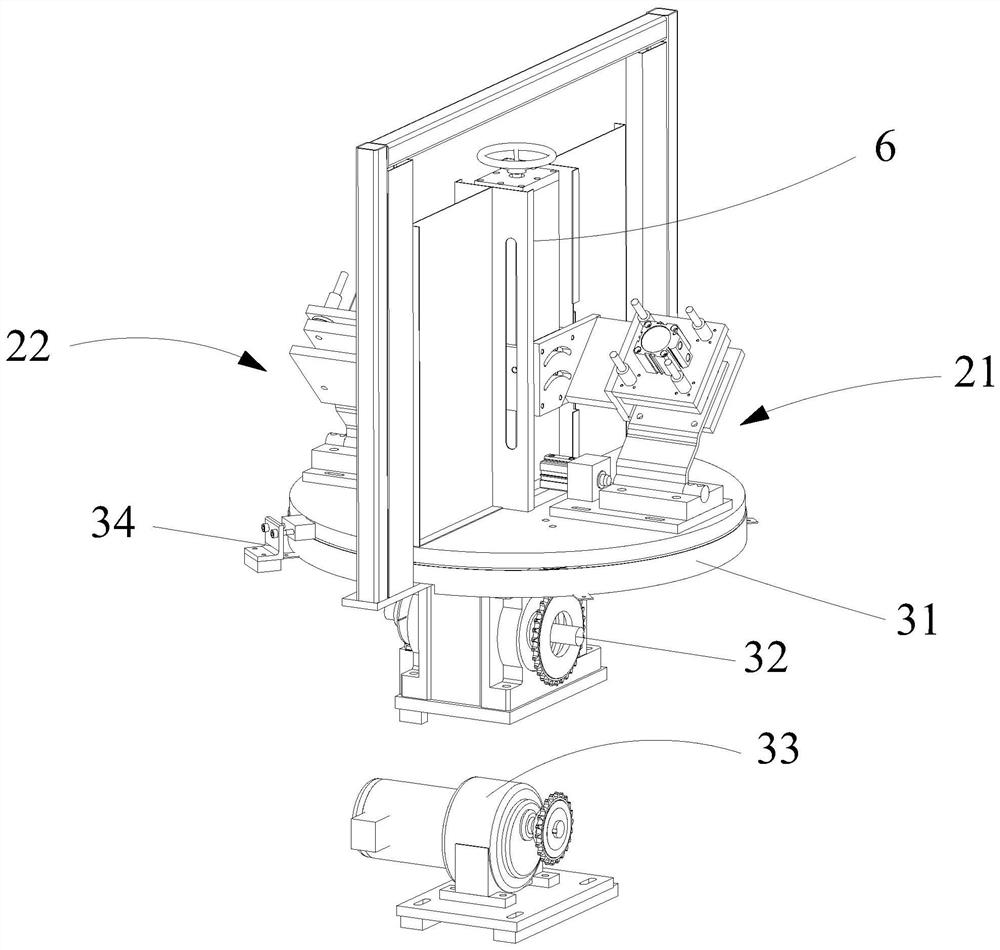

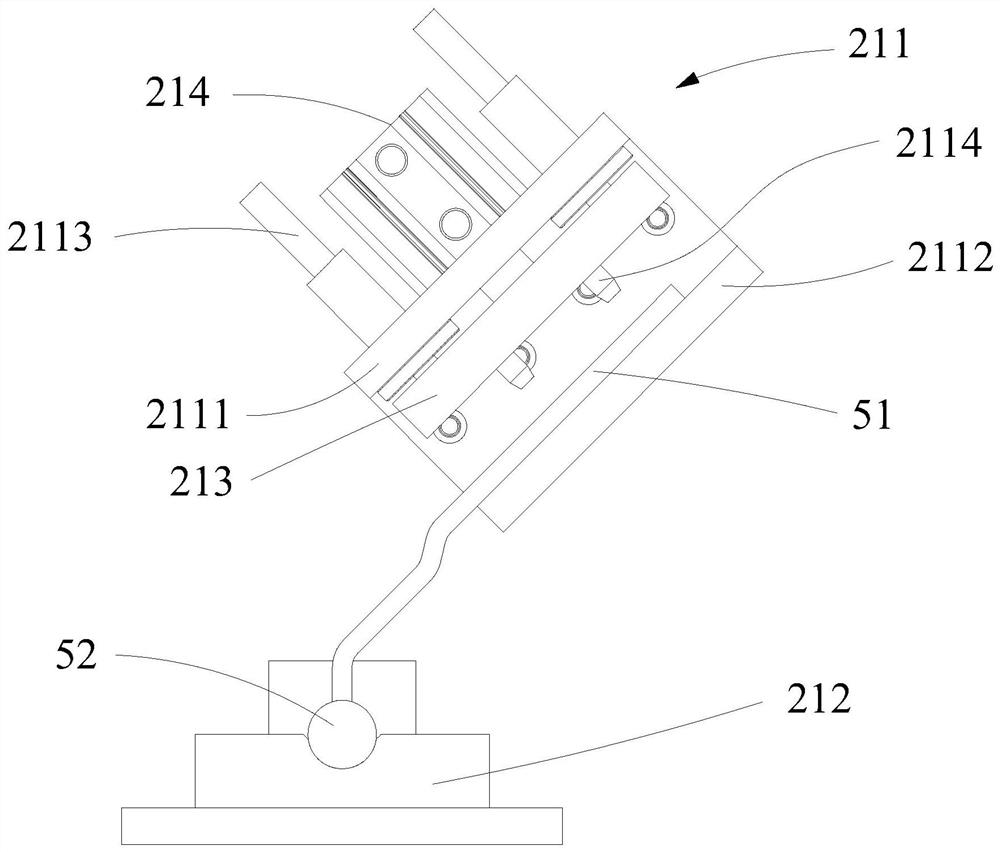

Spin welding system

ActiveCN113319458ARealize intelligent welding functionOvercome costsWelding/cutting auxillary devicesAuxillary welding devicesSpin weldingEngineering

Owner:江苏申牌万向轮有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap