Conductive aramid paper and method for producing same

A manufacturing method and conductive technology, applied in the field of conductive aramid paper for electromagnetic wave shielding and its manufacturing, can solve problems such as difficulty in making thin fabrics, low shape stability, and poor processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

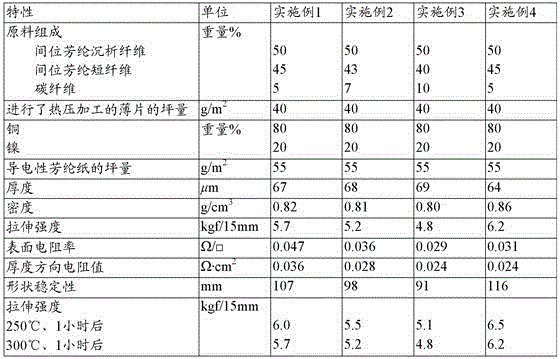

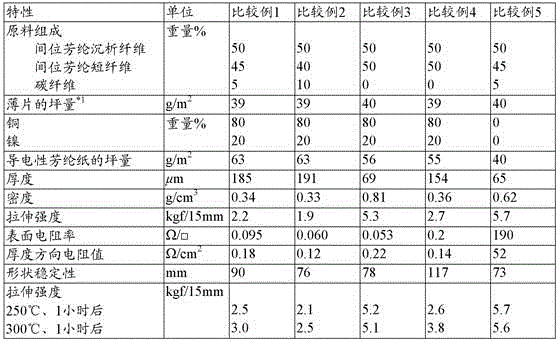

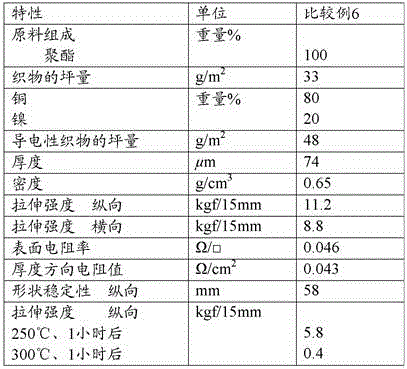

[0057] The above-prepared meta-aramid fibrids, meta-aramid short fibers, and carbon fibers (manufactured by Toho Tenacus Co., Ltd., fiber length 3 mm, single fiber diameter 7 mm) mu m, fineness is 0.67dtex, volume resistivity is 1.6×10 -3 Ω·cm) were dispersed in water to prepare a slurry. Mix this slurry to make meta-aramid precipitated fiber, meta-aramid short fiber and carbon fiber reach the proportioning shown in table 1, use TAPPI formula hand-drawn machine (cross-sectional area is 325cm 2 ) were processed to produce flakes. Next, the obtained sheet was hot-pressed at a temperature of 330° C. and a linear pressure of 150 kg / cm using a pair of metal calender rolls, and a metal (copper-nickel alloy) layer was formed on the surface of the obtained sheet by an electroless plating method to obtain Conductive aramid paper. The main characteristic values of the conductive aramid paper obtained in this way are shown in Table 1.

Embodiment 4

[0059]Utilize a pair of metal calendering rolls to carry out hot press processing according to the flake obtained by the same method as Example 1 at a temperature of 350° C. and a line pressure of 150 kg / cm, and form a metal (copper) on the surface of the gained flake by electroless plating. -nickel alloy) layer, a conductive aramid paper is obtained. The main characteristic values of the conductive aramid paper obtained in this way are shown in Table 1.

[0060] [Table 1]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Single fiber diameter | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap