Method for processing dust-collection sheet of living air device

A technology of air freshener and processing method, which is applied in the direction of metal processing equipment, wheels of working parts with flexibility, manufacturing tools, etc., can solve the problems of difficult processing, thick dust sheets, easy deformation, etc., and achieve reduction cost, avoid deformation, and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Please refer to shown in Figures 1 to 9, below in conjunction with the embodiment to illustrate a kind of processing method of the dust sheet on the air purifier provided by the present invention, its technological process:

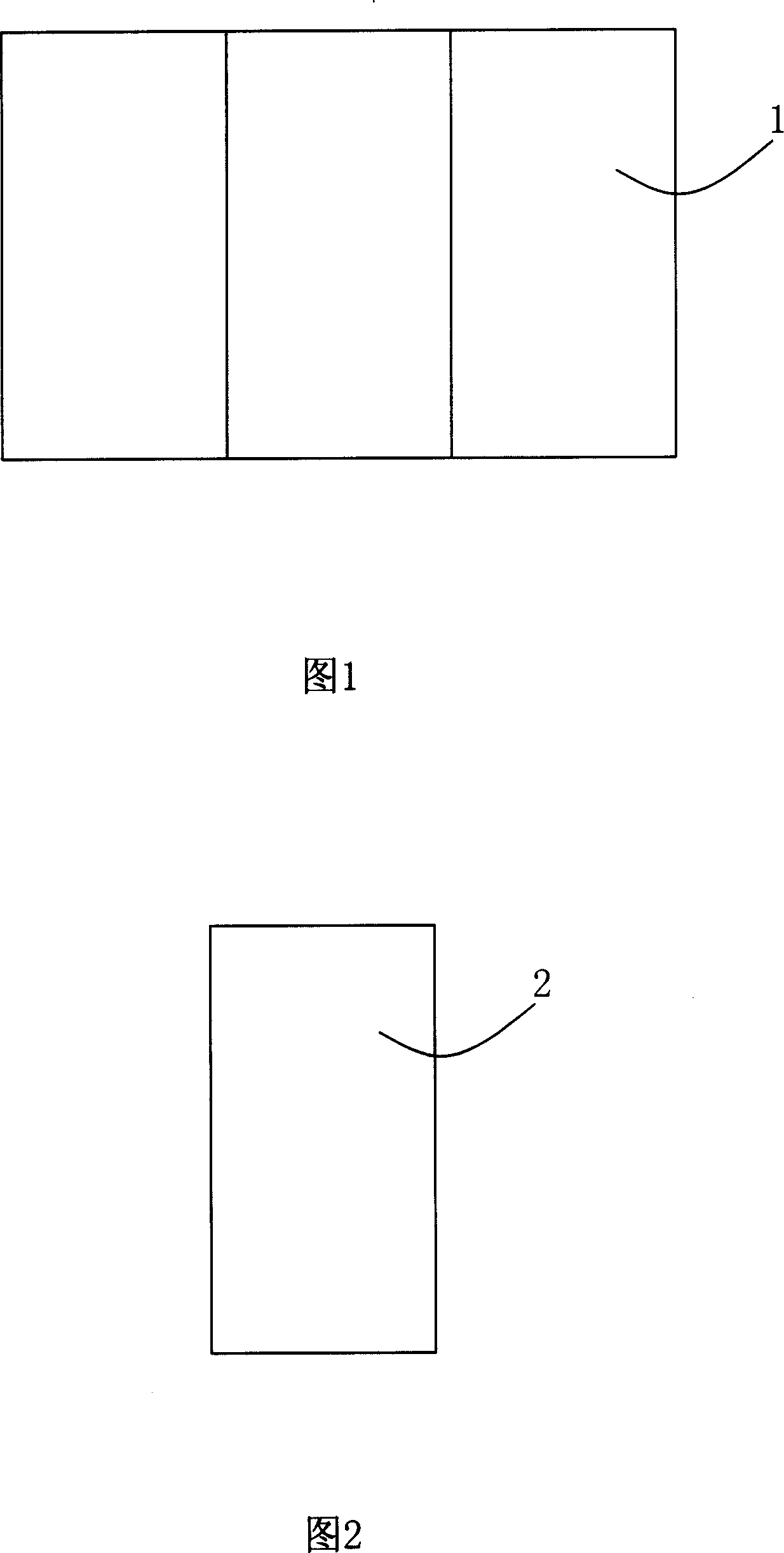

[0025] Firstly, the roll material 1 is divided into several strips 2 (as shown in Figures 1 and 2).

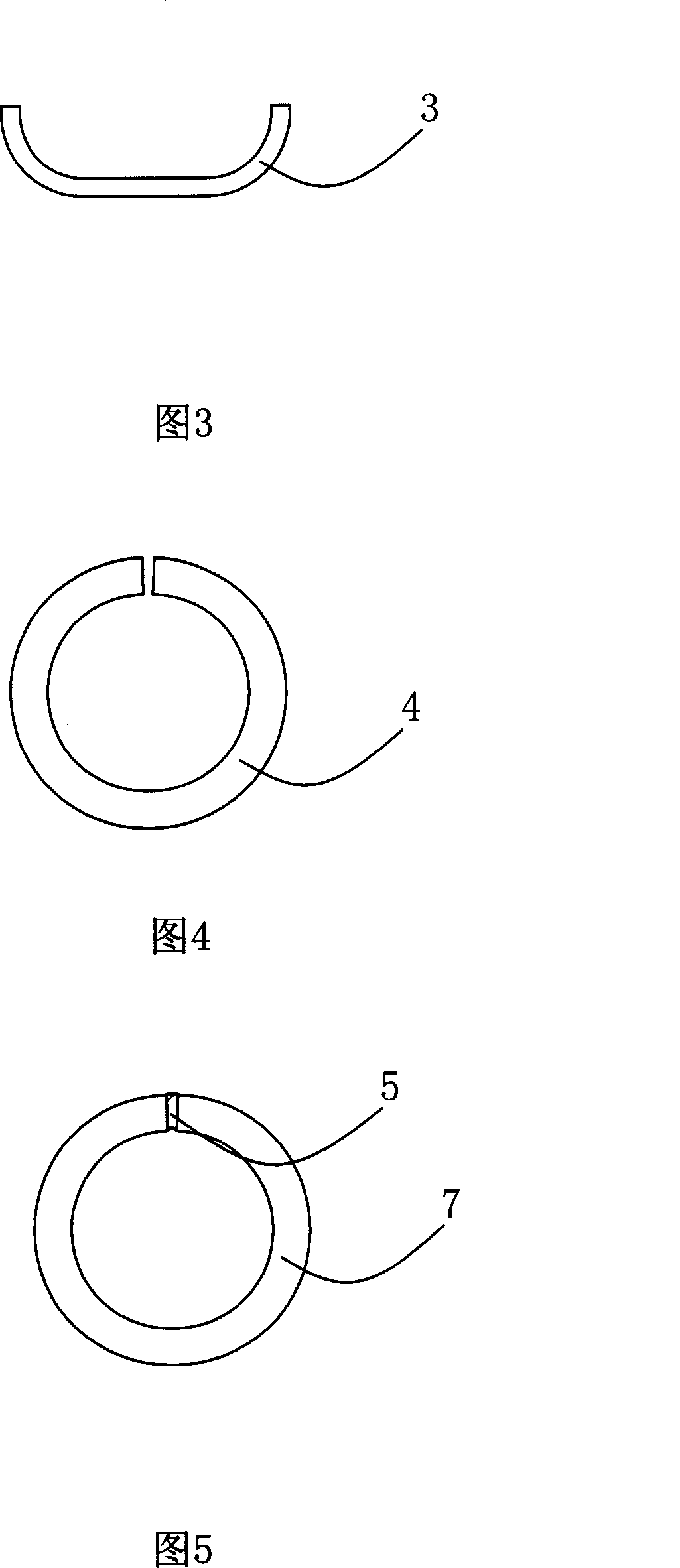

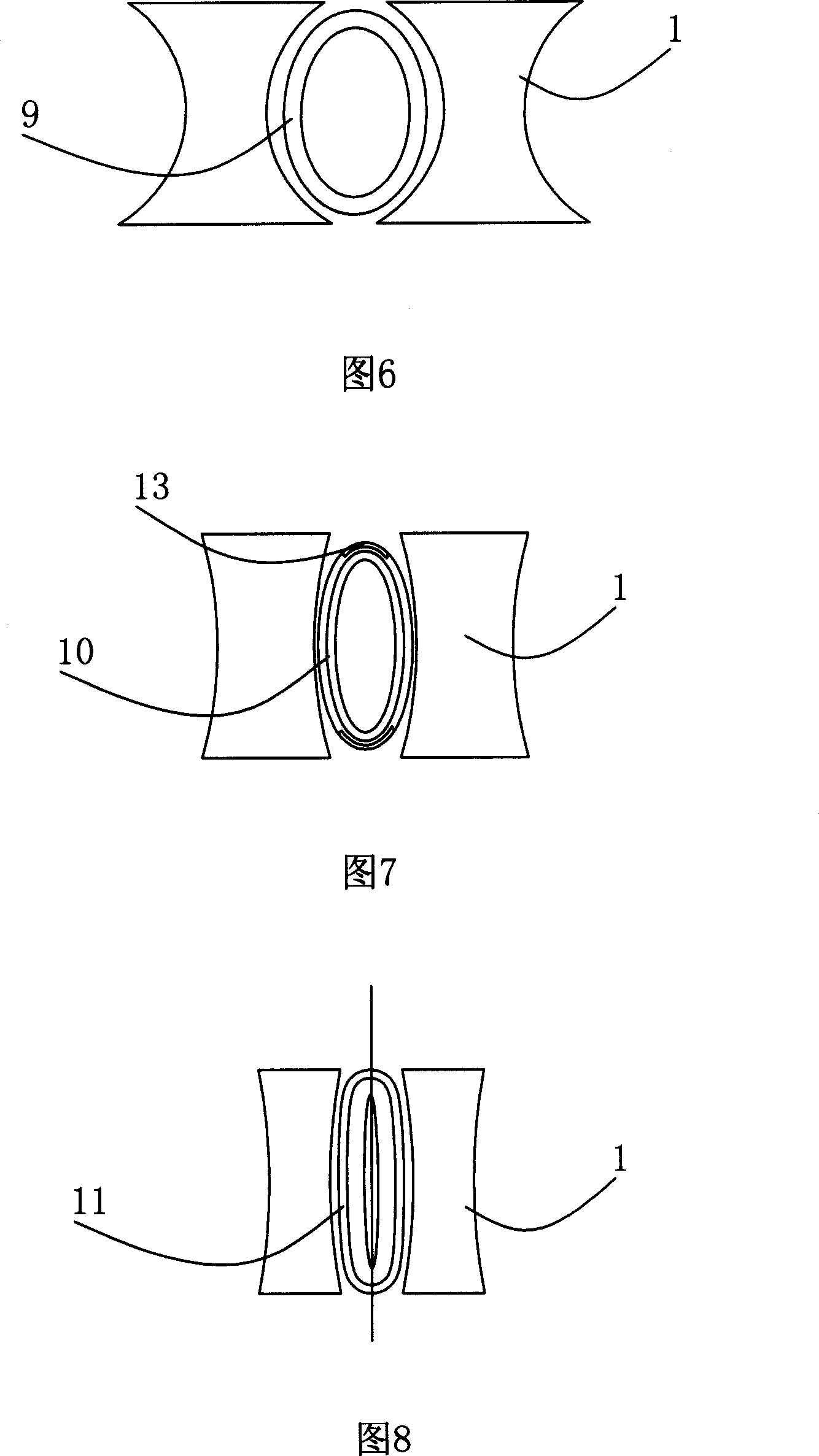

[0026] Next, pressure is gradually applied on both sides of the strip 2, so that the strip 1 is bent into a tile shape 3, an arc 4, and a cylindrical shape with a gap, and then passes through the gap on the cylindrical shape. The solder 5 is welded into a closed cylinder, and then the welded surface is polished to form a closed circular tube 7 (as shown in FIGS. 3 to 5 ).

[0027] Then, the waxed burlap wheel 12 is placed on the surface of the tubular pipe 7, and the surface of the above-mentioned tubular pipe 7 is polished and polished by placing the burlap wheel set in different positions, and the burlap wheel set is composed of several burlap wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap