Fixed blade of residue anode pressure-disengaging machine

A fixed blade, press-off-line technology, applied in the field of residual extreme pressure off-line fixed blade, can solve the problems of fast blade loss, high maintenance cost, deformation and cracking of the body, etc., and achieve long service life, low production cost, and high blade strength. Effect

Inactive Publication Date: 2014-10-29

扬州八方机电设备有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the single anode automatic residual pressure off-line used in the domestic aluminum industry is basically similar. It is mainly composed of the upper fixed knife group, the lower movable knife group and the clamping mechanism. After long-term tracking of the use of this type of equipment, the following deficiencies are found : 1. The positioning and clamping mechanism is easy to break from the root, and the body is deformed and cracked; 2. The blade wears quickly and is fragile, and the blade fastening screw is easy to break and is difficult to remove. It is inconvenient to maintain and replace the blade; The connecting screw is deformed by the residual carbon block for a long time, it is difficult to disassemble, and the connecting bolt of the movable blade is easy to break; 4. The two pressure release cylinders are not synchronized, the movable knife holder of the lower knife group is skewed, and the guide mechanism of the knife holder wears quickly and is not easy to replace; 5. 1. The failure rate of the hydraulic system is high, especially the spool of the flow diversion valve is easy to break, and debris often enters the hydraulic pipeline system and often damages the fluid; 6. The pressure system is difficult to troubleshoot, the inspection and repair period is long, and the maintenance cost is high. Valves have the same problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

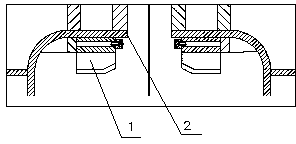

[0008] A kind of residual pole pressing off-line fixed blade, the fixed blade 1 is an inverted V shape, and the dovetail plug-in is installed on the machine body 2, and the fixed blade 1 is made of CrWuMn high-alloy tool steel. The hardness of the body quenching is HRC45-50, and the hardness of the nitriding surface of the cutting edge is as high as HRC63-65.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to a fixed blade of a residue anode pressure-disengaging machine. The fixed blade is inverted-V-shaped and installed on the body of the residue anode pressure-disengaging machine in a dovetail splicing manner, the blade is made from CrWuMn high alloy tool steel, the quenching hardness of the cutter body is HRC45-50, and the surface nitrogenation treatment hardness of the cutting edge is as high as HRC63-65. The fixed blade is simple in structure, convenient to install, high in strength, low in production cost and long in service life.

Description

technical field [0001] The invention relates to an off-line cutting part for extreme pressure residue, in particular to an off-line fixed blade for extreme pressure residue. Background technique [0002] At present, the single anode automatic residual pressure off-line used in the domestic aluminum industry is basically similar. It is mainly composed of the upper fixed knife group, the lower movable knife group and the clamping mechanism. After long-term tracking of the use of this type of equipment, the following deficiencies are found : 1. The positioning and clamping mechanism is easy to break from the root, and the body is deformed and cracked; 2. The blade wears quickly and is fragile, and the blade fastening screw is easy to break and is difficult to remove. It is inconvenient to maintain and replace the blade; The connecting screw is deformed by the residual carbon block for a long time, it is difficult to disassemble, and the connecting bolt of the movable blade is e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C25C3/12

Inventor 张兴荣

Owner 扬州八方机电设备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap