Polystyrene modified heat resistant composite plastic

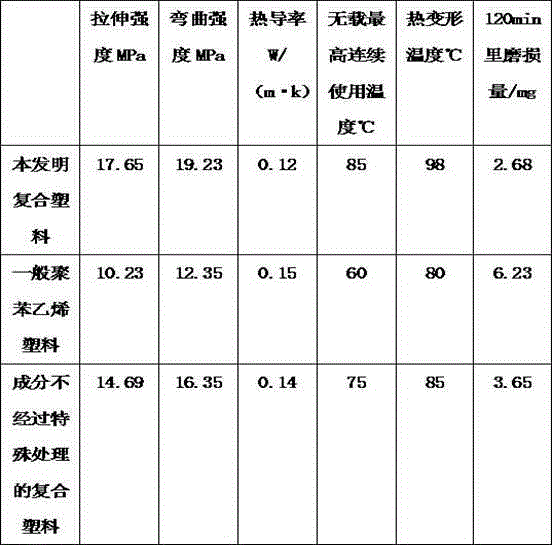

A polystyrene and composite plastic technology, applied in the field of polystyrene modified heat-resistant composite plastics, can solve the problems of high cost, unsuitable for industrialized production, low impact strength, brittle physical properties, etc. The effect of heat resistance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] A polystyrene-modified heat-resistant composite plastic is prepared from the following components in parts by weight: 80 parts of polystyrene, 16 parts of thermoplastic styrene-butadiene rubber, 15 parts of phenolic resin, 6 parts of oil shale slag, and modified carbonic acid. 4 parts of calcium, 3 parts of carbon fiber, 2 parts of sodium lauryl sulfate, 0.8 part of dispersant, 0.25 part of plasticizer, 0.2 part of heat stabilizer.

[0014] Further, the dispersant is sodium hexametaphosphate, the plasticizer is citrate ester, and the heat stabilizer is lead dibasic lead phosphite.

[0015] Further, the oil shale slag is pretreated, and the oil shale slag is soaked in a 3.5% concentration stearic acid solution at 75-80° C. for 1 hour, then dried and roasted at a temperature of 250° C. After 30min, pulverize to 150 mesh.

[0016] Further, the carbon fibers are subjected to process modification treatment: adding carbon fibers to a 3 mol / L nitric acid solution and heating t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap