Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Zero emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero emission refers to an engine, motor, process, or other energy source, that emits no waste products that pollute the environment or disrupt the climate.

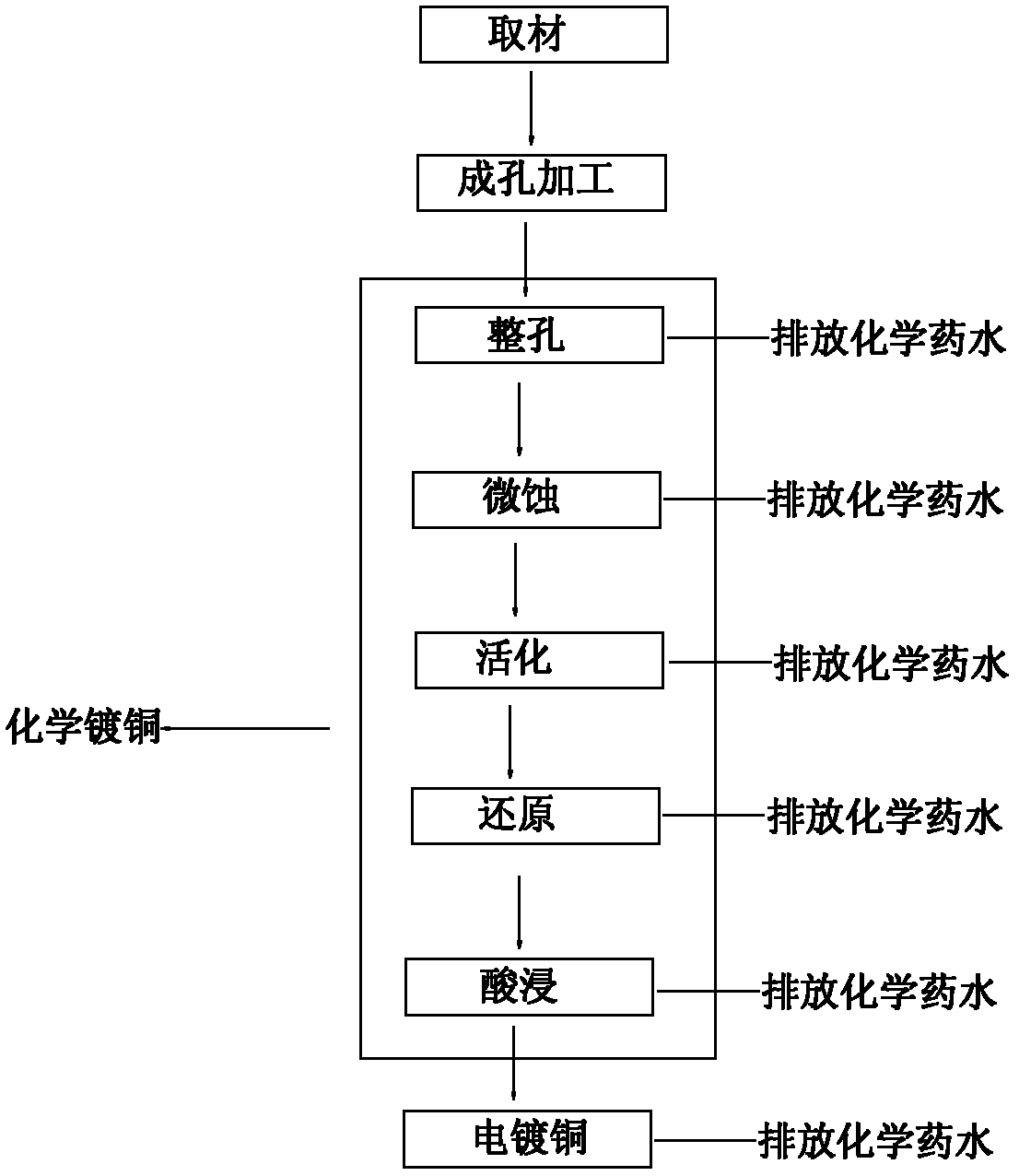

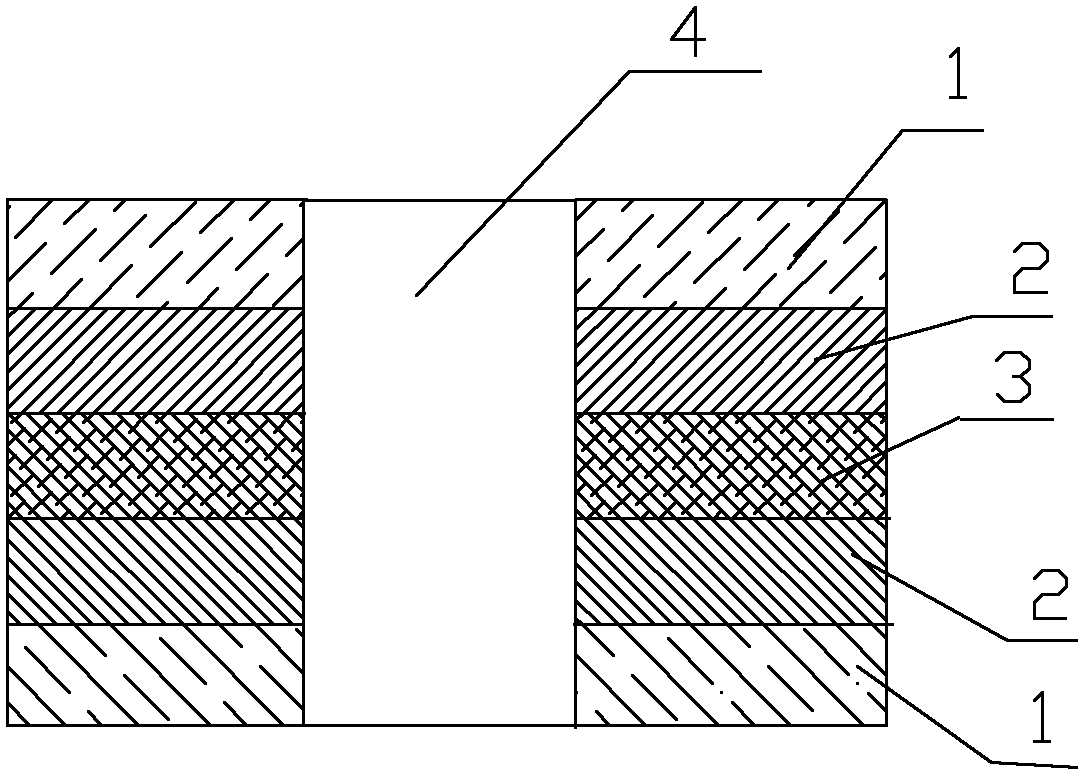

Manufacturing process of interlayer copper connector of printed circuit board

InactiveCN102638946AReduce investmentReduce investment riskPrinted element electric connection formationScreen printingInsulation layer

Owner:SHENZHEN HONGHAI ELECTRON MATERIAL TECH CO LTD

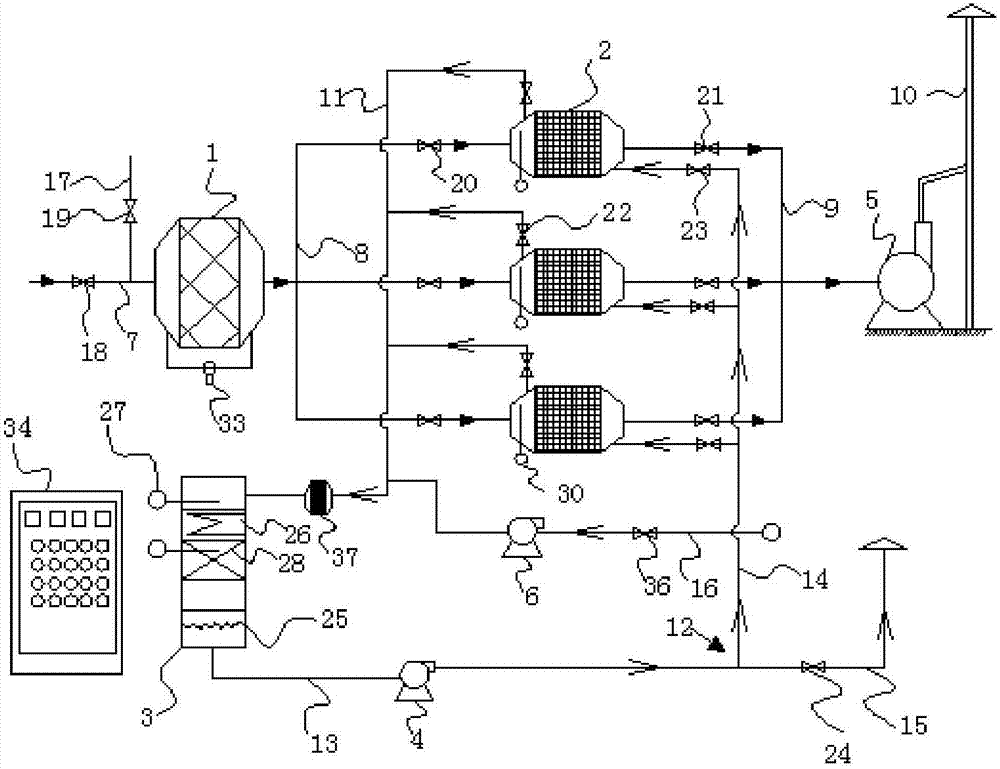

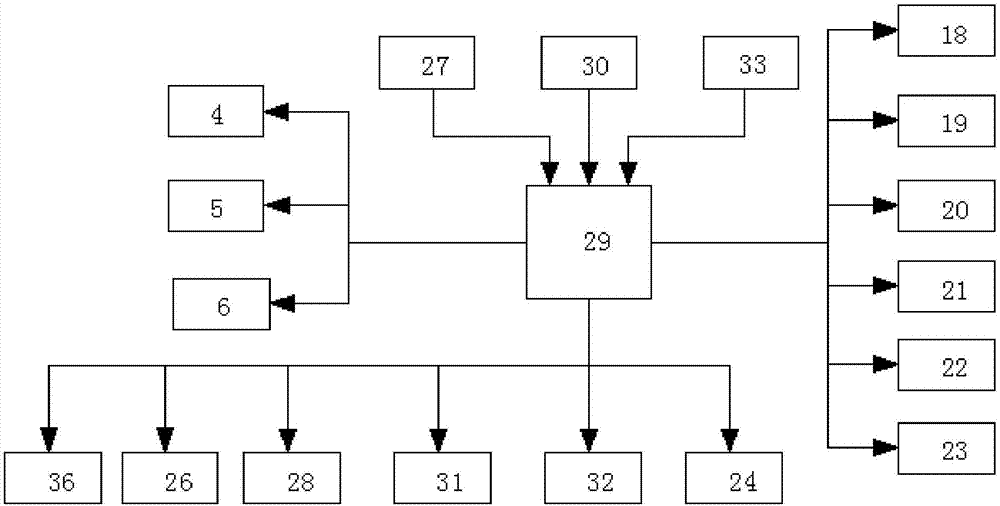

Spray booth organic waste gas treatment system

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

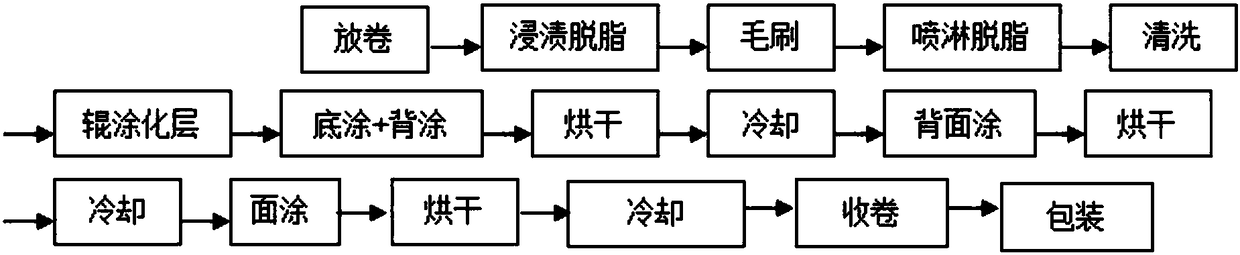

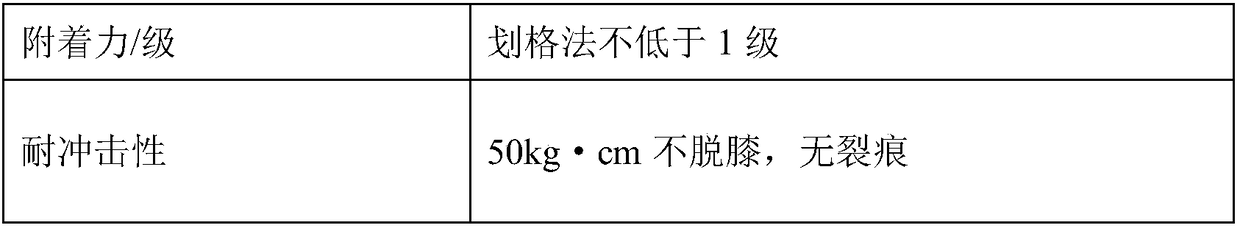

Double-face roller coating color aluminum plate preparing technology

InactiveCN108515010AGood effectImprove adhesionPretreated surfacesCoatingsSurface cleaningAssembly line

Owner:安徽墙煌彩铝科技有限公司

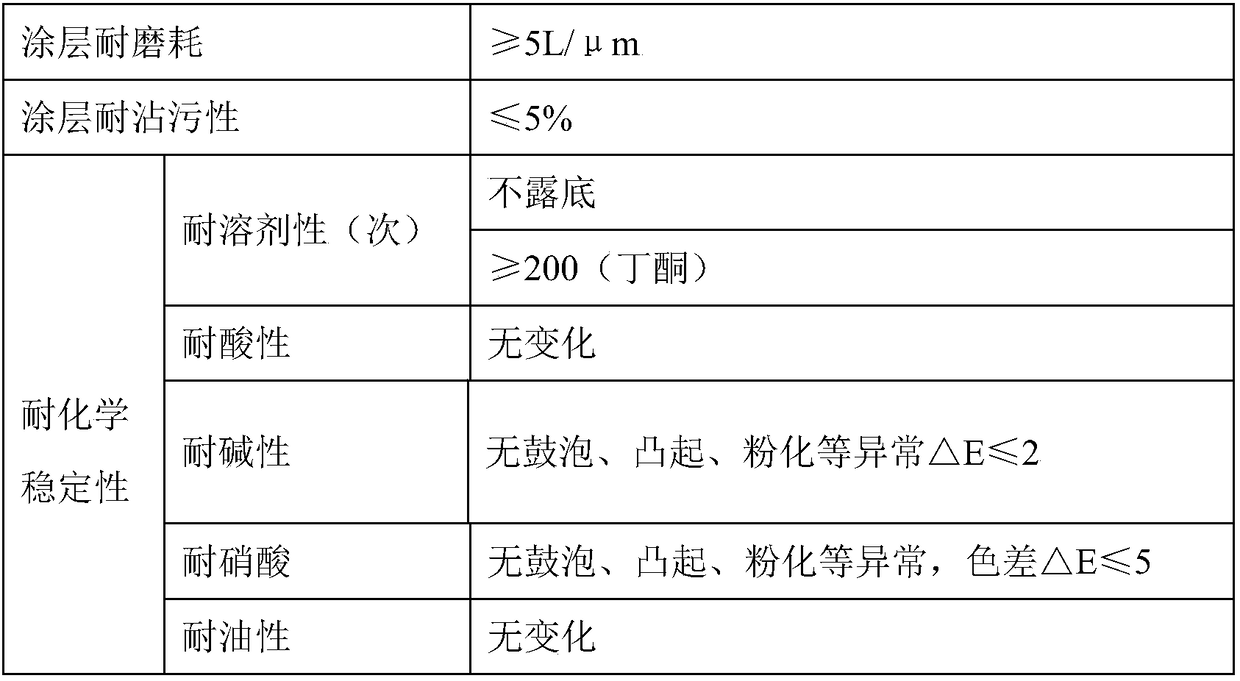

Ecological cycle breeding system and breeding method

Owner:JISHOU UNIVERSITY

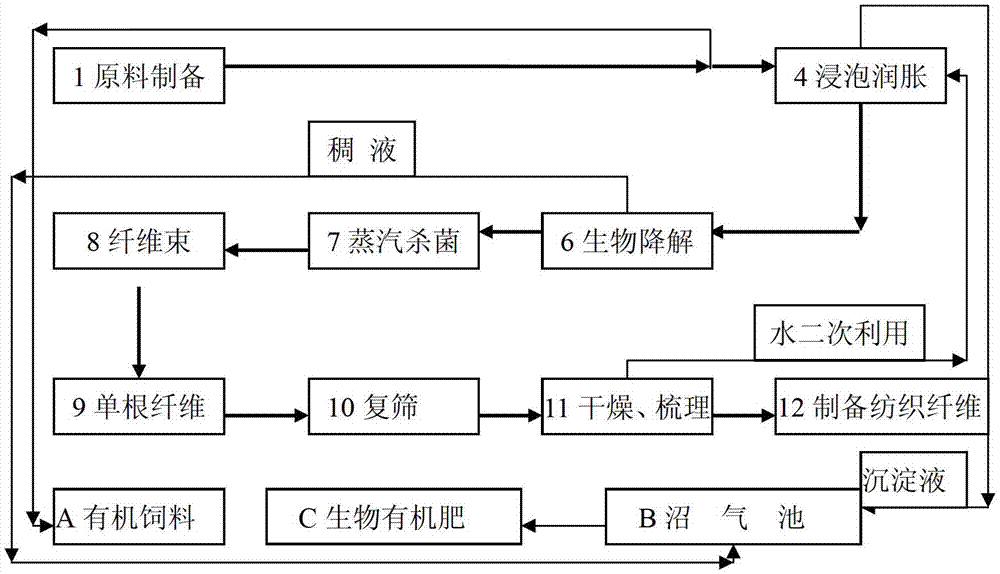

Composite flora and textile fiber preparation method by using the same

InactiveCN103074247APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberPseudomonas

Owner:BEIJING TIANAN BIOSCI & TECH

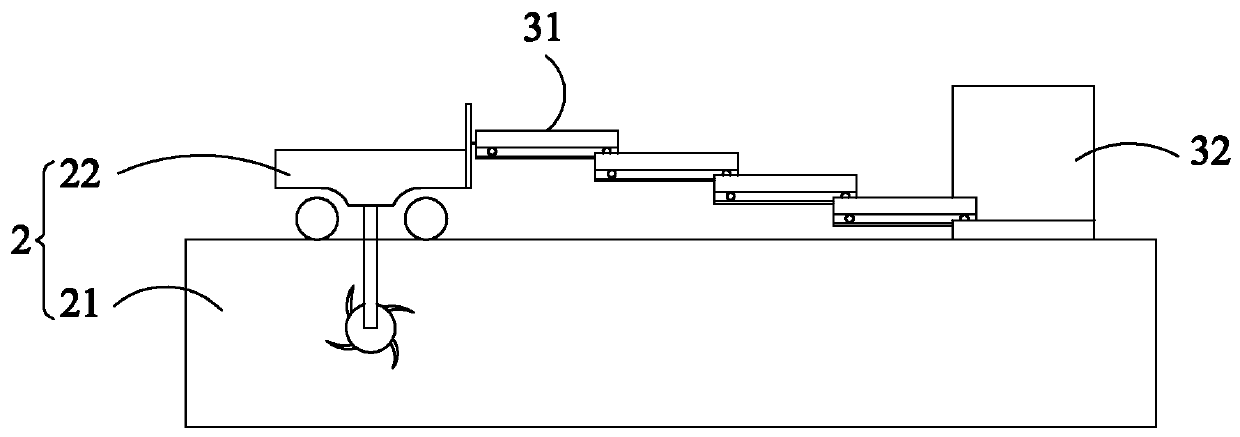

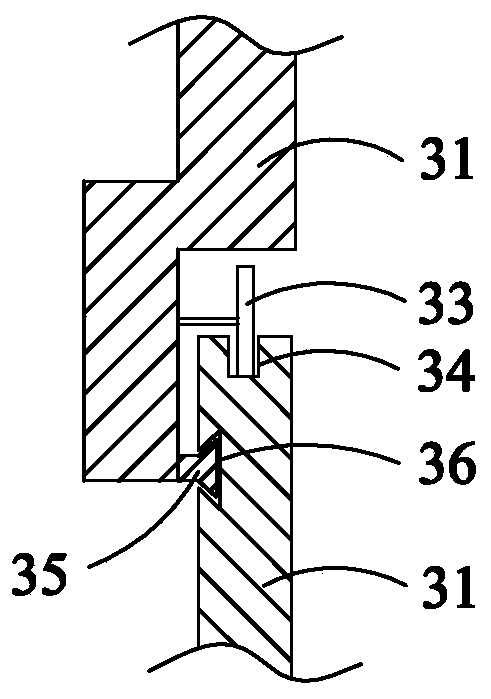

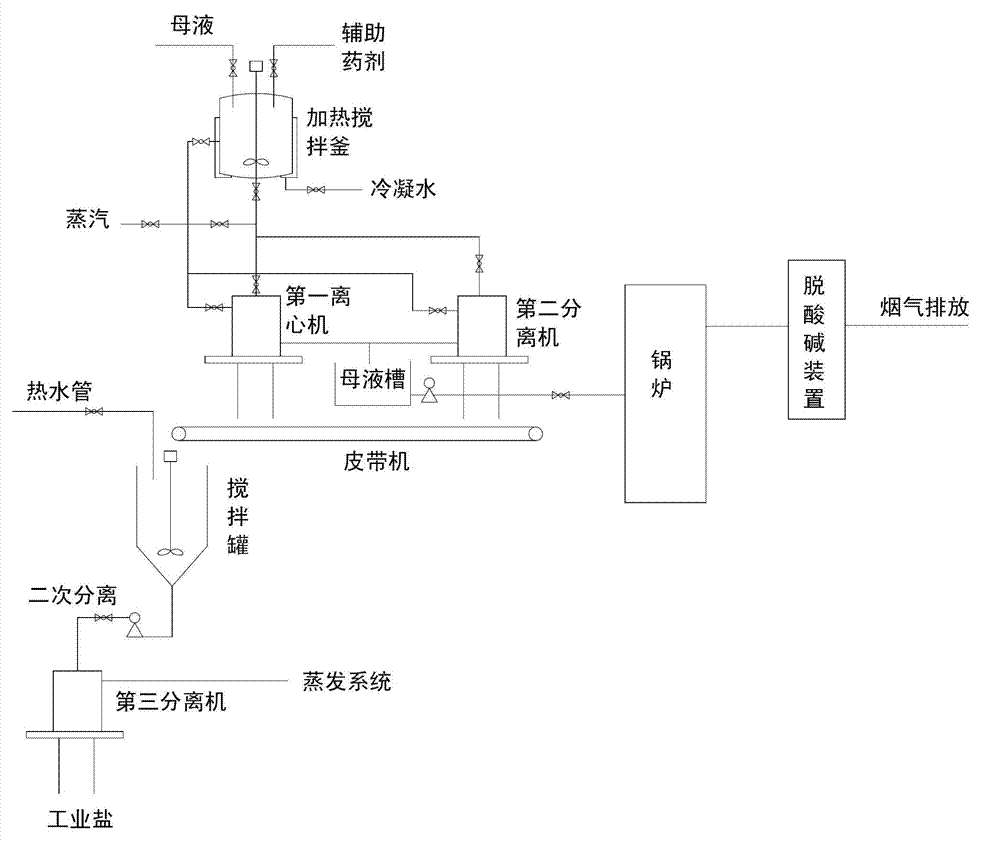

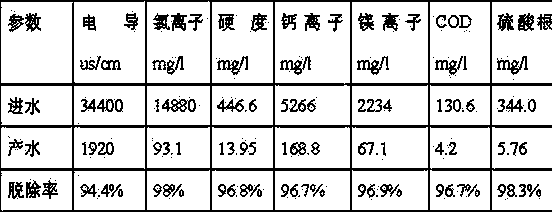

Membrane treatment method for desulfurization wastewater of coal-fired power plant

InactiveCN109467164ARealize fully automatic operationEasy to operateWaste water treatment from gaseous effluentsWater/sewage treatment bu osmosis/dialysisVibrating membraneWastewater

Owner:李卓坪

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap