Method for jointly testing horizontal displacement of pile head and stress of pile body of preformed pile

A technology of horizontal displacement and combined testing, which is applied in basic structure testing, construction, basic structure engineering, etc., can solve problems such as unsatisfactory installation of loading devices, inaccurate measurement data, inaccurate test results, etc. The effect of high precision and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

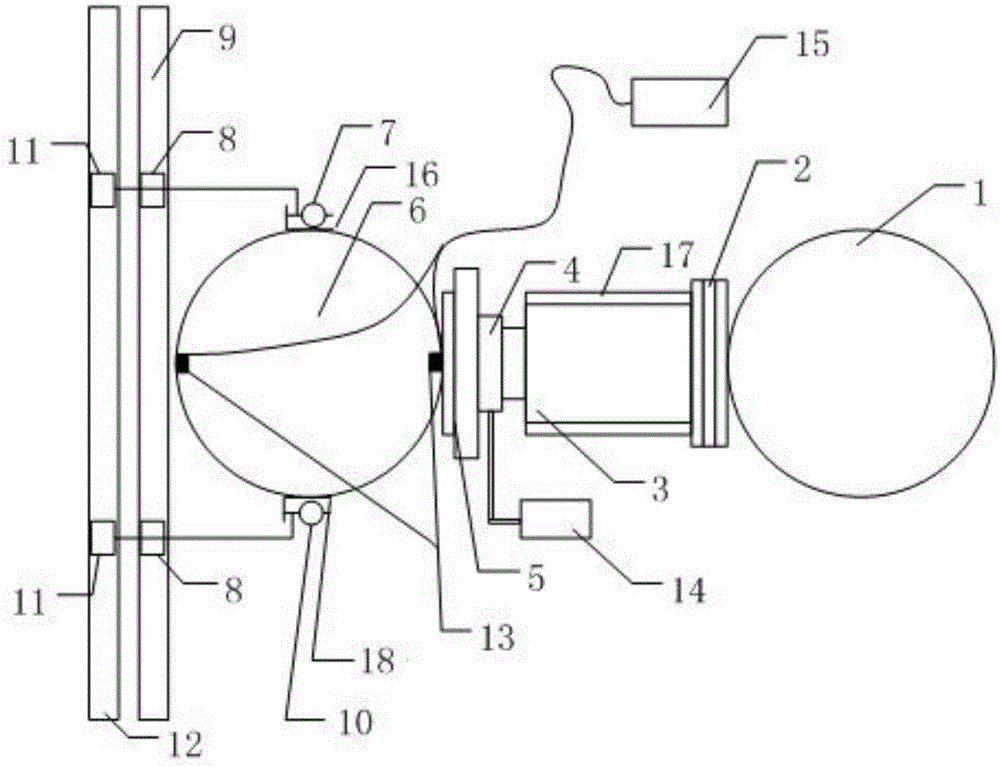

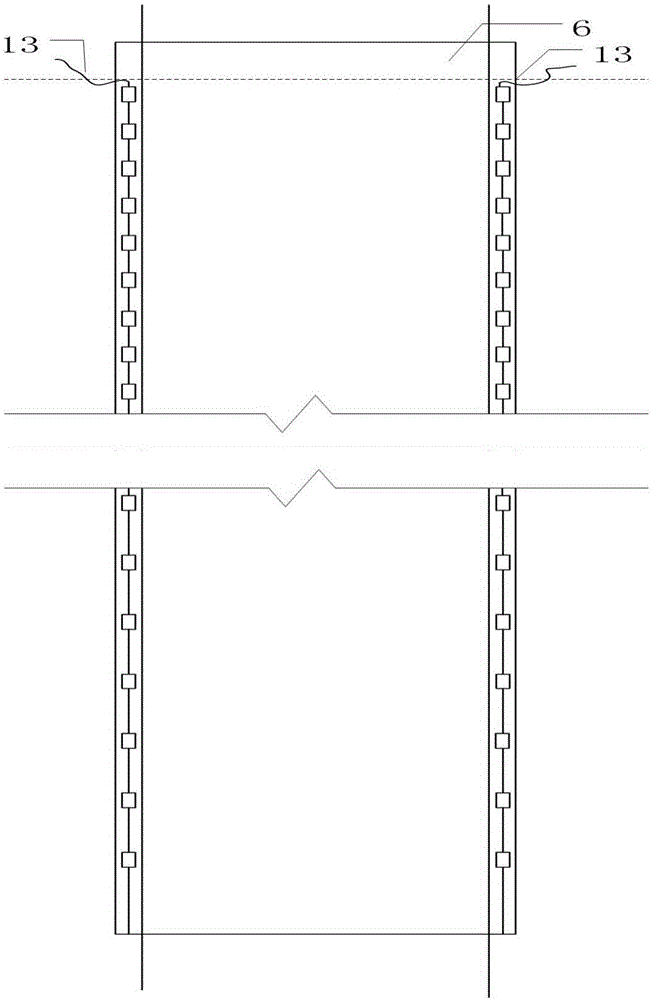

[0021] This embodiment is realized in the joint test device for the horizontal displacement of the pile top of the prefabricated pile and the stress of the pile body. The specific test process is: (1) before the pile is pressed, the two sides facing the test pile 6 are engraved with grooves of 5 mm × 5 mm, Put the self-compensating fiber grating strain sensor string 13 prefabricated in advance into two grooves, seal it with structural glue, and maintain it for two days. The self-compensating fiber grating strain sensor string 13 forms a dense structure at the top and a sparse structure at the bottom;

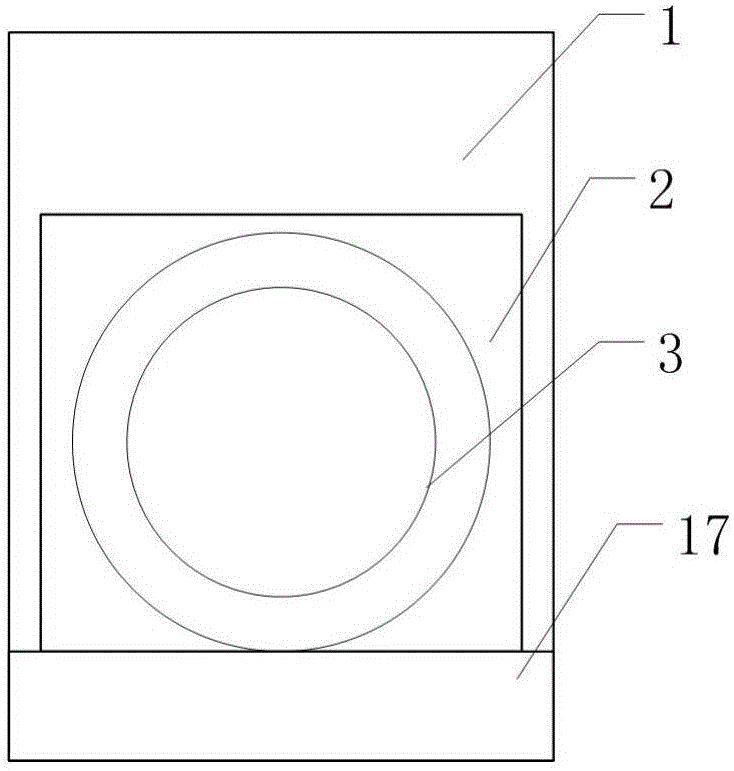

[0022] (2) When the test pile can be used normally, select a suitable engineering pile 1 to provide a reaction force to ensure that its bearing capacity is greater than or equal to the test pile 6;

[0023] (3) Between the test pile 6 and the engineering pile 1, the spherical hinge support 5, the load sensor 4, the jack 3, and the steel plate spacer 2 are placed in sequence. The di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap